A follow-up gravity unloading suspension device

A gravity unloading and suspension device technology, applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problem of large size range, poor adaptability, inability to simultaneously realize space lens follow-up and complete telescope assembly Splicing tasks and other issues to achieve the effect of good adaptability and high precision of gravity unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

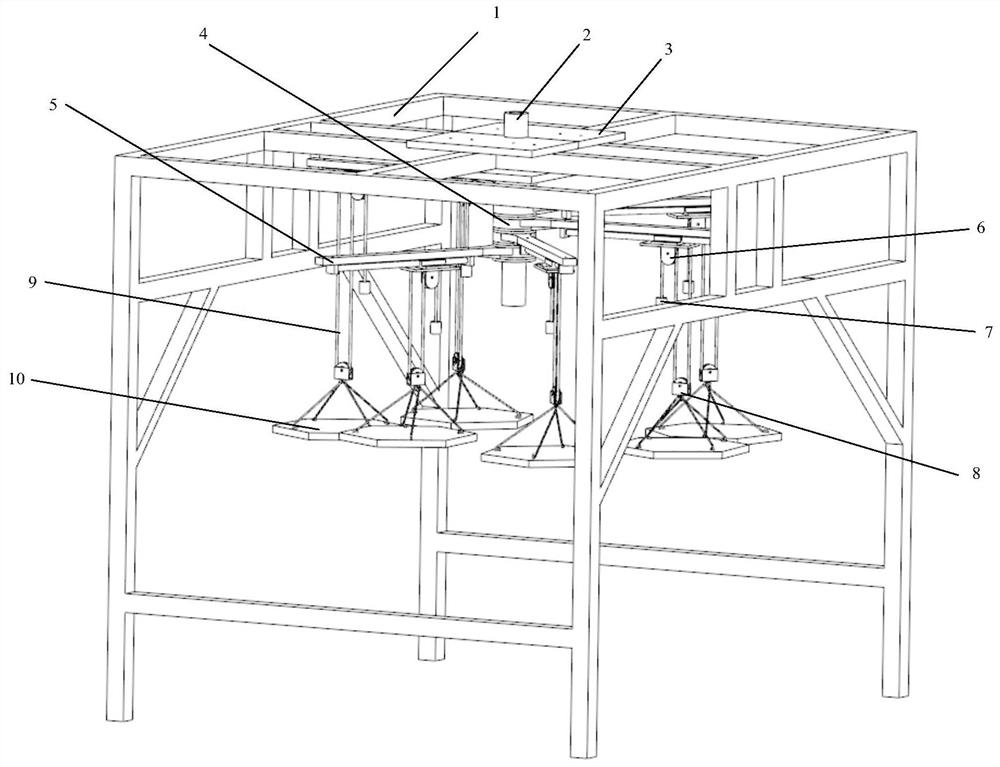

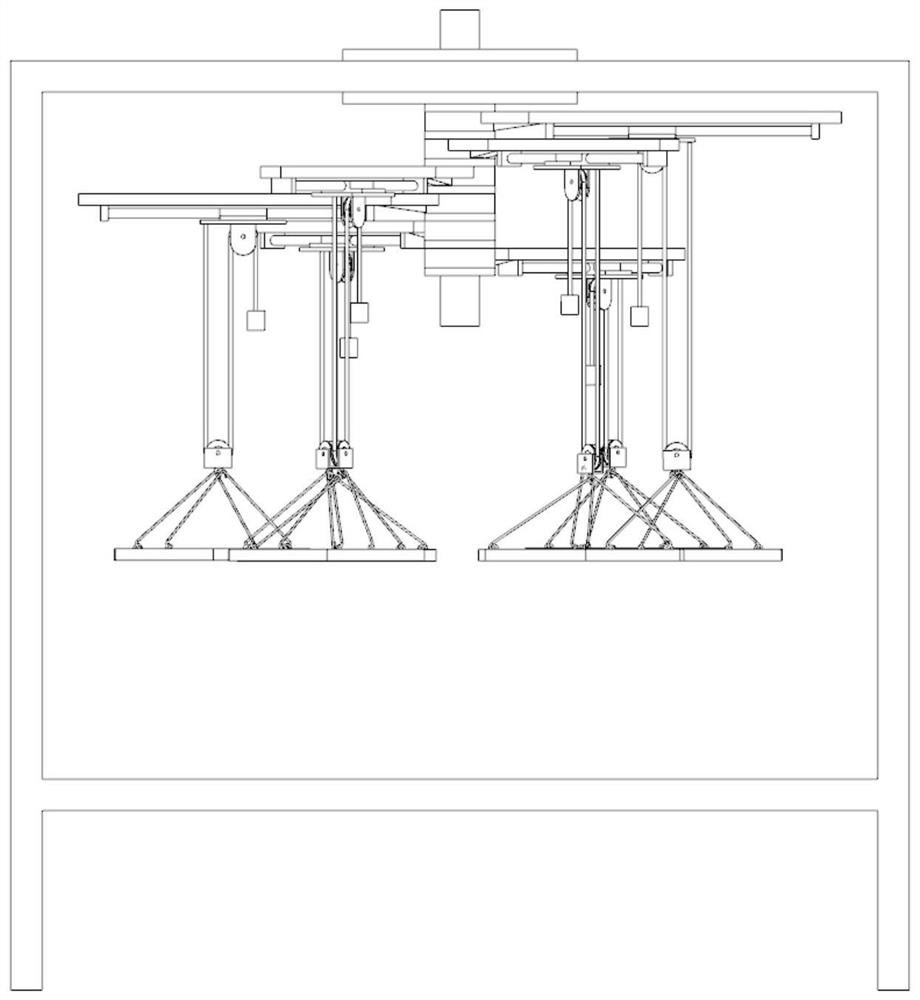

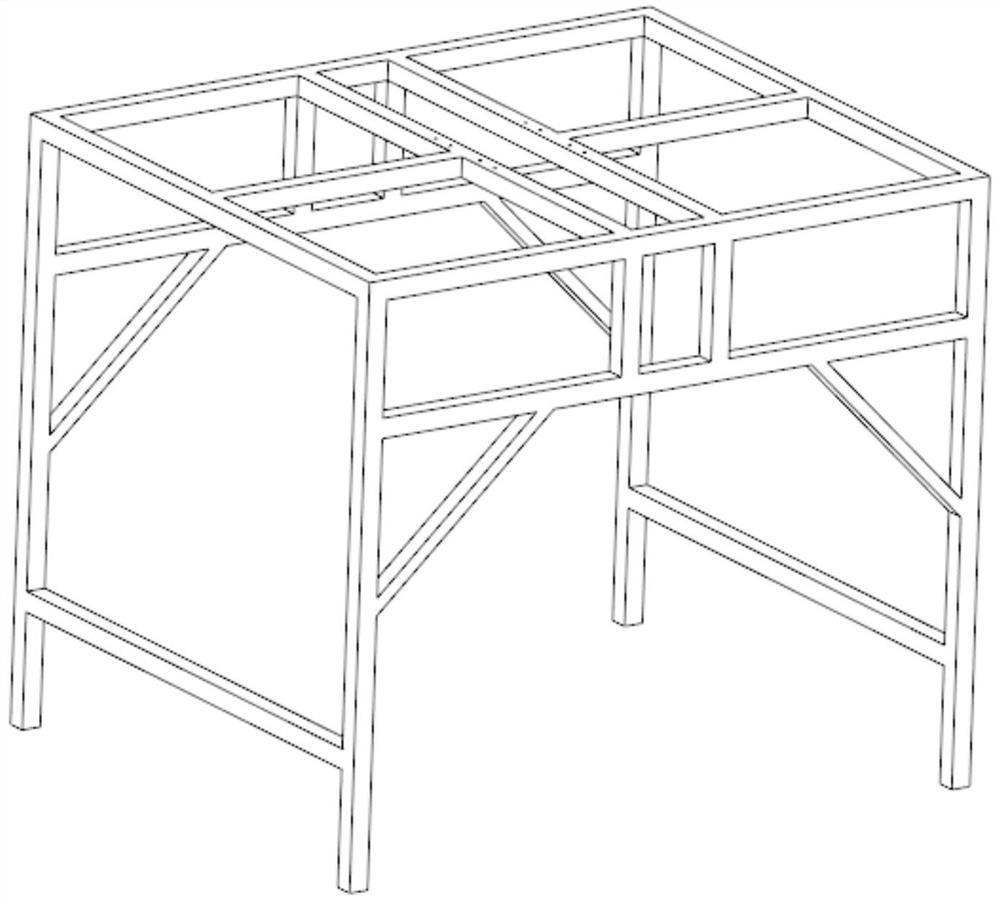

[0036] like figure 1 , figure 2 As shown in the figure, a follow-up gravity unloading suspension device disclosed in this embodiment includes a two-degree-of-freedom suspension bracket and an adjustable suspension device, wherein the two-degree-of-freedom suspension bracket includes a suspension bracket 1 and a vertical column 2 , Pillar fixing part 3, horizontal rotating guide rail 4, horizontal sliding guide rail 5, rolling bearing 2.1; The object of the ground microgravity simulation experiment is the space lens 10 . The counterweight 7 is used to unload the space lens by gravity. The suspension bracket 1 is used to support and protect the entire gravity unloading device. The horizontal rotation guide rail 4 and the horizontal sliding guide rail 5 generate two degrees of freedom in the horizontal direction, and through the rolling bearing 2.1 in the guide rail, the frictionless rotation and sliding of the space lens in the horizontal direction with the assembly process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com