Rotary joint ground gravity Lorentz force magnetic suspension unloading system

A rotary joint and magnetic levitation technology, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of complex structure, difficult to achieve, and small bearing capacity of the balloon suspension method, and achieve no disturbance in movement, high flexibility, and high flexibility. Strong structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further elaborated below in conjunction with embodiment.

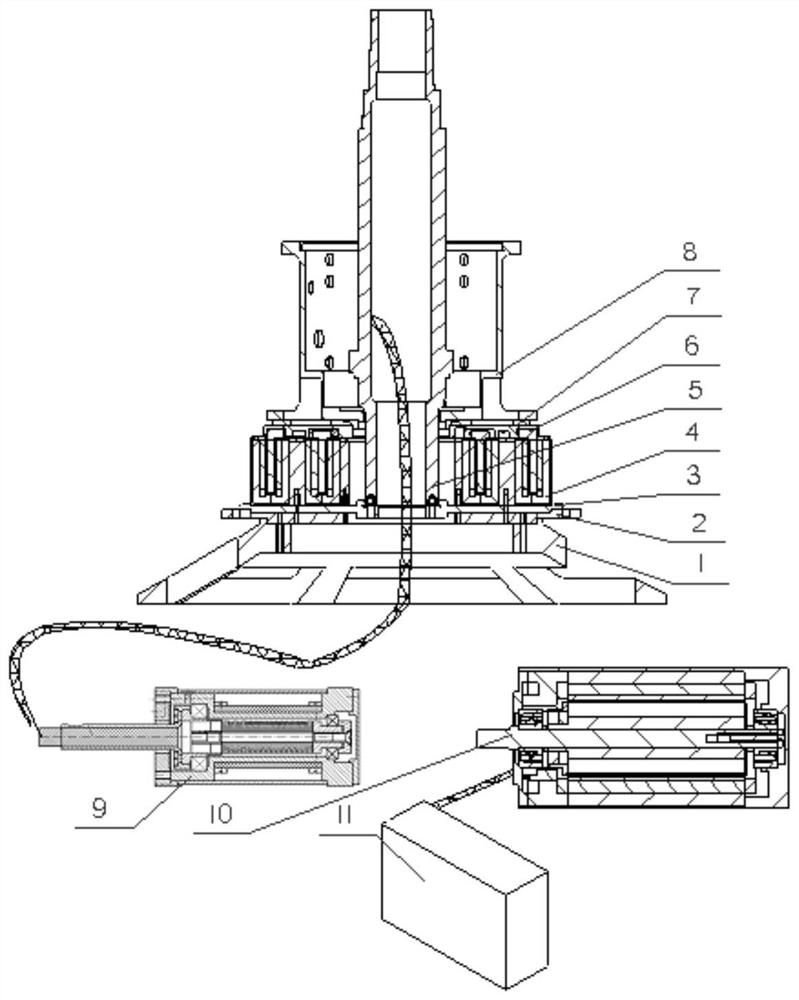

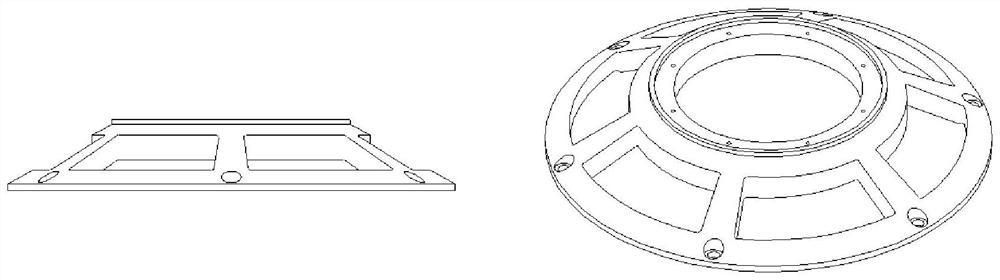

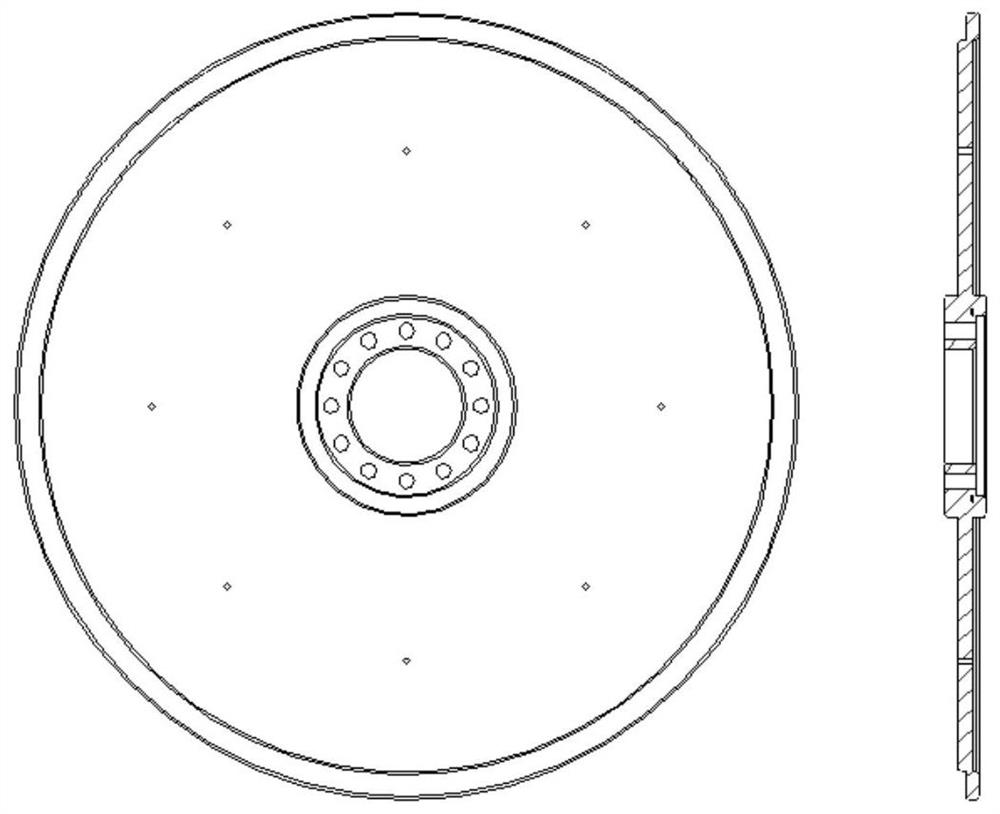

[0039] Such as Figure 1-11 As shown, the gravity unloading scheme of the present invention, by changing the installation adapters of the rotor assembly and the stator assembly, can realize the suspension of the outer casing part or the inner central axis part of the product under test, wherein the rotating part of the product under test must be the Suspended parts. The present invention is applied to the products whose outer shell parts are electrically connected. The scheme of suspending the outer shell parts requires more configurations than the scheme of suspending the internal central shaft parts. The specific implementation mode will now be described by taking the suspended outer shell parts as an example.

[0040] A rotary joint ground gravity Lorentz force magnetic levitation unloading system, including a stator assembly, a rotor assembly, a conductive ring assembly and a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com