Large-section rectangular pipe jacking machine jacking structure with external brim and construction method thereof

A pipe jacking machine, external technology, applied in the direction of earth square drilling, mining equipment, tunnels, etc., can solve the problems of soil collapse, affecting the operation safety of existing subway stations and entrances and exits, unresolved reception and disintegration, etc., to ensure that Operational Security Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions in the embodiments of the present invention will be clearly and completely described below. The embodiments of the present invention and all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

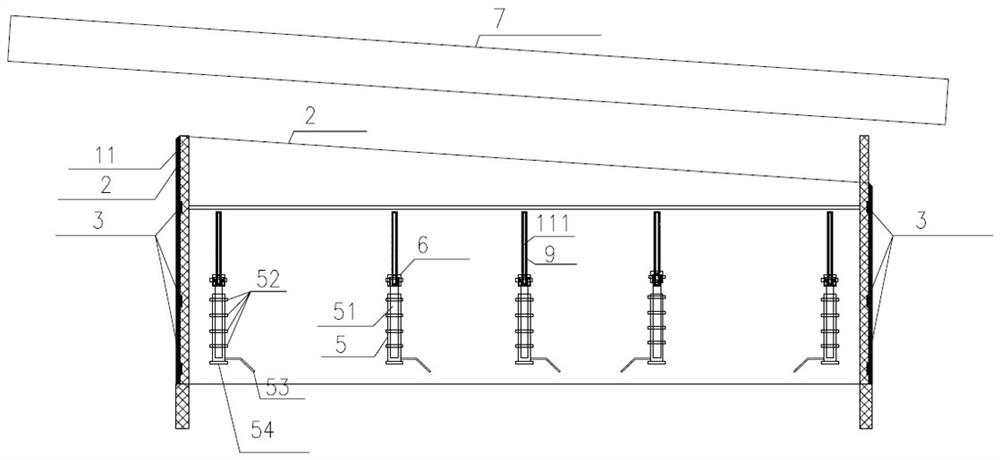

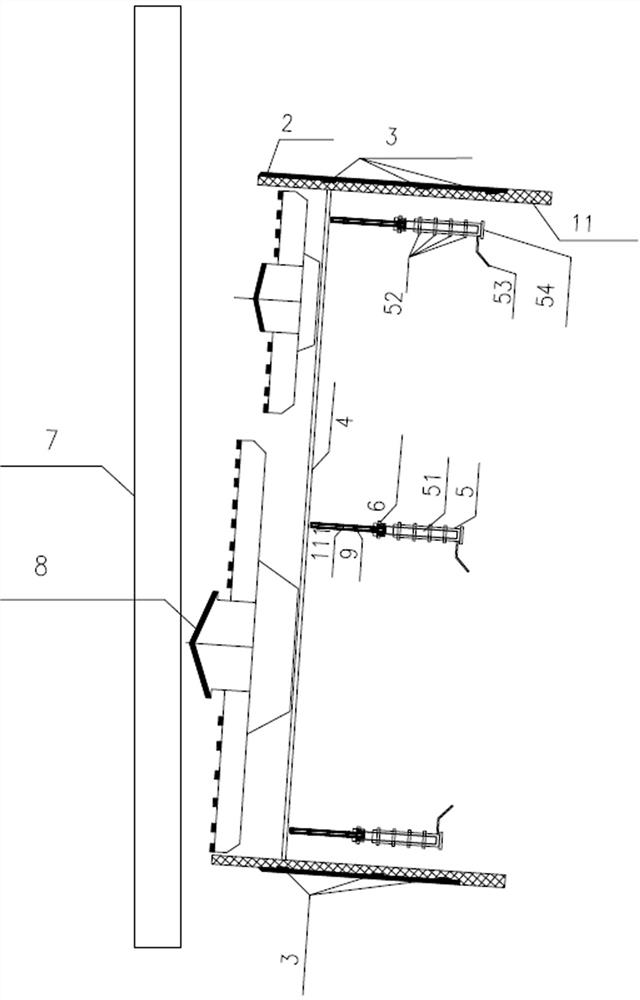

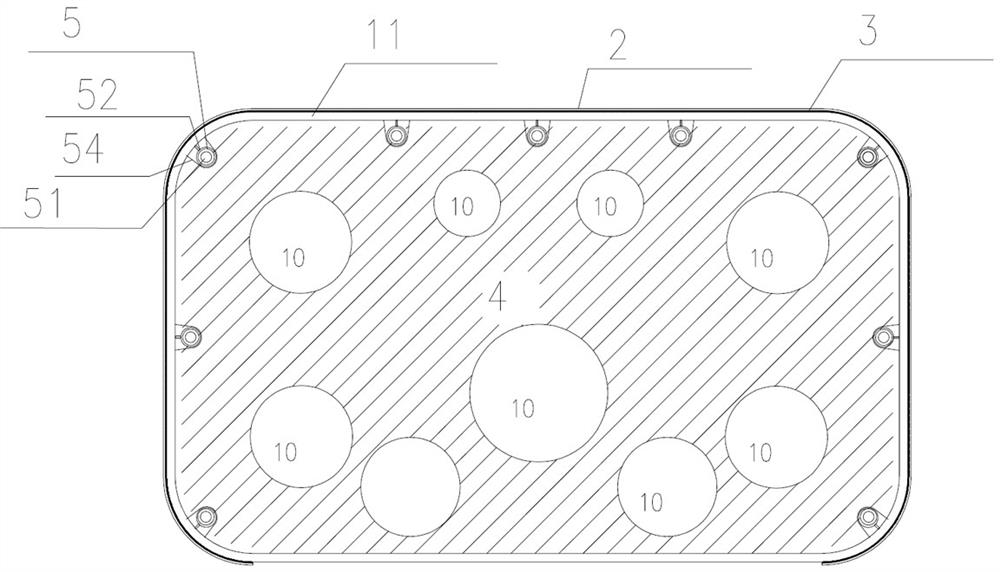

[0032] Such as Figure 1-8 As shown, the jacking structure of a large-section rectangular pipe jacking machine with an external hat brim in a preferred embodiment of the present invention includes: a rectangular pipe jacking machine 1, an external hat brim 2, a sliding seal 3, a chest plate 4, a jacking jack 5 and a jack Push the stopper 6. The external brim 2 is arranged on the outside of the pipe jacking machine shell 11. The external brim 2 has an inverted U-shaped structure. The front end of the external brim 2 is arranged obliquely, which fits the side wall of the entrance and exit of the subway station, and the rear end extends to the pipe jackin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com