A single-phase submerged liquid-cooled cabinet

An immersed, cabinet technology, used in cooling/ventilation/heating retrofits, electrical components, electrical equipment structural parts, etc., can solve problems such as high energy consumption and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to better understand the above-mentioned technical solutions, the exemplary embodiments of the present application will be described in detail below with reference to the accompanying drawings. Obviously, the described embodiments are only part of the embodiments of the present application, rather than all embodiments of the present application. It is understood that the application is not limited by the exemplary embodiments described herein.

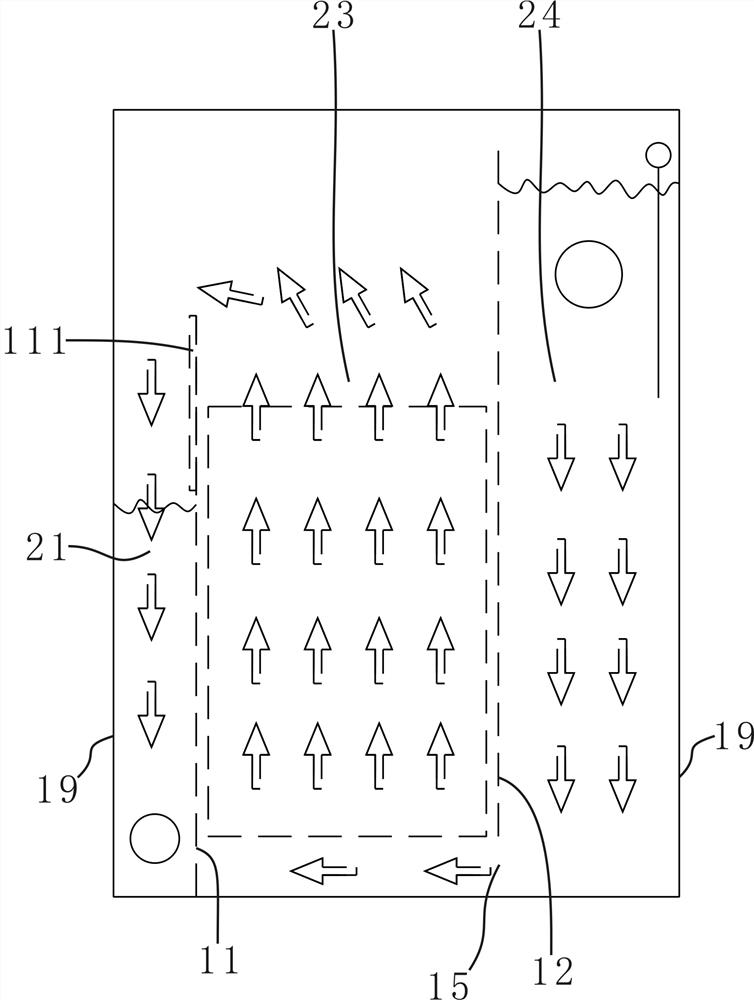

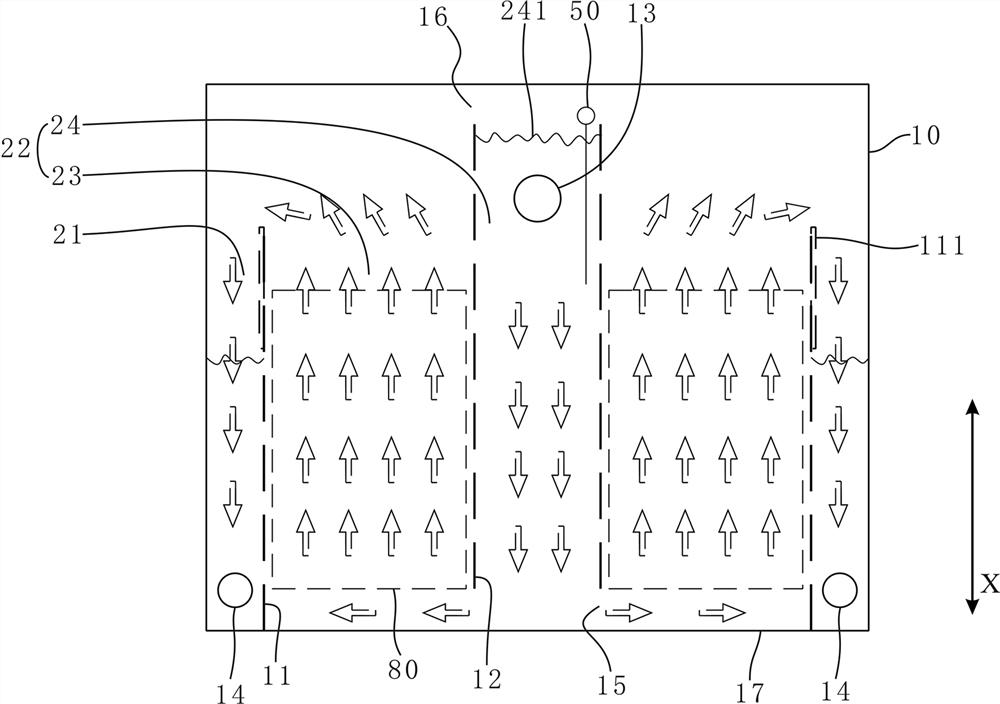

[0054] combine Figure 1-Figure 3, the embodiment of the present application provides a single-phase submerged liquid-cooled cabinet, the liquid-cooled cabinet includes a cabinet shell 10, the cabinet shell 10 has a bottom plate 17 and an accommodating space formed on the bottom plate 17; The bottom plate 17 extends and divides the accommodating space into a backflow tank 21 and a bearing tank 22; the second dividing plate 12 is arranged on the bearing tank 22, and divides the bearing tank 22 into an equipment area 23 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com