Single-phase immersed liquid cooling cabinet

An immersion and liquid cooling technology, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of poor heat dissipation effect of liquid cooling and large flow of coolant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

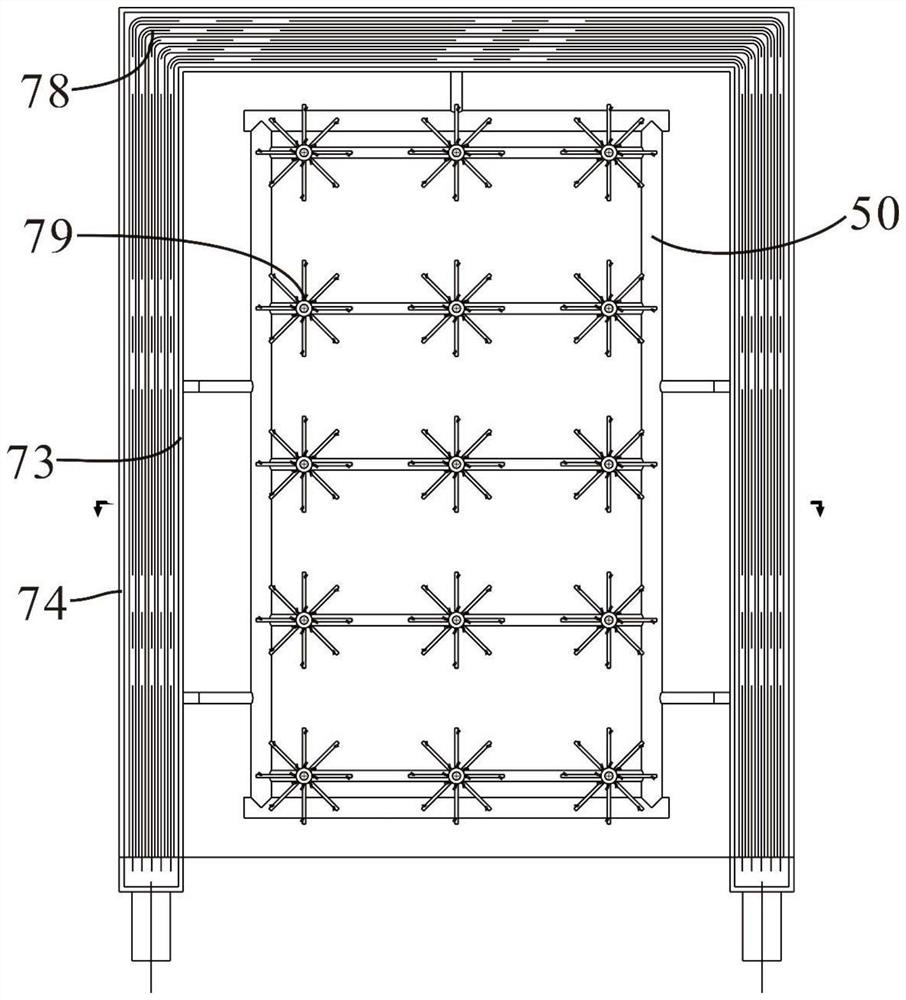

[0058] In order to better understand the above technical solutions, the exemplary embodiments of the present application will be described in detail below with reference to the accompanying drawings. Obviously, the described embodiments are only a part of the embodiments of the present application, not all the embodiments of the present application. It is understood that the present application is not limited by the exemplary embodiments described herein.

[0059] Submerged liquid-cooled cabinets dissipate heat from electronic equipment through circulating coolant.

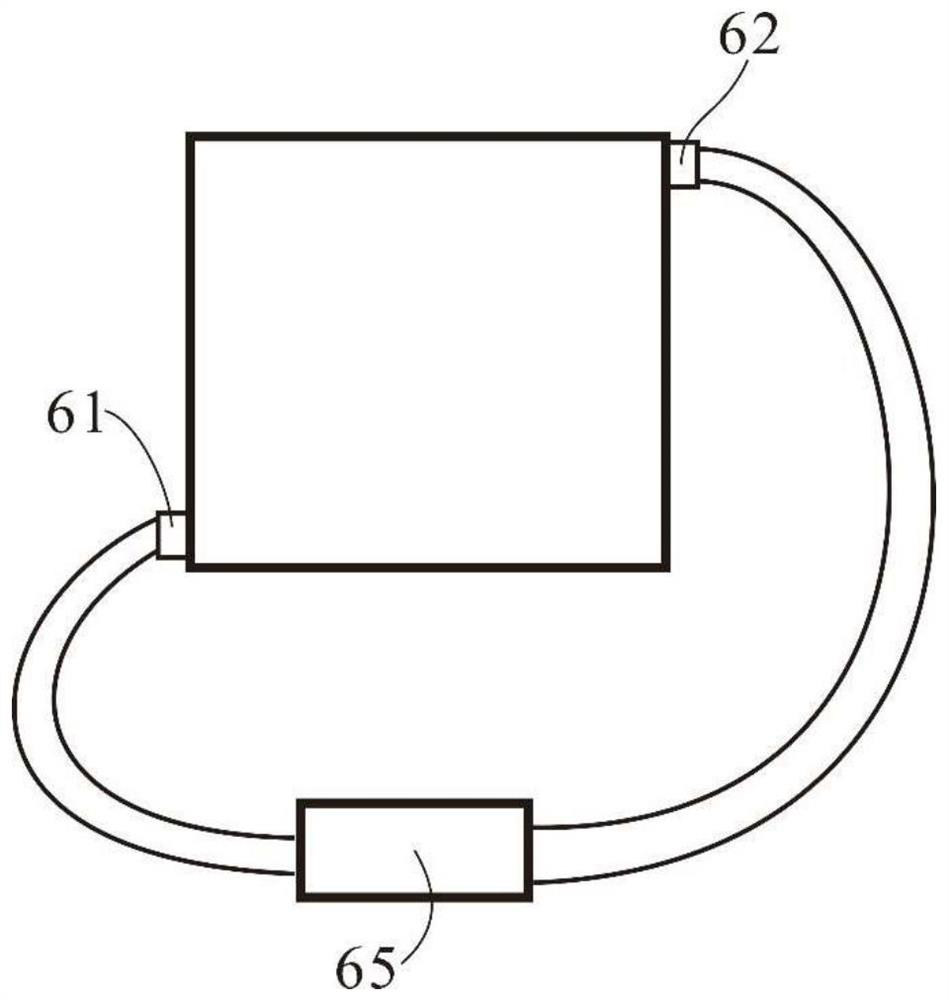

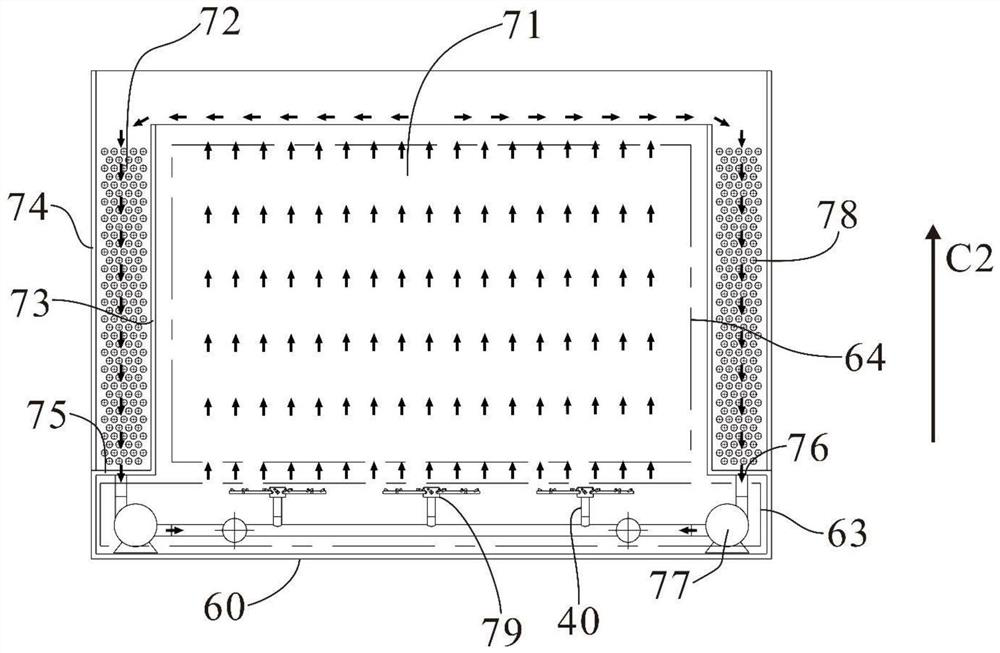

[0060] Common submerged liquid cooling cabinets are designed as a container with an upper opening and a certain volume, see figure 1 , multiple electronic devices can be installed in it, and it is filled with insulating cooling liquid. The liquid cooling cabinet is provided with a cooling liquid inlet 61 at the bottom and a cooling liquid outlet 62 at the top. The low-temperature cooling liquid exchanges heat with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com