Preparation method of atropa belladonna extract

A technology of belladonna extract and belladonna herb, which is applied in the field of medicine, can solve problems such as the inability to meet the content requirements of scopoletin and hyoscyamine sulfate, and achieve simple and easy steps, suitable for industrial production, and simple operation steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

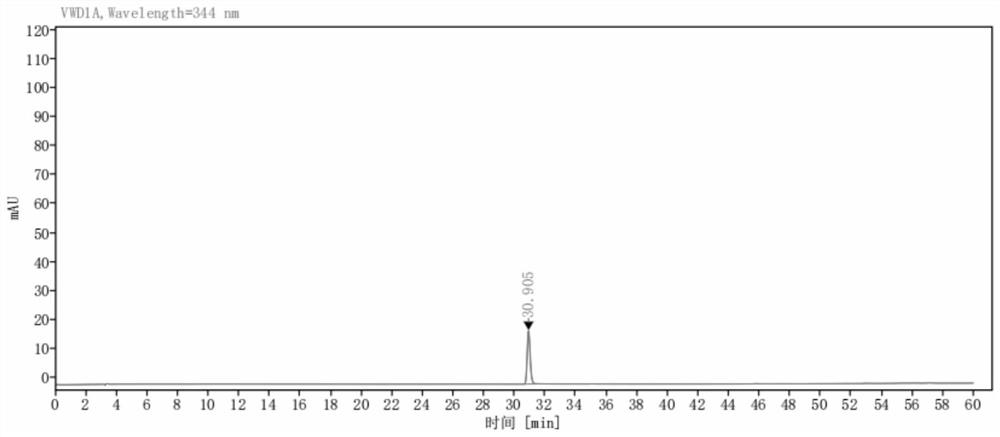

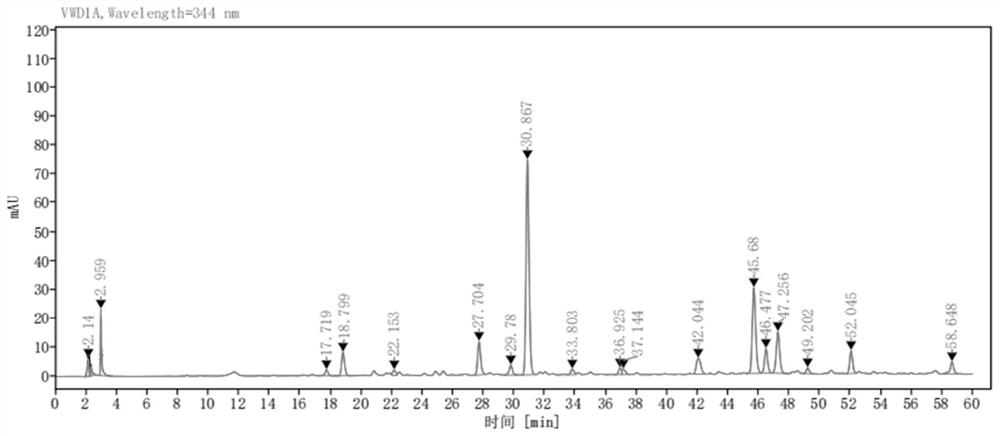

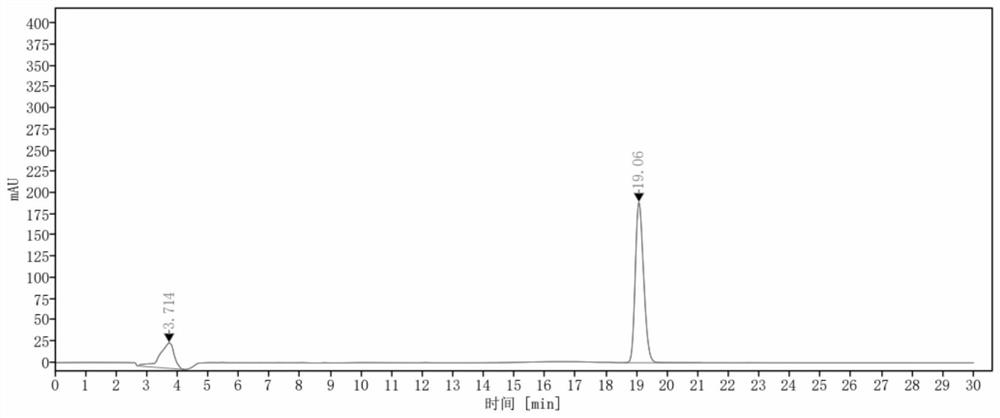

Image

Examples

preparation example Construction

[0037] The present invention provides the following method for preparing belladonna extract meeting the requirements of the 2020 edition of the Chinese Pharmacopoeia, which includes the following steps: S100 percolation extraction: belladonna and 85% ethanol are fed layer by layer alternately, using ethanol as a solvent After soaking with belladonna for 48 hours, percolation; S200 concentration: Concentrate the obtained primary liquid to a specific gravity of 1.200-1.300kg / m 3 (50°C) concentrated solution; S300 filtration: the obtained concentrated solution is filtered to remove chlorophyll; S400 concentrated extract: the obtained filtrate is concentrated to a specific gravity of 1.200-1.300kg / m 3 (50°C) thick paste; S500 alcohol precipitation: add 85% ethanol to the thick paste obtained from S400, stir and let it stand for alcohol precipitation; S600 concentration: the supernatant obtained after alcohol precipitation is concentrated to a specific gravity of 1.200-1.300 kg / m ...

Embodiment 1

[0049] The volume fraction 85% ethanol solution of belladonna after pulverizing 320kg and 1440kg is put into the multifunctional extraction tank by the mode alternately layer by layer, airtight, after soaking for 48 hours, collect the primary percolation from the outlet at a speed of 0.9L / min, It is 960kg to collect the initial liquid volume, and its quality is 3 times of the quality that belladonna adds;

[0050] Pump the primary liquid into the double-effect concentration tank, control the temperature of the first effect at 55°C to 65°C, and maintain the vacuum at -0.04MPa to -0.06MPa; control the temperature of the second effect at 50°C to 55°C, and maintain the vacuum at -0.06 Concentrate from MPa to -0.08MPa. The concentration time is 6h, and the specific gravity is detected, and the specific gravity is 1.22kg / m 3 (50°C);

[0051] After concentrating, use a 200-mesh double filter to filter the concentrated solution to remove chlorophyll; heat the obtained filtrate in an...

Embodiment 2

[0057] The volume fraction 85% ethanol solution of belladonna after pulverizing 320kg and 1440kg is put into the multifunctional extraction tank by the mode alternately layer by layer, airtight, after soaking for 48 hours, collect the primary percolation from the outlet at a speed of 0.9L / min, It is 960kg to collect the initial liquid volume, and its quality is 3 times of the quality that belladonna adds;

[0058] Pump the primary liquid into the double-effect concentration tank, control the temperature of the first effect at 55°C to 65°C, and maintain the vacuum at -0.04MPa to -0.06MPa; control the temperature of the second effect at 50°C to 55°C, and maintain the vacuum at -0.06 Concentrate from MPa to -0.08MPa. The concentration time is 6h, and the specific gravity is detected, and the specific gravity is 1.22kg / m 3 (50°C);

[0059] After concentrating, use a 200-mesh double filter to filter the concentrated solution to remove chlorophyll; heat the obtained filtrate in an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com