Patents

Literature

115 results about "Atropa belladonna" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A plant species of the genus ATROPA, family SOLANACEAE that contains ATROPINE; SCOPOLAMINE; BELLADONNA ALKALOIDS and other SOLANACEOUS ALKALOIDS. Some species in this genus are called deadly nightshade which is also a common name for SOLANUM.

Ecological pesticide-added fertilizer and preparation method thereof

InactiveCN104016813APromote growthPromote rooting and branchingFertilizer mixturesSide effectAdditive ingredient

The invention discloses an ecological pesticide-added fertilizer scientifically prepared from minerals and organic fertilizers as fertilizer efficiency ingredients and Chinese herbal medicines as pest-killing and pest-dispelling ingredients, and a preparation method of the ecological pesticide-added fertilizer, belonging to the field of fertilizers. The ecological pesticide-added fertilizer is prepared from the following raw materials by weight parts: 6-50 parts of the organic fertilizers, 6.5-65 parts of crude salt, 3.5-35 parts of lime, 2-25 parts of atropa belladonna, 2-15 parts of poinsettia, 2-25 parts of alocasia macrorrhiza, 2-15 parts of rohdea japonica, 2-25 parts of flos daturae, 2-20 parts of chili and 2-25 parts of garlic. The ecological pesticide-added fertilizer has the characteristics of being safe, environment-friendly and free of toxic side effects, pesticide and fertilizer effects are integrated, the environment can not be polluted, the human health can not be threatened, a production process is simple, the material source is wide, and the pesticide effect and the fertility are good.

Owner:茹晖

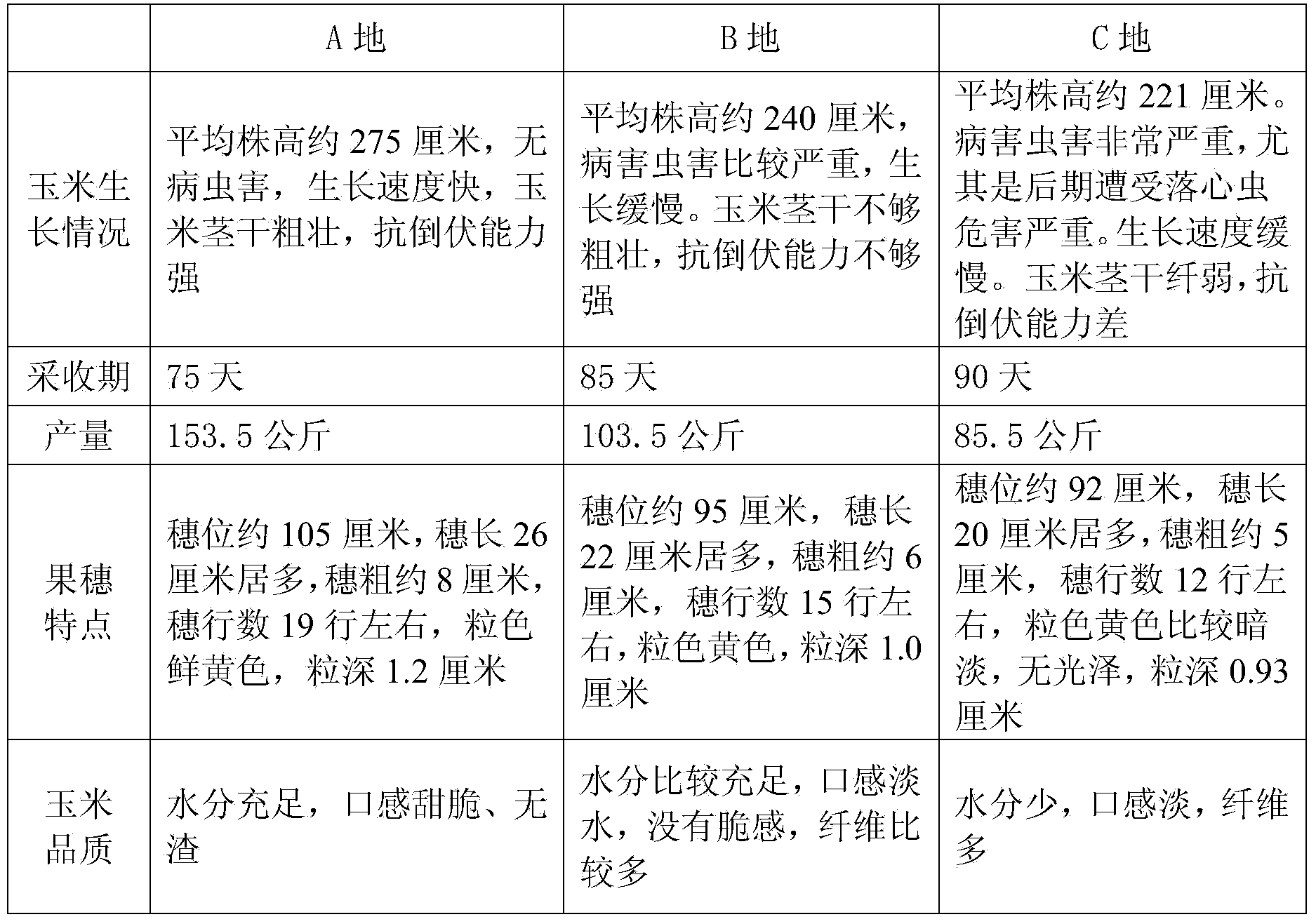

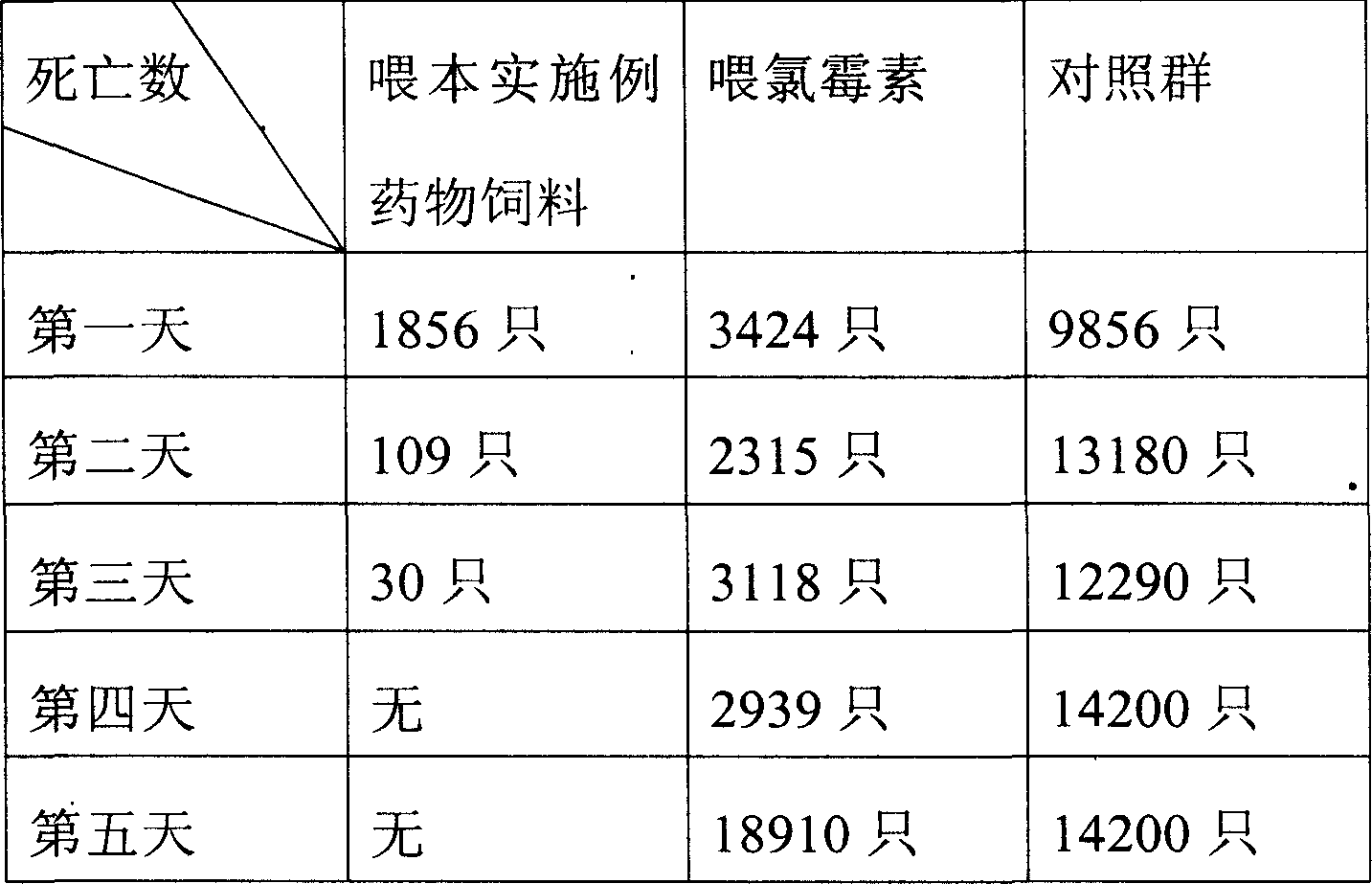

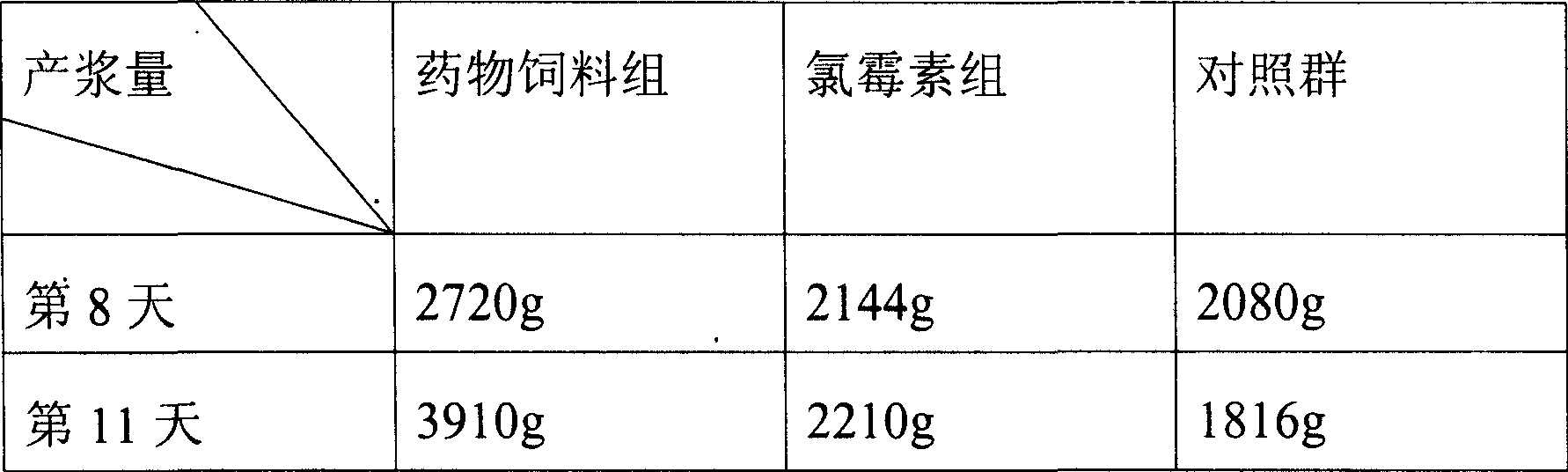

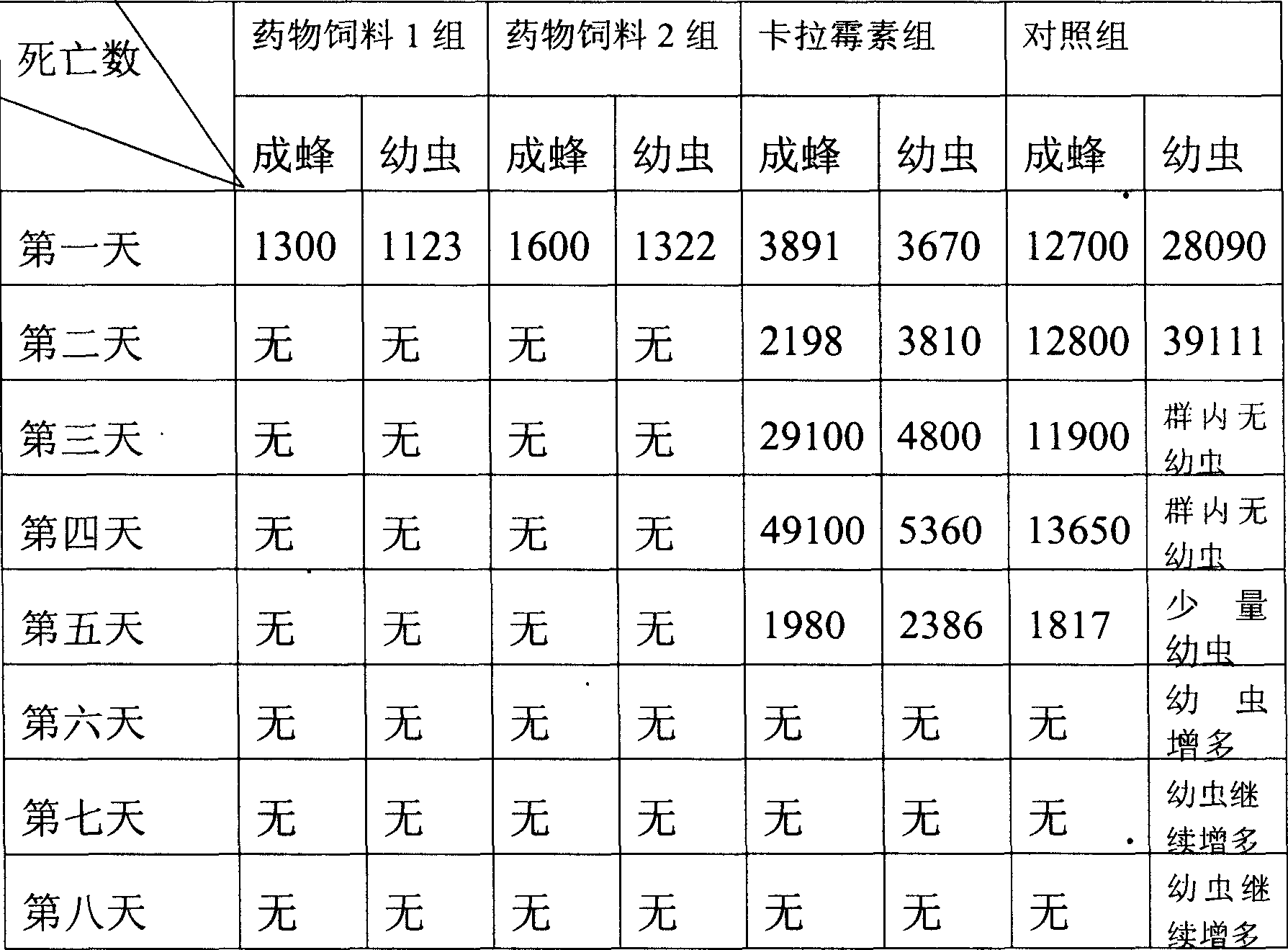

Composition for treating bee disease and medicinal fodder

The present invention provides a medicine composition for curing bee diseases of paralysis, dysentery and pest, etc. with obvious therapeutic effect. Said medicine composition is formed from (by weight portion) 1.5-3 portions of licorice, 0.5-2 portions of rhubarb, 1.5-2.5 portions of galangal root, 0.5-1.5 portions of bovine bezoar, 0.5-1.5 portions of atropa belladonna, 0.5-1.5 portions of ovate atractylodes root and 1-3 portions of isatis root.

Owner:叶达华

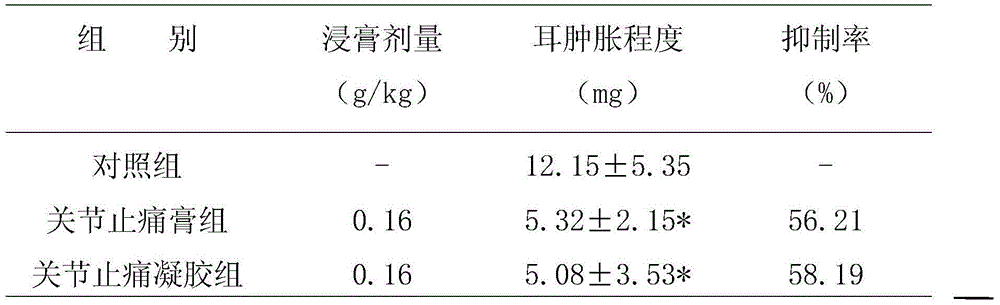

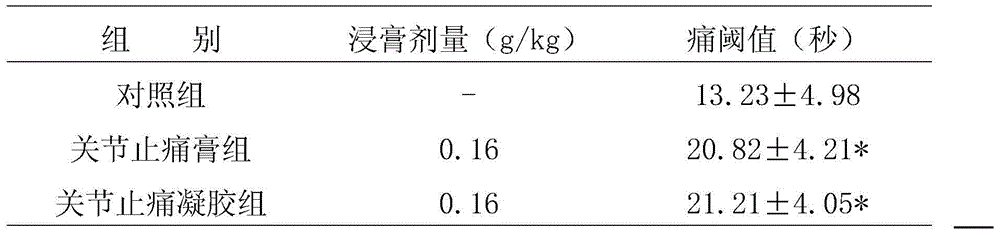

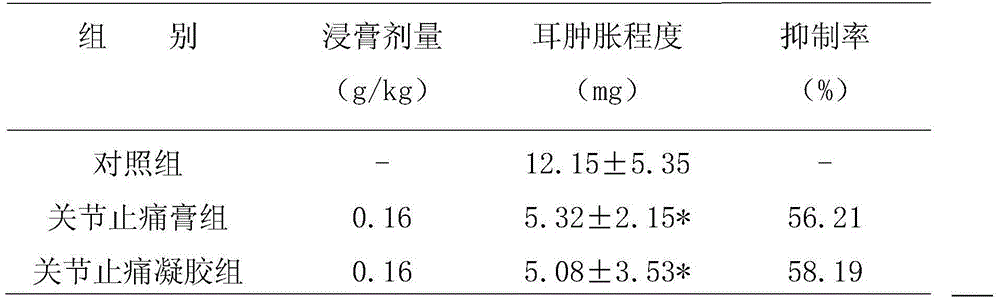

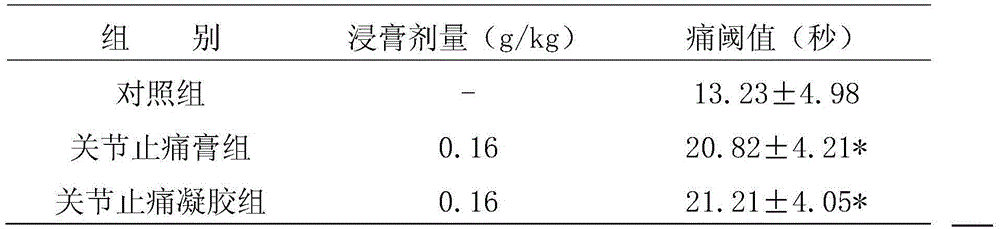

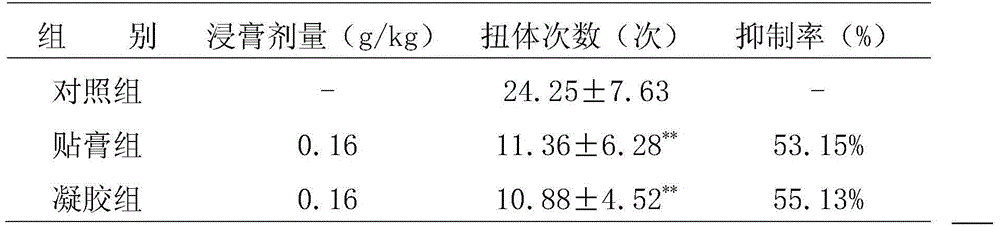

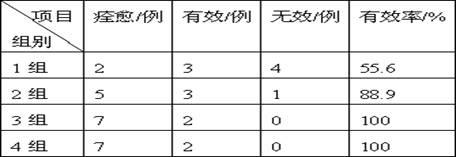

Arthralgia relieving gel and preparation method thereof

InactiveCN104013729APromote absorptionPromote softeningAntipyreticAerosol deliveryJoint arthralgiaPeppermints

The invention relates to the medicine field and specifically discloses an arthralgia relieving gel. The arthralgia relieving gel is prepared from raw materials including the following components in parts by weight: 160-240 parts of capsicum fluid extract, 90-140 parts of atropa belladonna fluid extract, 30-50 parts of dementholized peppermint oil, 70-90 parts of methyl salicylate, 160-240 parts of camphor, 10-15 parts of diphenhydramine hydrochloride, 1-10 parts of triethanolamine, 2-30 parts of carbomer, 1-3 parts of ethylparaben, 3-40 parts of hydroxypropyl methylcellulose, 50-100 parts of glycerin, 1-10 parts of ethanol, 1-5 parts of azone and a proper quantity of water; all the raw material components are of 1000 parts in total. The invention also discloses a preparation method of the arthralgia relieving gel. Compared with the existing arthralgia relieving plaster in the prior art, the arthralgia relieving gel has the advantages of good stability, easy absorption, remarkable medical effect, low skin irritation and safe production.

Owner:ANHUI ANKE YULIANGQING PHARMA

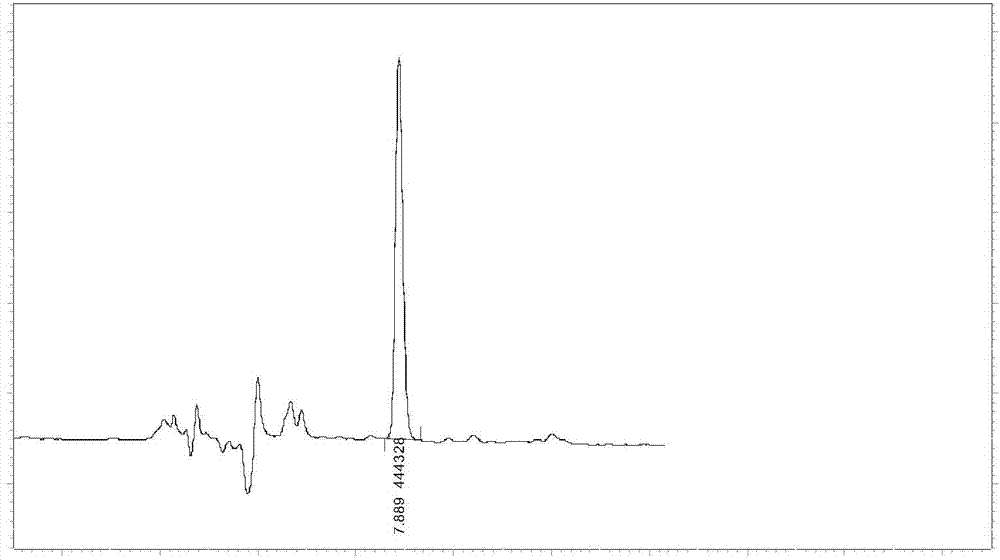

Belladonna extract and preparation method thereof

The invention provides a preparation method of a belladonna extract. The preparation method comprises the following steps: (A) soaking coarse powder of belladonna herb in ethanol, percolating the coarse powder, filtering the percolate and carrying out evaporation concentration on the filtrate, thus obtaining first thick paste; (B) adding water to dilute residual substances after filtration, adjusting the PH value to acidity, then separating upper chlorophyll, collecting lower clear liquor, adjusting the PH value to alkalinity and concentrating the clear liquor, thus obtaining second thick paste; (C) mixing the first thick paste with the second thick paste, thus obtaining the belladonna extract. The content of atropine sulfate in the belladonna extract obtained by adopting the preparation method is between 9.8mg / ml and 10mg / ml. The belladonna extract has the advantages that the belladonna extract has good effects and high purity; all the indexes meet the corresponding requirements of the national formulary and even outclass the effects superior to the quality indexes stipulated in the formulary.

Owner:重庆希尔安药业有限公司

Preparation method of traditional Chinese medicinal capsule

ActiveCN102349973AImprove powder propertiesLittle difference in loadingDigestive systemCapsule deliveryLiquoricesChinese drug

The invention discloses a preparation method of a traditional Chinese medicinal capsule. The stomach-recovering capsule is prepared from 317.5g of radix paeoniae alba, 238.1g of bletilla, 9.9g of pseudo-ginseng, 317.2g of liquorice root, 238.1g of tuckahoe, 158.7g of rhizoma corydalis, 31.7g of cuttlebone, 2.1g of extractum of Atropa belladonna and pharmaceutic adjuvant. By improvement on the process, the powder characteristic of capsule contents is improved and the gross deviation is reduced.

Owner:杨文龙

Atropa belladonna WRKY transcription factor gene and recombinant plant expression vector and application thereof

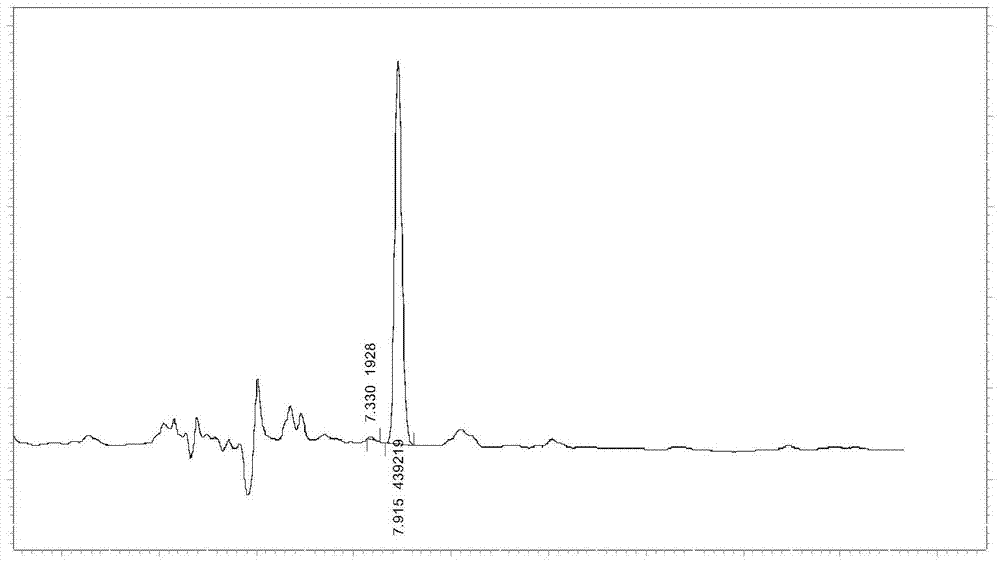

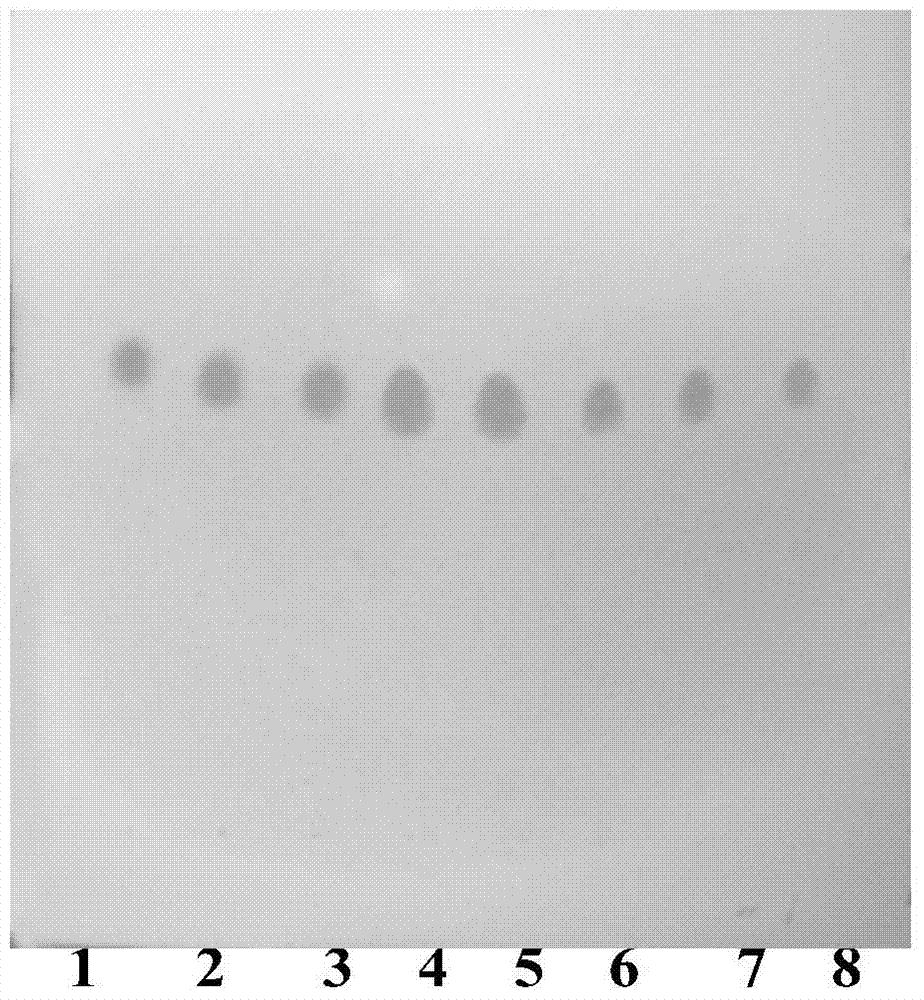

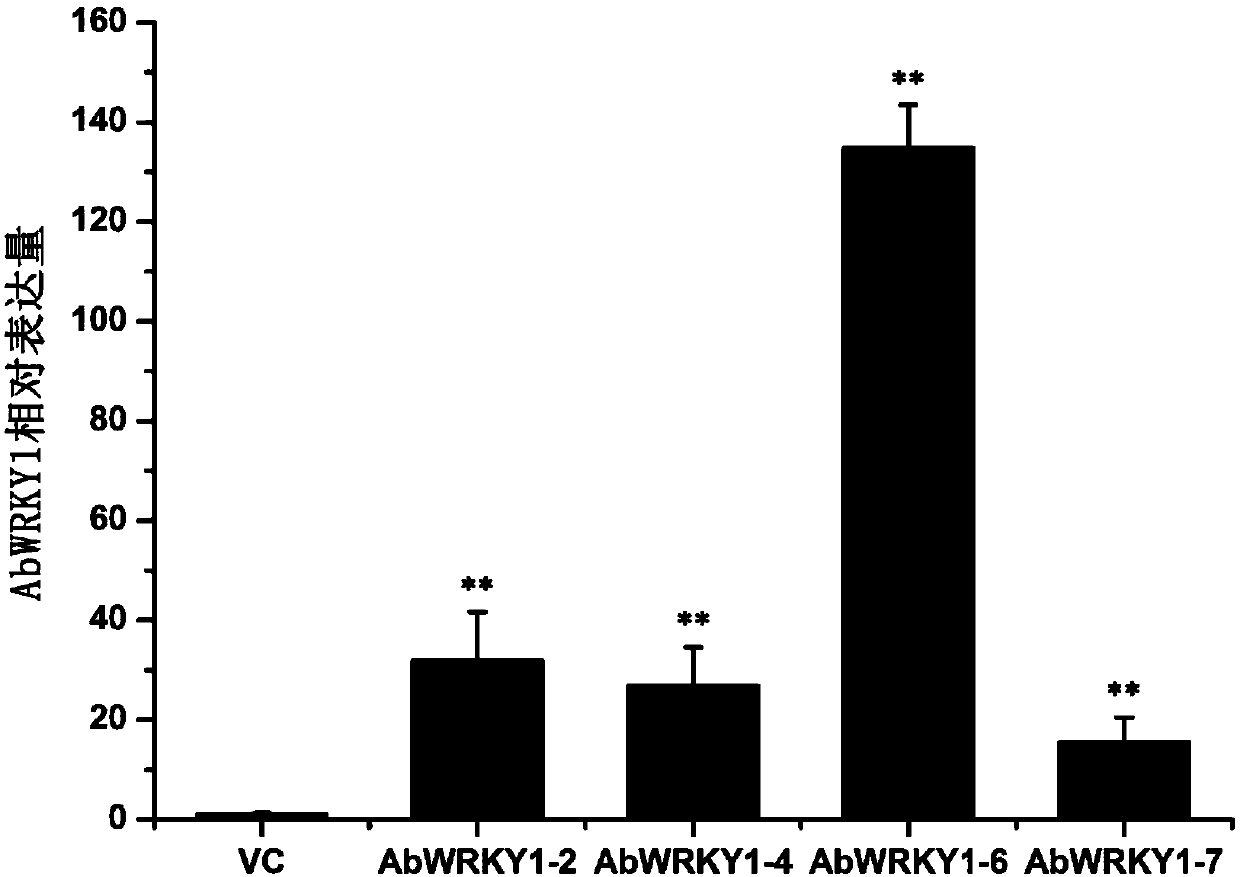

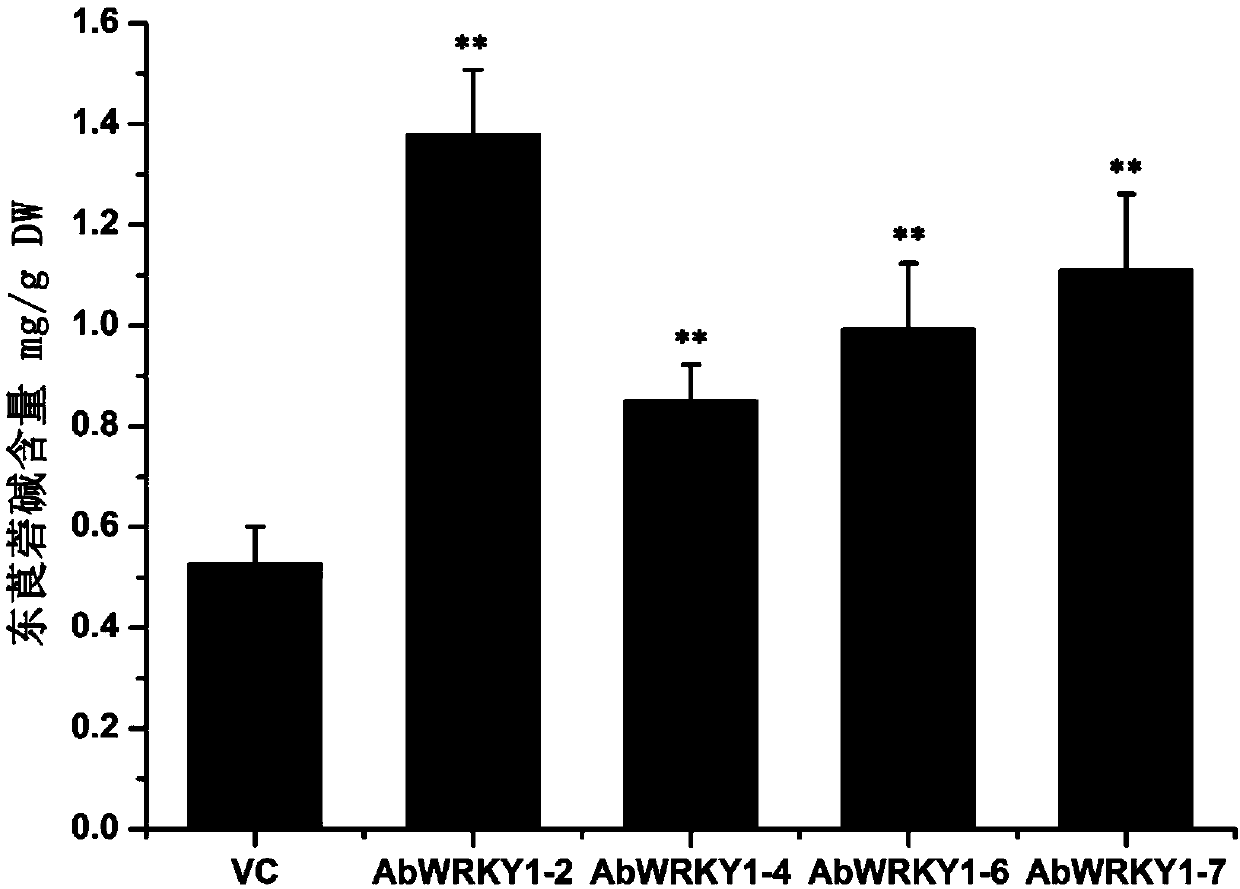

ActiveCN107937414AIncrease scopolamine contentSignificantly regulatedPlant peptidesFermentationNucleotideWRKY transcription factor

The invention relates to an atropa belladonna WRKY transcription factor gene and a recombinant plant expression vector and application thereof. The gene has a specific gene promoter activation role for synthesis of scopolamine, wherein the nucleotide sequence thereof is as shown in SEQ ID NO.3, and the coded amino acid sequence is as shown in SEQ ID NO.4. The AbWRKY1 gene is overexpressed in atropa belladonna, so that the content of scopolamine in atropa belladonna hairy root is increased, therefore, the gene can be applied to improvement of quality of the atropa belladonna, and can increase the content of scopolamine in the atropa belladonna.

Owner:成都上交致远生物科技有限公司

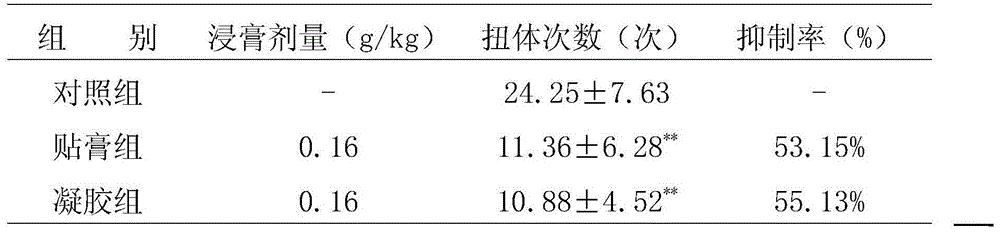

Hyperostosis cold compress paste and preparation method thereof

InactiveCN107296852AGuaranteed respiratory metabolismIncrease contact surfaceHydroxy compound active ingredientsSkeletal disorderDihydroxyaluminum aminoacetateIrritation

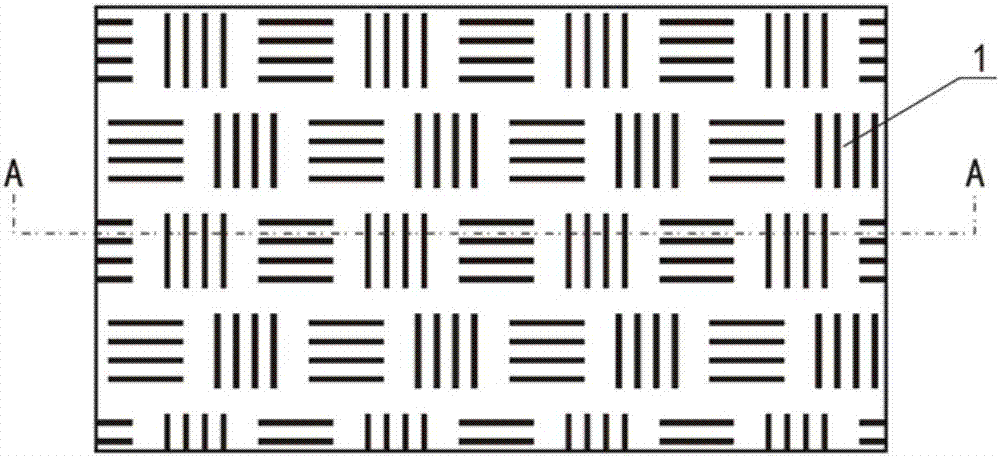

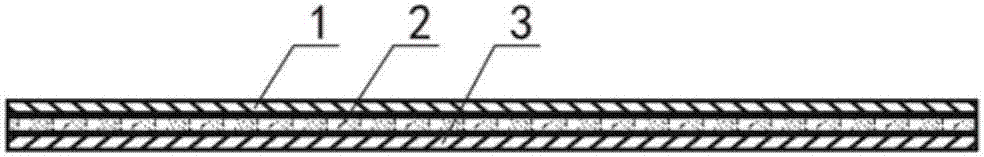

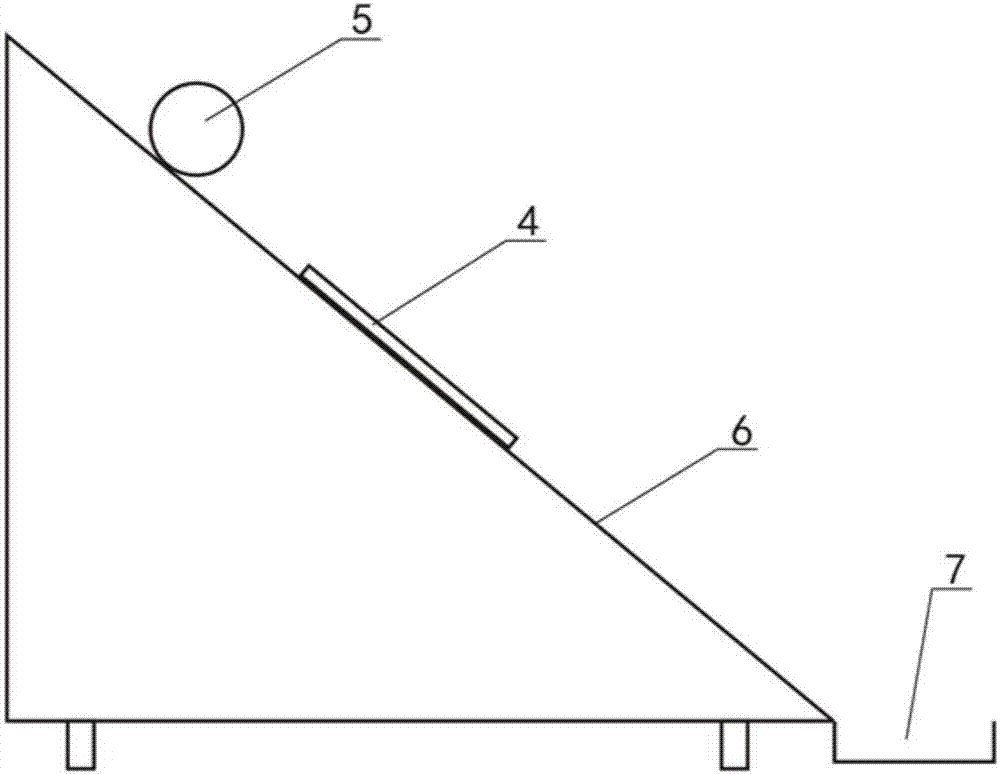

The invention discloses a hyperostosis cold compress paste which comprises a backing layer, a gel drug layer and an anti-bonding layer, wherein the gel drug layer contains the following raw materials: sodium polyacrylate, carbomer, glycerol, dihydroxyaluminum aminoacetate, tartaric acid, purified water, medical borneol, camphor, diclofenac sodium, menthol, atropa belladonna fluid extract, clove oil, propylene glycol, glycerol, medical azone, diphenhydramine, oleum menthae and capsaicin. The invention also discloses a preparation method for the hyperostosis cold compress paste. The method comprises the following steps: preparing a gel drug and then coating the backing layer with the gel drug by machine so as to form a gel drug layer; covering the gel drug layer with the anti-bonding layer; cutting, puncturing and slicing, thereby acquiring the hyperostosis cold compress paste. No organic solvent is added into the bruise cold compress paste disclosed by the invention; the cold compress paste can be directly coated and does not need to be heated; the technology is simple and no chemical residue exists; the cold compress paste is free from irritability and stimulation, is high in drug loading capacity and moisture retention, has high compatibility with skin, is anti-ageing, has excellent weather fastness and lasting viscidity and can be repeatedly uncovered and pasted.

Owner:四川利佰生物科技有限公司

Ointment capable of removing dampness and relieving pain and preparation method of ointment

InactiveCN104906544ASimple preparation processShort processHydroxy compound active ingredientsAntipyreticMentholMedicine

The invention discloses an ointment capable of removing dampness and relieving pain and a preparation method of the ointment. The ointment capable of removing dampness and relieving pain comprises the following components in parts by mass: 45-55 parts of fluid extract capable of removing dampness and relieving pain, 12-18 parts of methyl salicylate, 8-12 parts of menthol, 8-12 parts of borneol, 18-22 parts of camphor, 10-15 parts of rue fluid extract, 25-35 parts of atropa belladonna fluid extract, 185-195 parts of rubber, 60-70 parts of rosin, 2-4 parts of liquid paraffin, 265-275 parts of rubberlith, 10-15 parts of zinc oxide, 13-15 parts of yellow soft paraffin and 7-11 parts of wool fat. The preparation method of the ointment is simple, and is few in processes; the ointment is obvious in function, stable in property and low in cost.

Owner:吉林万通药业集团郑州万通复升药业股份有限公司

Preparation method and application of atropa belladonna extract

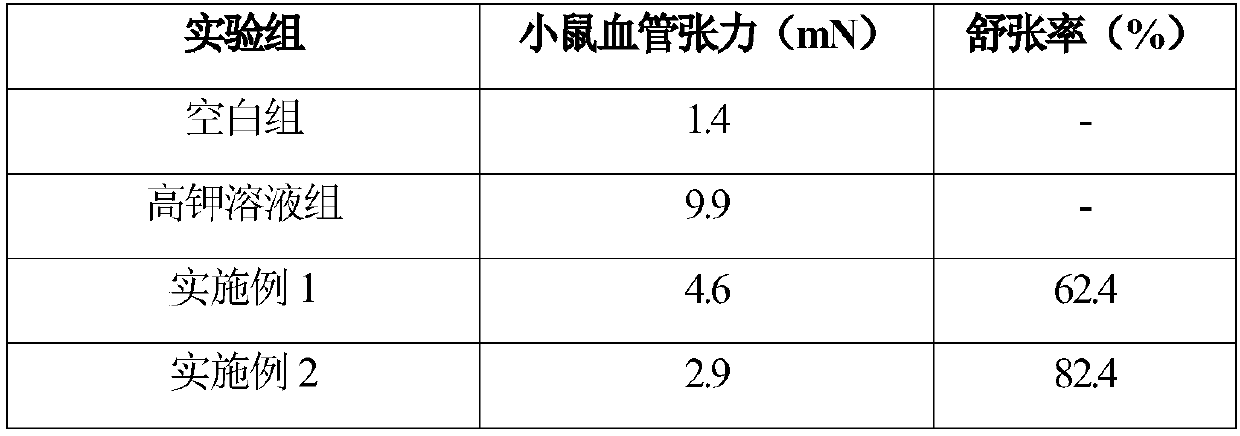

InactiveCN107582729AAvoid enteringPromote leachingCardiovascular disorderPlant ingredientsWarm waterCell wall

The invention discloses a preparation method and an application of an atropa belladonna extract. The preparation method comprises processes as follows: soaking in warm water, ethanol extraction, percolation and the like. According to the medicine preparation method, the inside of a percolator is covered with multiple layers of cellulase membranes, cell walls consisting of cellulose in atropa belladonna are broken with cellulase, leaching of effective components in cells is accelerated, and the utilization rate of raw materials is greatly increased; the atropa belladonna extract prepared with the method can be taken as a novel vascular smooth muscle relaxing medicine and used for preparing medicines for treating hypertension, and a new scheme can be provided for clinical treatment of hypertension.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

a drug to treat cancer

InactiveCN102283976AReduce expensesGood anti-cancer effectAmphibian material medical ingredientsAnthropod material medical ingredientsSide effectAdditive ingredient

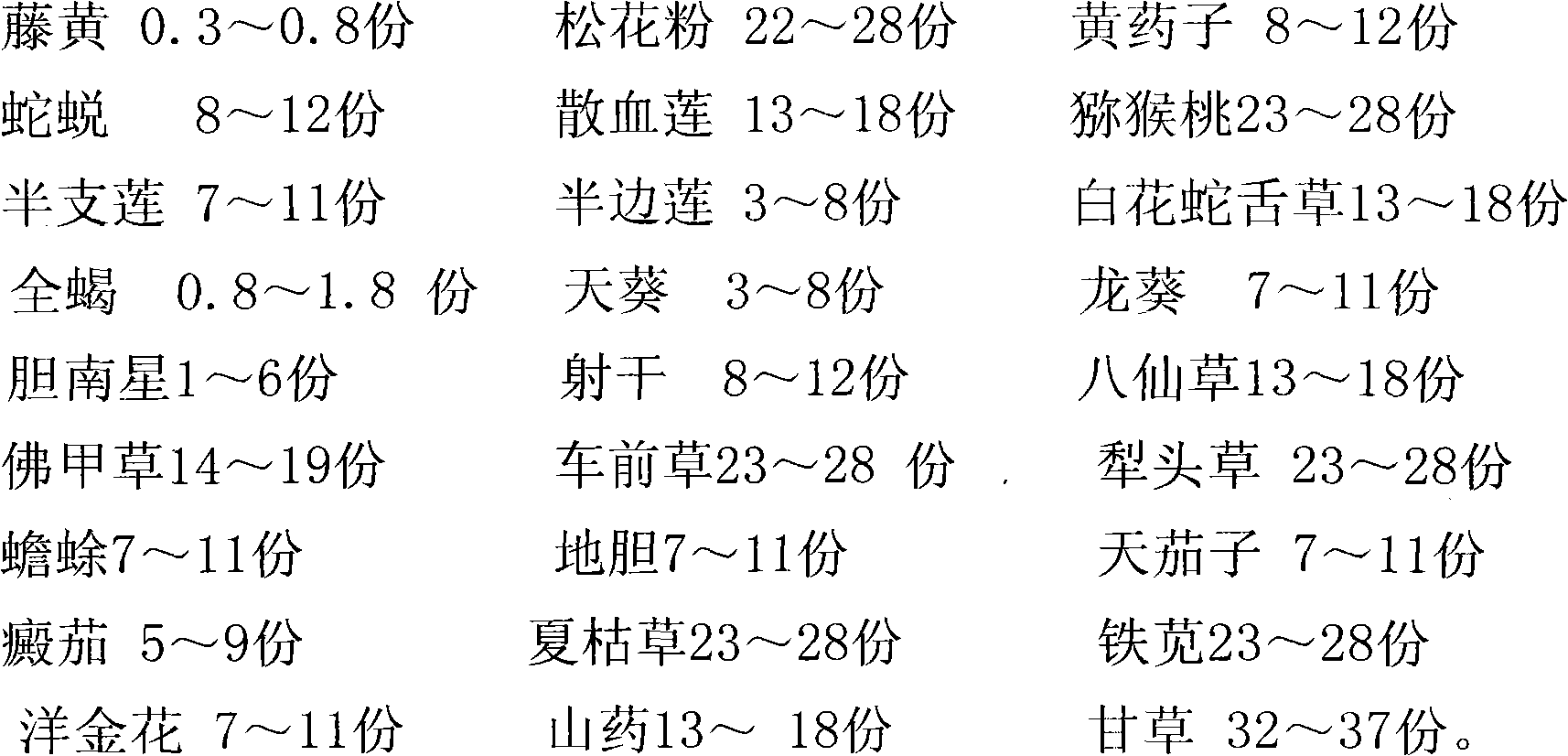

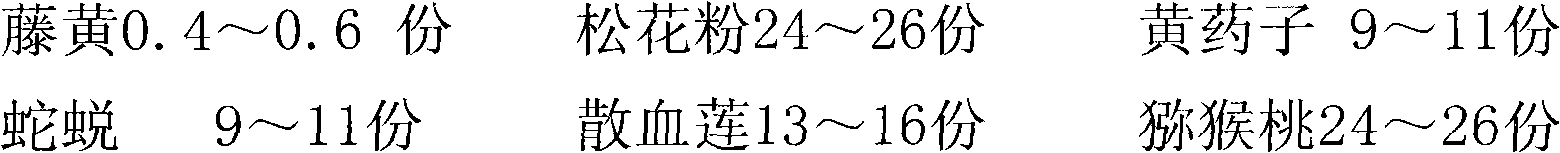

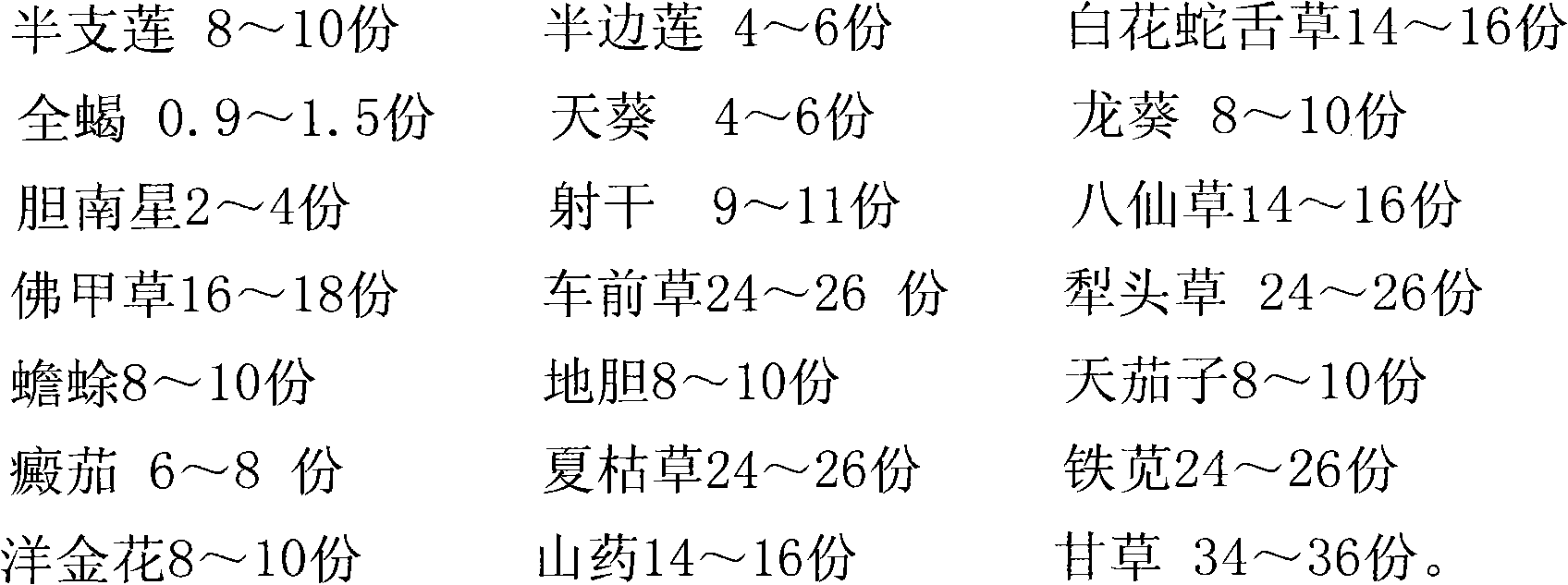

The invention relates to a drug for treating cancer. The drug is prepared from the following raw materials: gamboge, pine pollen, airpotato yam, periostracum serpentis, Japanese coniogramme rhizome, kiwi fruits, Portulaca grandiflora Hook., Herba Lobeliae Chinensis, Hedyotis diffusa, Scorpio, semiaquilegia adoxoides, Solanum nigrum, Arisaema cum bile, blackberry lily, catchweed bedstraw herb, Sedum lineare, plantain, viola japonica, toad, Meloe coarctatus, Calonyction muricatum, Atropa belladonna, selfheal, copperleaf herb, datura flower, yam and licorice. The drug extracts anticancer and tumor-eliminating effective ingredients from traditional Chinese medicines, has the effects of resisting cancer and eliminating tumor, diminishing inflammation and relieving pains as well as repairing organism injury, and has the advantages of low toxic or side effect, low cost and good effect.

Owner:曹春徕

Belladonna liquid extract preparation method and application

InactiveCN106214837AFully extractedEasy to shapeInorganic non-active ingredientsPlant ingredientsAlcoholActive component

The invention provides a belladonna liquid extract preparation method which is characterized by particularly including the steps: 1) pre-treating belladonna herbs and then impregnating the belladonna herbs by ethyl alcohol; 2) percolating the belladonna herbs after impregnation, and combining and concentrating percolating liquid; 3) sinking and filtering the concentrated percolating liquid; 4) concentrating filtrate in the step 3) into extract, performing alcohol precipitation and then filtering the extract; 5) preparing and filling the belladonna liquid extract. The invention further provides the belladonna liquid extract prepared by the method. Compared with the prior art, the method has the advantages that effective active components in the belladonna herbs can be more sufficiently extracted, purer extract can be obtained, and the belladonna liquid extract prepared by the method conforms to all regulations of pharmacopeia and has good characters, higher purity and better efficacy.

Owner:CHONGQING WANWUCHUNSHENG PHARMA CO LTD

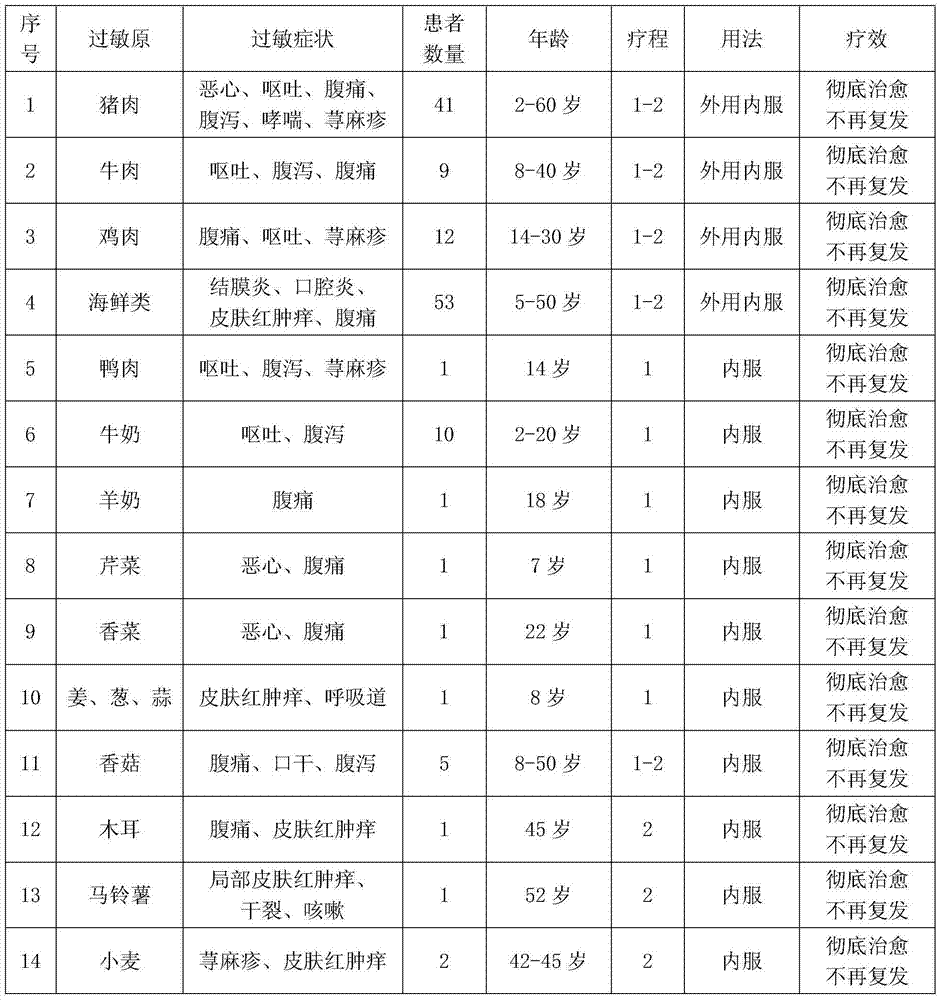

Pure traditional Chinese medicine formulation for treating allergy and preparation method of pure traditional Chinese medicine formulation

ActiveCN103690840ANo dependencyHormone freeImmunological disordersFish material medical ingredientsDiseaseCitrus medica

The invention provides a pure traditional Chinese medicine formulation for treating allergy and a preparation method of the pure traditional Chinese medicine formulation. The pure traditional Chinese medicine formulation is prepared from the following raw materials in parts by weight: 10-20 parts of seahorse, 20-40 parts of American ginseng, 20-40 parts of medlar, 20-40 parts of fructus jujubae, 10-20 parts of ginseng, 10-20 parts of saffron crocus, 10-20 parts of fingered citron, 10-20 parts of magnolia officinalis, 40-60 parts of hawthorn, 20-40 parts of malt, 20-40 parts of white atractylodes rhizome, 20-40 parts of radix ophiopogonis, 30-60 parts of schisandra chinensis, 20-40 parts of rhizoma atractylodis, 10-20 parts of pericarpium citri reticulatae, 20-40 parts of salvia miltiorrhiza, 20-40 parts of polygala tenuifolia, 1-5 parts of atropa belladonna, 60-80 parts of Chinese herbaceous peony, 20-40 parts of gastrodia elata, 10-20 parts of rubus parviaraliifolius hayata, 20-40 parts of mint leaf, 20-40 parts of duckweed, 10-20 parts of rhizoma smilacis glabrae, 10-30 parts of white atractylodes rhizome, 20-40 parts of radix saposhnikoviae, 20-40 parts of coix seeds, 10-20 parts of paliurus ramosissimus, 10-20 parts of astragalus membranaceus and 10-20 parts of safflower. The pure traditional Chinese medicine formulation is capable of curing patients suffering food allergy once and relieving the pain of the allergic patients; therefore, the allergic patients can intake various nutrient substance trustingly to boost immunity and enhance the disease resisting ability.

Owner:赵升瑞

Medicament for treating muscle and skeletal diseases

The present invention concerns the field of therapy of muscle, joint and / or skeletal diseases. In particular, the invention relates to a composition comprising a first solution comprising preparations of Aconitum napellus, Arnica montana, radix, Bellis perennis, Belladonna, Calendula officinalis, Chamomilla, Echinacea, Echinacea purpurea, Hamamelis virginiana, Hepar sulfuris calcareum, Hypericum perforatum, Mercuris solubilis, Millefolium, and Symphytum officinale, and a second solution comprising preparations of Arnica montana, radix, Dulcamara, Rhus toxicodendron, Sanguinaria Canadensis, and Sulphur. Further provided is a method of treating and / or preventing the progression of a disease comprising administering to a subject in need of a treatment a therapeutically effective amount of the said composition or said first and said second solution. The invention also contemplates a kit comprising said first and said second solution.

Owner:BIOLOGISCHE HEILMITTEL HEEL

Chinese medicament and western medicament combined formulation for treating cancerous diarrhea and processing method thereof

InactiveCN101564527AImprove the quality of lifeGood reliefTetracycline active ingredientsDigestive systemLife qualityChinese cinnamon

The invention relates to a Chinese medicament and western medicament combined formulation for treating cancerous diarrhea, which comprises selected Chinese medicinal materials and selected and used western medicament. The selected Chinese medicinal materials comprise the following components in portion by weight: 30 portions of medicine terminalia fruit, 20 portions of rice husk, 20 portions of nutmeg, 20 portions of angelica, 20 portions of Cinnamomum cassia, 15 grams of costus root, 30 portions of rhizoma atractylodis macrocephalae, 20 portions of radix paeoniae alba, 25 portions of radix codonopsitis and 10 portions of honey-fried licorice root, and also comprises three slices of ginger, and five dates; and the selected and used western medicament comprises spectrum antibiotic and antispasmodic, wherein the antispasmodic comprises terramycin and belladonna. The combined formulation not only can effectively control the cancerous diarrhea, but also has remarkable relieving effects on symptoms such as anorexia, emaciation and the like caused by cancer, is used for diarrhea caused by various cancers, and remarkably improves the life quality of cancerous diarrhea sufferers.

Owner:刘岑

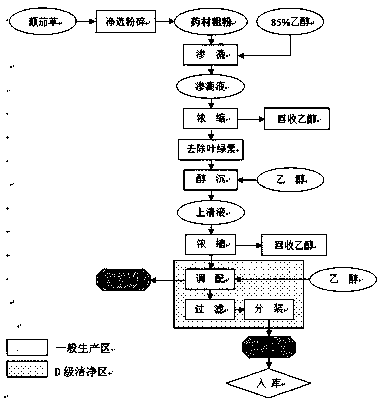

Production process of extractum belladonnae liquidum

The invention discloses a production process of extractum belladonnae liquidum. The production process comprises the following steps: digging belladonna herb, removing impurities, worm damage parts, mildewing parts and non-medicinal parts, washing away silt, softening the processed parts in the sun, stacking the softened parts, arranging the products at a shady, cool and ventilated place and drying the products after sweating of a covering woven bag, cutting the dried products into sections, and carrying out pulverizing to obtain coarse powder; putting the belladonna herb coarse powder into anextraction tank, adding ethanol and an acidic pepsase solution and then carrying out airtight impregnation, collecting a primary percolate from an outlet, recovering the primary percolate into a percolating cylinder, controlling the outlet of the percolating cylinder to percolate slowly, and collecting the percolate after complete percolating out of alkaloid; carrying out ultrasonic extraction onthe percolate, recovering ethanol till alcohol smell removing of a soup, and carrying out separation to remove chlorophyll; continuously concentrating the soup without chlorophyll into a thick paste,cooling the thick paste to a room temperature, and then removing chlorophyll on the surface; stirring and diluting the thick paste with ethanol, carrying out ultrasonic extraction, and then standingfor precipitation; taking supernatant after alcohol precipitation, recovering ethanol, carrying out concentration into a thick paste, and carrying out filtering; and then adding ethanol and purified water into the atropa belladonna thick paste to prepare extractum belladonnae liquidum, carrying out filtering, putting the filtered product into a clean container, and carrying out sealing and inspecting.

Owner:安徽恒达药业有限公司

Rheumatism cold compress paste and preparation method thereof

InactiveCN107296951AGuaranteed respiratory metabolismIncrease contact surfaceAnthropod material medical ingredientsHydroxy compound active ingredientsRheumatismGlycerol

The invention discloses a rheumatism cold compress paste which comprises a backing layer, a gel drug layer and an anti-bonding layer, wherein the gel drug layer contains the following raw materials: sodium polyacrylate, carbomer, glycerol, dihydroxyaluminum aminoacetate, tartaric acid, purified water, medical borneol, camphor, diclofenac sodium, menthol, atropa belladonna liquid extract, ginger oil, propylene glycol, glycerol, medical azone, diphenhydramine, oleum menthae and capsaicin. The invention also discloses a preparation method for the rheumatism cold compress paste. The method comprises the following steps: firstly, preparing a gel drug, and then coating the backing layer with the gel drug by machine so as to form the gel drug layer, coating the gel drug layer with the anti-bonding layer, cutting, puncturing and slicing, thereby acquiring the bruise cold compress paste. No organic solvent is added into the rheumatism cold compress paste disclosed by the invention; the rheumatism cold compress paste can be directly used for coating and does not need to be heated; the technology is simple and no chemical residue exists; the rheumatism cold compress paste is free from irritability and stimulation, is high in drug loading capacity and moisture retention, has high compatibility with skin, is anti-ageing, has excellent weather fastness and lasting viscidity and can be repeatedly uncovered and pasted; the production cost is lower.

Owner:四川利佰生物科技有限公司

Medicinal composition for treating gastropathy and its preparing method and use

InactiveCN1899558ARelieve symptomsSignificant therapeutic effectDigestive systemMolluscs material medical ingredientsMedicinal herbsActive component

The medicine composition for treating gastropathy contains the extracts of twoleaf swertia herb root, hairy birtwort root, corydalis rhizome, round cardamon seed, cablin potchouli herb and other nine kinds of Chinese medicinal materials as the active components, belladonna and pharmaceutically acceptable supplementary material. It has simple preparation process, fast acting, short treating period, high curative effect and less recurrence.

Owner:彭国全 +1

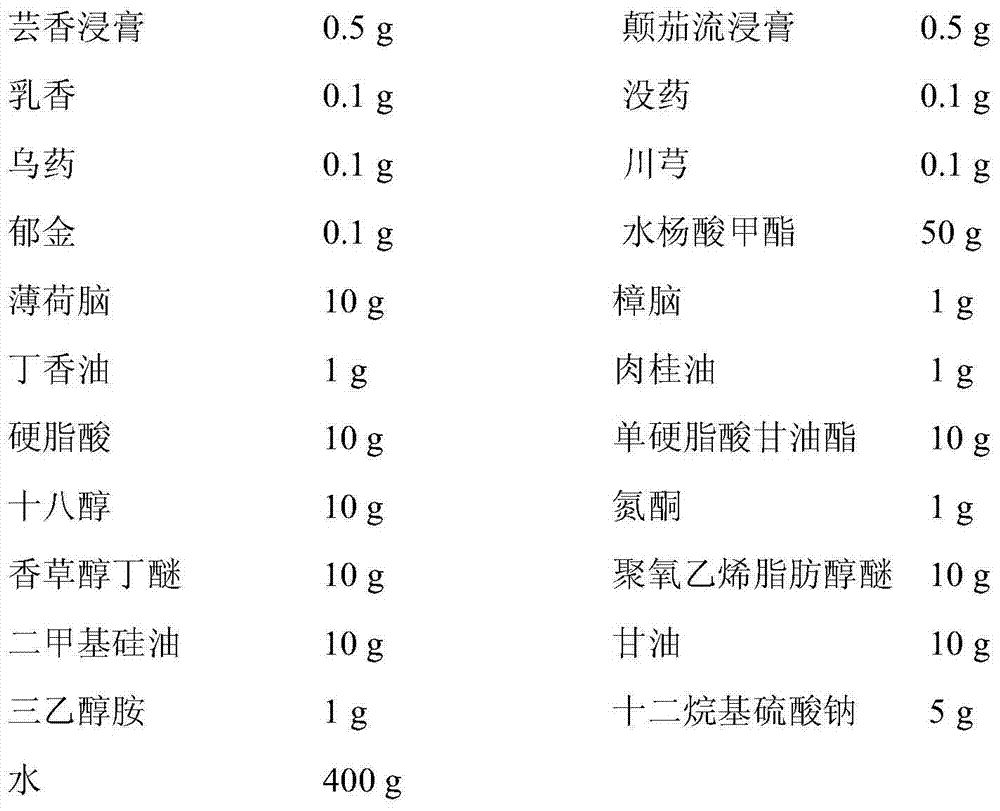

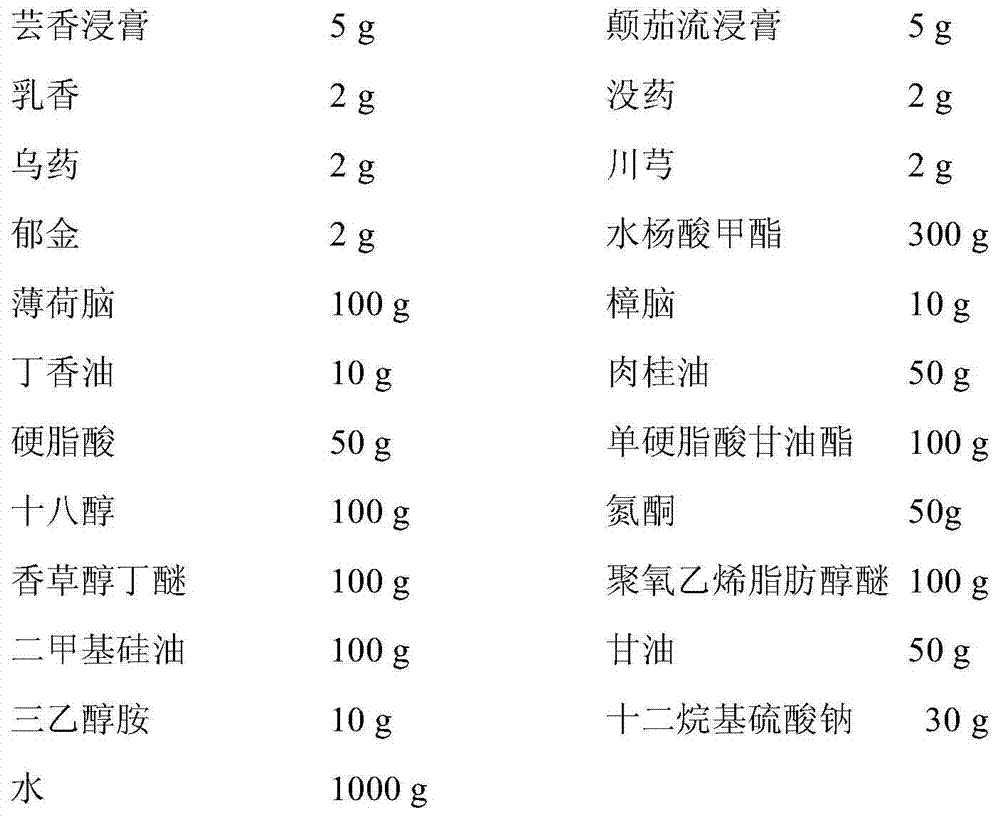

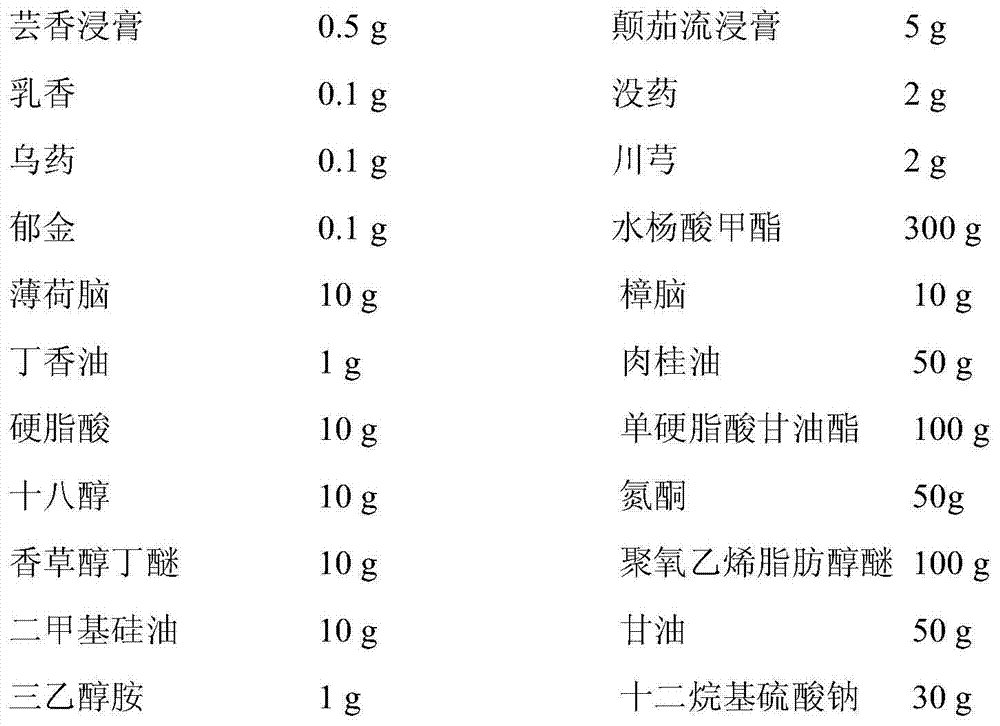

Hot massaging ointment capable of promoting blood circulation, removing blood stasis, dredging collaterals and relieving pain and preparation method of hot massaging ointment

ActiveCN104840892AGood effectFast competitive stateOrganic active ingredientsAntipyreticOil phaseMethyl salicylate

Owner:SHINEWAY PHARMA GRP SHANDONG

Joint pain relieving gel and preparation method thereof

InactiveCN104922289AImprove stabilityImprove rheologyOrganic active ingredientsAntipyreticJoint arthralgiaPeppermints

The invention relates to the medicine field and specifically discloses an arthralgia relieving gel. The arthralgia relieving gel is prepared from raw materials including the following components in parts by weight: 160-240 parts of capsicum fluid extract, 90-140 parts of atropa belladonna fluid extract, 30-50 parts of dementholized peppermint oil, 70-90 parts of methyl salicylate, 160-240 parts of camphor, 10-15 parts of diphenhydramine hydrochloride, 1-10 parts of triethanolamine, 2-30 parts of carbomer, 1-3 parts of ethylparaben, 3-40 parts of hydroxypropyl methylcellulose, 50-100 parts of glycerin, 1-10 parts of ethanol, 1-5 parts of azone and a proper quantity of water; all the raw material components are of 1000 parts in total. The invention also discloses a preparation method of the arthralgia relieving gel. Compared with the existing arthralgia relieving plaster in the prior art, the arthralgia relieving gel has the advantages of good stability, easy absorption, remarkable medical effect, low skin irritation and safe production.

Owner:ANHUI ANKE YULIANGQING PHARMA

Process for preparing belladonna liquid extract by ultrasonic dynamic multi-stage countercurrent extraction

ActiveCN106620008AIncrease concentrationReduce dosageCounter-current extractionEnergy based chemical/physical/physico-chemical processesUltrasonic cavitationAngina

The invention discloses a new process for preparing a traditional Chinese medicine belladonna liquid extract. The belladonna liquid extract is a domestic widely-used plant intermediate and clinically mainly used for gastric acid duodenal ulcer, angina of gastrointestinal tract, kidney and gallbladder and the like and has functions of removing smooth muscle spasm, restraining glandular secretion and the like. Original medicinal materials of the belladonna liquid extract are belladonna herb, and the belladonna herb is whole herb of Atropa belladonna L. A current main preparation method of the belladonna liquid extract is a percolation method, and the percolation method is long in consuming time, more in solvent consumption and insufficient in effective component enrichment. The invention discloses a process for preparing the belladonna liquid extract by ultrasonic dynamic multi-stage countercurrent extraction based on the conditions. According to the process, effective plant components are sufficiently extracted by the aid of ultrasonic cavitation effect, the dynamic multi-stage countercurrent extraction saves energy, and organic solvents are circularly used, so that the belladonna liquid extract is rapidly and effectively prepared. According to the process, an ultrasonic method is used in a dynamic multi-stage countercurrent extraction system for the first time.

Owner:CSPC JIANGXI GOLDEN LOTUS PHARMA CO LTD

Insecticide for stevia rebaudiana

InactiveCN106614831ANo drug resistanceReduce pollutionBiocideDead animal preservationNerium oleanderStemona

The invention provides an insecticide for stevia rebaudiana. The insecticide is prepared from raw materials in parts by weight as follows: 20-25 parts of pyrethrum, 5-8 parts of tobacco stems, 25-30 parts of nerium oleander, 12-16 parts of macleaya cordata, 10-15 parts of atropa belladonna, 8-14 parts of lycoris radiate, 8-12 parts of jequirity beans, 13-17 parts of wisteria, 15-20 parts of stemona, 12-18 parts of radix aconite and 18-26 parts of phytolacca acinosa. The insecticide is obtained by combining the raw materials after the raw materials are extracted. The insecticide for stevia rebaudiana is prepared from plant raw materials, has the advantages of being green and safe, free from causing pesticide resistance, low in environment pollution and the like and has a good control effect on insect damage of stevia rebaudiana.

Owner:MINGGUANG DAQUAN STEVIA PROFESSIONAL COOP

Medicine for treating hepatomegaly

InactiveCN102526509ALow costGood value for moneySalicyclic acid active ingredientsTetracycline active ingredientsPharmaceutical SubstancesAstragalus mongholicus

The invention relates to a medicine for treating hepatomegaly. The medicine for treating the hepatomegaly comprises the medicinal raw materials as follows: 7g of gastrodia elata, 7g of Rhizoma Pinelliae, 7g of taro pulp, 5g of pharbitis seed, 3g of garden burnet, 3g of Astragalus mongholicus, 5g of fructus psoraleae and 5g of date kernel; and the medicine for treating the hepatomegaly also comprises the components as follows: 20 furazolidone tablets, 20 terramycin tablets, 15 compound acetylsalicylic acid tablets, 2 belladonna tablets and 5 flu-treating capsules. The medicine for treating the hepatomegaly has the advantages that the medicine for treating the hepatomegaly can treat hepatomegaly caused by various reasons, has an obvious therapeutic effect and takes effect quickly; and through combined therapy of the traditional Chinese medicine and Western medicine, the used Western medicinal raw materials are finished medicines sold in the market, with wide source, easy obtainment and low price, so that the medicine for treating the hepatomegaly is low in cost and high in cost performance.

Owner:孙义岭

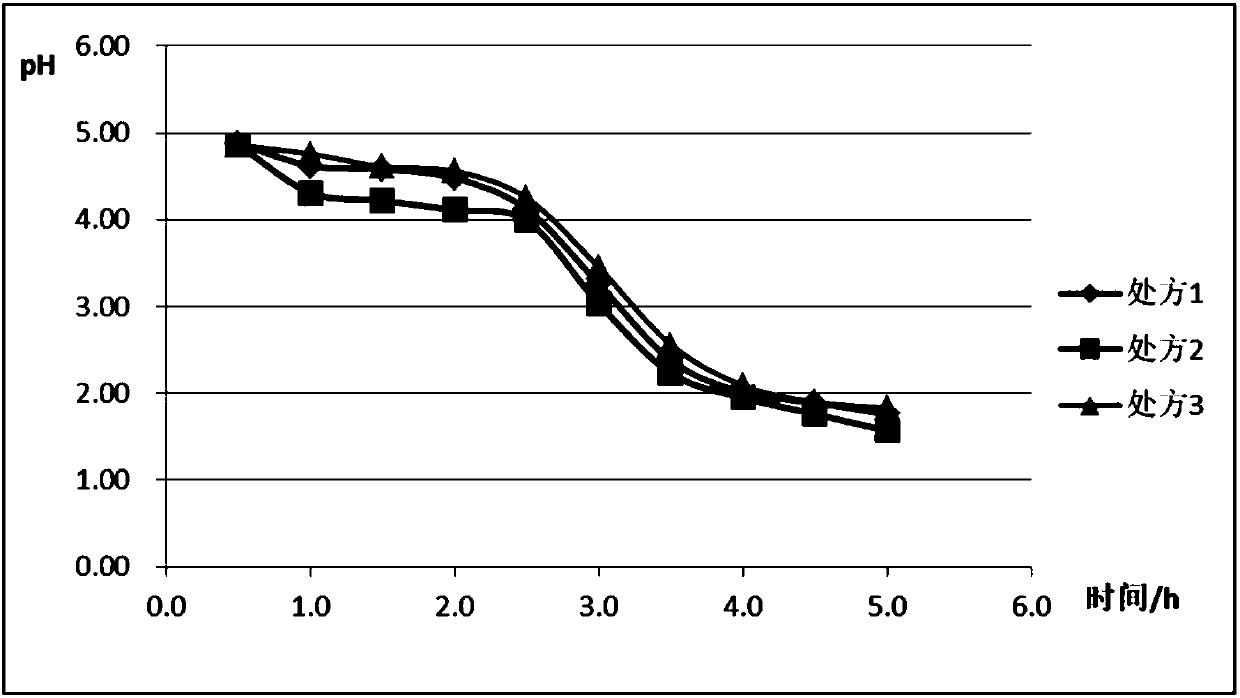

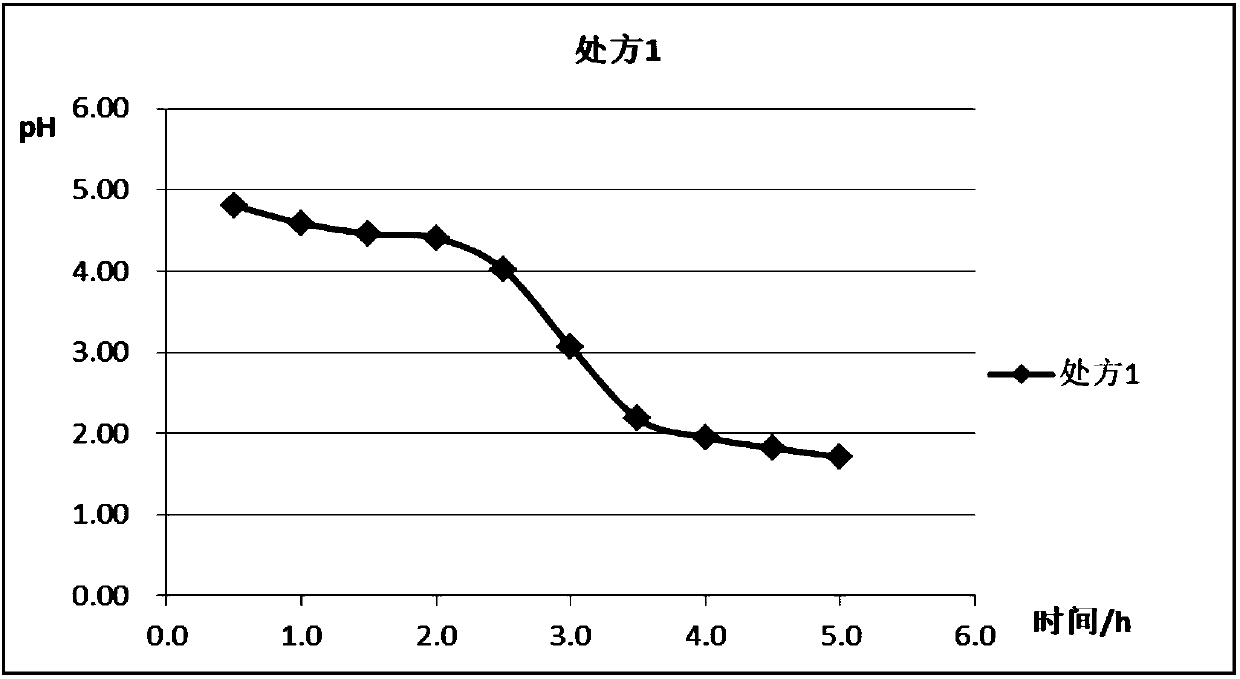

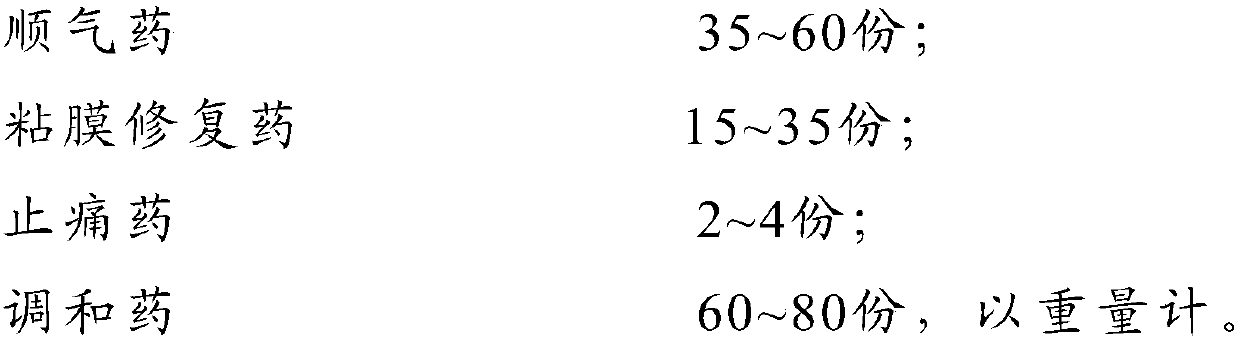

Novel medicine composition for preventing and treating chronic gastritis and relieving diseases caused by hyperacidity and preparation method thereof

ActiveCN109771649AFast onsetRapid relief of symptomsOrganic active ingredientsPeptide/protein ingredientsCombined treatmentBiology

The invention provides a novel medicine composition for preventing and treating chronic gastritis and relieving stomachache, heartburn and sour regurgitation caused by hyperacidity. The composition isa traditional Chinese medicine and western medicine compound preparation. The compound preparation mainly contains aluminum hydroxide, radix aucklandiae, a licorice root extract and a belladonna fluid extract. The composition improves the curative effect. The invention further provides a preparation method of a medicine for traditional Chinese medicine and western medicine combined treatment of chronic gastritis and diseases caused by hyperacidity. The preparation method comprises a prescription containing traditional Chinese medicine components, a preparation process of an adhesive, preparation of a soft material, preparation of wet granules and a drying technology. The production process is optimized.

Owner:SHANGHAI JINCHENG PHARMACEUTICAL CO LTD

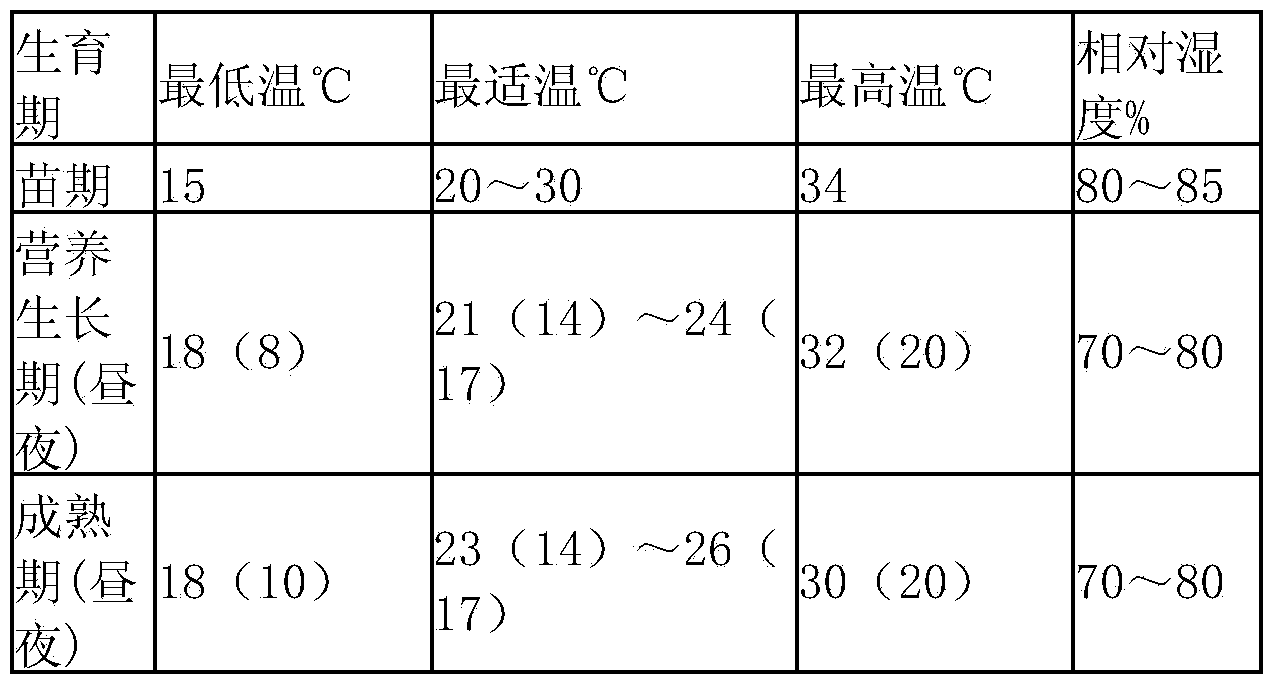

High-yield method for planting atropa belladonna

InactiveCN104025839AProlong reproductive periodReproductive healthHorticulturePesticide residueInsect pest

Owner:梁晓

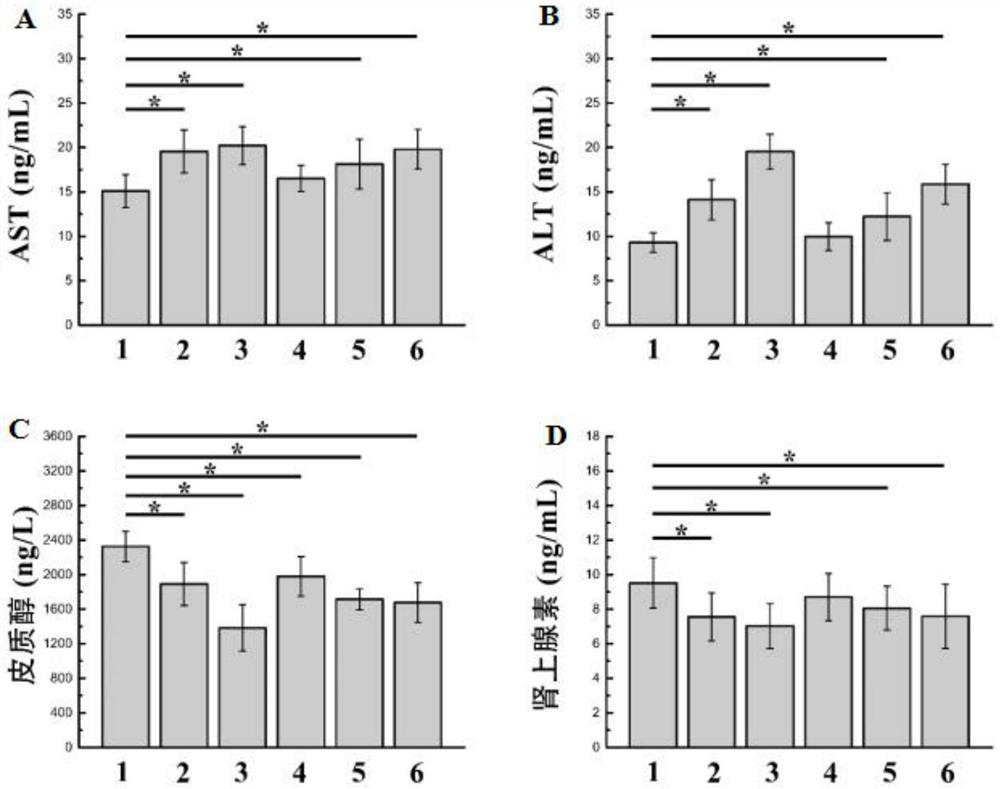

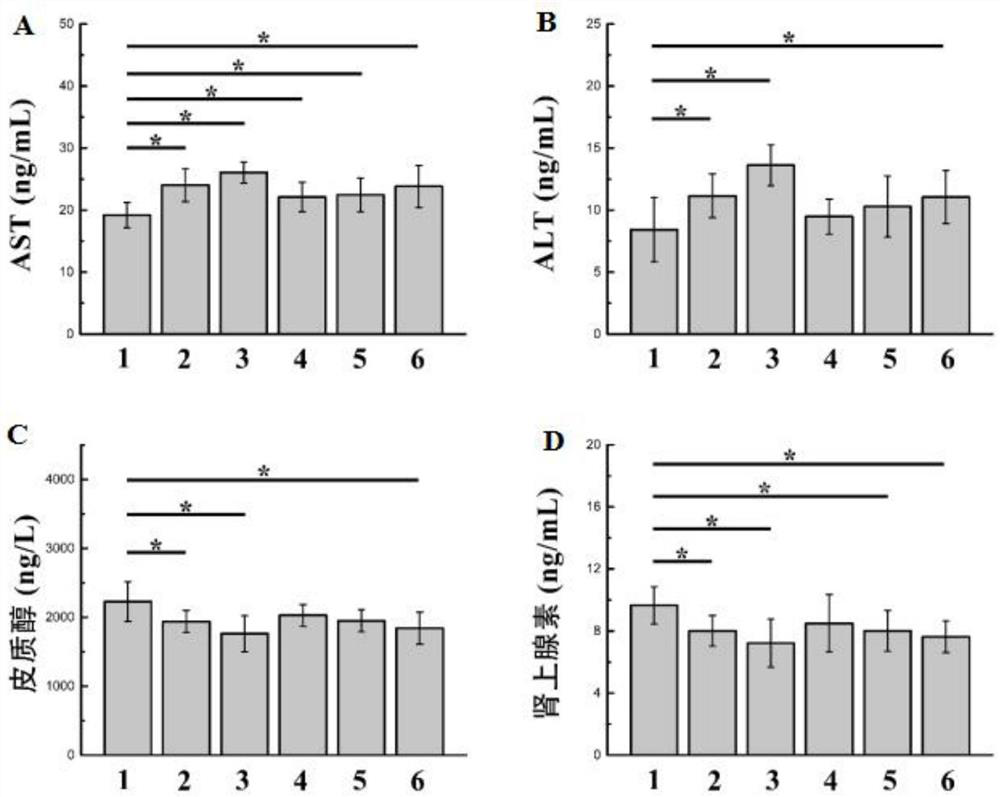

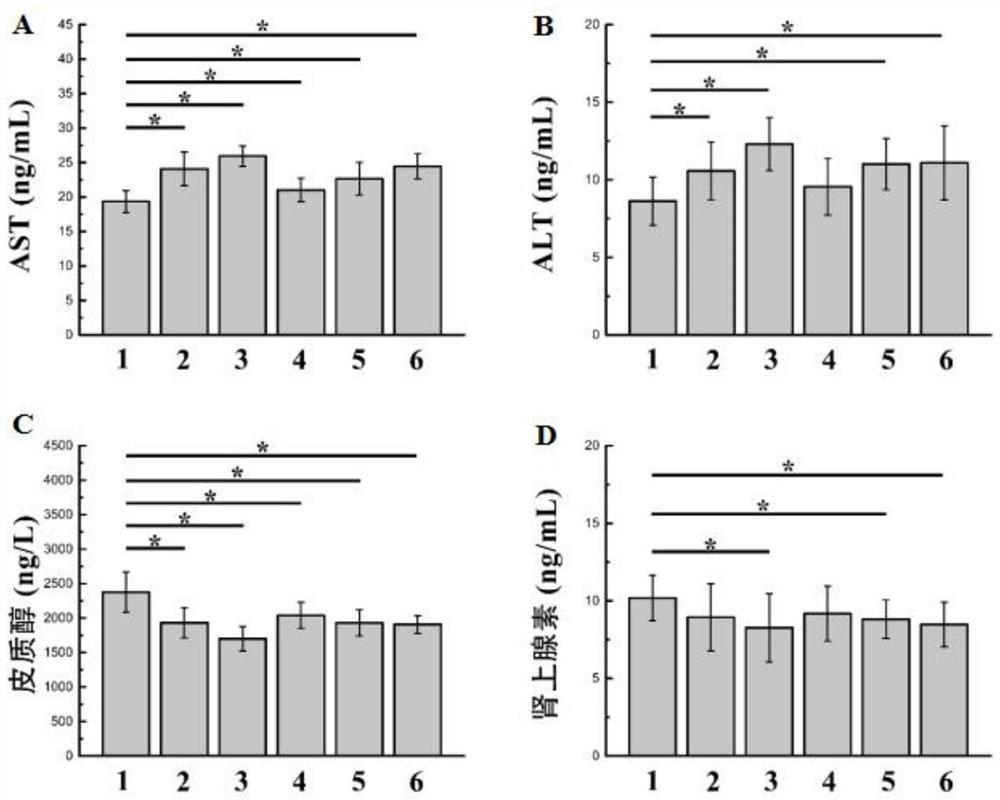

Composition for reducing fishing and transportation stress of fishes as well as preparation method and application of composition

ActiveCN113134049AReduce the riseReduce mortalityNervous disorderHydroxy compound active ingredientsFlosAnimal science

The invention relates to a composition for reducing fish catching and transportation stress and a preparation method and application thereof, and belongs to the technical field of fishery breeding. The composition is prepared from the following components in parts by weight: 10 to 40 parts of flos daturae, 10 to 40 parts of Atropa belladonna, 5 to 20 parts of rhizoma arisaematis, 5 to 25 parts of semen ziziphi spinosae, 5 to 25 parts of pepper, 5 to 25 parts of mint and 1 to 5 parts of multivitamins. The composition has a good sedative effect, proper anesthesia depth and small damage to the liver, and can improve the immunity of live fishes, reduce caught casualties of fishes cultured in a pond, reduce the death rate of caught fishes in the transportation process and improve the survival rate of the caught fishes in temporary culture or re-culture.

Owner:湖南渔经生物技术股份有限公司 +1

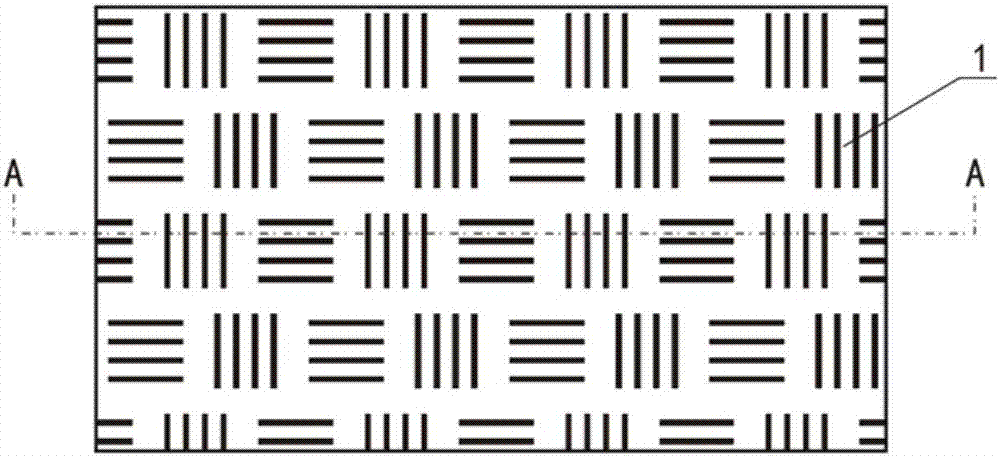

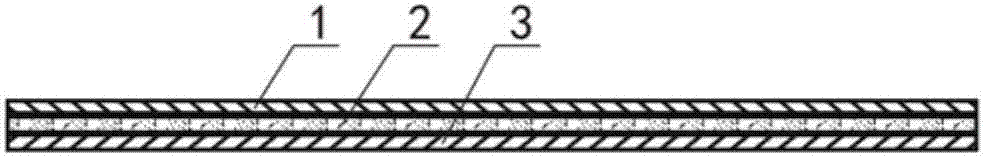

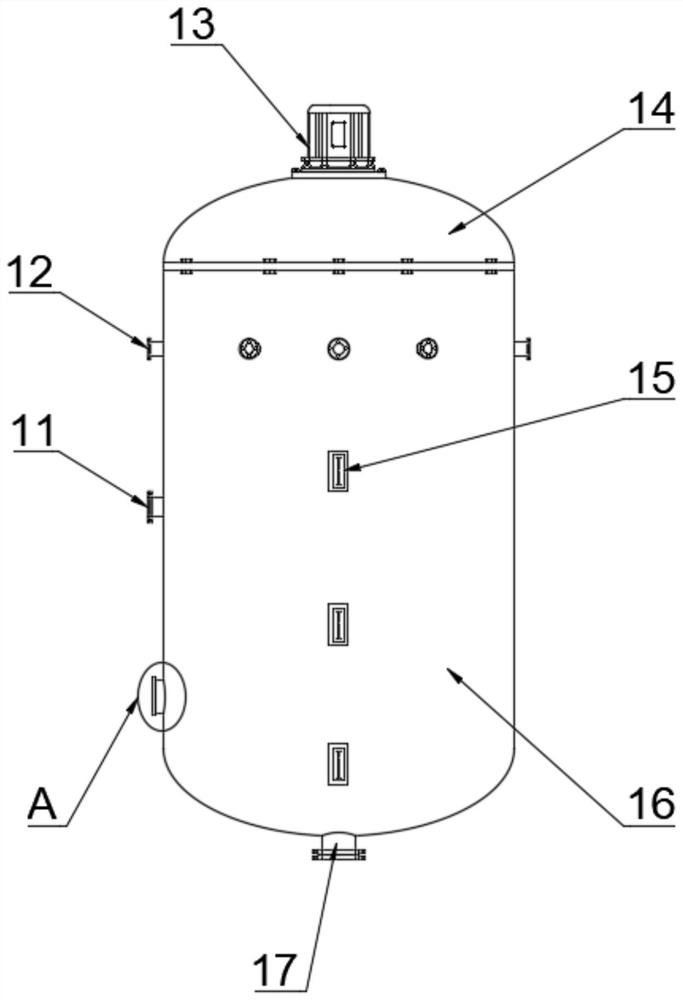

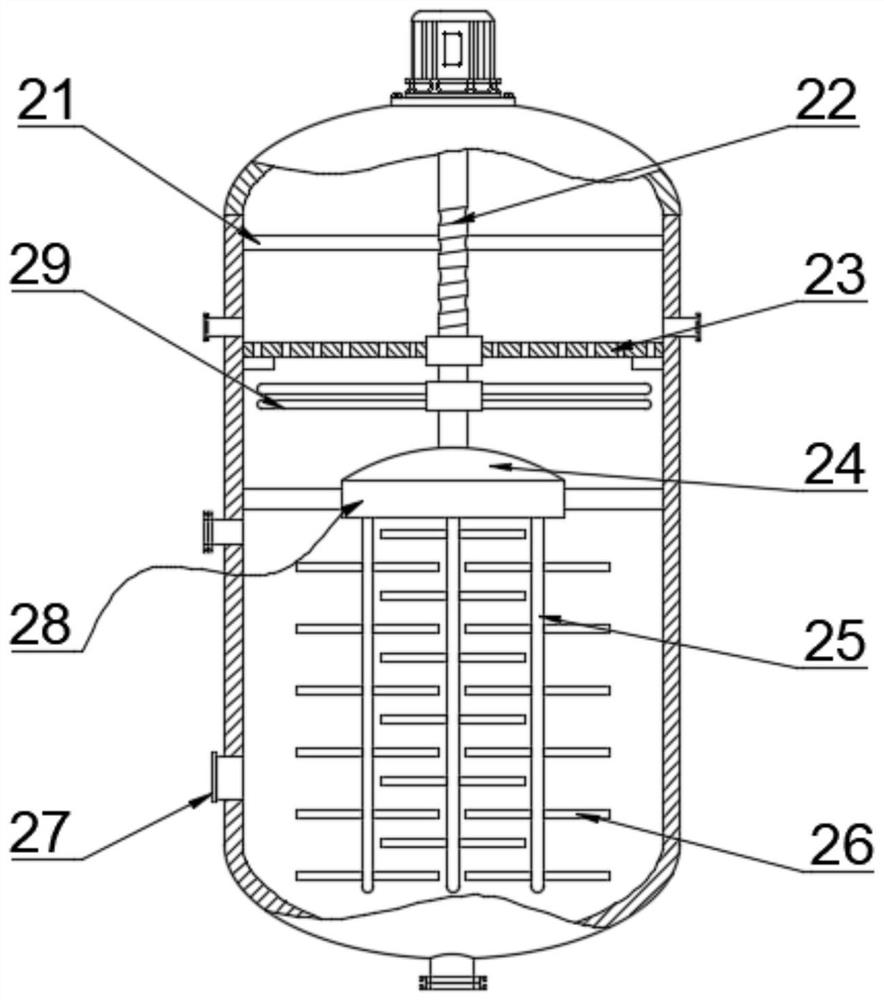

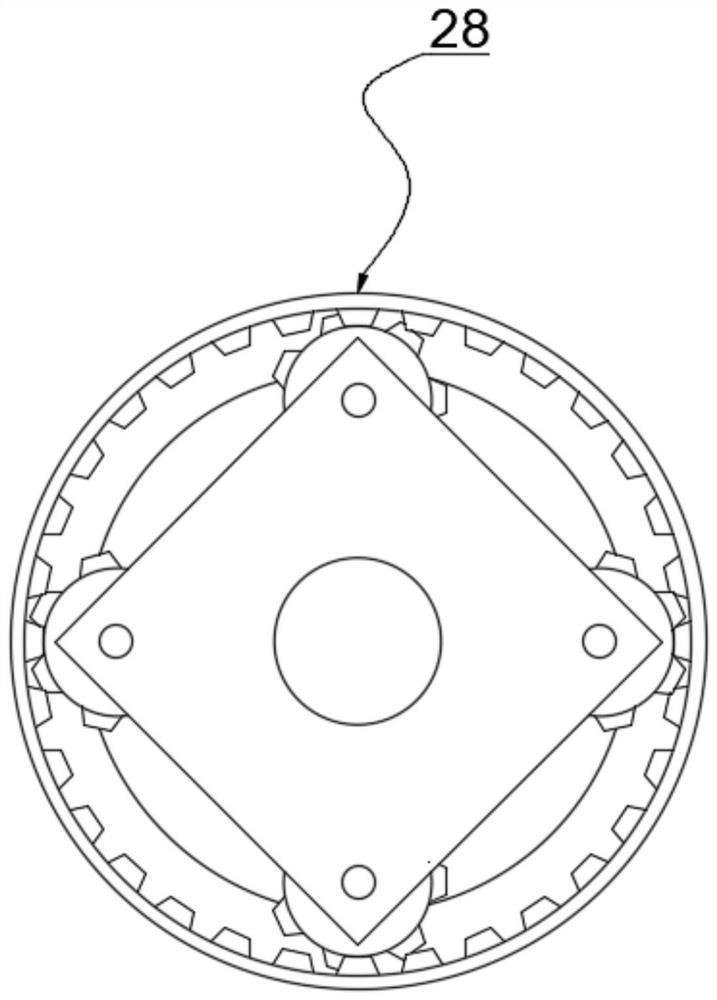

Blending device of belladonna liquid extract

PendingCN113976005ASolve the problem of thick paste that is easy to be mixed with agglomeratesImprove allocation efficiencyRotary stirring mixersTransportation and packagingMechanical engineeringLiquid extract

The invention relates to a blending device of a belladonna liquid extract, and belongs to the technical field of pharmaceutical equipment. According to the device, a material extruding plate, a net plate and a cutter are sequentially arranged on the upper side of a blending tank, a thick paste and an ethanol blending liquid are premixed and supplied, then the thick paste is extruded into strips, then the strips are cut up by the cutter, the thick paste is mixed with the ethanol blending liquid in the form of uniform fine particles and falls into the blending tank, then the thick paste is stirred, mixed and diluted,the material extruding plate intermittently works, stirring is continuously performed, and the extruded mixture is timely stirred and dispersed, so that quantitative batch blending is realized;and a planetary gear loaded with four groups of planetary wheels is adopted to drive a stirring shaft, and stirring blades which are distributed alternately are arranged, and rotate by themselves and rotate around the rotating center of a sun gear, so that stirring is sufficient, the problems that thick paste is difficult to mix and agglomerated thick paste is easily mixed in a finished product are solved, and the blending efficiency is also improved.

Owner:安徽恒达药业有限公司

Method for preparing enteromorpha extract solution for inhibiting prorocentrum micans and phaeodactylum tricornutum bohlin

InactiveCN103550392AHigh content of active ingredientsReduce dissolutionBiocideDigestive systemDissolutionBULK ACTIVE INGREDIENT

The invention discloses a method for preparing an enteromorpha extract solution for inhibiting prorocentrum micans and phaeodactylum tricornutum bohlin, belongs to the technical field of medicines, in particular relates to a method for preparing an atropa belladonna extract and provides a method for preparing the atropa belladonna extract, wherein the method is short in process flow, high in product purity, sewage-free, environment-friendly and pollution-free. The preparation method comprises the following steps: by taking herba belladonnae as a raw material, crushing the raw material, adding a sulfuric acid or hydrochloric acid solution for stirring, filtering the stirred solution, adsorbing and separating the filtered solution by using resin, eluting by using an ethanol solution, and concentrating the eluate to obtain the atropa belladonna extract. Because a normal-temperature acid solution extraction method is adopted, the dissolution of chlorophyll and impurities is small, and the atropa belladonna alkaloid is easily extracted from the acid solution, so that the active ingredient content in the extracted solution is high, and fewer impurities are contained in the extracted solution.

Owner:WEIHAI JINLIN AQUATIC PROD

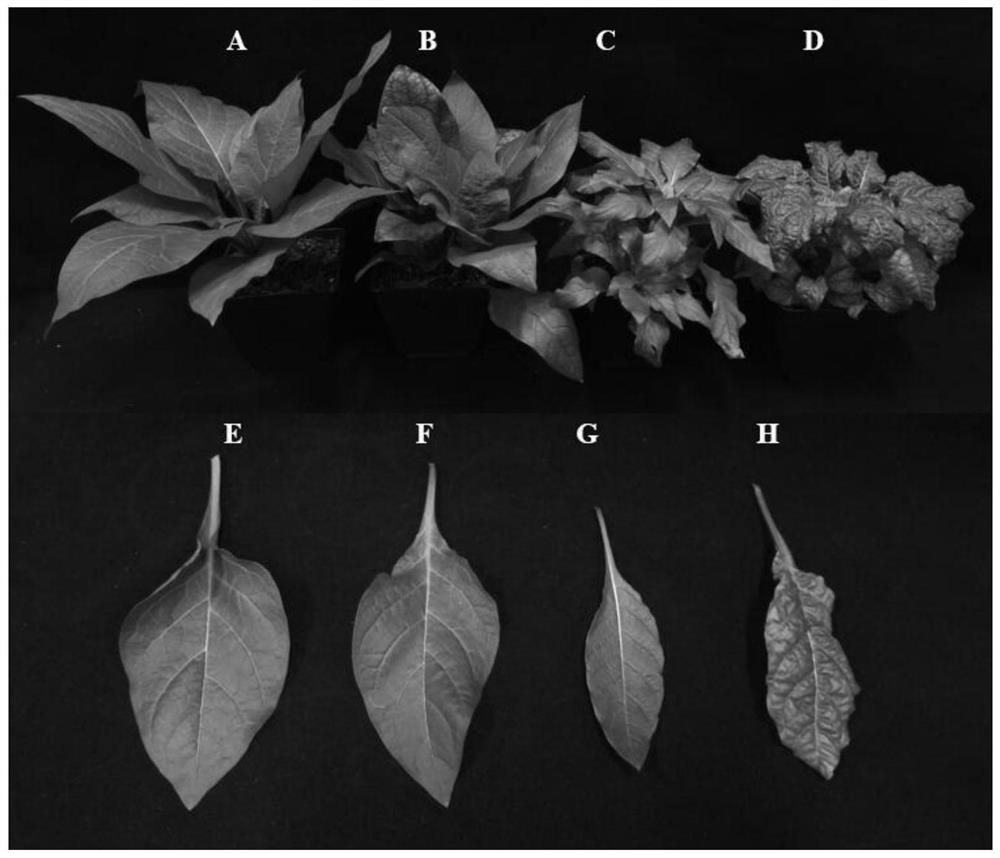

Method for increasing content of tropane alkaloid in atropa belladonna

ActiveCN111944844AIncreased gene expression in synthetic pathwaysIncrease gene expressionBacteria peptidesGenetic engineeringL-HyoscyamineTropane alkaloid

The invention discloses a method for increasing the content of tropane alkaloid in atropa belladonna. The gene expression quantity of a TAs alkaloid synthesis pathway is effectively increased by expressing a gene rolC or rolB in the atropa belladonna, and the content of hyoscyamine and anisodamine in the atropa belladonna is increased, but variation influence is caused on plant phenotype; and thegene rolC or rolB expressed by H6H-p tissue localization does not influence plant phenotypic growth while the alkaloid content is increased. By selective control of the gene rolC or rolB, a foundationis laid for further cultivating a high-alkaloid-yield atropa belladonna strain in the medicinal field of the atropa belladonna, and a new method is provided for further developing TAs alkaloid gene engineering metabolism research of the atropa belladonna.

Owner:GUIZHOU UNIV

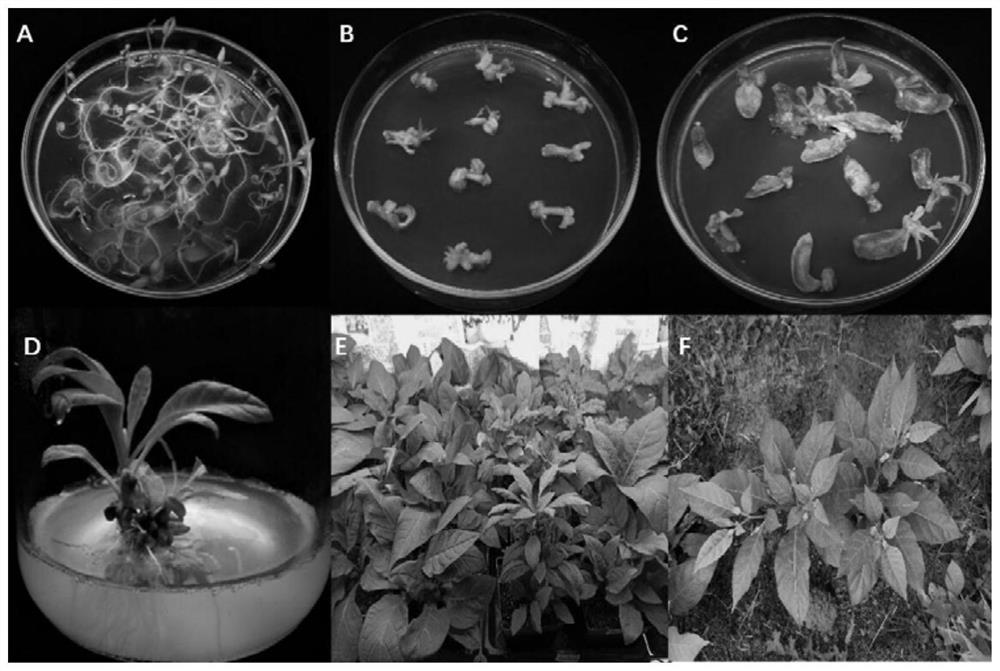

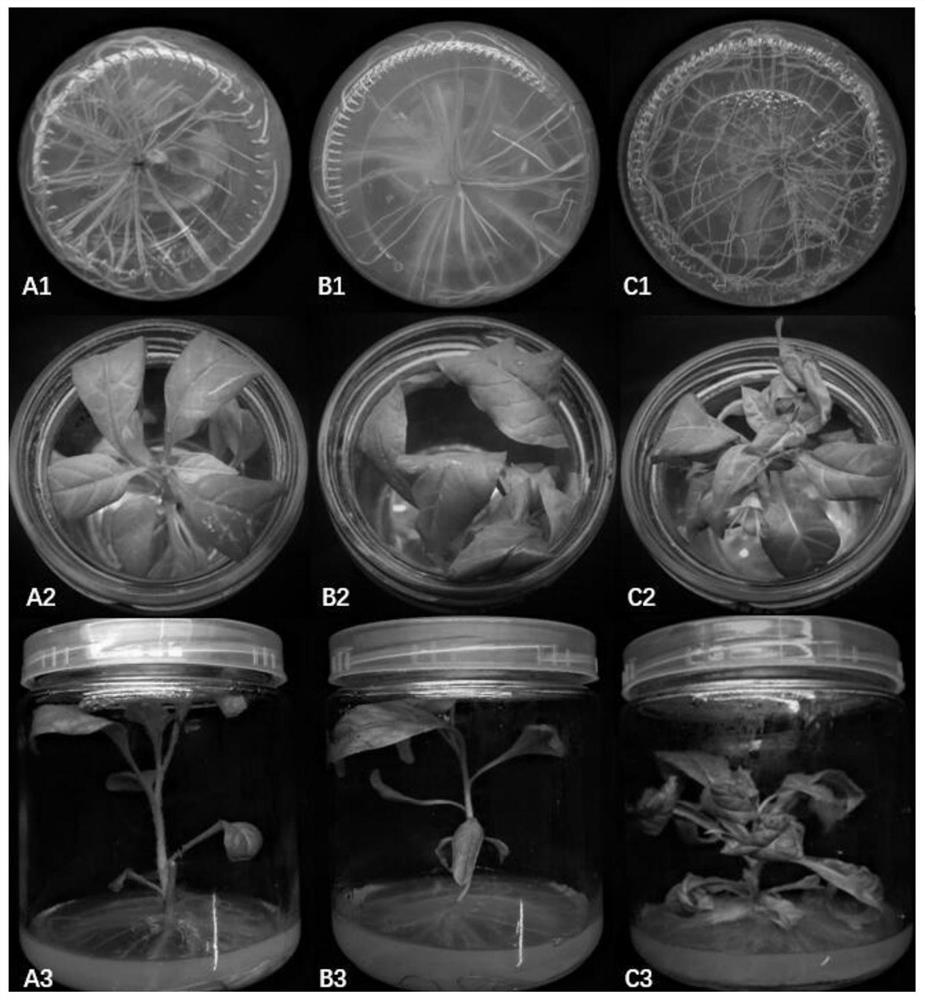

Method for inducing embryogenic cells by using Atropa belladonna L explant

InactiveCN102396417ARapid transgenic belladonnaHigh-efficiency transgenic belladonnaPlant tissue cultureHorticulture methodsGenetic MaterialsTropane alkaloid

The invention provides a method for inducing embryogenic cells by using an Atropa belladonna L explant. The method relates to establishment of an in-vitro culture system, induction of the embryogenic cells, suspension culture of the embryogenic cells, and regeneration of plants obtained by using the embryogenic cells. The method comprises the following steps: inducing the embryogenic cells by using Atropa belladonna L aseptic seedling, propagating and subculturing the embryogenic cells, and inducing plants to regenerate by the embryogenic cells. The embryogenic cells obtained by the method can be used for producing virus-free seedling, and can produce new induction strain by using induction and mutation of a genetic material, and can be used as a transformation receptor to obtain a transformant capable of producing tropane alkaloids.

Owner:SOUTHWEST UNIVERSITY

Formula of ointment for activating blood, dissolving stasis and relieving pain

InactiveCN106075367AHeavy metal active ingredientsAnthropod material medical ingredientsDiseaseAristolochia mollissima

The invention discloses a formula of an ointment for activating blood, dissolving stasis and relieving pain. The formula comprises safflower, raw common monkshood mother root, raw kusnezoff monkshood root, processed strychnos nux-vomica, asarum heterotropoide, atractylodes lancea, pericarpium zanthoxyli, Chinese sapium snakes, artemisia rupestris, girald daphne bark, dragon's blood, rhizoma drynariae, lycopodium clavatum, radix rehmanniae, impatiens balsamina, rhizoma corydalis, pawpaw, cassia twigs, radix dipsaci asperoidis, aristolochia mollissima, radix clematidis, saposhnikovia divaricata, dried ginger, stiff silkworm, camphor, caulis spatholobi, borneol, datura stramonium, folium artemisiae argyi, root of angelica sinensis, atropa belladonna, polygonum cuspidatum, raw ephedra, honeycomb, elderberry, ground beetles, native copper, acacia catechu, cortex acanthopanacis, forsythia viridissima lindl, crude scorpion and achyranthes bidentata. The ointment has functions of promoting blood circulation to remove stasis, dispelling wind and eliminating dampness as well as relaxing tendon and activating blood, and can treat diseases such as hyperostosis, spondylolysis, sore and pain, tendon retraction, ankylosing spondylitis, rheumatoid arthritis, scapulohumeral periarthritis, osteoarthritis and the like.

Owner:厦门市卫立康保健服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com