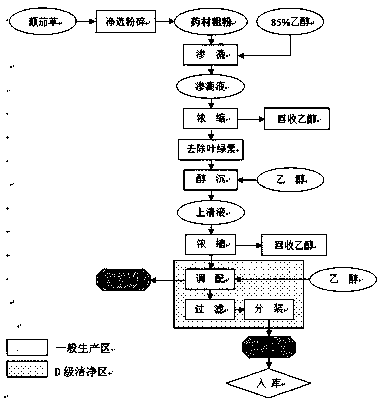

Production process of extractum belladonnae liquidum

A technology of belladonna liquid extract and production process, which is applied in the production process field of belladonna liquid extract, to achieve the effects of improving extraction efficiency, reducing cost, and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of production technology of belladonna liquid extract, is characterized in that, comprises the steps, and following raw material is by weight:

[0025] (1) Medicinal material treatment: excavate belladonna during the period from flowering to fruiting, remove impurities, insects, mildew and non-medicinal parts, wash away the sediment, sun-soften and pile up, cover the woven bag to sweat, and then Put it in a cool and ventilated place to dry, cut into sections, crush into coarse powder, and set aside;

[0026] (2) Percolation: put belladonna coarse powder into the extraction tank, add ethanol and acidic pepsin solution with a concentration of 80%, make the liquid level 2cm higher than the powder, seal it, soak it for 48 hours, and quickly collect it from the outlet The initial percolation liquid is recovered into the percolation cylinder, the outlet of the percolation cylinder is controlled, and the percolation is slowly percolated at a rate of 2ml / min per Kg of me...

Embodiment 2

[0034] A kind of production technology of belladonna liquid extract, is characterized in that, comprises the steps, and following raw material is by weight:

[0035] (1) Medicinal material treatment: excavate belladonna during the period from flowering to fruiting, remove impurities, insects, mildew and non-medicinal parts, wash away the sediment, sun-soften and pile up, cover the woven bag to sweat, and then Put it in a cool and ventilated place to dry, cut into sections, crush into coarse powder, and set aside;

[0036] (2) Percolation: put belladonna coarse powder into the extraction tank, add ethanol and acidic pepsin solution with a concentration of 85%, make the liquid level 4cm higher than the powder, seal it, soak it for 48 hours, and quickly collect it from the outlet The initial percolation liquid is recovered into the percolation cylinder, the outlet of the percolation cylinder is controlled, and the percolation is slowly percolated at a rate of 3ml / min per Kg of me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com