Assembling structure of split type toner cartridge

An assembly structure and split-type technology, which is applied in the fields of electrical recording technology using charge graphics, equipment for using electrical recording technology using charge graphics, and electrical recording technology. It can solve problems such as high replacement costs, dust jams, and polluted printed images. , to achieve the effect of convenient work, simple operation and low requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

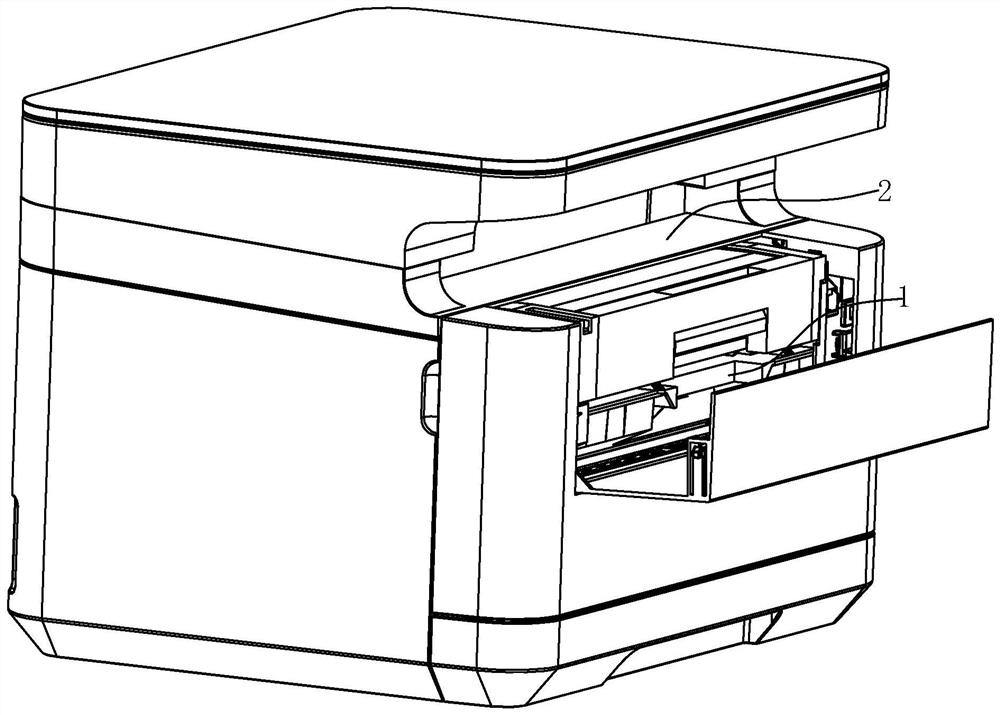

[0025] like figure 1 As shown, the assembly structure of the split-type toner cartridge in this embodiment is arranged in the casing of the printer and matched with the toner cartridge main body 100 installed in the casing.

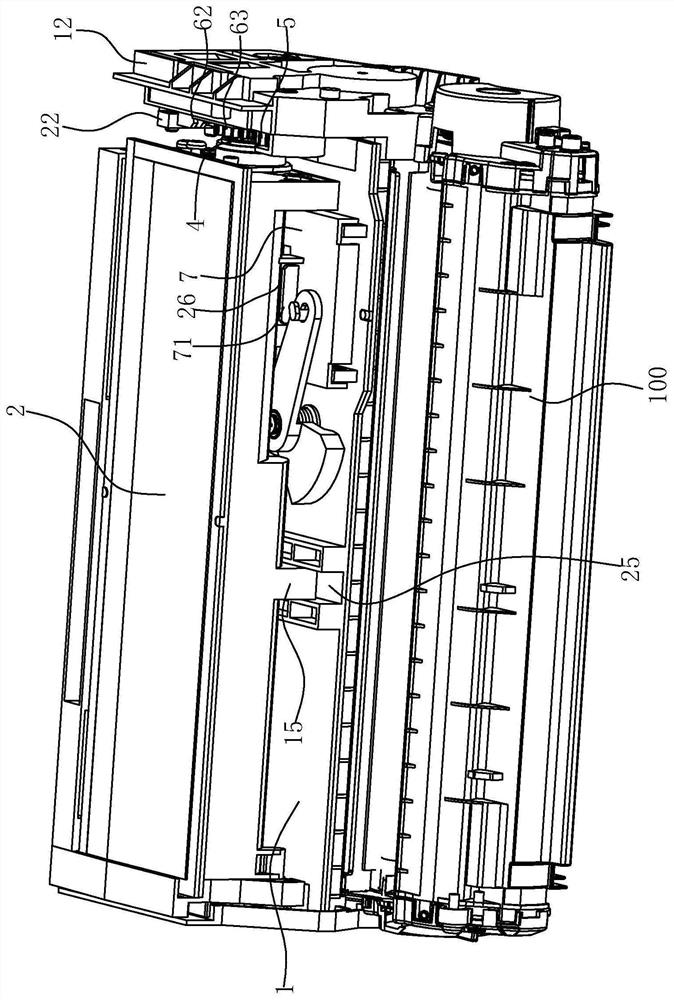

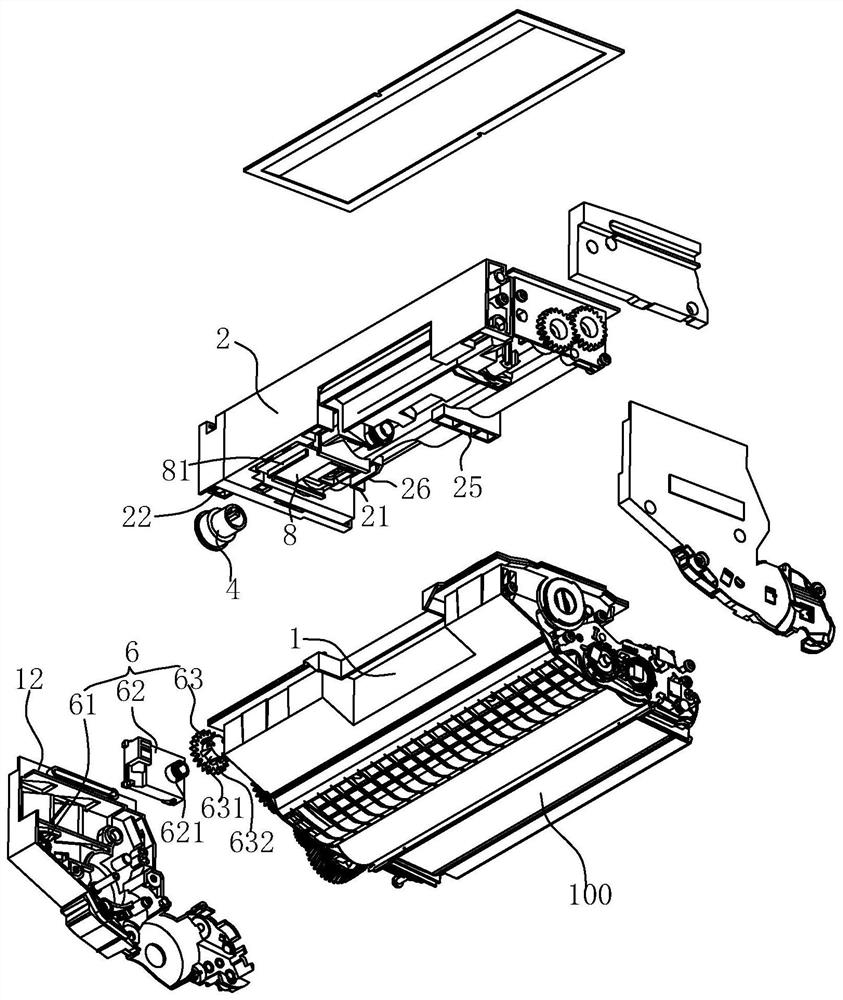

[0026] The toner cartridge main body 100 in the casing can adopt various types of toner cartridge main bodies 100 in the prior art, such as the toner cartridge main body 100 comprising a photosensitive drum, a developing roller, a transfer roller, a charging roller and the toner chamber 1 above the developing roller. and other components, the toner cartridge main body 100 in this embodiment extends in the left-right direction as a whole.

[0027] like Figure 2 to Figure 6 As shown, the assembly structure of the split toner cartridge includes a toner box 2 that can be detachably docked on the toner box 1 of the toner ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com