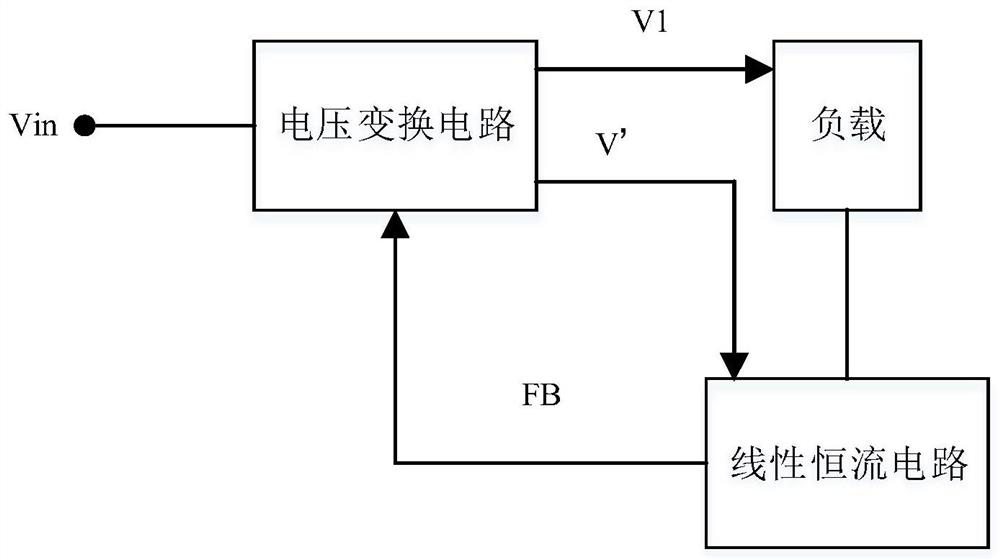

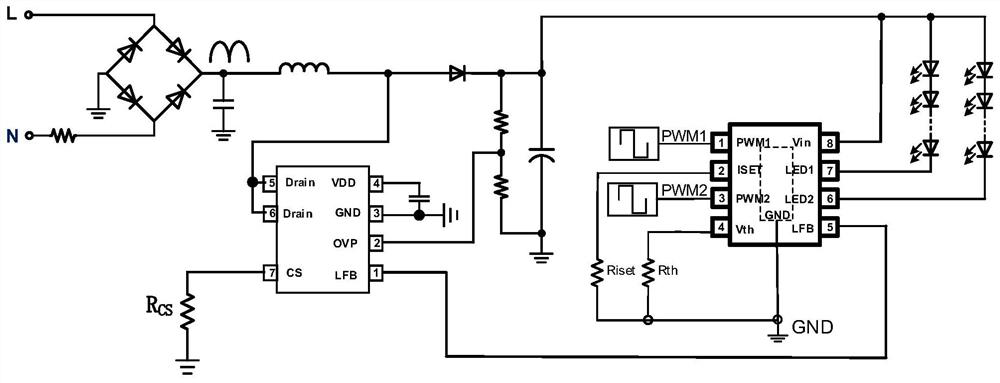

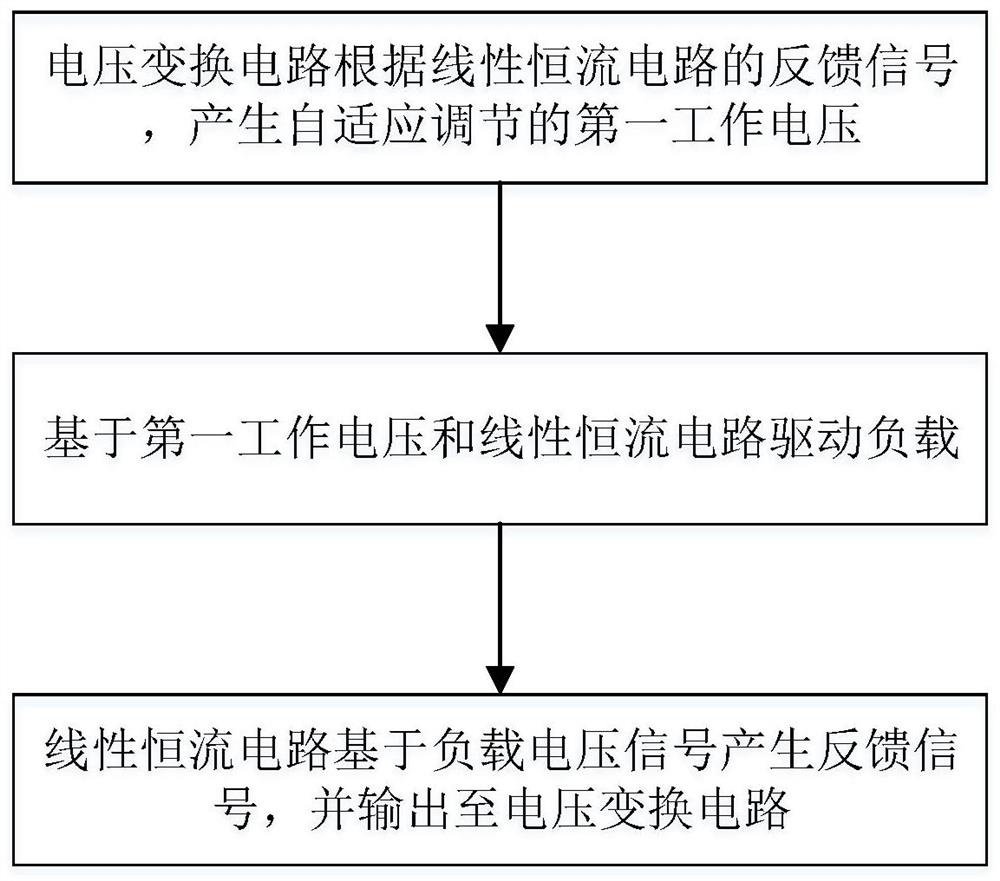

Load driving circuit and driving method

A technology of load driving circuit and load voltage, which is applied in the electronic field, can solve the problems of switching color temperature flickering, low overall efficiency, large current, etc., and achieve the effect of improving system efficiency and stabilizing dimming or color adjustment functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

[0037] The description in this part is only for several typical embodiments, and the present invention is not limited to the scope of the description of the embodiments. Combinations of different embodiments, mutual replacement of some technical features in different embodiments, mutual replacement of the same or similar prior art means and some technical features in the embodiments are also within the scope of description and protection of the present invention.

[0038] "Coupling" or "connection" in the specification includes both direct connection and indirect connection. An indirect connection is a connection through an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com