Roundness hydraulic adjusting mechanism of arc rolling guide

A rolling guide rail and adjustment mechanism technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of long adjustment time and manual adjustment of mechanical adjustment blocks, etc., and achieves simple structure, large deformation driving force, and convenient installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

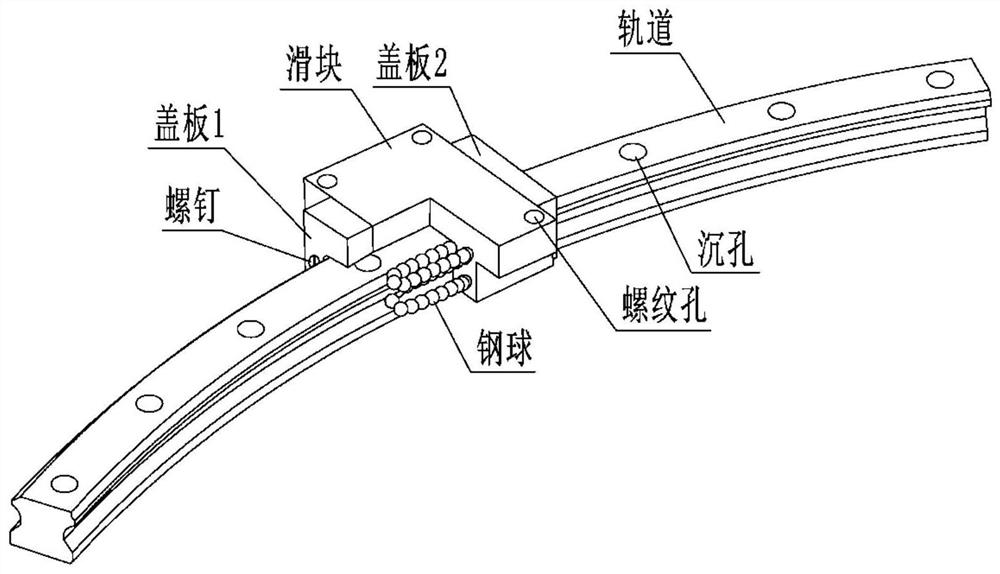

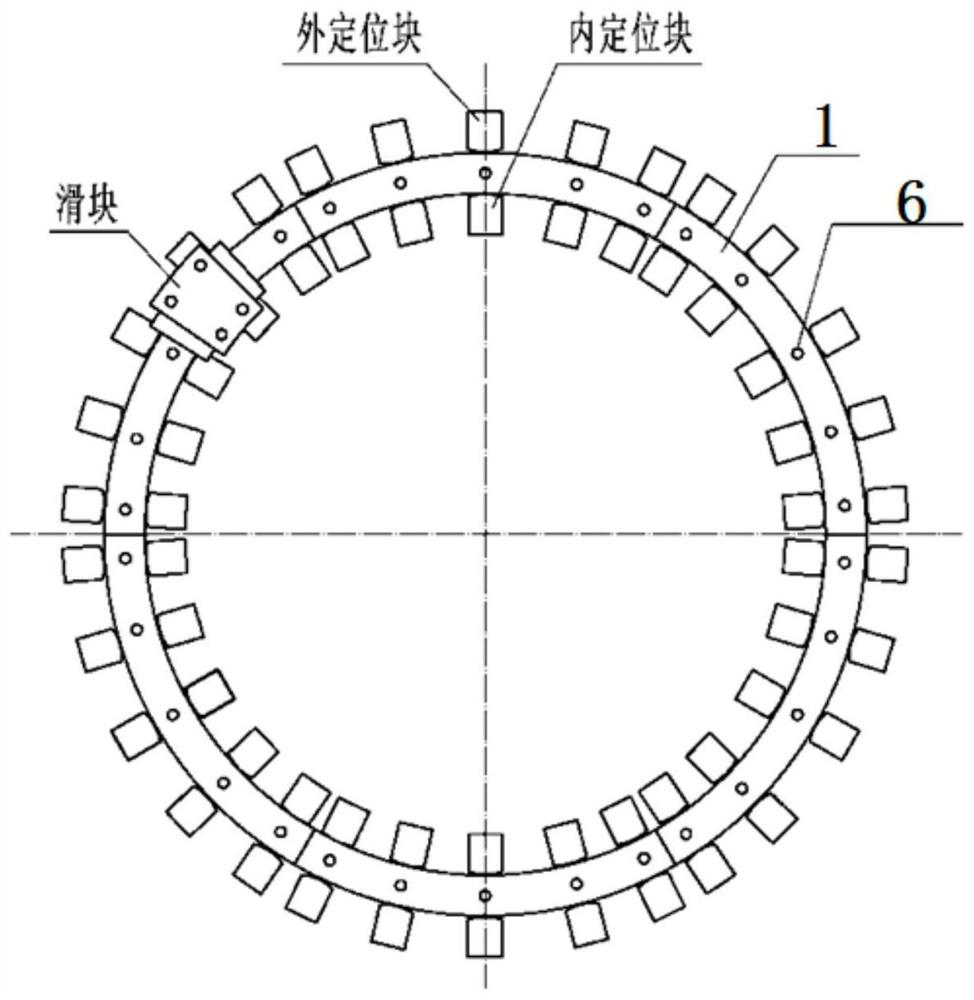

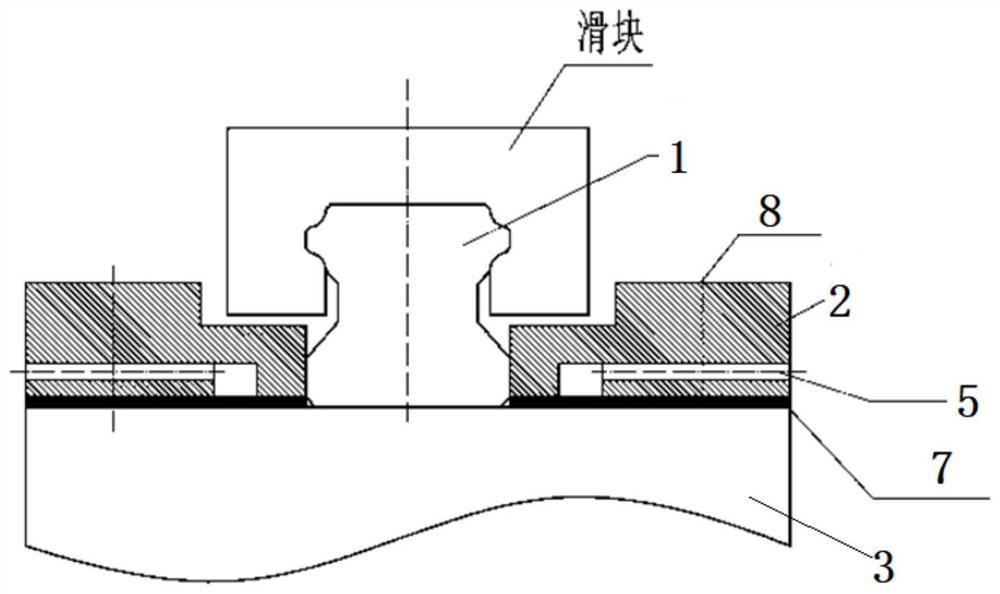

[0026] The roundness hydraulic adjustment mechanism of a circular arc rolling guide rail according to the present invention has a structure such as image 3 As shown, it includes multiple pairs of roundness adjustment blocks 2 evenly arranged in pairs on both sides of the track 1 of the arc rolling guide, as shown in Figure 4-5 As shown, one end of the roundness adjustment block 2 is fixed on the track base 3 on the corresponding side of the arc rolling guide rail, the other end of the roundness adjustment block 2 contacts the corresponding side wall of the track 1, and the roundness adjustment block 2 is close to the track 1 An oil chamber 4 is opened inside one side of the side wall, and the oil chamber 4 is connected with an oil passage 5. The oil passage 5 is located inside the roundness adjustment block 2 and extends away from the end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com