Elastic rotor traffic anti-collision guardrail

A technology of anti-collision guardrails and elastic rotors, which is applied in the direction of traffic signals, roads, road signs, etc., can solve the problems of easily twisted guardrails, secondary accidents of the vehicle causing the accident, and easy disintegration of the connection, so as to reduce the loss and death rate of traffic accidents , reduce traffic accidents, and avoid visual fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

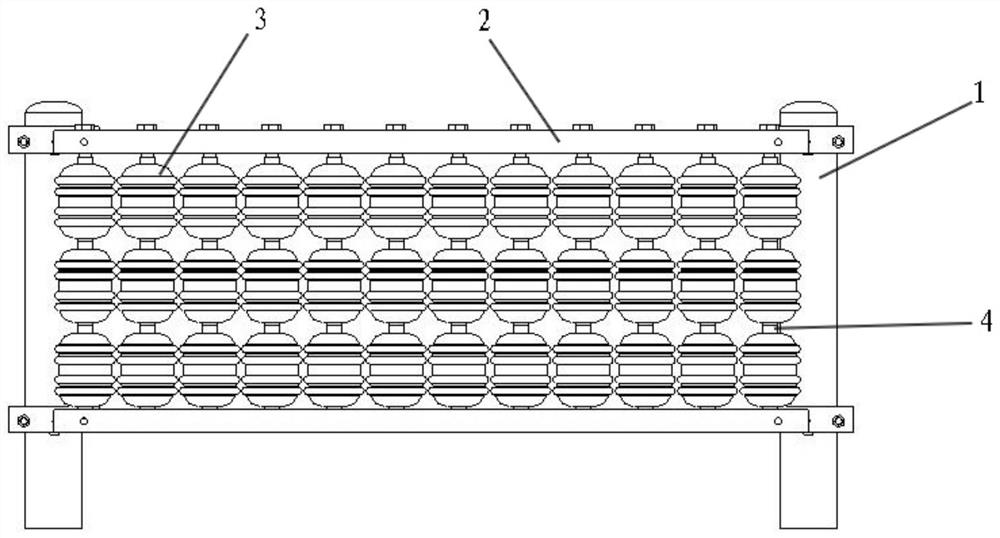

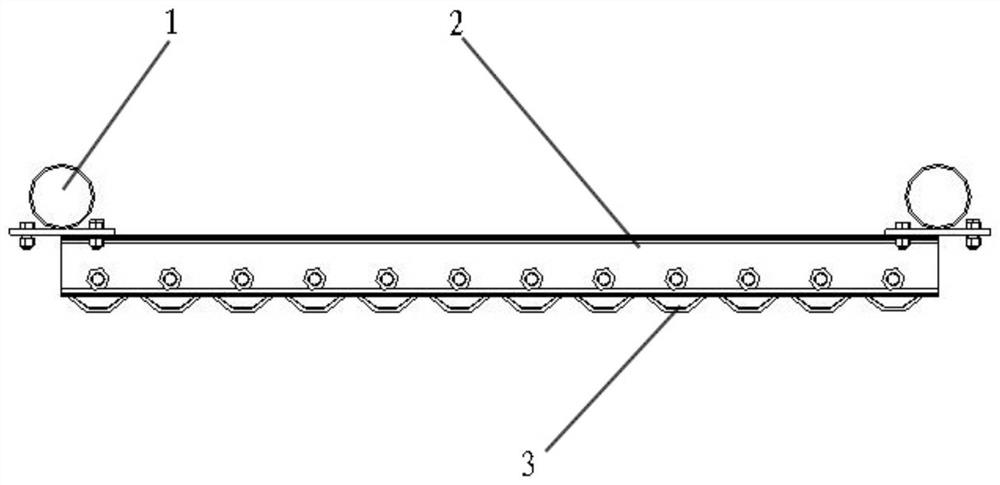

[0018] see figure 1 and figure 2 , the present invention provides an elastic rotor traffic crash barrier, comprising a rotor 3 and a frame.

[0019] The rotor 3 is cylindrical, and a through hole is opened at the center of the rotor 3 for mounting on the rotor shaft 4 . There are several annular protrusions on the outer surface of the rotor 3, and the material of the rotor 3 is elastic material.

[0020] The frame body includes a column 1 and a beam 2, which are detachably connected between the column 1 and the beam 2, and two beams 2 are horizontally erected between the two main forces 1, which are respectively an upper beam and a lower beam. Several rotor shafts 4 are arranged between the lower beam and the lower beam. The rotating shaft 4 is detachably connected to the beam 2 .

[0021] Several rotors are installed on each rotating shaft 4, so that the rotors 3 are arranged in several rows in the frame. In this embodiment, the number of rotors on each rotor shaft 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com