Submersible fuel-filled tank with compensating ground pins and method of operation

A technology for submersibles and oil tanks, which is applied to valve operation/release devices, air-filled/oil-filled cable fittings, cable joints, etc. It can solve the problems of difficult connection work and grounding work, troublesome operation, etc., and achieve processing and material Ease of acquisition, ease of installation, and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

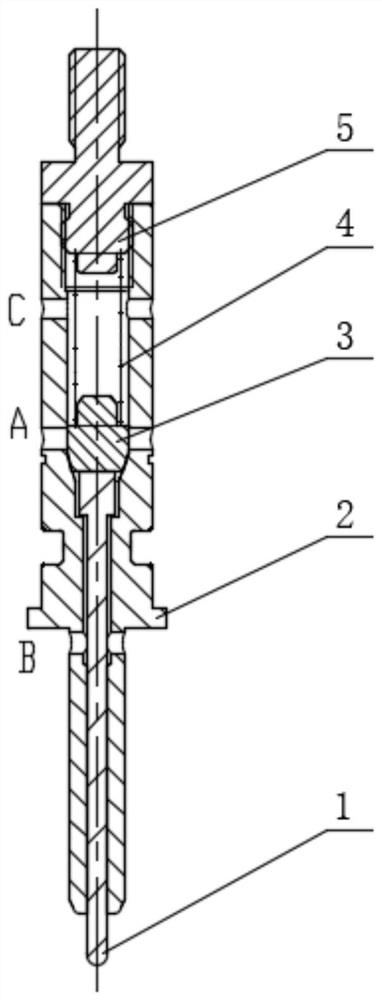

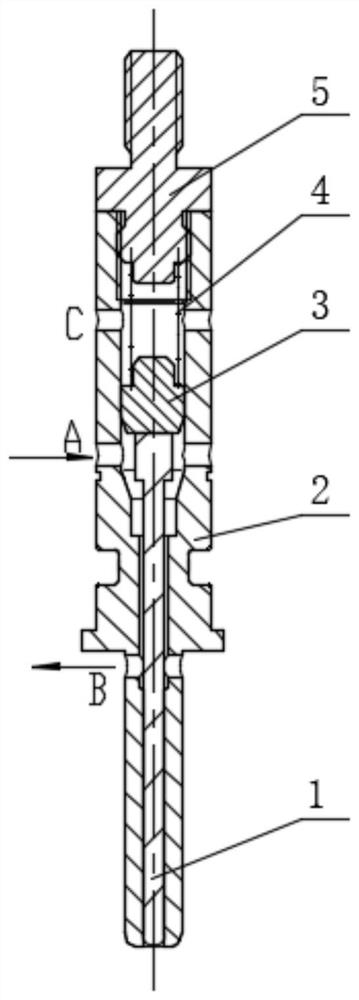

[0046] The specific embodiments of the present invention will be described below with reference to the drawings.

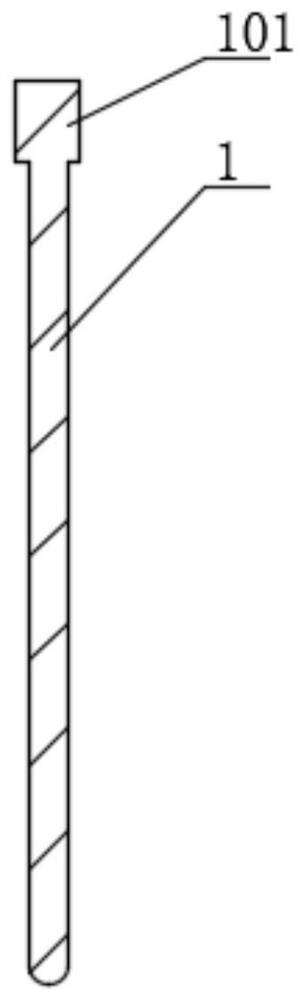

[0047] like Figure 1-Figure 8 As shown, the submersible oil-filled tank body with compensation ground pins of this embodiment includes a plurality of oil tanks stacked up and down in sequence, and the two adjacent oil tanks are an upper oil-filled oil tank 10 and a lower oil-filled oil tank 11, and the upper oil-filled oil tank is The bottom surface of the fuel tank 10 is provided with a through hole, the through hole is installed with a pin through the sealing ring 6, the upper part of the pin is tightly connected with the upper fuel tank 10 through the circlip 7, and the bottom of the pin is connected with the lower fuel tank 11. The top surface of the needle is installed with the common ground wire 8 through the compression nut 9;

[0048] The structure of the pin includes a housing 2, the middle of the housing 2 is provided with an inner conical surface 202,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com