High-precision pressure reducing valve for medical gas

A pressure reducing valve and high-precision technology, applied in the field of pressure reducing valves, can solve the problems of low precision, no dust cleaning effect, cumbersome disassembly, maintenance and replacement process, etc., and achieve the effect of convenient maintenance process and high adjustment accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

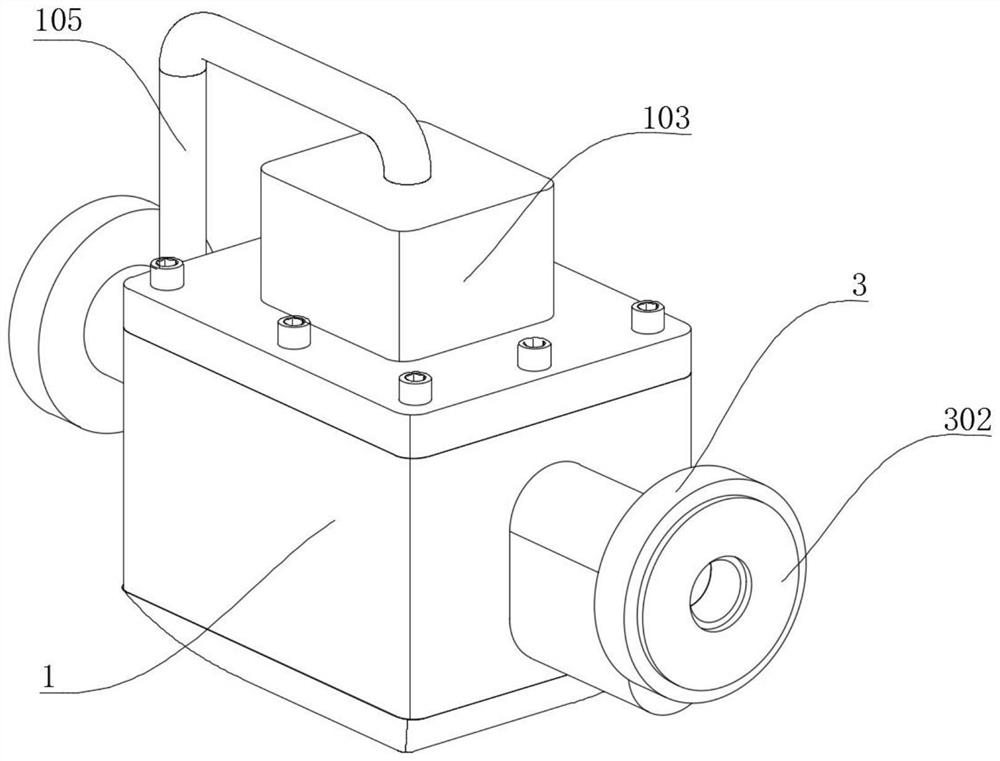

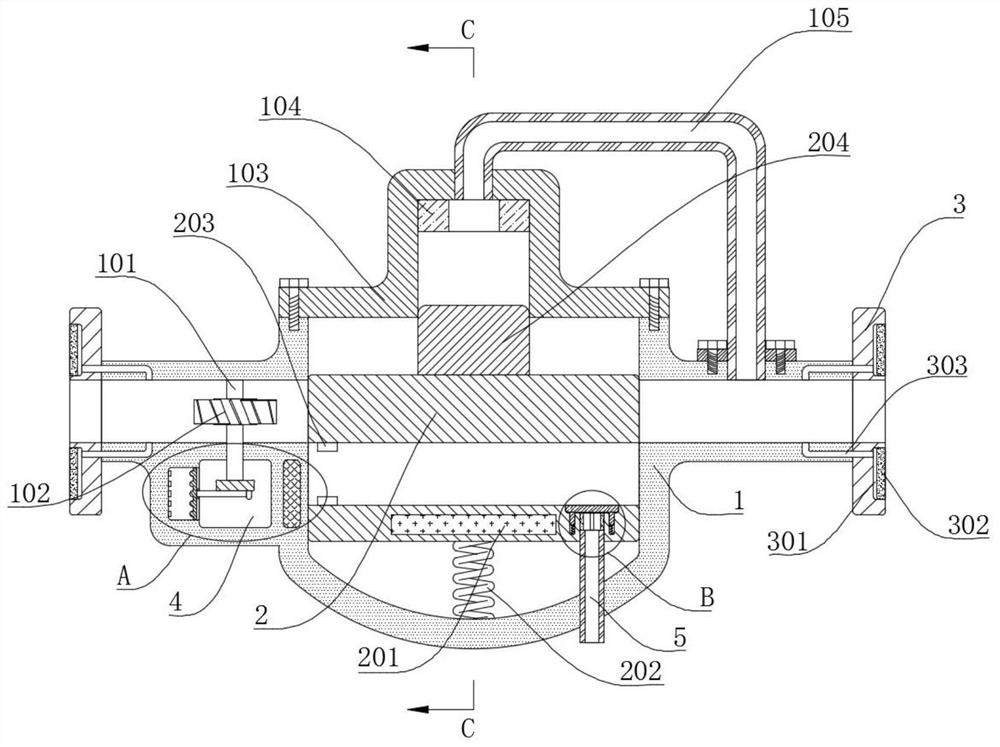

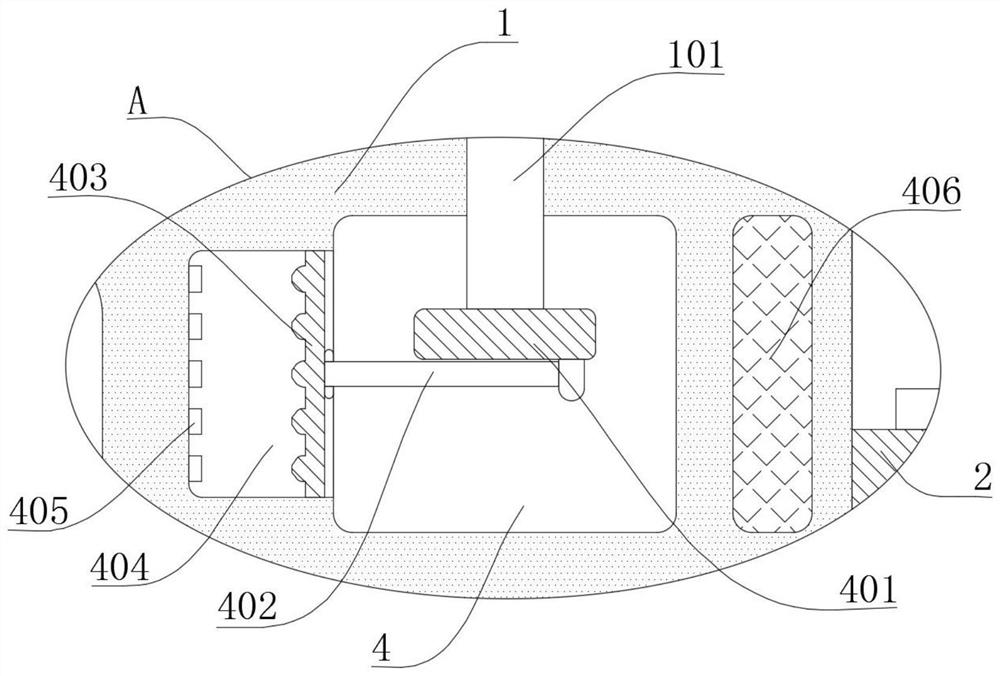

[0030] refer to Figure 1-7 , a high-precision medical gas pressure reducing valve, including a valve body 1, a rotating shaft 101, an impeller 102, a valve cover 103, a metal block 104, a connecting pipe 105, a pressure regulating mechanism, a power generating mechanism, a cleaning mechanism, and a leak-proof mechanism. Such as figure 1 As shown, the valve body 1 includes an output end and an input end. The valve body 1 is a hollow structure. The valve body 1 and the valve cover 103 are fixedly connected by bolts. Extending to the input end of the valve body 1, the impeller 102 is also arranged in the input end of the valve body 1. The impeller 102 is driven to rotate by the input high-pressure gas, and the power generation mechanism is used to generate electricity. The impeller 102 and the rotating shaft 101 are located in the valve body. 1 An interference fit inside, the section of the bonnet 103 is convex and has a groove, the inner top wall of the groove of the bonnet 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com