Method and equipment for measuring damage of shear wall based on digital image and medium

A technology of digital image and measurement method, which is applied in the direction of optical testing flaws/defects, etc., to achieve the effect of suppressing the influence of light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

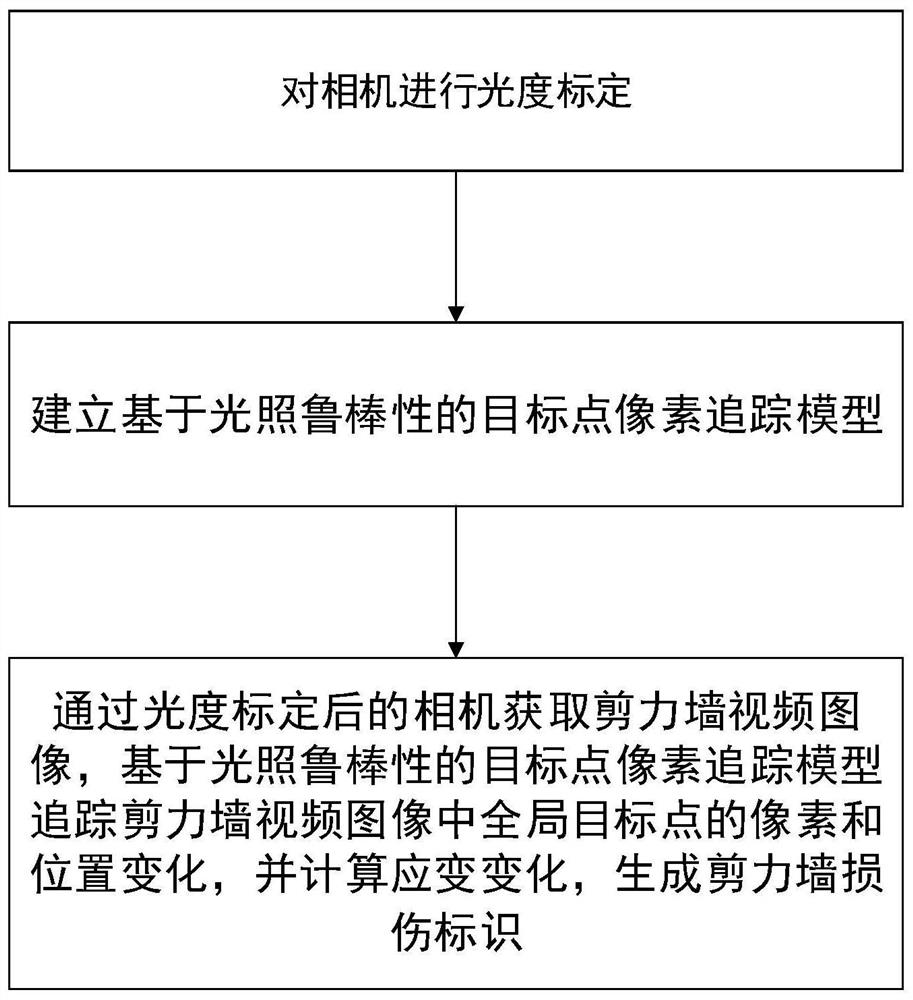

[0091] see figure 1 , a method for measuring shear wall damage based on digital images, comprising the following steps:

[0092] Photometric calibration, setting the camera for collecting shear wall images, and calibrating the response and vignetting of the camera based on the response function and vignetting function of the camera;

[0093] Establish a target point pixel tracking model based on illumination robustness, and determine the correlation function of any point in the camera coordinate system from the reference image of the previous frame to the current image position change of the next frame:

[0094]

[0095]

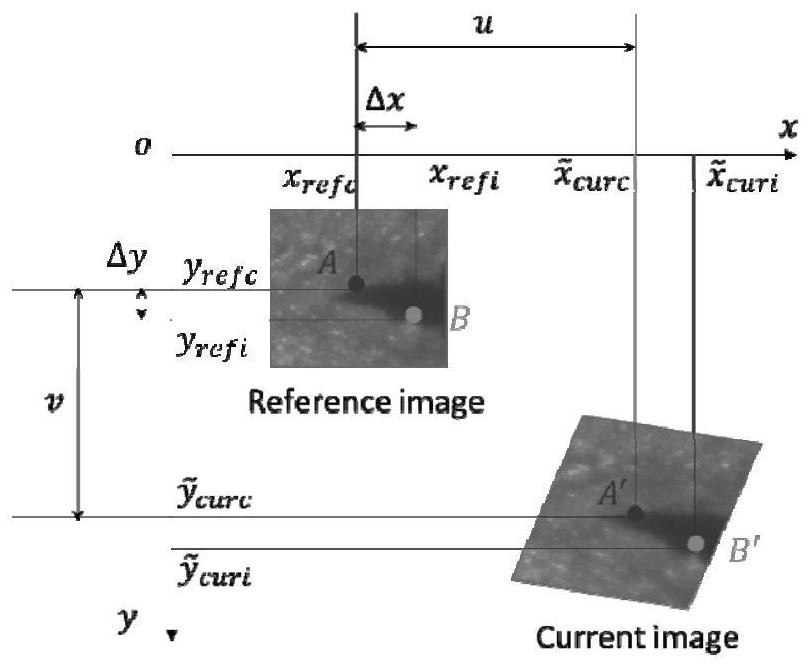

[0096] see figure 2 , in the above formula, u and v are the horizontal and vertical displacements of the midpoint of the reference image in the current image respectively, (x refc ,y refc ) and (x refi ,y refj ) represent the coordinates of the center point A and any point B of the reference image, respectively. and Respectively represent the...

Embodiment 2

[0172] The equipment for measuring shear wall damage based on digital images includes a memory, a processor, and a computer program stored on the memory and operable on the processor, wherein the processor implements the program as described in the present invention. The method described in any embodiment.

Embodiment 3

[0174] The medium for measuring shear wall damage based on digital images has a computer program stored thereon, and is characterized in that, when the program is executed by a processor, the method according to any embodiment of the present invention is realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com