Fault visualization method and system for fixed-shaft gear box

A gearbox and fixed-axis technology, which is applied in the field of signal processing, can solve the problems that the amplitude and quantity cannot guarantee accurate local fault diagnosis, and the method is not intuitive enough, so as to achieve the effect of reliable fixed-axis gearbox fault diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

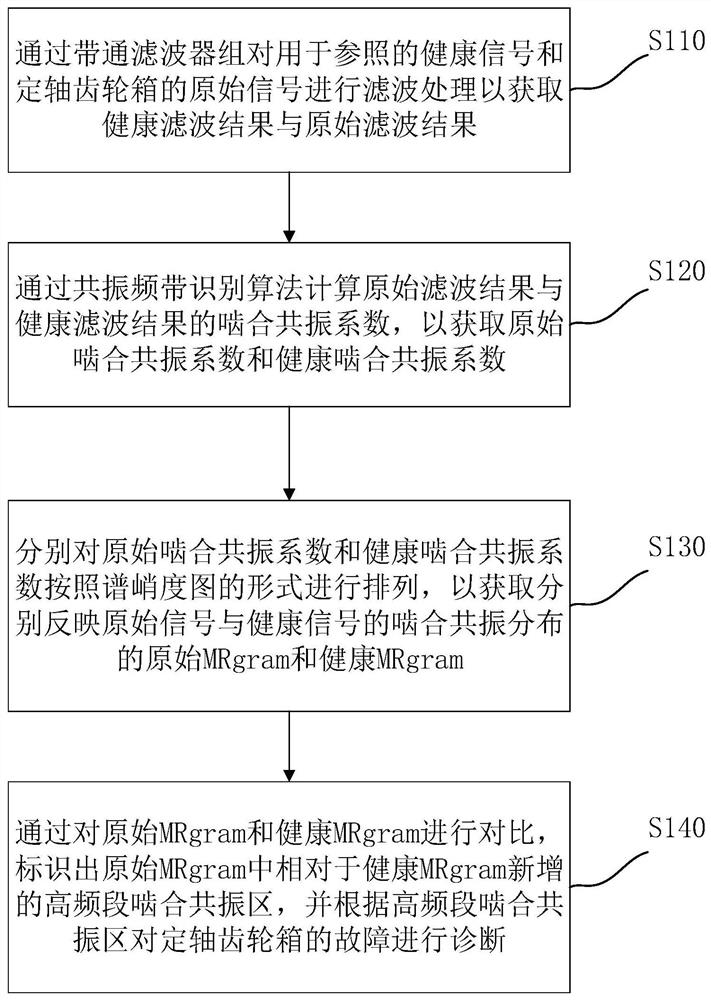

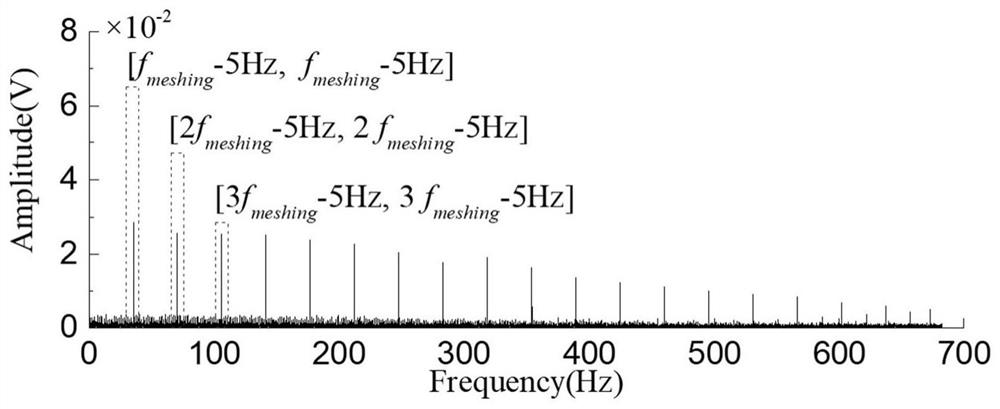

[0049] It is a gear fault diagnosis strategy to compare the meshing frequency and its harmonic sidebands under the fault with the healthy state to identify the fault of the fixed-axis gearbox, but this method is not intuitive enough, only by judging the amplitude of the fault characteristic sideband And the increase in number cannot guarantee accurate local fault diagnosis.

[0050] In view of the above problems, the present invention provides a fault visualization method for a fixed-axis gearbox. Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0051]The following description of the exemplary embodiments is merely illustrative in nature and in no way is taken as any limitation of the invention and its application or use. Techniques and equipment known to those of ordinary skill in the relevant art may not be discussed in detail, but where appropriate, techniques and equipment should be considered pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com