Combined mechanism of rotating joint

A combined mechanism and rotary joint technology, applied in the direction of pipes/pipe joints/pipes, dryers, paper machines, etc., can solve the problems of short service life, poor sealing performance, troublesome installation, etc., and achieve simple manufacturing and easy troubleshooting. , The effect of convenient maintenance and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

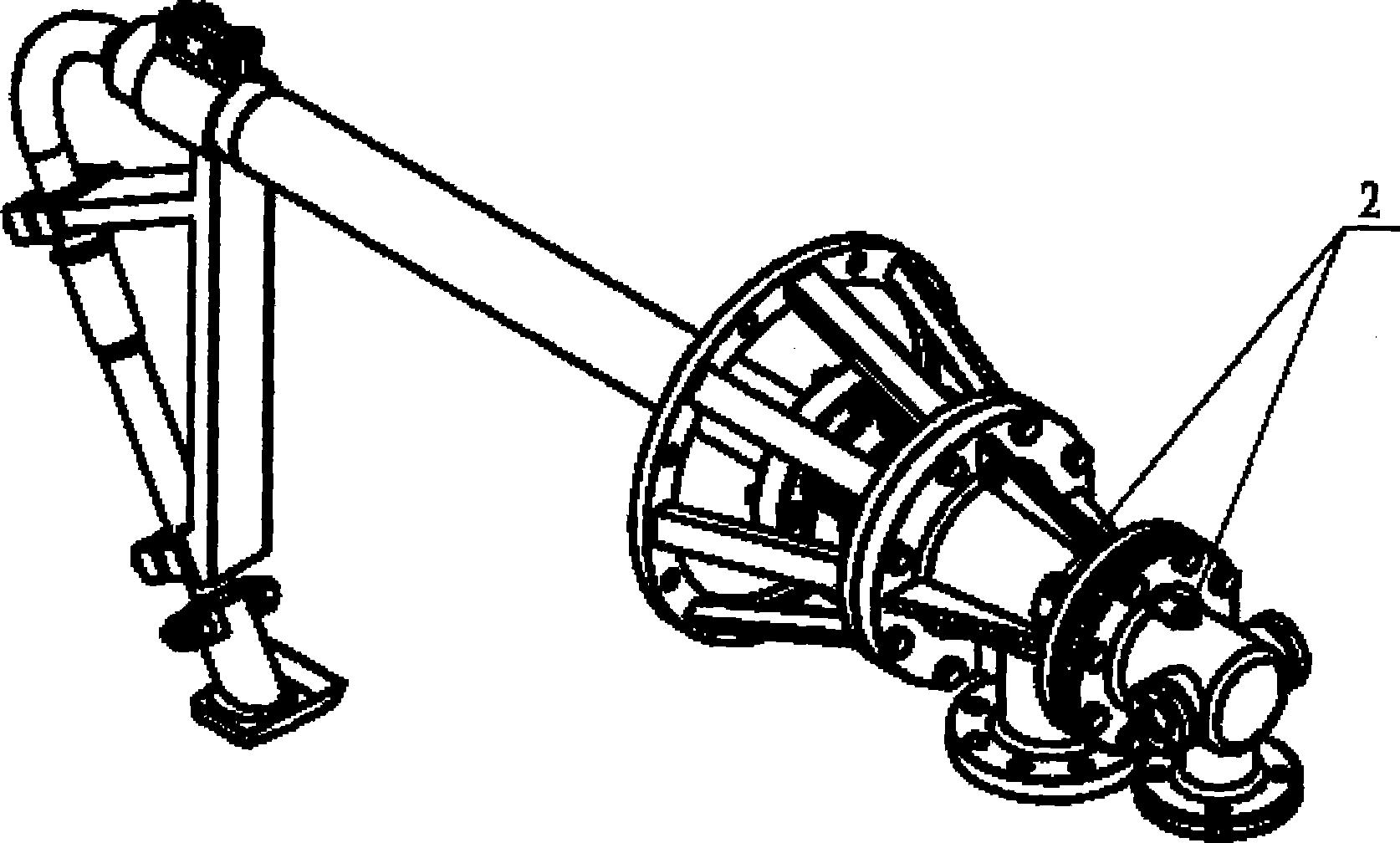

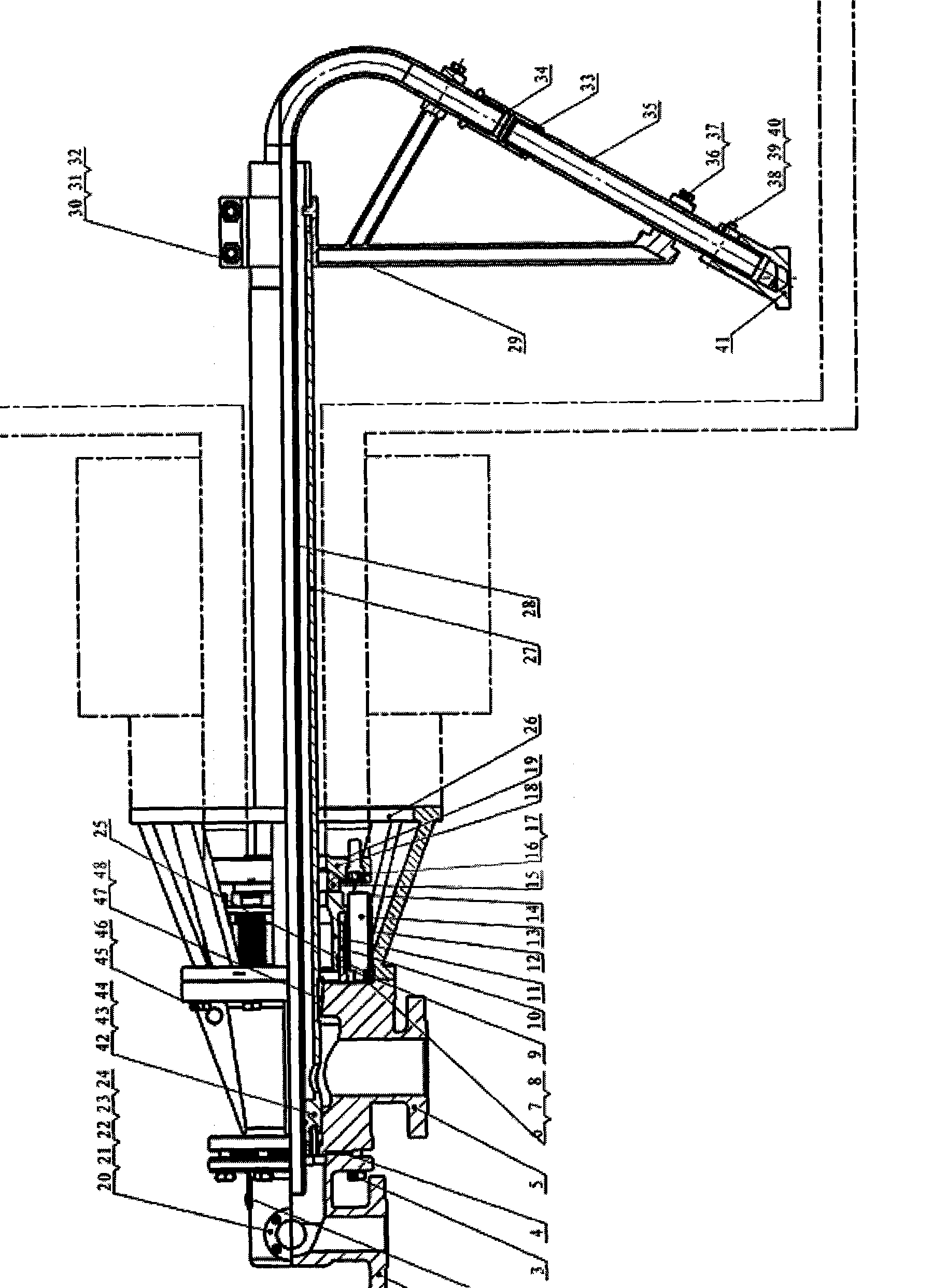

[0021] like Figure 1 ~ Figure 2 Shown: including: end cover 1, screw plug 2, bolt 3, gasket 4, housing 5, hexagon socket screw 6, spring washer 7, gasket 8, sealing ring 9, sliding sleeve 10, sliding outer tube 11 , spring 12, guide rod 13, retaining ring 14, floating sealing spherical ring 15, hexagon socket screw 16, spring washer 17, concave spherical end cap 18, gasket 19, gasket 20, mica sheet 21, mirror glass 22 , pressure ring 23, screw 24, sliding support sleeve 25, bracket 26, cantilever spacer steam pipe 27, siphon elbow 28, triangular bracket 29, hexagonal bolt 30, spring washer 31, anti-loosening nut 32, O-ring 33 , inner sleeve 34, siphon tube 35, bolt 36, pressure plate 37, hex bolt 38, spring washer 39, anti-loosening nut 40, suction nozzle 41, hexagon socket screw 42, spring washer 43, elastic cylindrical pin 44, bolt 45, nut 46, hal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com