Integrated machining device for cutting boards

A processing device and cutting board technology, which can be used in wood processing utensils, manufacturing tools, forming/shaping machines, etc., can solve the problems of low efficiency and high risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

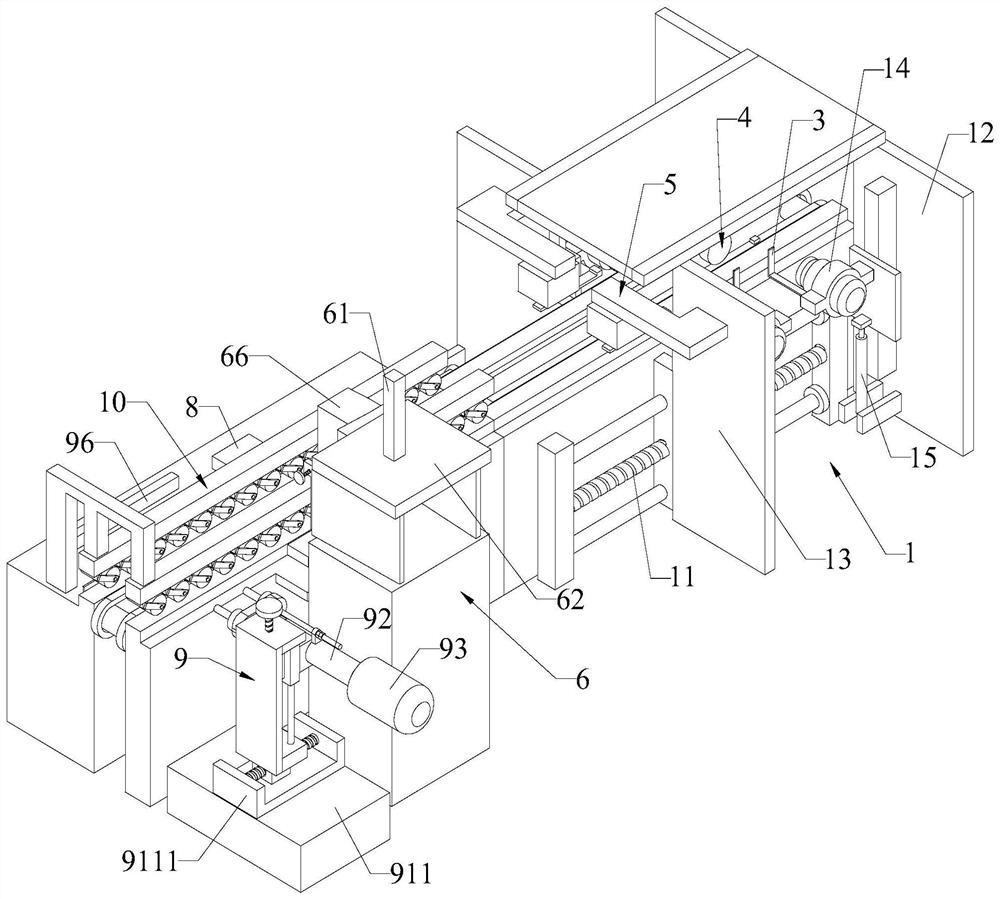

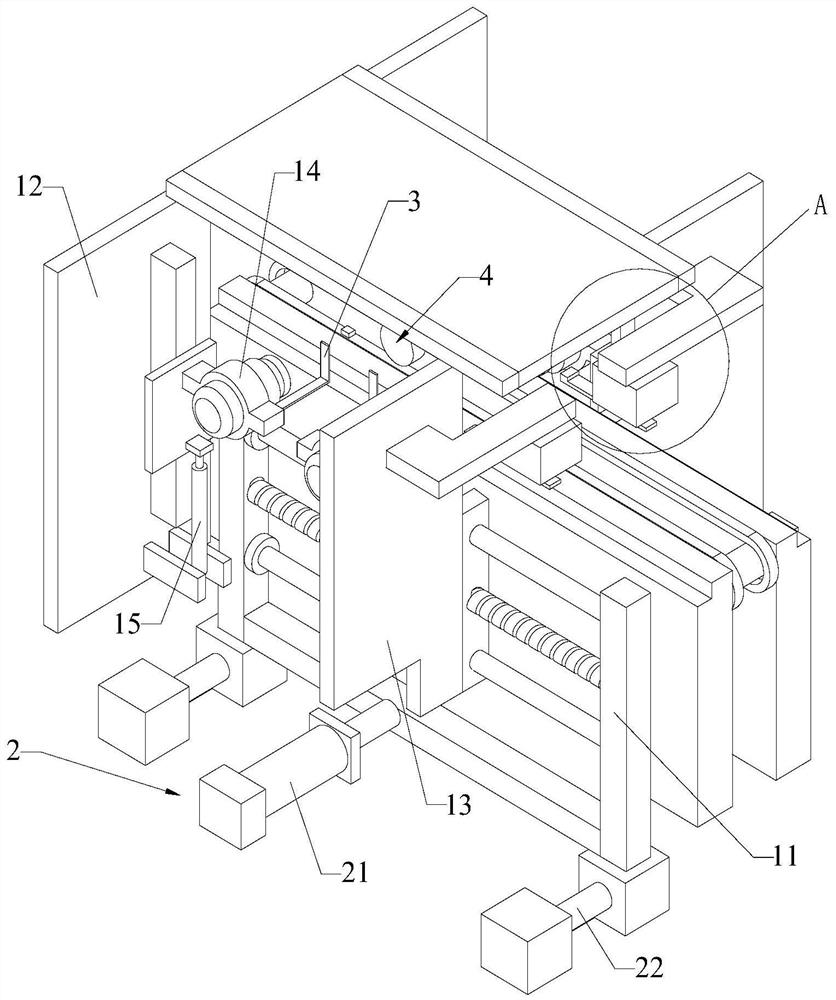

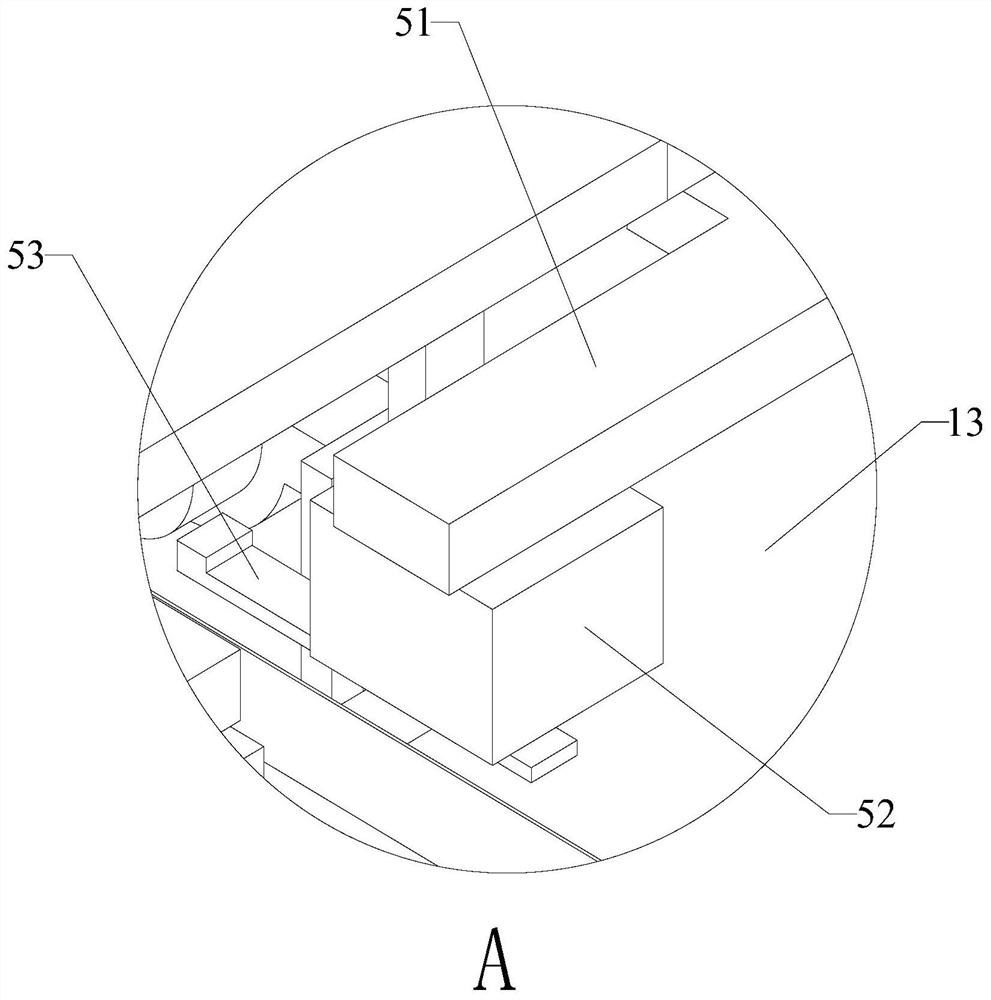

[0051] Please refer to Figure 1 to Figure 8 As shown, a cutting board integrated processing device includes chamfering devices 1 arranged on both sides of the conveying track. Angle device 1 is fixedly installed on the support, and described chamfering device 1 comprises the first linear slide table 11, the first track plate 12, the second track plate 13, the chamfering machine 14 and the first cylinder 15, the first A track plate 12 is installed on the first linear slide table 11, and the second track plate 13 is installed on the slide table of the first linear slide table 11, the first track plate 12, the second track plate 13 The chamfering machine 14 is respectively slidably installed on the track, and the first cylinder 15 is respectively installed on the first track plate 12 and the second track plate 13, and the piston of the first cylinder 15 controls the chamfering machine 14 on the track. move up. A sliding device 2 is provided below the chamfering device 1 on the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap