A wire drawing machine for processing plastic woven bags

A technology of plastic woven bag and wire drawing machine, which is applied in textile and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of poor use flexibility, fluctuation of diaphragm, and insufficient pressing of diaphragm, so as to improve cutting effect of quality, reduced volatility, increased flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

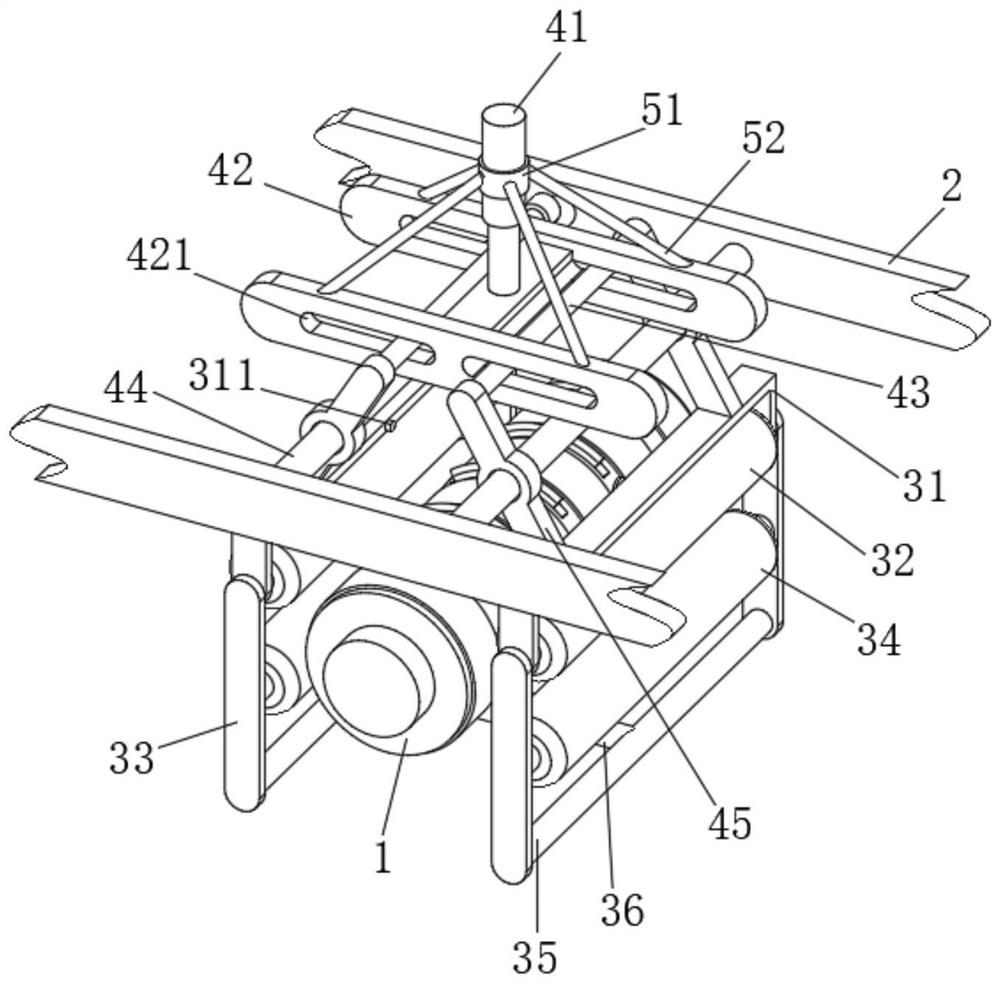

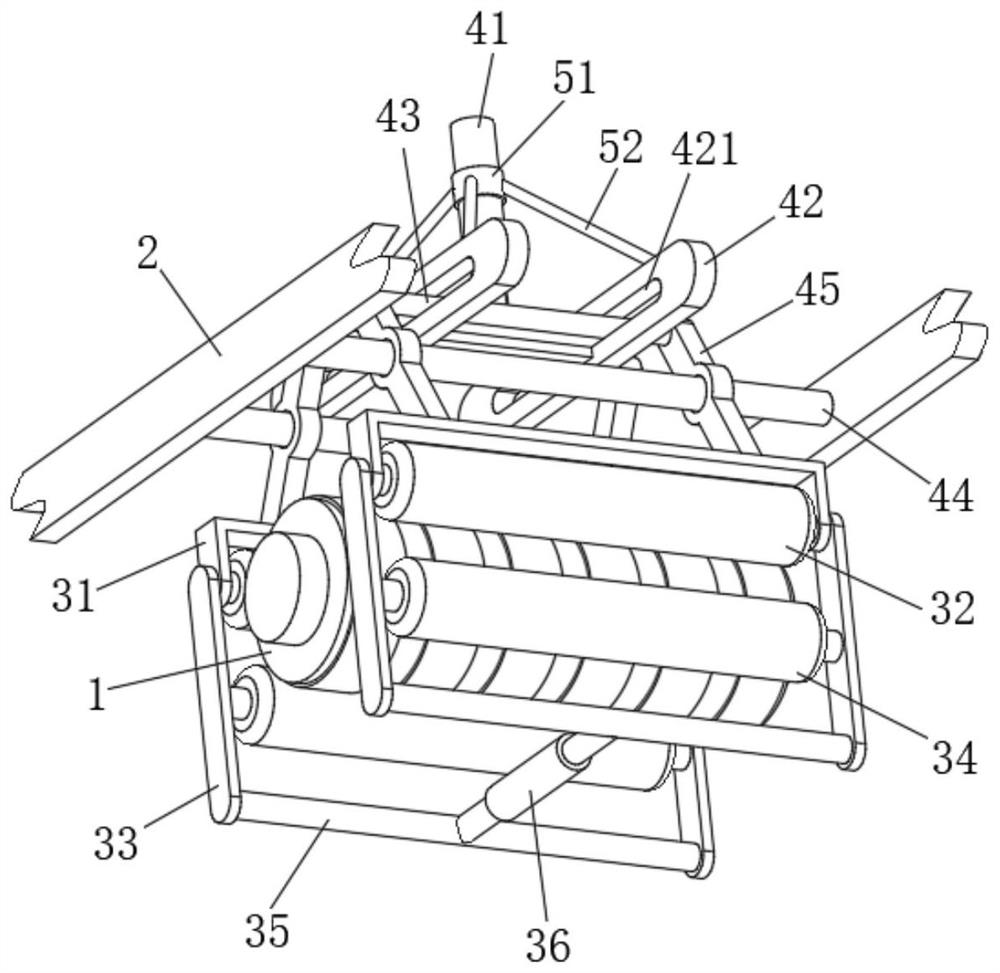

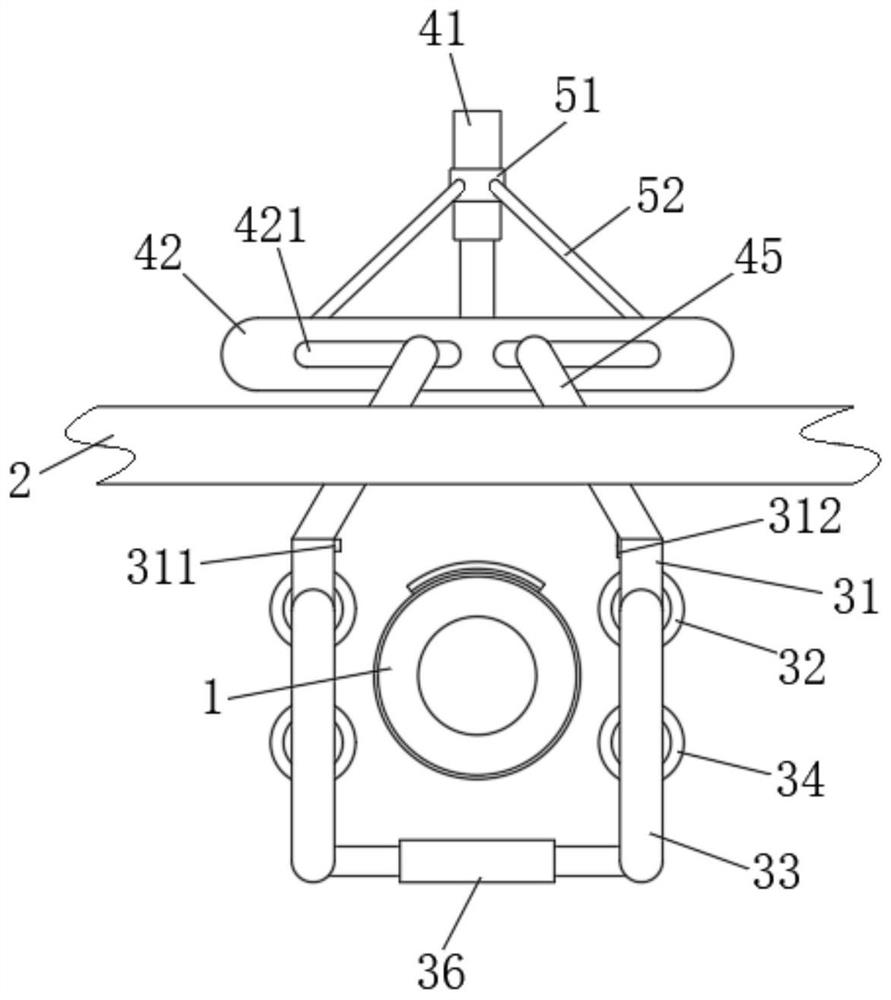

[0032] As shown in Figures 1-4, the pressing mechanism includes a lower pressing telescopic piece 41, two lower pressing plates 42 and a chute 421, and the downward pressing telescopic piece

[0034] When in use, start and extend the downward pressing telescopic piece 41, and the bottom end of the downward pressing telescopic piece 41 drives the horizontal frame to move downward,

[0035] As shown in Figures 1-4, the pressure roller mechanism includes a first mounting frame 31, a first pressing roller 32, two second mounting frames 33, a second

[0037] As shown in Figures 5 and 6, the cutting mechanism 1 includes a cylindrical housing 11, a plurality of first cutting knives 15, and a plurality of second cutting knives

[0038] When in use, the diaphragm is pressed against the top surface of the cutting mechanism 1 by two pressing roller mechanisms, and then the outer end of the diaphragm is pulled,

[0039] As shown in Figures 7 and 8, the top surface of the cylindrical shell 11 is...

Embodiment 2

[0043] As shown in Figure 1-4, between the lower pressing telescopic piece 41 and the lower pressing plate 42, a stability maintenance mechanism is provided, and the stability maintenance mechanism is used to press down the lower pressure plate 42.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com