Wafer storage box

A storage box and wafer technology, applied in packaging, external frame, bottle/can components, etc., can solve the problems of inability to guarantee the accuracy of wafer placement, misplacement of wafer storage boxes, etc., to improve the accuracy of wafer placement and storage efficiency, avoiding the effect of mis-insertion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

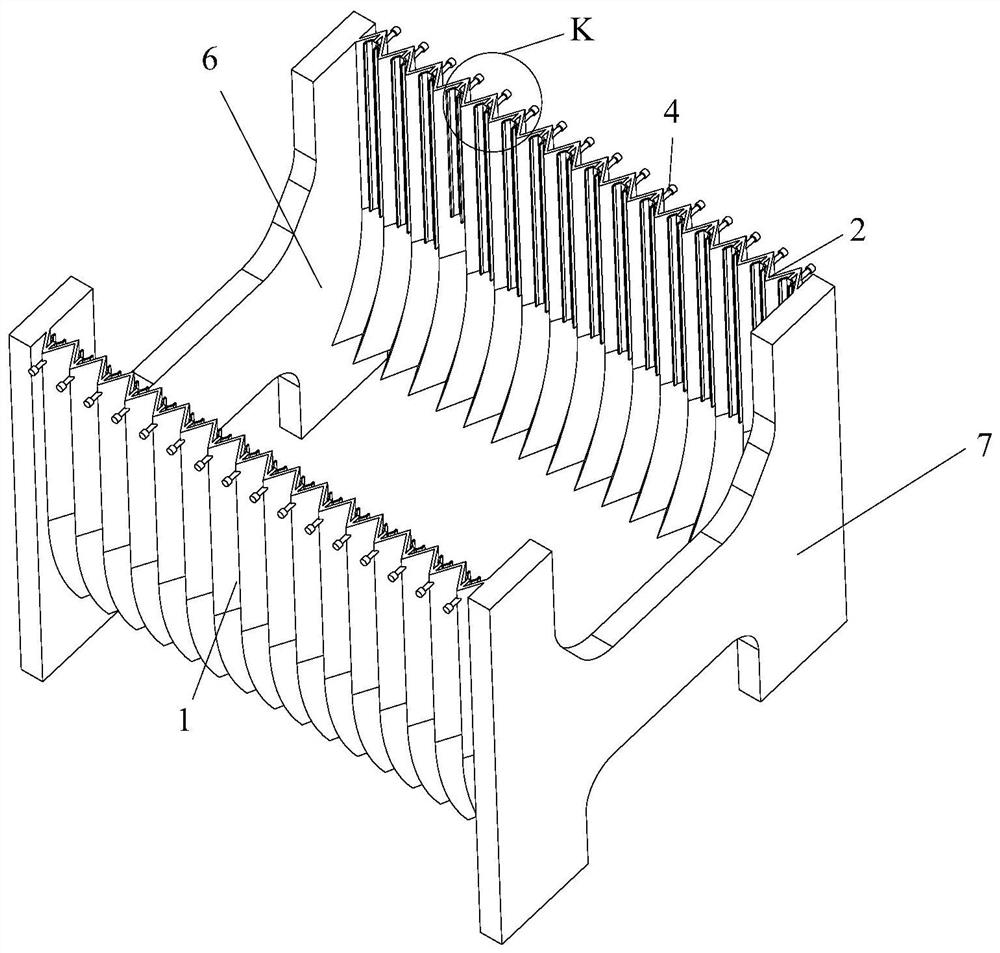

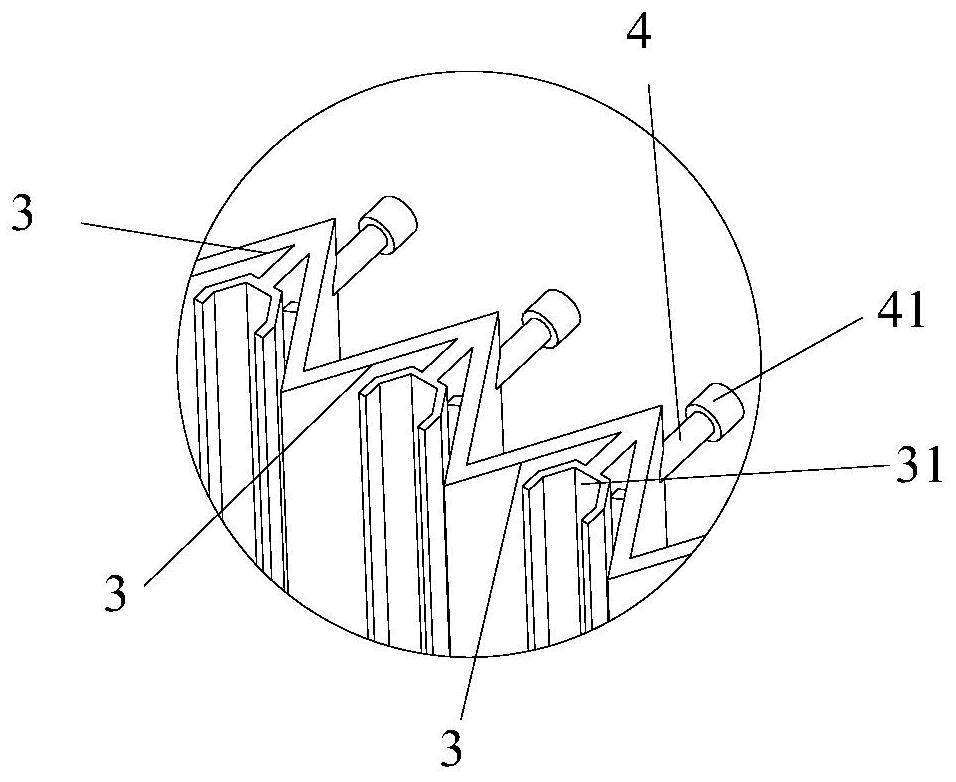

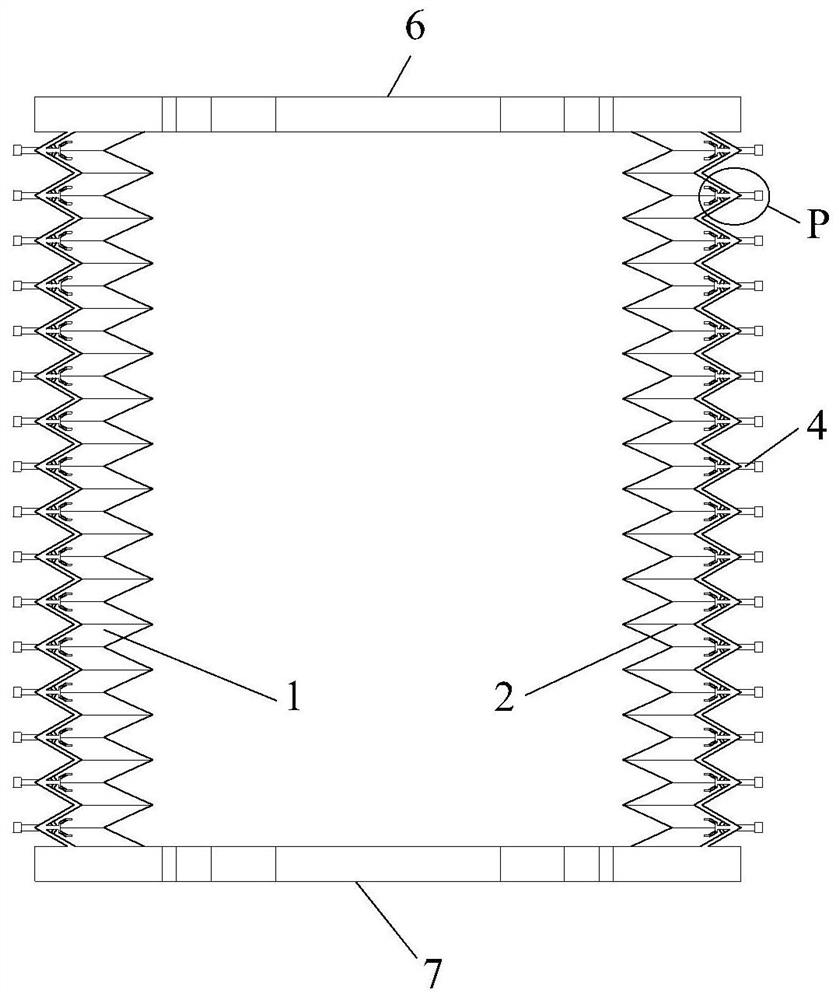

[0029] refer to Figure 1-Figure 2 As shown, the present invention discloses a wafer storage box, comprising a first telescopic board 1 and a second telescopic board 2, and a plurality of folding grooves 3 are formed on the first telescopic board 1 and the second telescopic board 2, the first The folding slots on the telescopic board 1 correspond to the folding slots 3 on the second telescopic board 2 one by one, and the storage wafers are formed between the folding slots 3 on the first telescopic board 1 and the corresponding folding slots 3 on the second telescopic board 2 The outer wall of each folding groove 4 is connected with a push-pull rod 4, the first end of the push-pull rod 4 passes through the folding groove 3 and is connected with a support member 33, and one end of the support member 33 is hinged on the first end of the push-pull rod 4 One end and the other end are hinged on the inner wall of the folding groove 4 .

[0030] Through the setting of the support mem...

Embodiment 2

[0043] The difference between this embodiment and Embodiment 1 is:

[0044] refer to Figure 6 , Figure 7 and Figure 9, the bottom of the locator 31 in the corresponding folding groove 3 of the first telescopic plate 1 and the second telescopic plate 2 is connected by a U-shaped slot 5, and the groove shape of the U-shaped slot 5 is compatible with the locator 31. For example, if the shape (cross section) of the positioning member 31 is V-shaped, then the groove body shape (cross section) of the U-shaped locking groove 5 is also V-shaped. Since the telescopic plate stretches and contracts, it will exert a slight force on the placed wafer to make it move, and the wafer is easily squeezed and damaged during the moving process. In order to avoid the above phenomenon, the above-mentioned U-shaped slot 5 is designed so that the The round bottom can be supported in the above-mentioned U-shaped groove 6 , so that the entire wafer can be fixed, and it is not easy to fall or be da...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap