High-precision measuring method for concrete pouring surface elevation of cast-in-situ bored pile

A technology of bored piles and measurement methods, applied in the direction of height/level measurement, measurement devices, radio wave measurement systems, etc., can solve the problems of inaccurate measurement and inconvenient use, and achieve cost saving, easy disassembly and reuse , The effect of improving the efficiency of engineering construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Step 1: Surveyors enter the site after being allowed by the on-site construction workers, communicate with the on-site construction workers on precautions, and conduct on-site safety inspections;

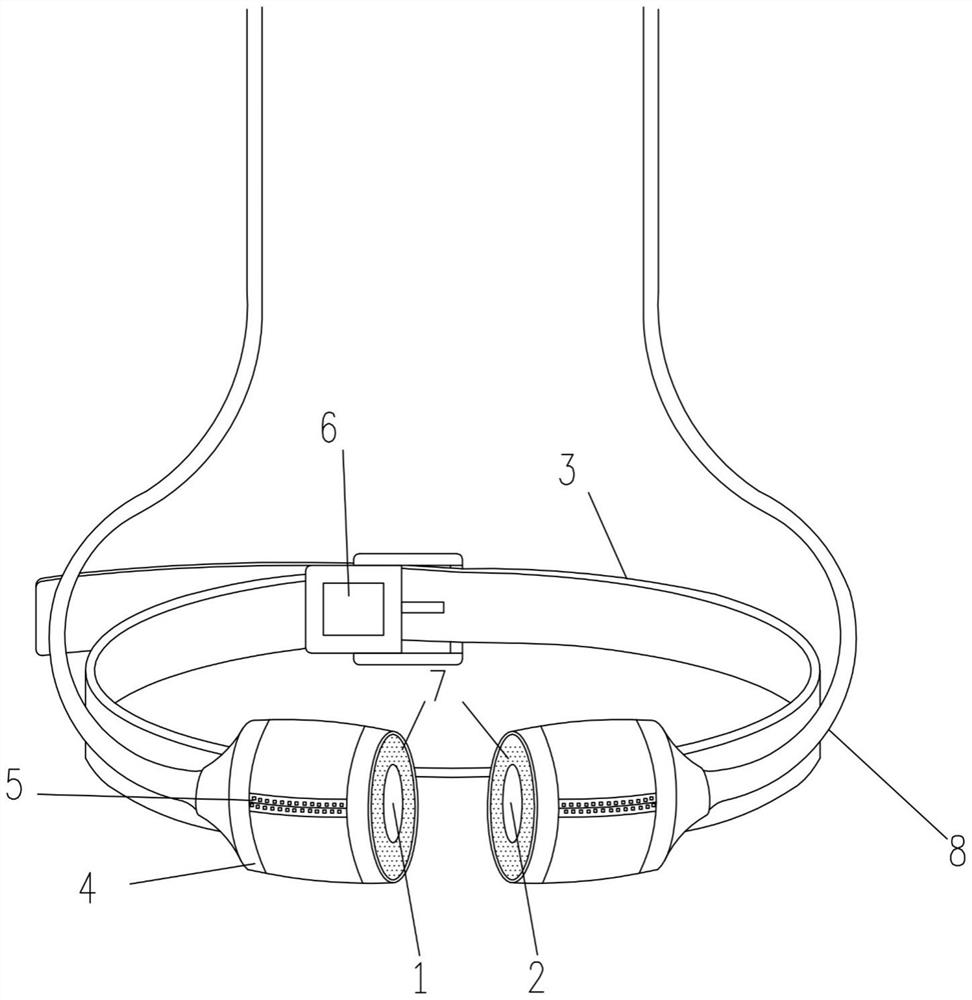

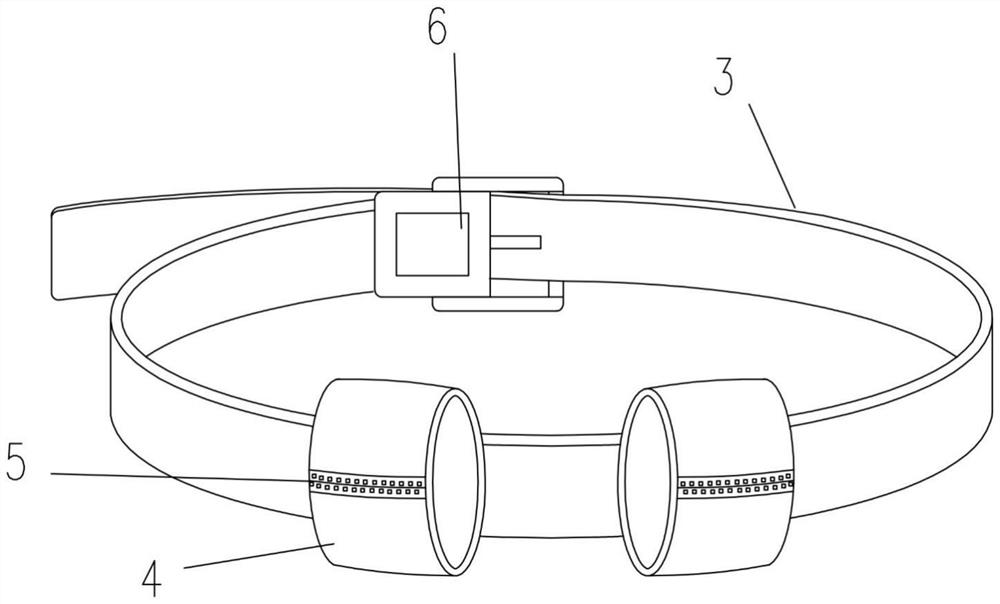

[0075] Step 2: According to the construction requirements, bind the high-precision detection device for the concrete filling surface elevation of the bored pile to the exact position of the concrete conduit. The exact position should be at the highest limit point of the concrete conduit, and the corresponding design elevation of the concrete pouring surface on the concrete conduit;

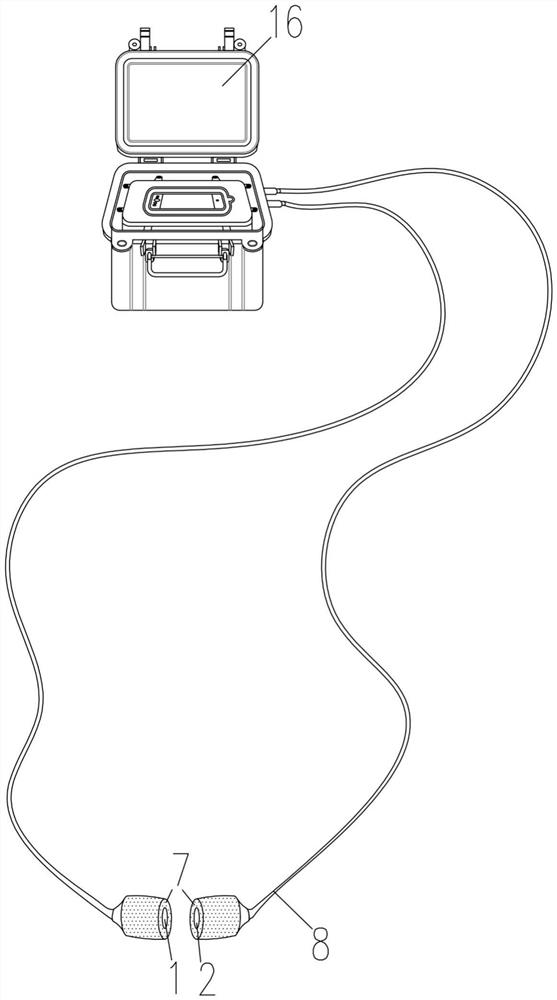

[0076] Step 3: Turn on the monitoring data of the ultrasonic detection device. Concrete is poured into the bored pile through the concrete conduit according to the standard construction procedure, and the liquid level in the hole rises accordingly. The ultrasonic probe measures different ultrasonic signals with different media. The grinding data line is transmitted to the ultrasonic signal process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com