On-line monitoring and early warning method of milling cutter status during complex curved surface machining

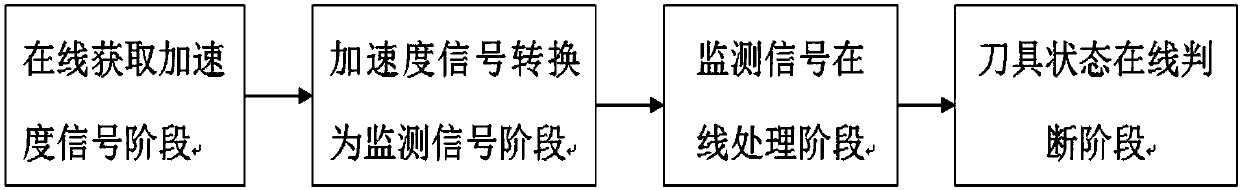

A technology for processing and complex surfaces, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., to achieve the effects of simple measurement, simple programming, and fast running speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The specific implementation manners of the present invention will be further described below in conjunction with the technical solutions and accompanying drawings.

[0053] A total of 80 sets of experimental data were collected at a compressor impeller milling production site in a domestic enterprise. During the collection process, the milling cutter was stopped at intervals to observe the state of the milling cutter, and the 61st group of milling cutters was found to be chipped. The experimental parameters are shown in Table 1.

[0054] Table 1 Experimental parameters

[0055]

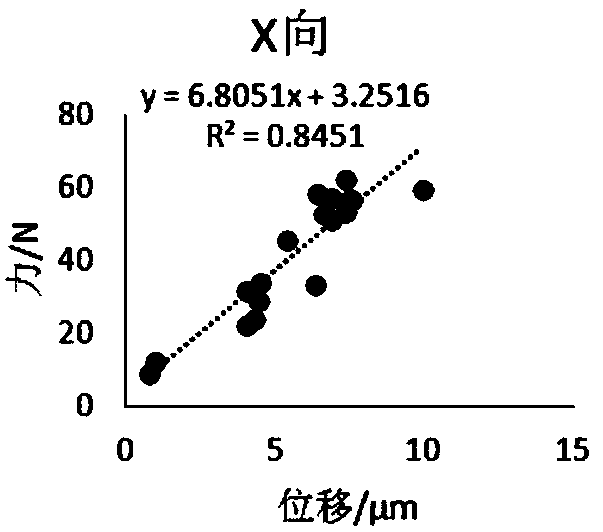

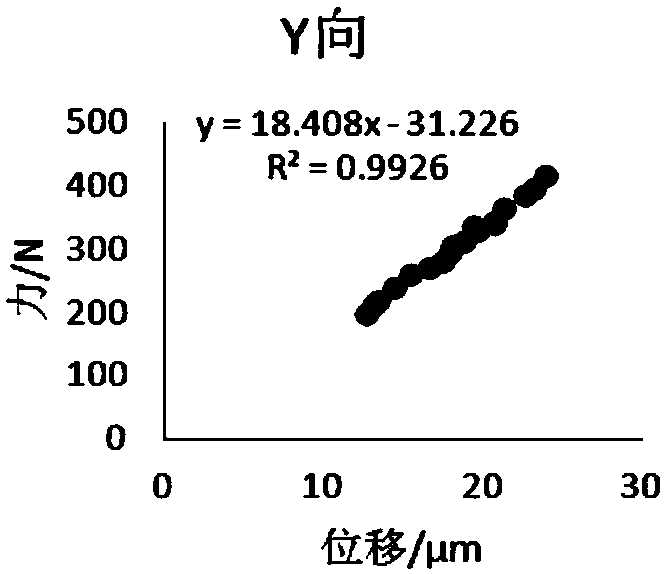

[0056] The 14th group and the 64th group of data are the data before and after the chipping of the milling cutter, and the synchronous average cycle is 10 rotation speed cycles. Figure 4a , Figure 4b Corresponding to the calculation results of the first-order and second-order cumulants of the eddy current displacement signal of the 14th group of data, Figure 4c , Figure 4d Correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com