Intelligent fish weight checking and sorting machine and operation method thereof

A sorter, intelligent technology, applied in fish sorting, sorting and other directions, can solve the problems of affecting the weighing quality, easy to accumulate water, unable to transport products, etc., to achieve simple and convenient operation method, mature technology to buy, cheap price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

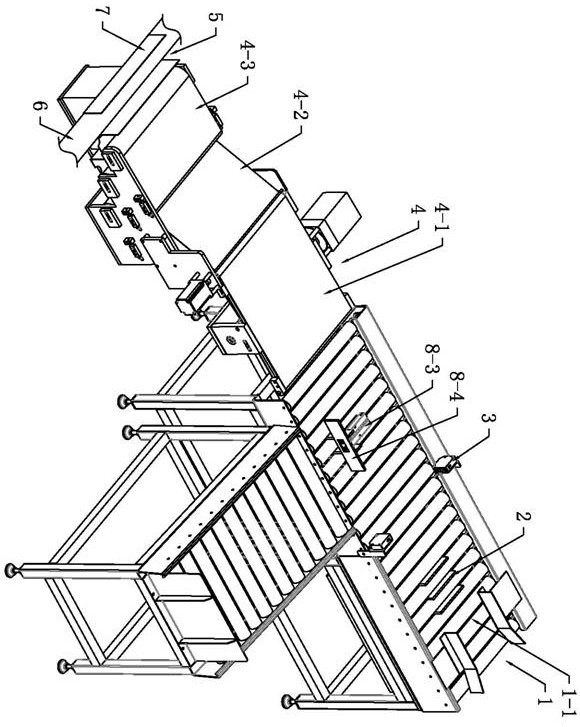

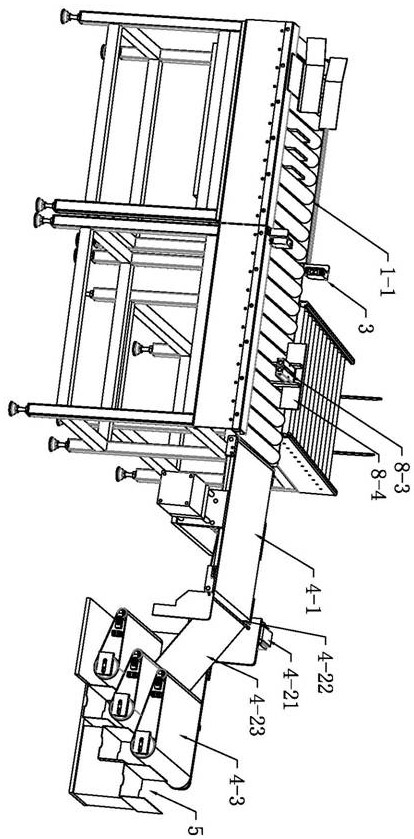

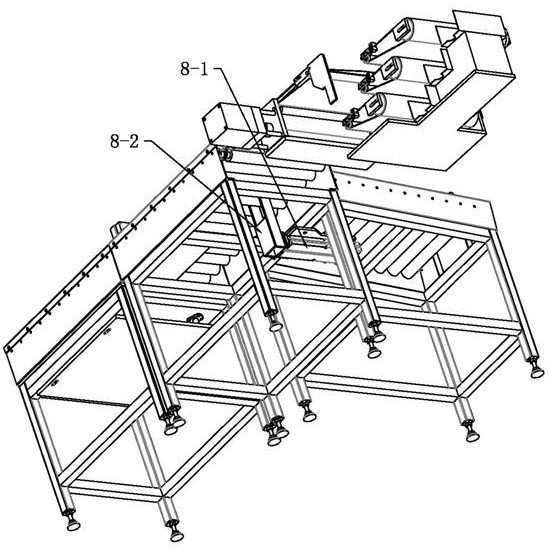

[0033] Such as Figures 1 to 4 As shown, the fish intelligent checkweighing and sorting machine of this embodiment includes a PLC controller, a feeding device 1, a weighing device 2 and a sorting device 4, and the above-mentioned motors are all controlled by the PLC controller to operate cooperatively.

[0034] Wherein, the feeding device 1 is composed of a plurality of transmission rollers 1-1, a transmission system and a motor. The motor drives the rotation of the plurality of transmission rollers 1-1 through the transmission system, and the operation of the motor is controlled by a PLC controller. The traditional system consists of gears and transmission chains, and the transmission mode of the transmission system is conventional technology, which should be clearly understood by those skilled in the art. The intelligent fish weighing sorting machine of the present invention adopts the transmission roller 1-1 to transport the fish, and the gap between the transmission roller...

Embodiment 2

[0045]The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The intelligent weighing and sorting of fish in this embodiment is also provided with a waste rejecting device. The waste rejecting device includes a first cylinder, a connecting seat, a second cylinder and a push plate, and the first cylinder is installed on the bottom of the frame and connected by drive. The seat translates laterally, and the second cylinder is installed on the connecting seat and drives the telescopic movement of the push plate. A discharge conveying device is installed in the direction in which the push plate pushes and rejects waste products, and is composed of a plurality of drive rollers 1-1, and the discharge conveying device is arranged inclined from top to bottom from the feeding direction to the discharging direction. The processor of the PL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com