Industrial robot cleaning equipment

A technology for industrial robots and cleaning equipment, which is applied in the direction of cleaning methods using tools, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems affecting work efficiency, troublesome cleaning of robots, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

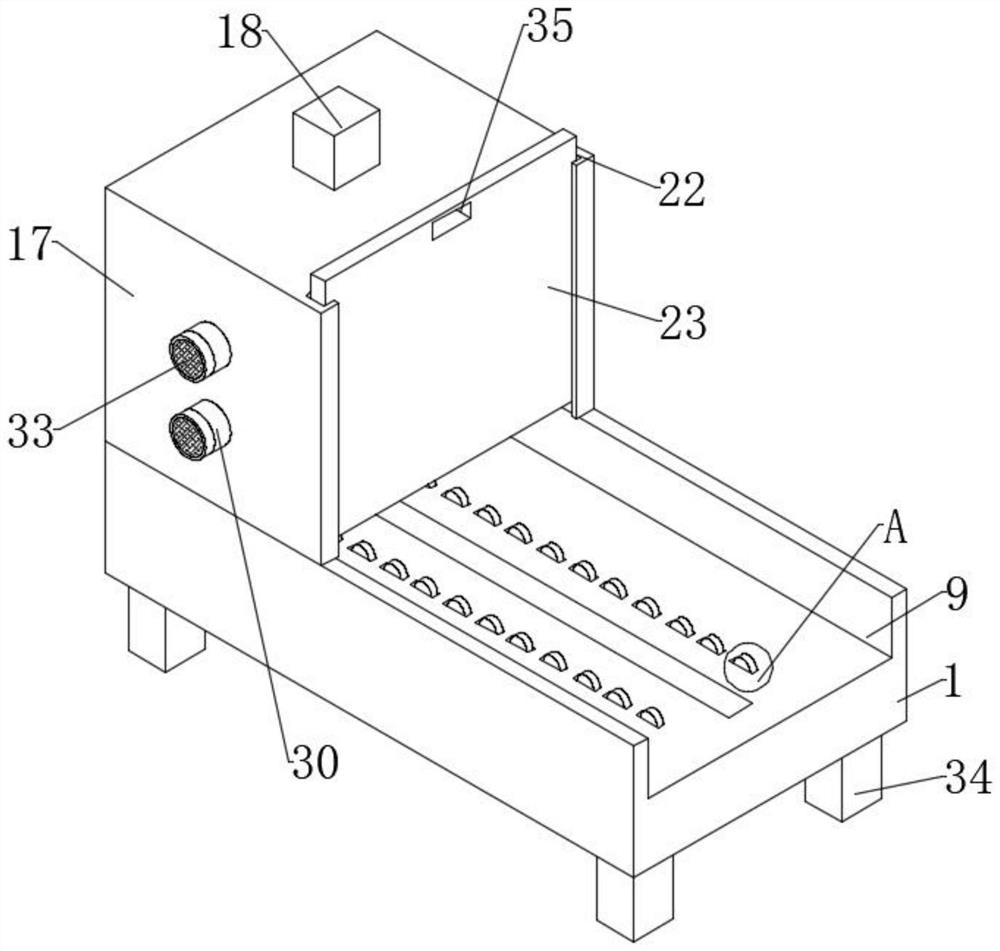

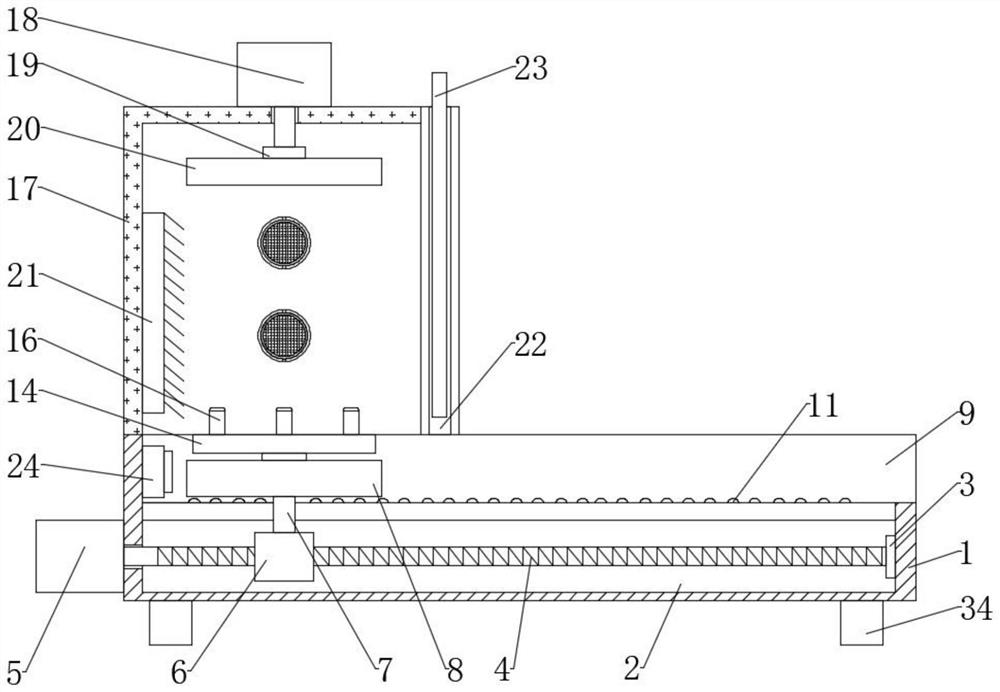

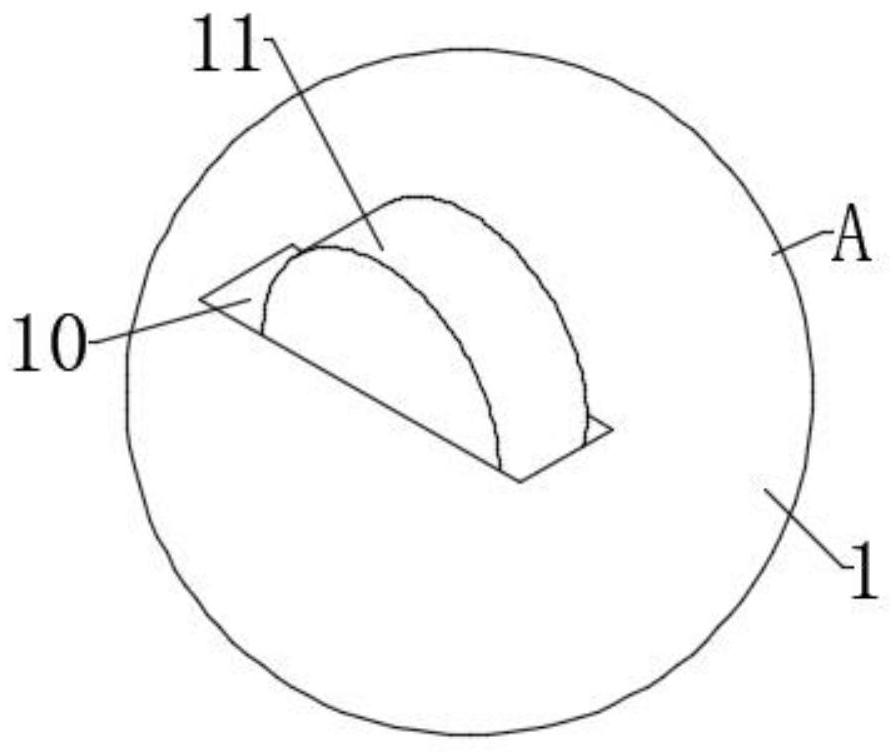

[0035] Such as Figure 1-7 As shown, the embodiment of the present invention provides an industrial robot cleaning equipment, including a base 1, the inside of the base 1 is provided with a movable groove 2, and the inner side of the movable groove 2 is fixedly connected with a first bearing seat 3, by setting the first bearing seat 3. It is convenient to rotate the threaded rod 4 with the inner wall of the movable groove 2. The inside of the first bearing seat 3 is fixedly connected with the threaded rod 4. The side surface of the base 1 is fixedly connected with the drive motor 5. The threaded rod 4 is controlled by the drive motor 5. Rotate, and control the threaded block 6 to drive the support rod 7, the slide plate 8, and the placement plate 14 to move, thereby controlling the industrial robot to move, avoiding manually pushing the industrial robot into the cleaning box 17, and the output shaft of the drive motor 5 extends to the movable slot 2 and is fixedly connected wi...

Embodiment 2

[0041] The difference between the present embodiment and the first embodiment is that an inclined block is set on the side surface of the base 1 and on the side opposite to the drive motor 5, and the inclined surface of the inclined block is provided with balls, which facilitates the industrial robot to pass through the inclined block. The shaped block slides onto the placement plate 14, avoiding manually lifting the industrial robot onto the placement plate 14, thereby reducing the labor force.

Embodiment 3

[0043] The difference between this embodiment and the first embodiment is that the driving motor 5 and the threaded rod 4 in the first embodiment can be replaced by hydraulic cylinders and telescopic rods, and the same can control the threaded block 6, the support rod 7, the slide plate 8, and place The plate 14 moves and moves the industrial robot into the cleaning tank 17 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com