Rotor broaching and finish turning device

A technology for hole drawing and finishing turning and rotors, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of low efficiency of rotor drawing and finishing turning, and high labor intensity of personnel, so as to shorten the transfer time and reduce personnel Labor intensity, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0034] Aiming at the problems of low processing efficiency and high labor intensity of existing rotor broaching and finishing turning, the invention provides a rotor broaching and finishing turning device.

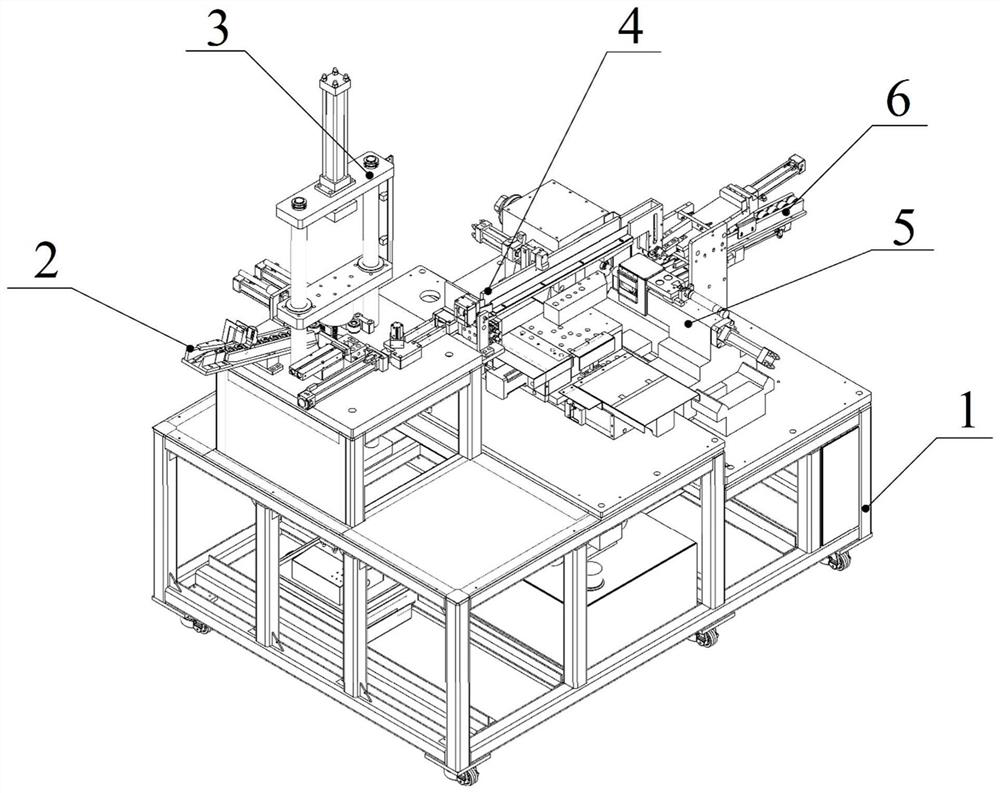

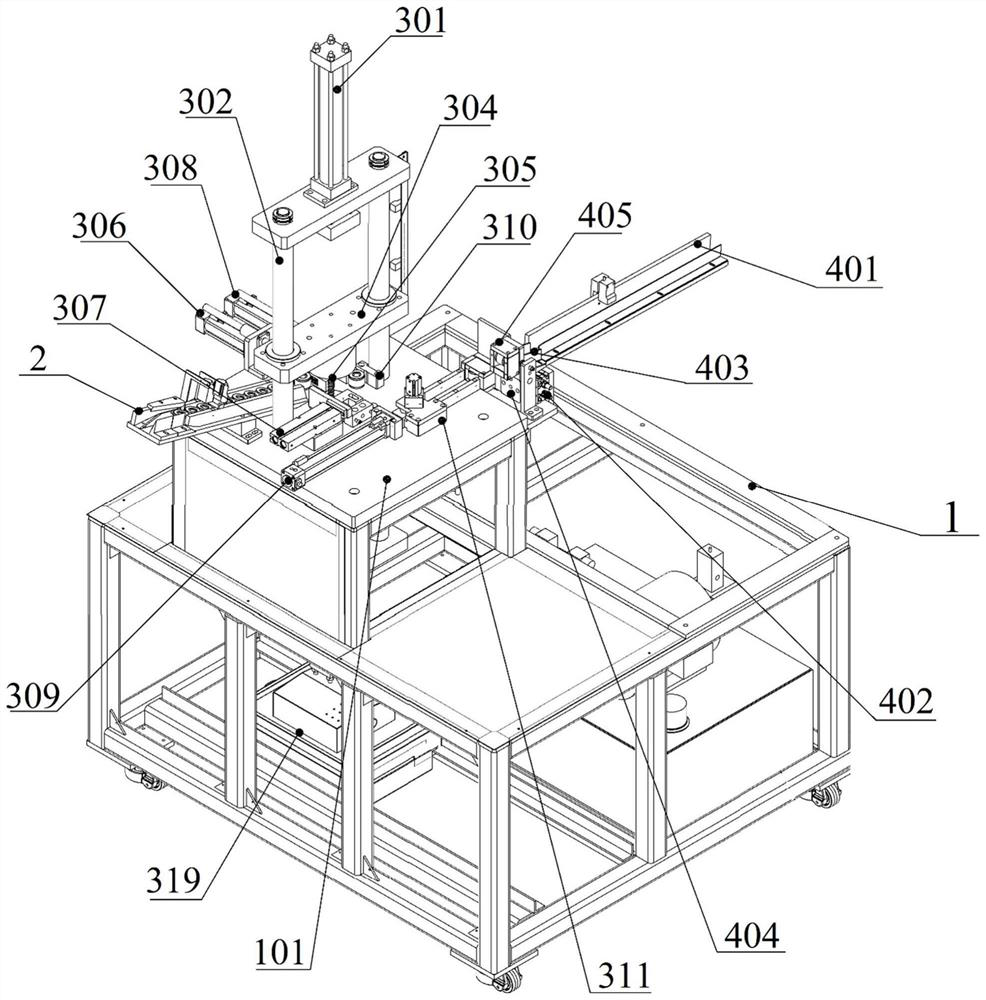

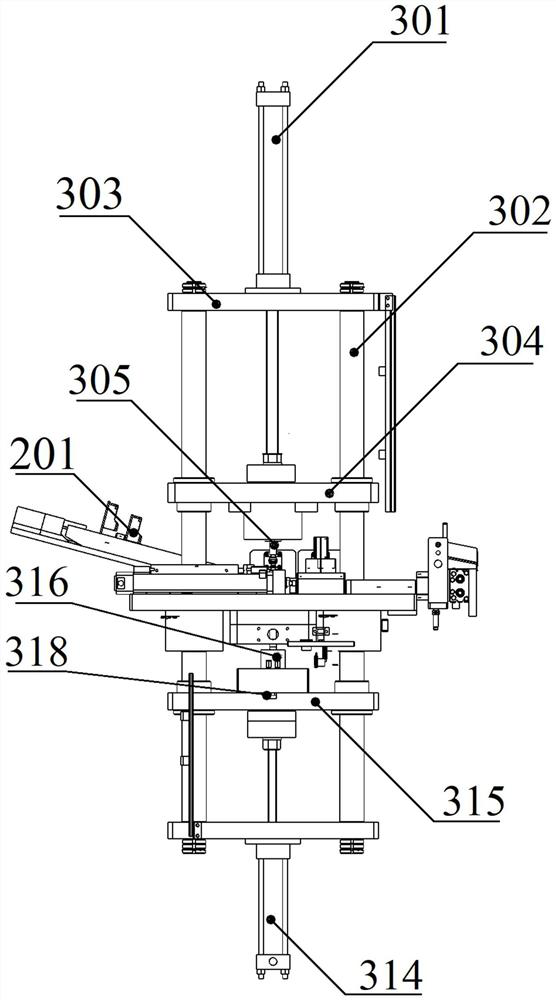

[0035] like Figure 1 to Figure 9As shown, the embodiment of the present invention provides a rotor punching and finishing device, including: a mounting frame 1, the mounting frame 1 is provided with a punching platform 101 and a turning platform 102; a rotor feeding track 2, The rotor feeding track 2 is erected on one side of the punching platform 101, and a counting sensor 201 is arranged on the rotor feeding track 2; a punching mechanism 3, and the punching mechanism 3 is arranged on the punching platform 101, the broaching platform 101 is provid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap