Dust removal device and dust removal method for granary discharging process

A dust removal device and granary technology, applied in the direction of loading/unloading, transportation and packaging, conveyors, etc., can solve the problems of incomplete dust removal of grain, affecting the quality of grain, and the inability of the dust removal device to fully remove dust, so as to improve quality and realize The effect of dust removal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

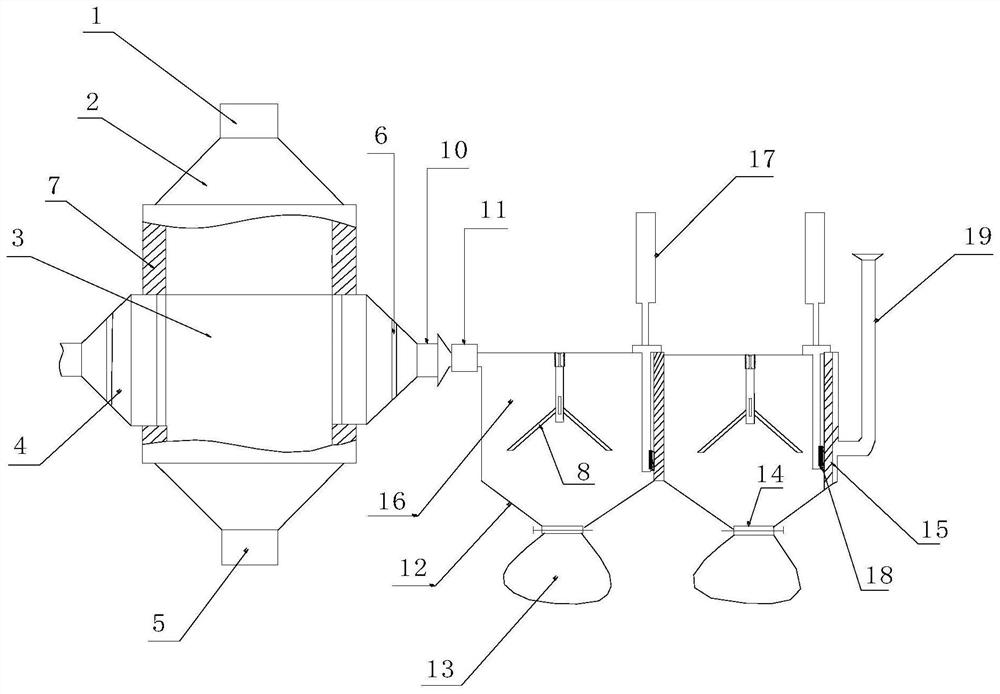

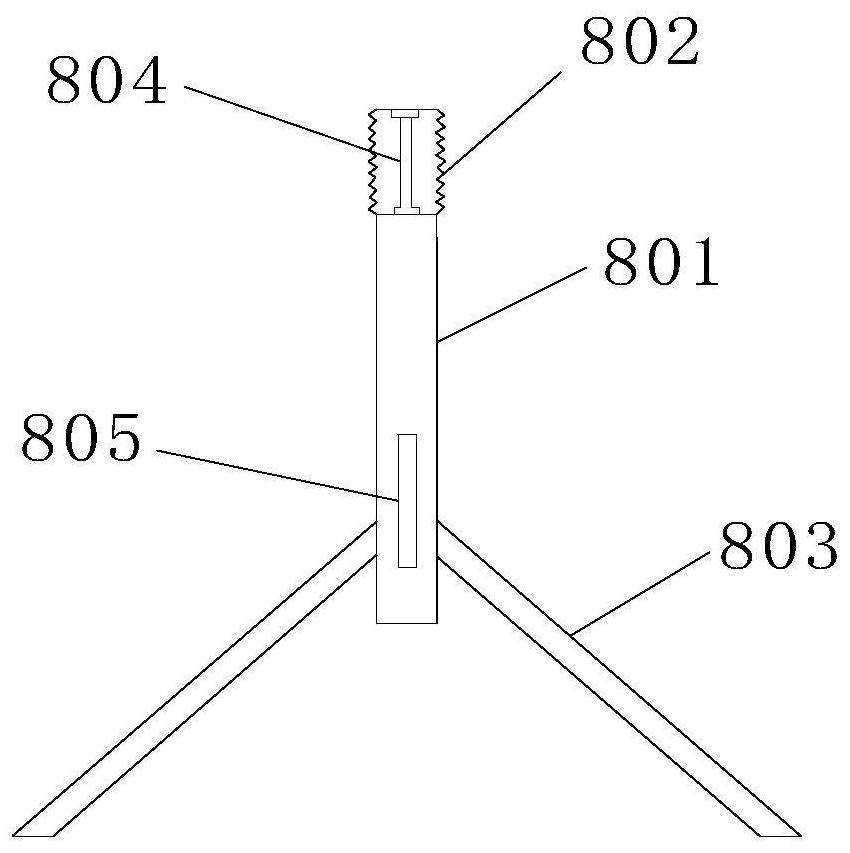

[0035] like Figure 1-3 As shown, a dust removal device for the feeding process of a granary in this embodiment includes a dust removal box 3, a dust suction mechanism, an adsorption device 8, a dust detector 6 and a controller. The opposite sides of the dust removal box 3 are fixedly connected with a dust collection cover 4, and the dust collection cover 4 is externally connected with a dust suction mechanism for extracting the dust in the dust removal box 3. The bottom of the dust removal box 3 is fixedly connected with a discharge pipe 5 for dust removal. The upper side of the box 3 is connected with the dispersion box 7, and the upper side of the dispersion box 7 is fixedly connected with the feeding cover 2, and the upper side of the feeding cover 2 is fixedly connected with the feeding pipe 1, so that the dust removal box 3 is airtight, and the dispersion box 7 is fixedly connected with the dust removal unit. Box 3 upper side.

[0036] The dust suction mechanism is conn...

Embodiment 2

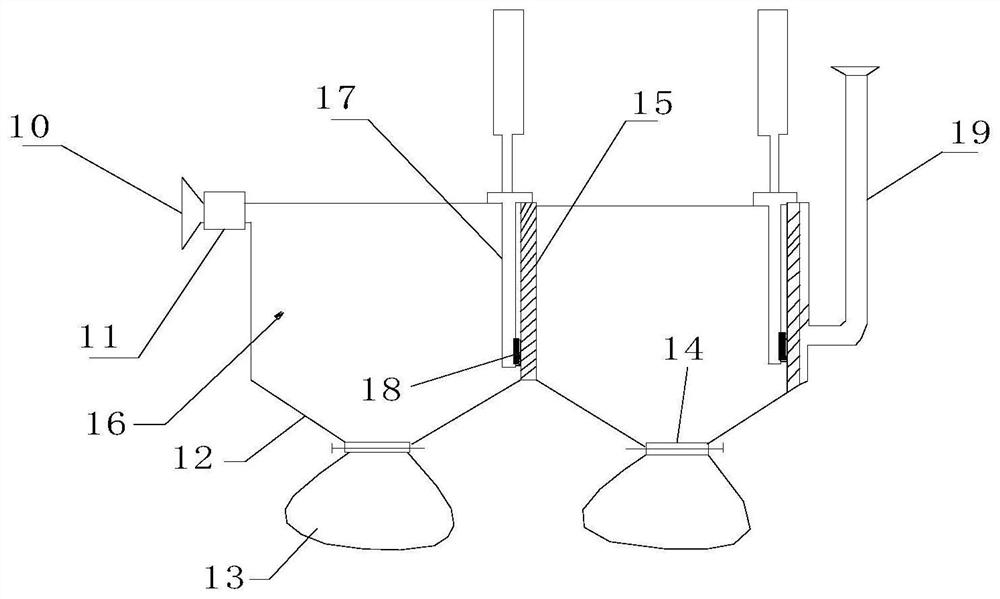

[0042] This embodiment is basically the same as Embodiment 1, and the only difference is that the dust suction mechanism in this embodiment also includes cleaning equipment, and the cleaning equipment includes a plurality of cleaning brushes 18 respectively corresponding to a plurality of filter screens 15, and each cleaning brush 18 passes through a The hydraulic rod 17 is movably connected to the top wall of the dust collection bin 16; each cleaning brush 18 cleans the corresponding filter screen 15 when the hydraulic rod 17 moves up and down.

[0043]During specific work, the hydraulic rod 17 can be moved up and down by connecting an oil pump, and the cleaning brush 18 at one end of the hydraulic rod 17 rubs on the corresponding filter screen 15, thereby utilizing the cleaning brush 18 to clean the corresponding filter screen 15, thereby maintaining the filter screen. The filtration efficiency of net 15 also prolongs the service life of filter net 15.

Embodiment 3

[0045] This embodiment is basically the same as Embodiment 1, the only difference is that the dust suction mechanism in this embodiment also includes a plurality of sensors-12, a plurality of electronic valves 14 and a plurality of cloth bags 13; Each dust collection bin 16 corresponds, and each sensor one 12 is arranged on the bottom wall of the corresponding dust collection bin 16, and each sensor one 12 is used to detect the pressure value one generated by the dust accumulated in the corresponding dust collection bin 16; A plurality of electronic valves 14 are respectively corresponding to the plurality of dust collection bins 16, and each electronic valve 14 is arranged at the bottom of the dust collection bin 16; a plurality of cloth bags 13 are respectively corresponding to the plurality of dust collection bins 16, each Each cloth bag 13 corresponds to an electronic valve 14 respectively, and each cloth bag 13 communicates with the corresponding dust collection bin 16 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com