Automatic shearing machine control device based on GE PLC (General Electric Co. Programmable Logic Controller)

A technology of automatic control device and shearing machine, which is applied in shearing device, device for cutting with nibbling action, shearing machine equipment, etc. Harmful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

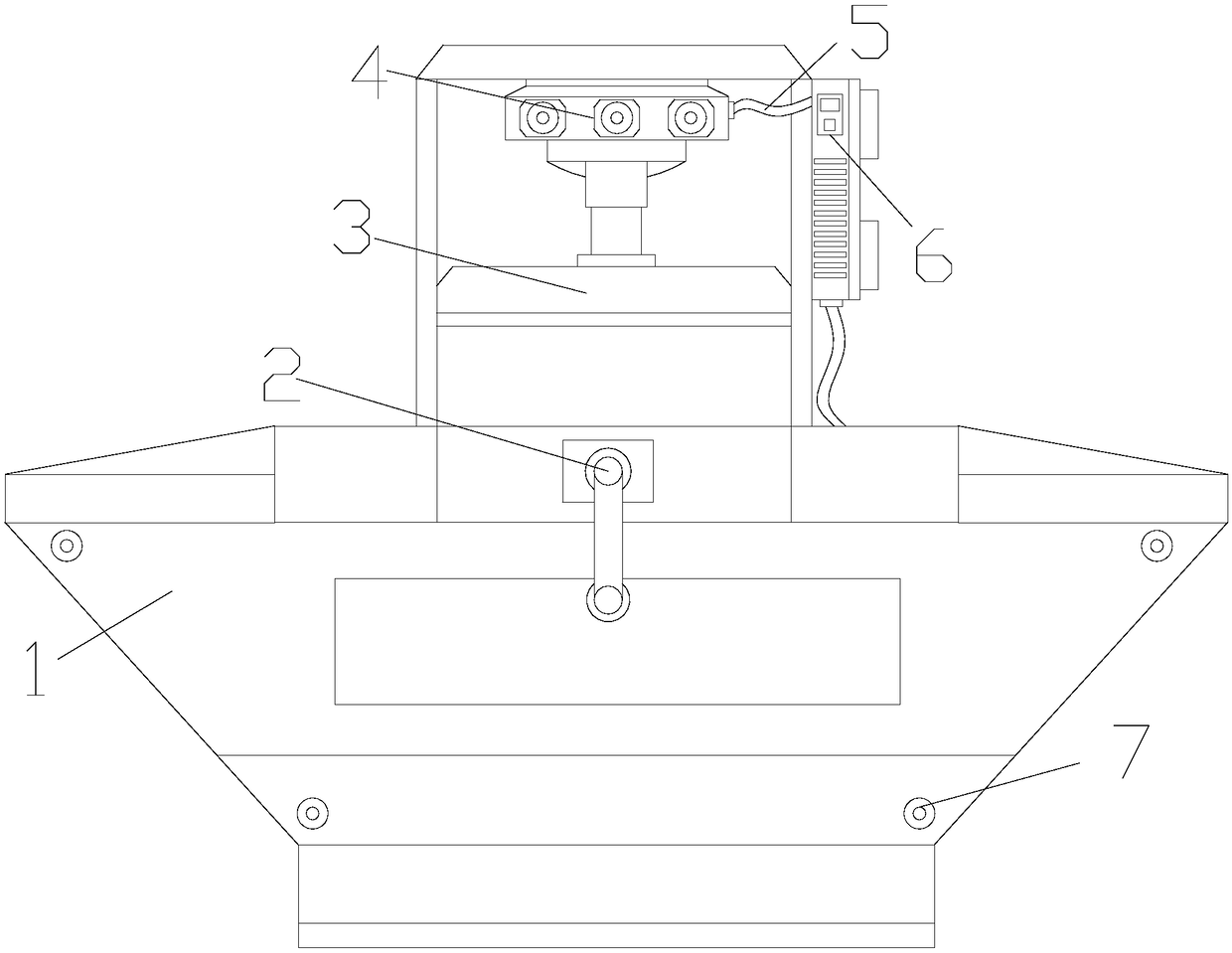

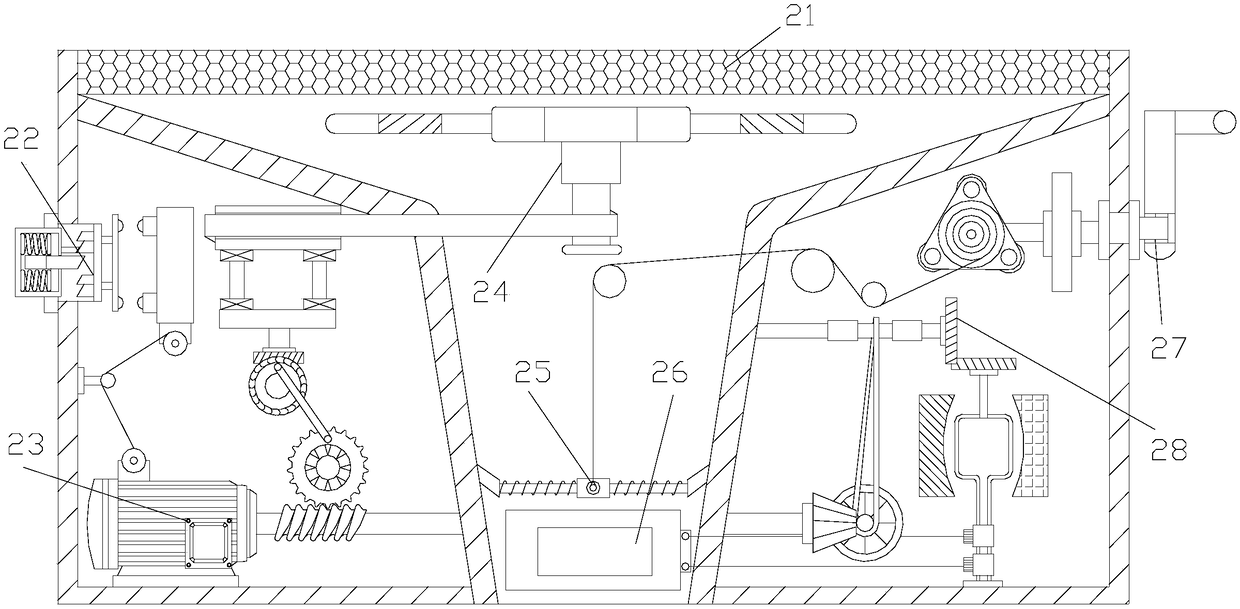

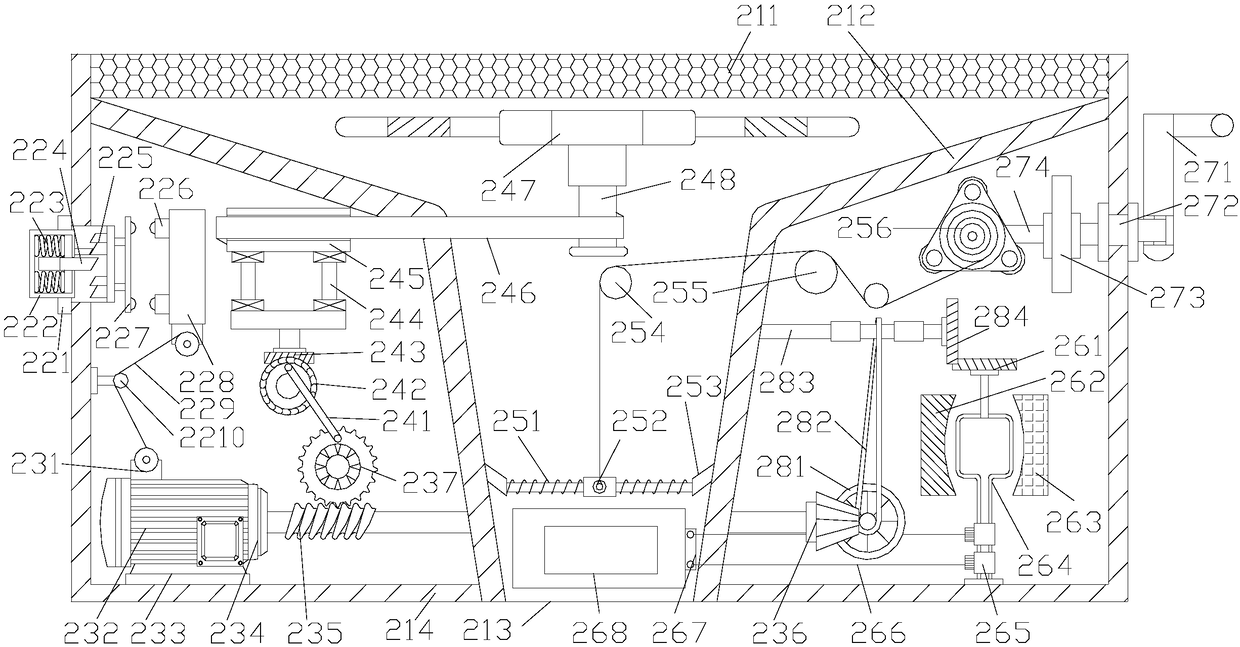

[0023] see Figure 1-Figure 3, the present invention provides an automatic control device for a shearing machine based on GE PLC, its structure includes a shearing machine body 1, an adsorption chip removal device 2, a cutting knife 3, a hydraulic press 4, a power cord 5, a control box 6, and a locking bolt 7. The front surface of the shearing body 1 is provided with four locking bolts 7, and they are screwed together. The adsorption chip removal device 2 is installed on the inner head end of the shearing body 1 by embedding, and the cutting knife 3 The head end is mechanically connected to the end of the hydraulic press 4, one end of the power cord 5 is electrically connected to the control box 6, the control box 6 and the shear body 1 are welded together by electric welding, and the adsorption chip removal device 2 includes a filter protection Cover 21, start switch mechanism 22, power motor mechanism 23, fan adsorption mechanism 24, upper and lower wall hanging mechanism 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com