Assembly detection device for powder adding system of copying machine

A technology for assembly testing and duplicating machines, applied in liquid tightness measurement using liquid/vacuum degree, pollution prevention method, cleaning method and utensils, etc., which can solve problems such as inaccurate detection results and human hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

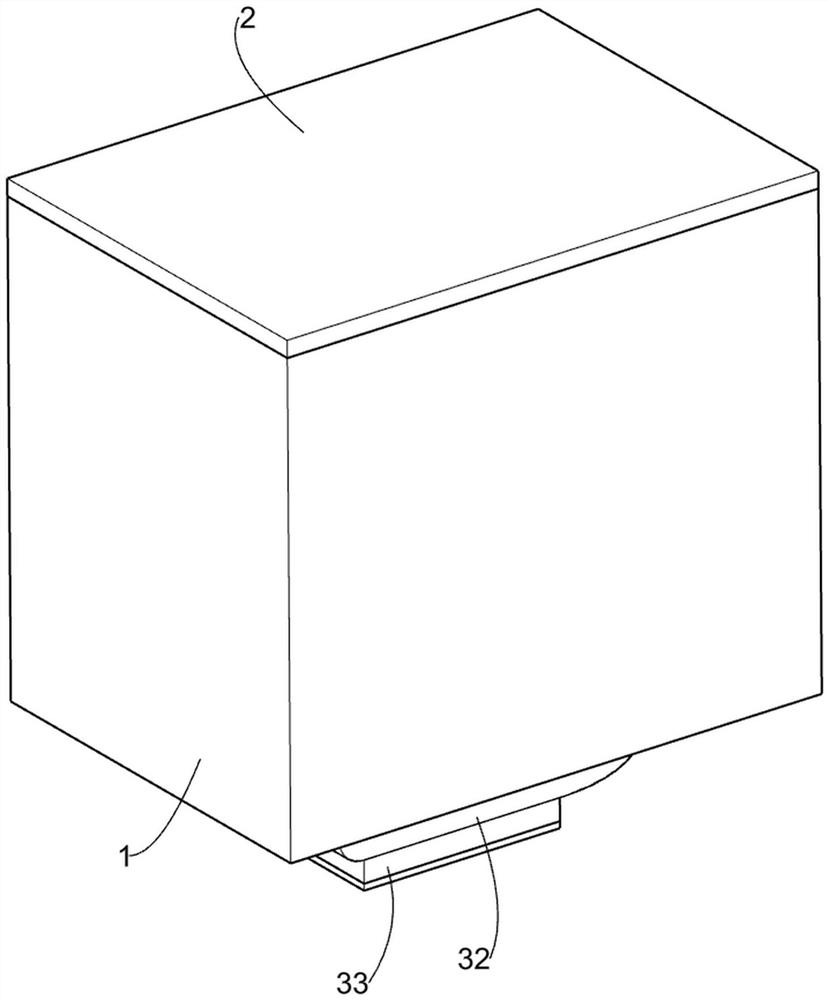

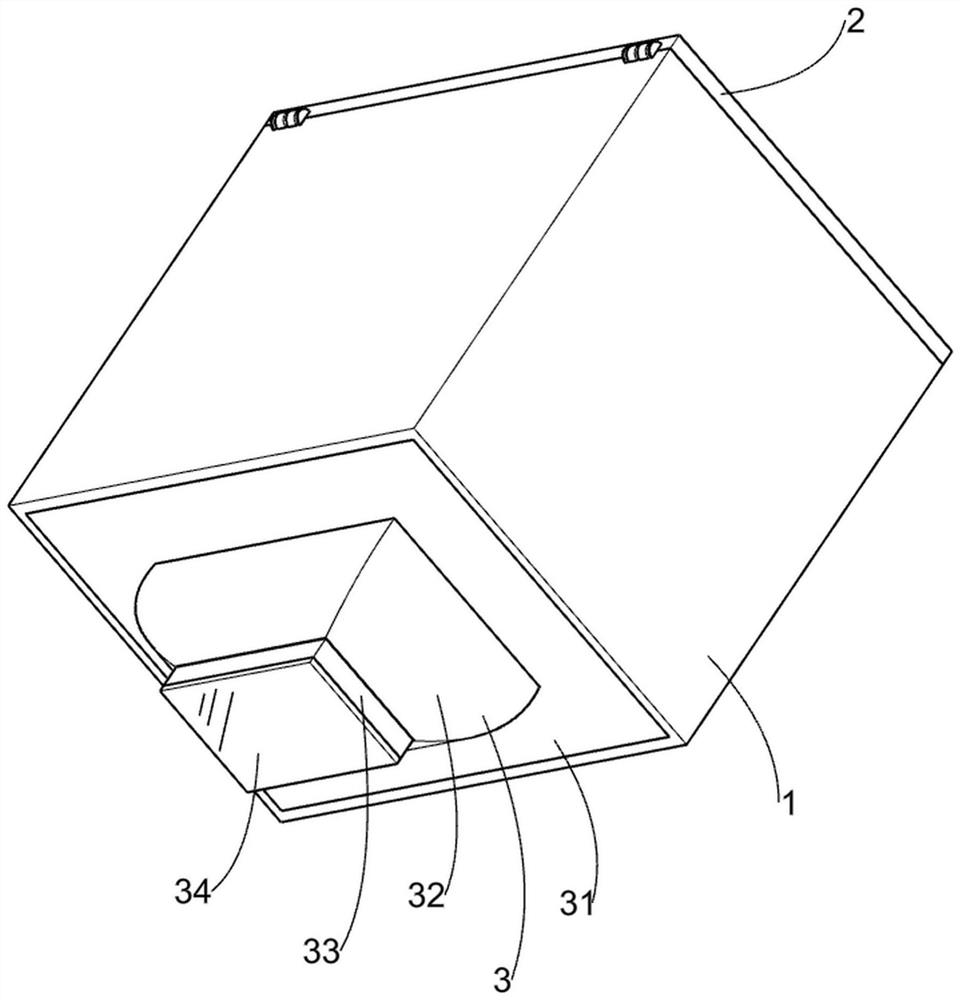

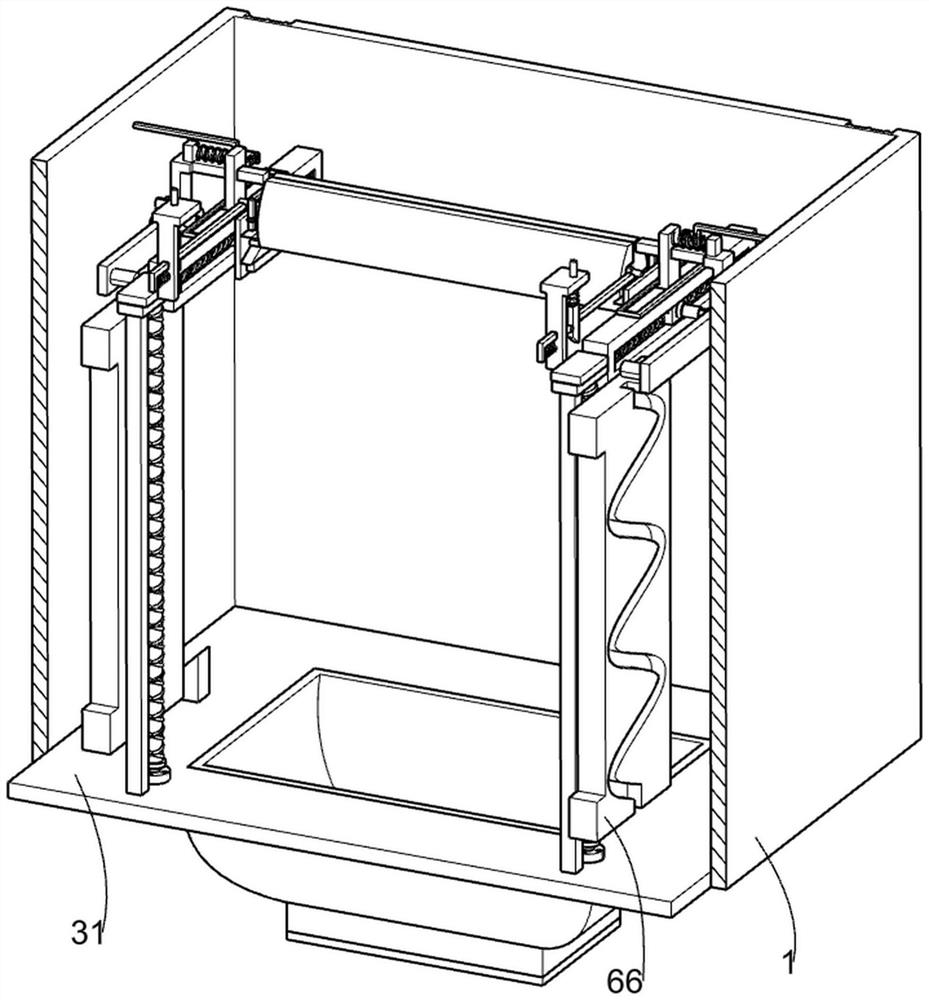

[0030] An assembly detection device for a powder adding system of a copier, such as Figure 1-10 As shown, it includes a box frame 1, a cover plate 2, a collection assembly 3, a reciprocating drive assembly 4, a clamping assembly 5, a reciprocating swing assembly 6, an adjustment assembly 7 and a rotation assembly 8, and the top of the box frame 1 is connected by a hinge. The cover plate 2 and the box frame 1 are provided with a collecting assembly 3, which is used to collect the thrown out toner particles, the collecting assembly 3 is provided with a reciprocating drive assembly 4, and the reciprocating drive assembly 4 is provided with a clamping assembly 5. The clamping assembly 5 is used to clamp the assembled toner cartridge. The reciprocating drive assembly 4 is provided with a reciprocating swing assembly 6. The reciprocating swing assembly 6 is used to check whether the sealing performance of the assembled toner cartridge is qualified. The assembly 6 is provided with a...

Embodiment 2

[0043] On the basis of Example 1, such as Figure 10 As shown, it also includes a stretching assembly 9, which is arranged on the guide frame 41. The stretching assembly 9 includes a guide seat 91, a lower pressing bar 92, a second tension spring 93, a push rod 94 and a third puller. Stretching spring 95, guide frame 41 is connected with guide seat 91, and guide seat 91 is slidably connected with lower pressing bar 92, and lower pressing bar 92 is used to push push rod 94 to reset, and lower pressing bar 92 contacts with cover plate 2, and lower pressing bar 92 contacts with cover plate 2. A second tension spring 93 is connected between the guide seats 91, the second tension spring 93 is used to drive the lower bezel 92 to move upward, and a push rod 94 is slidably connected to the guide seat 91, and the push rod 94 is used to push the top movable support The seat 53 moves upwards, and the push rod 94 is in contact with the lower bar 92. A third extension spring 95 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com