High-pressure water jet pile-forming device suitable for special-shaped filling pile and construction method thereof

A high-pressure water jet, cast-in-place pile technology, applied in excavation, sheet pile wall, foundation structure engineering, etc., can solve problems such as time-consuming, manpower and material resources, poor versatility, affecting construction progress and project cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

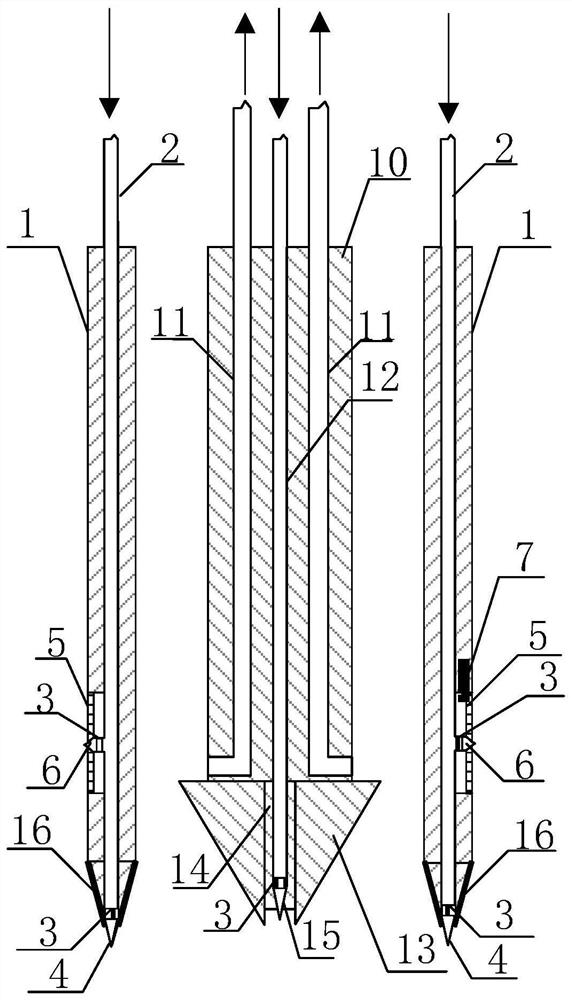

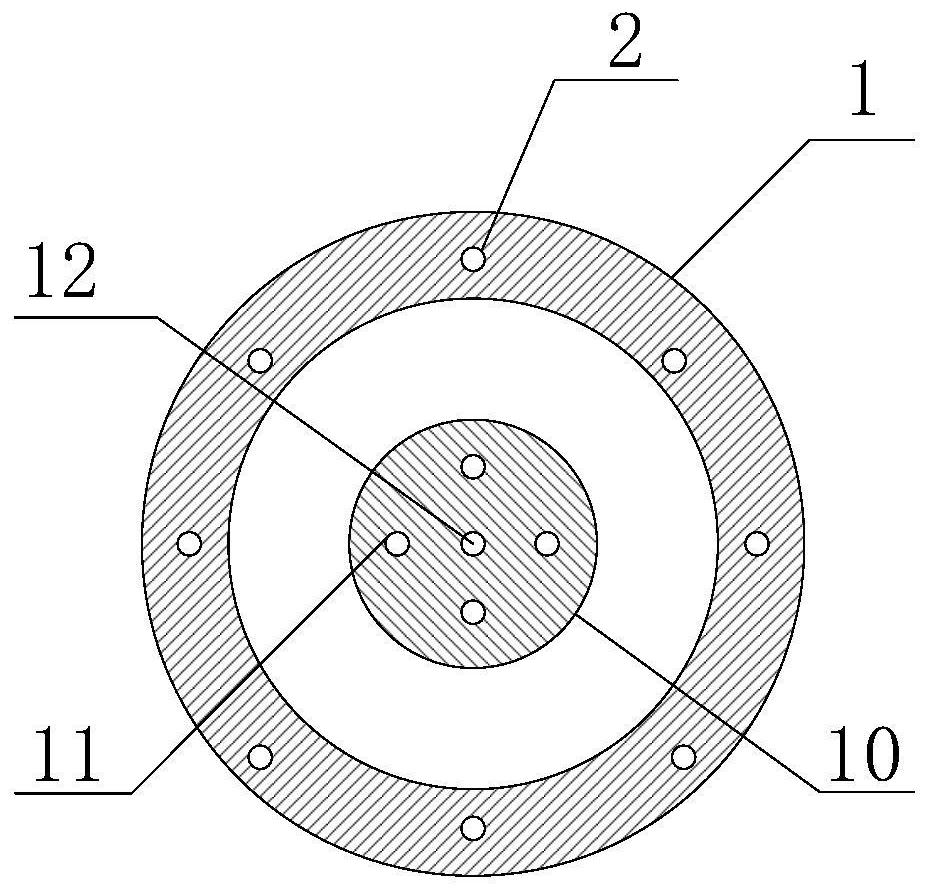

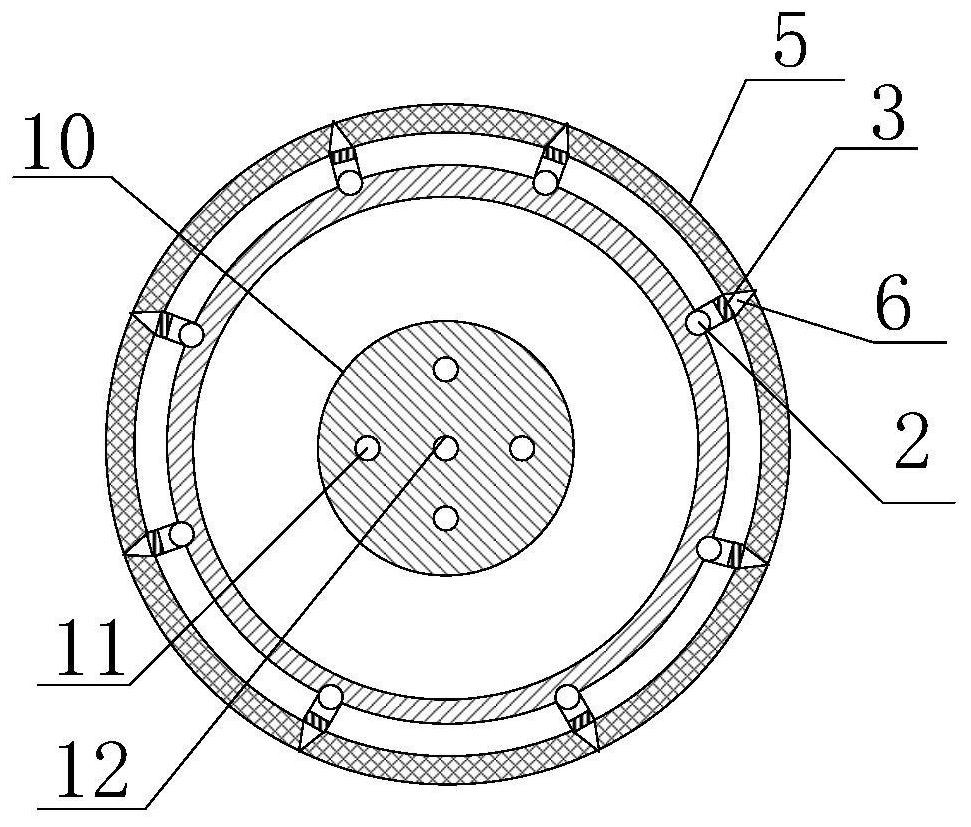

[0042] Such as Figure 1 to Figure 5As shown, a high-pressure water jet pile-forming device suitable for special-shaped cast-in-situ piles includes a spraying device, a suction device 10 and a controller. The spraying device includes a hollow cylindrical shell skeleton 1 and 8 water injection pipes I2, and the inside of the shell skeleton 1 Eight water injection pipelines I2 are arranged symmetrically along the ring to the bottom. One end of the water injection pipeline I2 is connected to the water storage and sedimentation tank 20 through the water inlet valve I17, and the other end is connected to the high-pressure nozzle controller 3 and the high-pressure nozzle I4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com