Underground carry-scraper bucket floating control unit

A scraper and bucket technology, applied in the field of underground scraper work control hydraulic system, can solve problems such as easy misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

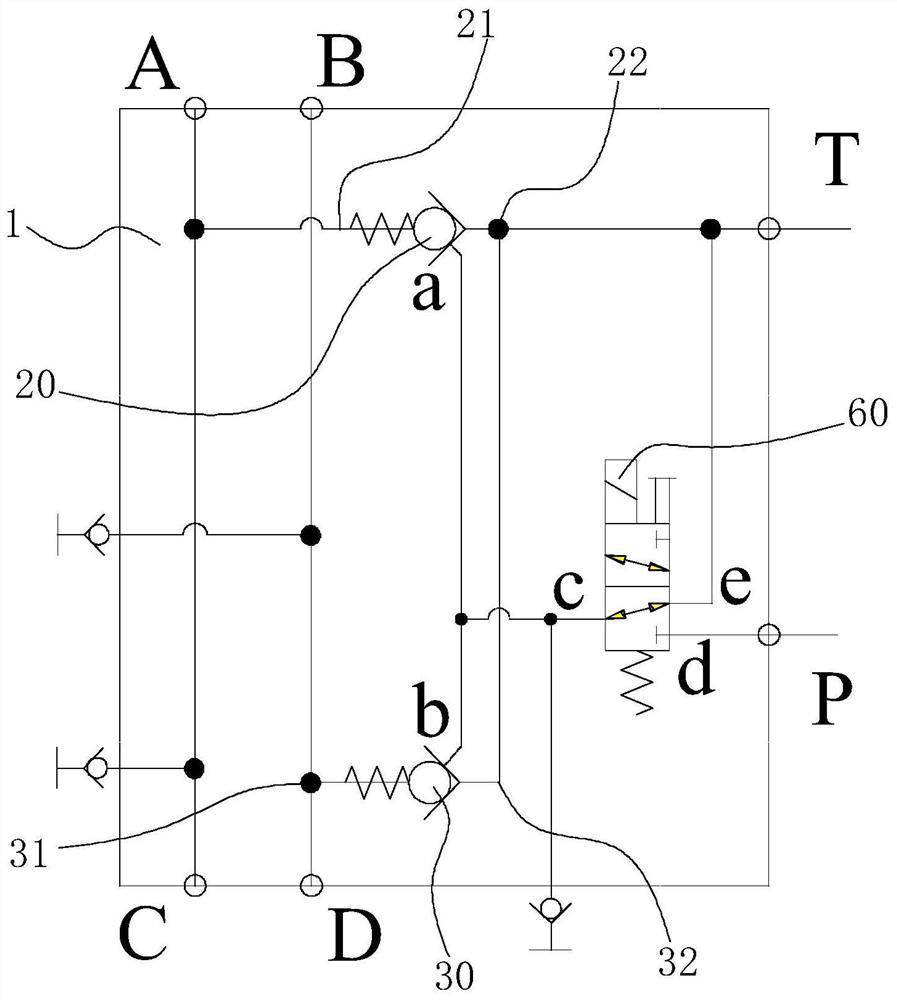

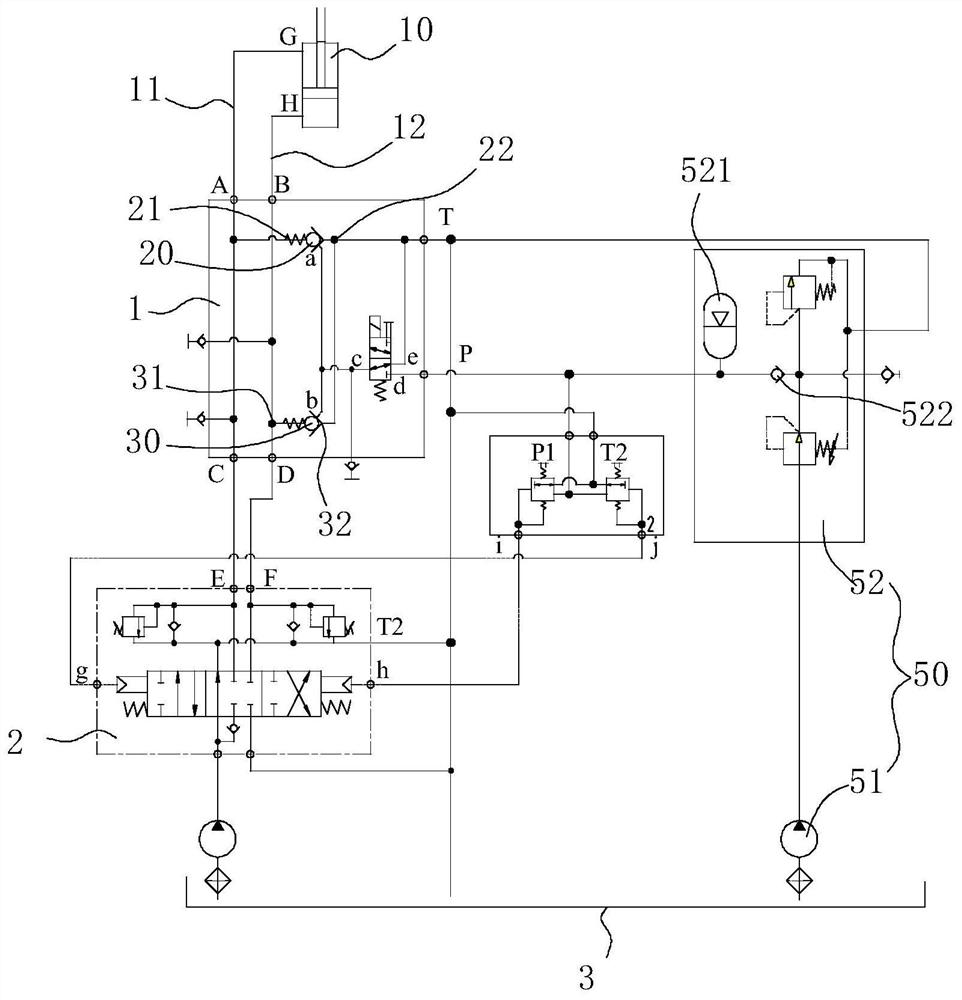

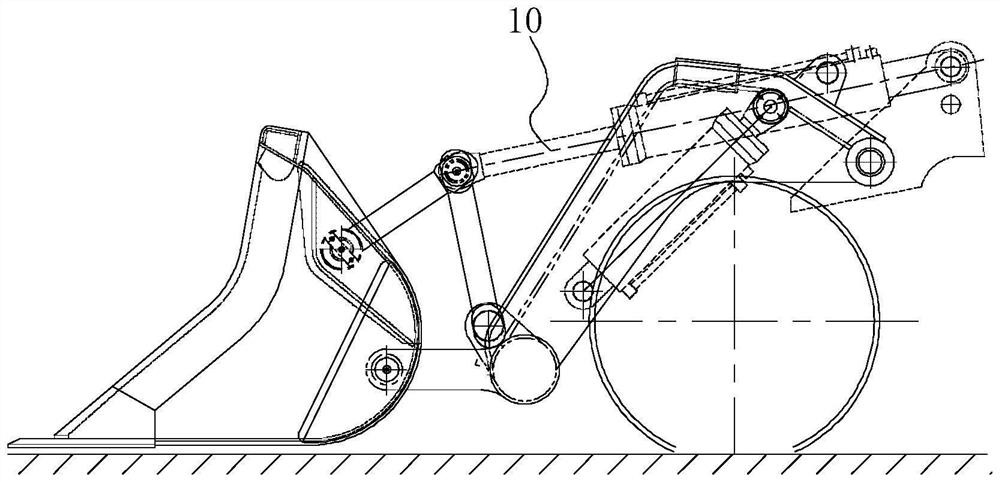

[0010] Such as figure 1 As shown, a bucket floating control unit of an underground scraper, the rod chamber pipeline 11 and the rodless chamber pipeline 12 of the bucket driving cylinder 10 are respectively connected to the first check port of the first hydraulic control check valve 20 21. The second check port 31 of the second hydraulically controlled one-way valve 30 is connected, the first inlet 22 of the first hydraulically controlled one-way valve 20, the second oil inlet 32 of the second hydraulically controlled one-way valve 30 and the oil tank When the hydraulic control interface of the first hydraulic control check valve 20 and the second hydraulic control check valve 30 is connected to the pilot control oil, the rod chamber pipeline 11 and the rodless chamber pipeline 12 of the bucket drive cylinder 10 Connect to fuel tank.

[0011] The purpose of the above technical solution is to control the tipping cylinder of the bucket, also known as the bucket drive cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com