Waterproof optical cable connection box

A waterproof optical cable and splice box technology, which is applied in the direction of light guides, optics, optical components, etc., can solve the problems of safety production threats, poor sealing effect, and inability to prevent water vapor from entering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

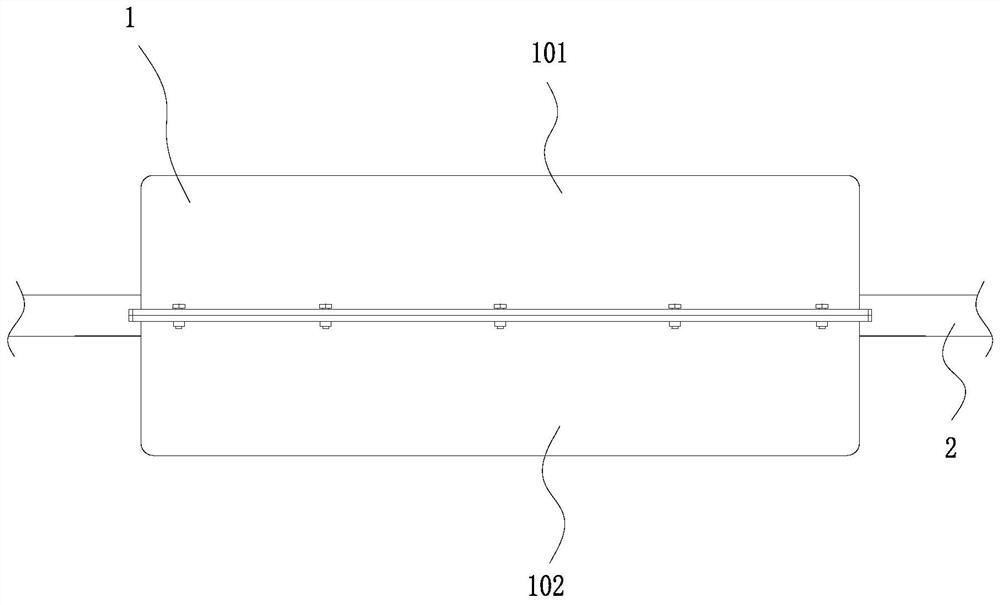

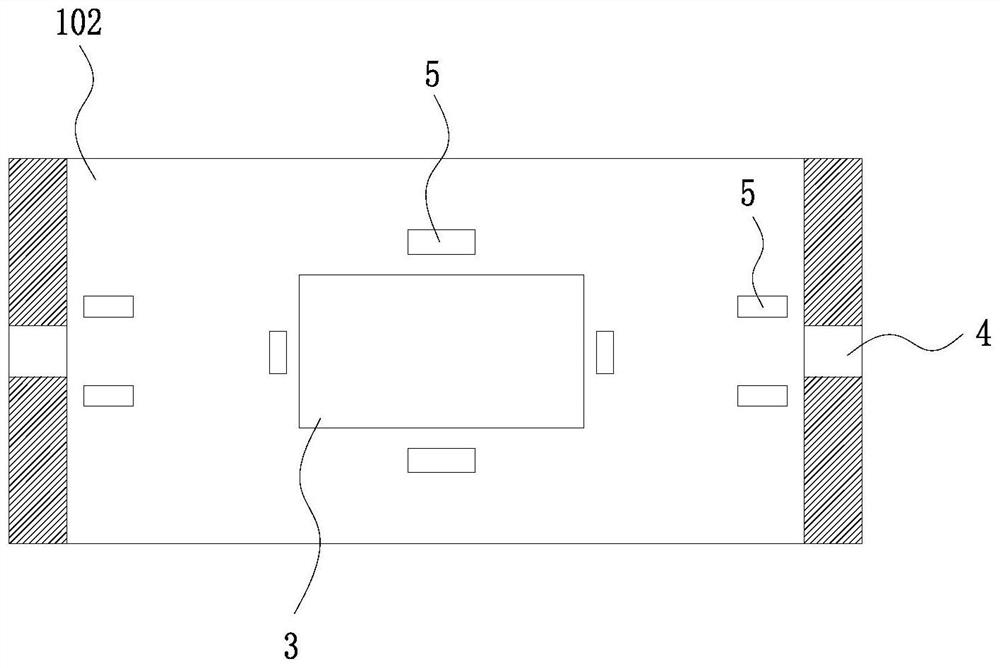

[0027] Such as figure 1 and figure 2 As shown, this embodiment shows a waterproof optical cable splicing box, including an outer box 1 and an inner box 3, the inner box 3 is installed inside the outer box 1, and the surface of the outer box 1 and the inner box 3 is coated with waterproof paint , the slit of the outer box 1 is provided with a sealing strip, and the sealing strip expands after absorbing water, and the surface of the outer box 1 is provided with a window for observing the inside, and the window is provided with an observation plate sealed and connected with the outer box 1, A desiccant is provided inside the outer box 1, and the desiccant changes color after absorbing water.

[0028] This embodiment includes an outer box 1 and an inner box 3, the surfaces of the outer box 1 and the inner box 3 are coated with waterproof paint, which can reduce moisture remaining on the surface of the box body, and keep the surfaces of the outer box 1 and the inner box 3 as dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com