Petroleum refining pipeline flange butt joint equipment capable of avoiding abrasion and dislocation

A technology for equipment and pipelines, which is applied in the field of pipeline flange butt joint equipment for petroleum refining, and can solve problems such as falling dislocation, flange plate collision friction, and affecting pipeline sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

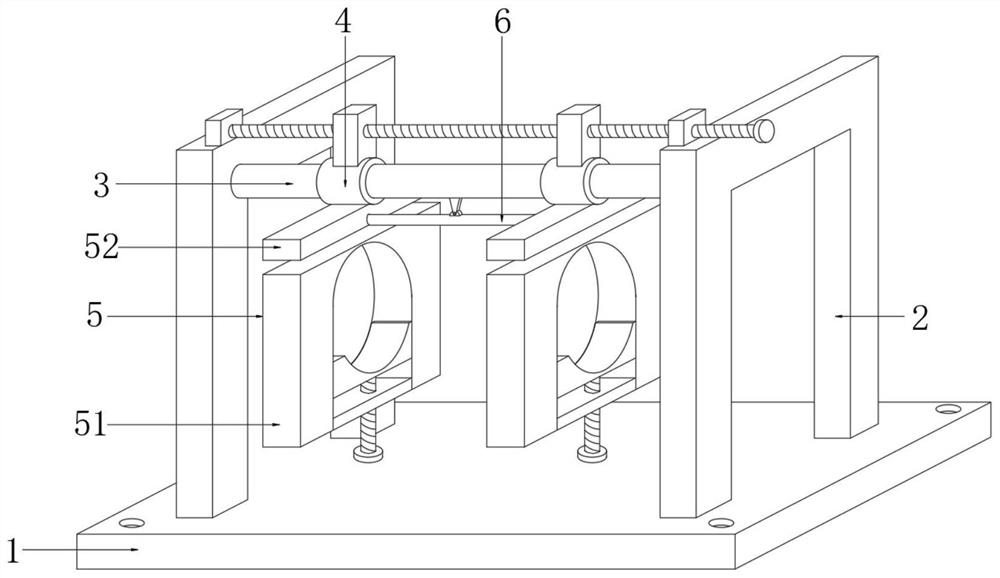

[0023] The present invention provides a technical solution: pipeline flange butt joint equipment for petroleum refining that can avoid wear and dislocation, please refer to figure 1 , including base plate 1, mounting frame 2, sliding rod 3 and sliding sleeve 4;

[0024] see figure 1 , the installation frame 2 is installed on the top outer wall of the bottom plate 1, the left and right ends of the slide bar 3 are respectively fixedly connected with the inner walls of the left and right sides of the installation frame 2, and the sliding sleeves 4 have two groups with the same structure, and the two sets of sliding sleeves 4 are all slid on the On the outer wall of the slide bar 3, the outer walls on the left and right sides of the top of the mounting frame 2 are fixedly installed with mounting seats, and a threaded rod is installed rotating between the two groups of mounting seats, and the outer wall of the threaded rod is sleeved with two sets of connecting blocks, and the conn...

Embodiment 2

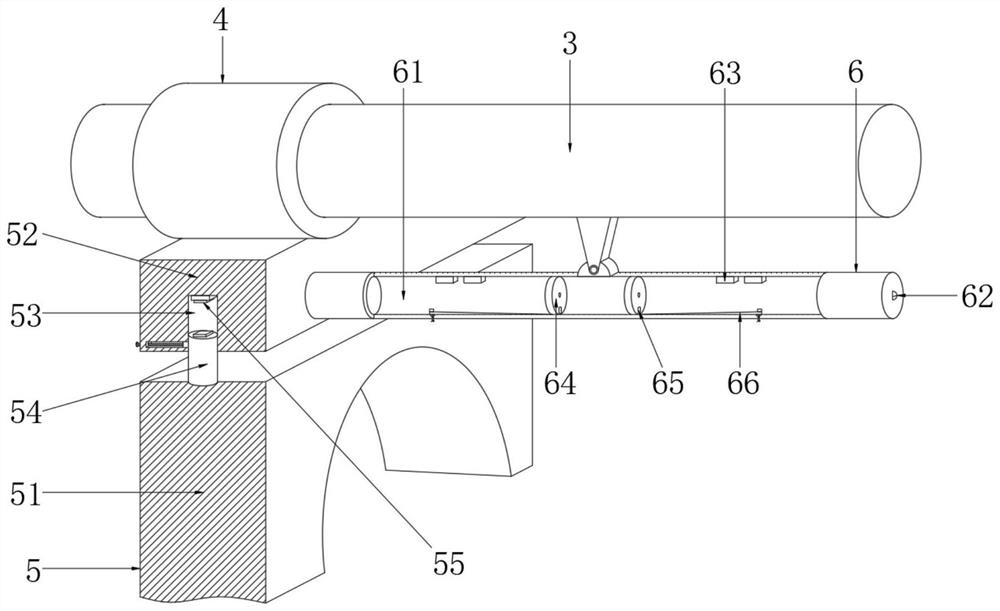

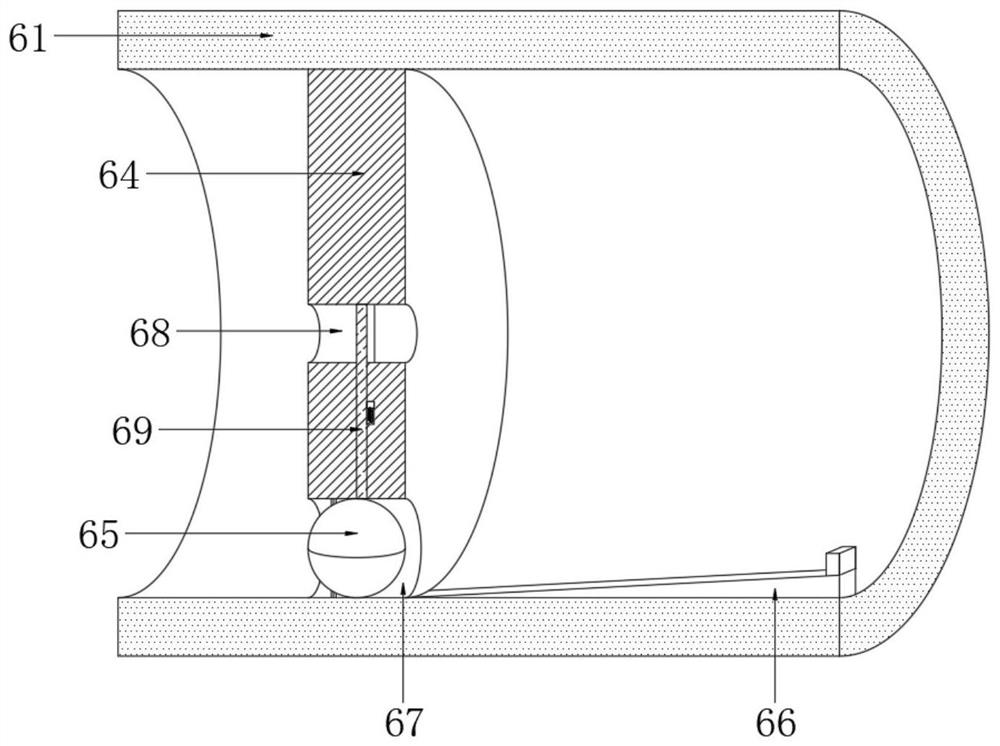

[0031] see figure 1 and figure 2 , on the basis of Embodiment 1, the fixing device 5 includes a mounting plate 52 fixedly connected to the outer wall of the bottom of the sliding sleeve 4, the outer wall of the bottom of the mounting plate 52 is provided with a mounting groove 53, and the bottom of the mounting groove 53 is slidably inserted with a moving rod 54 , the bottom end of the moving rod 54 is fixedly installed with a fixed plate 51, the top end of the moving rod 54 is fixedly installed with a magnetic block, and the top of the installation groove 53 is equipped with an electromagnetism device 55, which is electrically connected to the inner conductive sheet 63 , when the installation rod 61 is inclined to connect the two groups of conductive sheets 63, the electromagnetism device 55 will also be energized to generate magnetic force, and the generated magnetic force will attract the magnetic force of the magnetic block, so that the moving rod 54 moves upward with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com