High-quality multi-bundle fiber circumferential winding method

A multi-bundle fiber and hoop winding technology, applied in the field of fiber winding, can solve the problems of low winding efficiency, manual intervention, and inability to realize continuous production, and achieve the effects of improving production efficiency, avoiding bottle deformation, and improving winding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions in the embodiments of the present invention will be described below, apparent, as described herein is merely embodiments of the invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

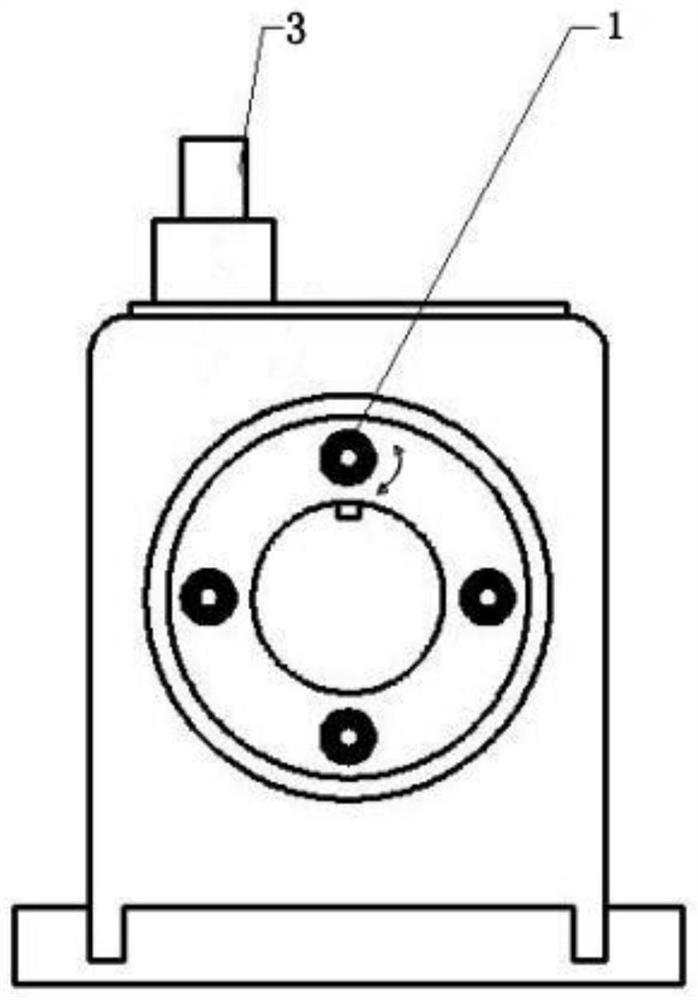

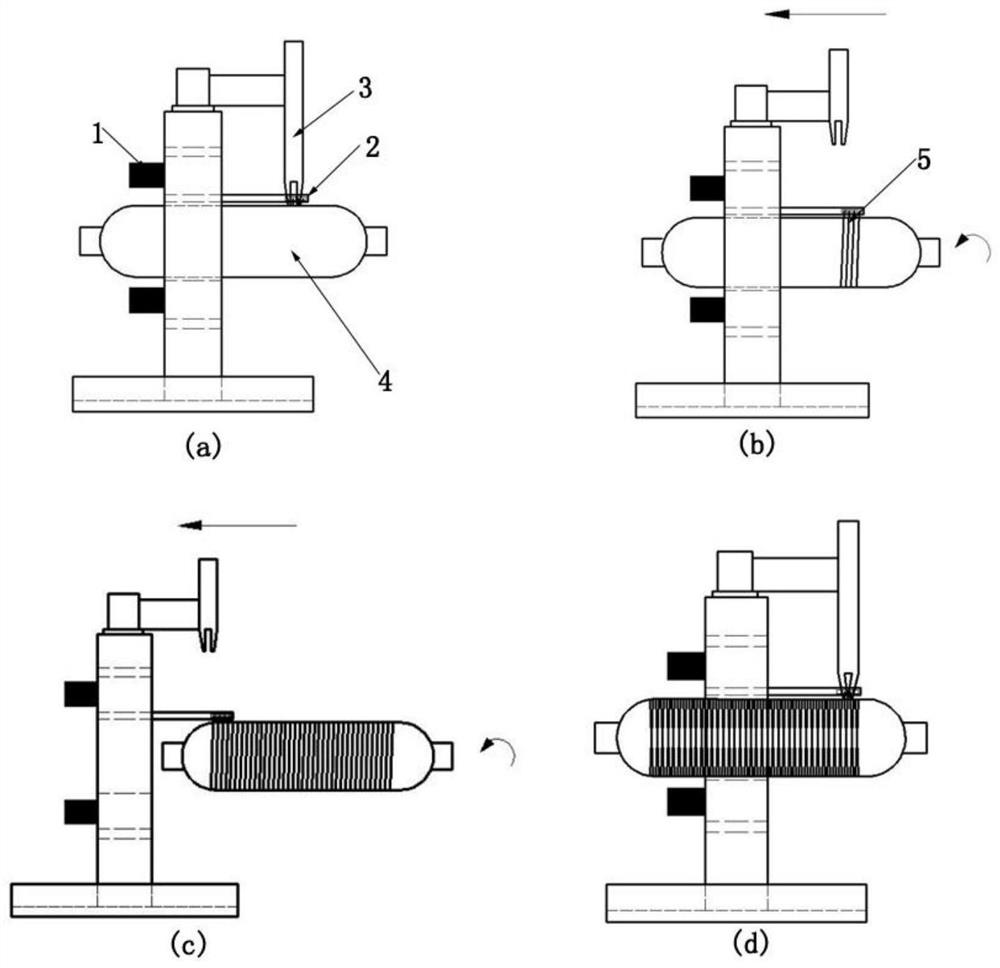

[0029] A high-quality multi-beam fiber ring winding method, the single musical fibers leading from the fibrous reel are wound along the surface of the wound member to be wound, and the fiber reel is provided with several, and several fibrous reels are in the circumferential distribution of the part. Single fibers wound around each fibrous reel are gathered by a guide wire, and each of the individual fibers are arranged side by side, and the multi-beam fibers are wrapped around the surface of the part to be wound.

[0030] When each sominous fiber is in parallel, there is no interval between the single musical fibers, or minim...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap