Water hammering prevention adjusting air exhaust valve

A technology for adjusting air and exhaust valves, which is applied in the direction of valve devices, functional valve types, and valves for ventilation, etc. It can solve problems such as the inability to meet flexible and instantaneous pressure release adjustments, and the solidification of the self-weight pressure adjustment range of the sealing cover, to achieve Wide application range, high economic value, remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

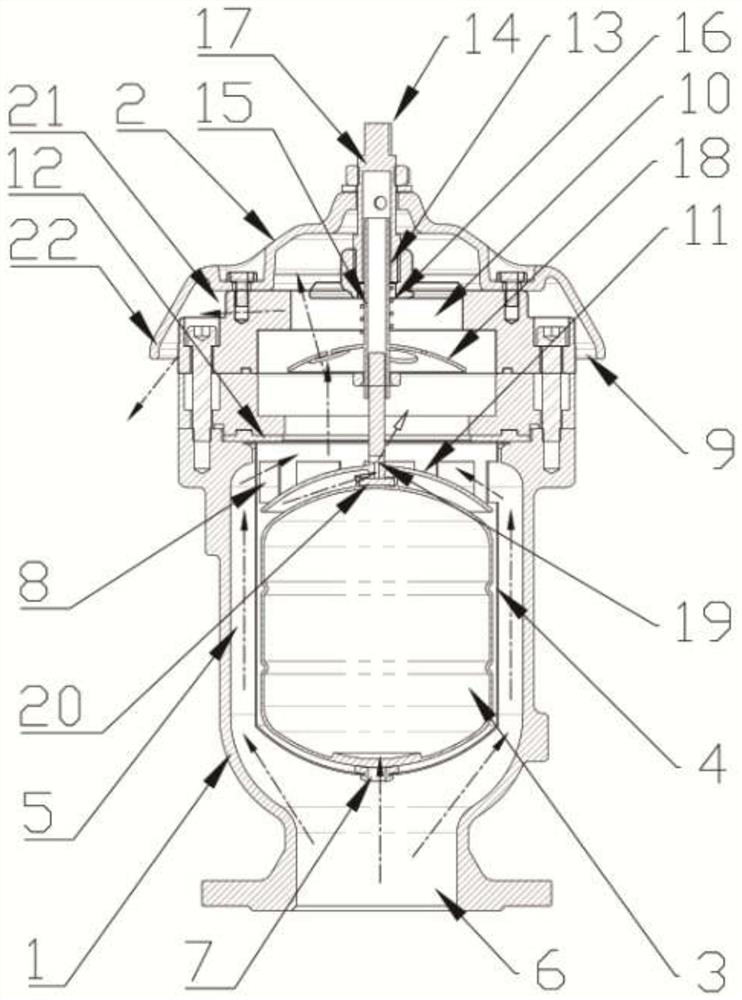

[0021] The present invention provides a water hammer regulated air discharge valve. The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to make it easier to understand and grasp.

[0022] Anti-hammer adjustment air discharge valve, such as figure 1 As shown, the main body of the exhaust valve 1 and the valve cover 2 are included. The main body of the exhaust valve 1 is provided with a float chamber 4 with a float body 3 and an annular chamber 5 located at the outer periphery of the float chamber 4. The annular chamber The bottom of the chamber 5 is provided with a connecting flange pipe end 6, the bottom of the float chamber 5 is provided with a water inlet pipe end 7, and the top is provided with a number of exhaust hollows 8 communicating with the annular chamber 5, and the valve cover 2 has Exhaust portion 9, the exhaust chamber 10 that communicates with the float chamber, the exhaust chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com