Industrial internet green energy management system

An industrial Internet and green energy technology, applied in the field of industrial Internet green energy management systems, can solve the problem of inability to balance workpieces, time and energy consumption, and achieve the effect of reducing energy consumption and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

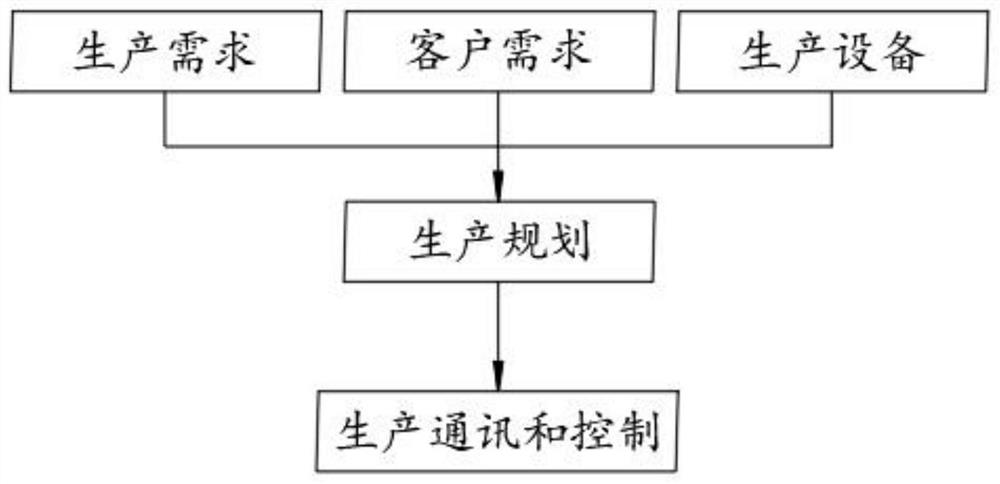

[0028] Such as figure 1 As shown, the embodiment of the present invention provides an industrial Internet green energy management system, including the following:

[0029] Step 1. Production demand: Obtain the required workpiece according to the customer's order, and know the structural size of the workpiece;

[0030] Step 2. Customer demand: The customer is concerned with the production quantity (S) of the workpiece, the limited production time, and the specified processing method. The limited production time is the delivery time, and the production limited time is a consideration for determining the production plan;

[0031] Step 3. Production equipment: determine the existing production equipment and its location information in the factory, and at the same time determine the average time (T) and average energy consumption required for the production equipment to process a single workpiece during the continuous production of workpieces by the production equipment (E), the a...

Embodiment 2

[0035] Such as figure 1 As shown, the embodiment of the present invention provides an industrial Internet green energy management system, including the following:

[0036] Step 1. Production demand: Obtain the required workpiece according to the customer's order, and know the structural size of the workpiece;

[0037] Step 2. Customer demand: The customer is concerned with the production quantity (S) of the workpiece, the limited production time, and the specified processing method. The limited production time is the delivery time, and the production limited time is a consideration for determining the production plan;

[0038] Step 3. Production equipment: determine the existing production equipment and its location information in the factory, and at the same time determine the average time (T) and average energy consumption required for the production equipment to process a single workpiece during the continuous production of workpieces by the production equipment (E), the a...

Embodiment 3

[0042] Such as figure 1 As shown, the embodiment of the present invention provides an industrial Internet green energy management system, including the following:

[0043] Step 1. Production demand: Obtain the required workpiece according to the customer's order, and know the structural size of the workpiece;

[0044] Step 2. Customer demand: The customer is concerned with the production quantity (S) of the workpiece, the limited production time, and the specified processing method. The limited production time is the delivery time, and the production limited time is a consideration for determining the production plan;

[0045] Step 3. Production equipment: determine the existing production equipment and its location information in the factory, and at the same time determine the average time (T) and average energy consumption required for the production equipment to process a single workpiece during the continuous production of workpieces by the production equipment (E), the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com