Agricultural corn threshing treatment device

A processing device and peeling technology, which is applied in agriculture, agricultural machinery and tools, threshing equipment, etc., can solve the problems of unsafe threshing splash and inability to integrate peeling and collection, and achieve integrated peeling collection and peeling safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

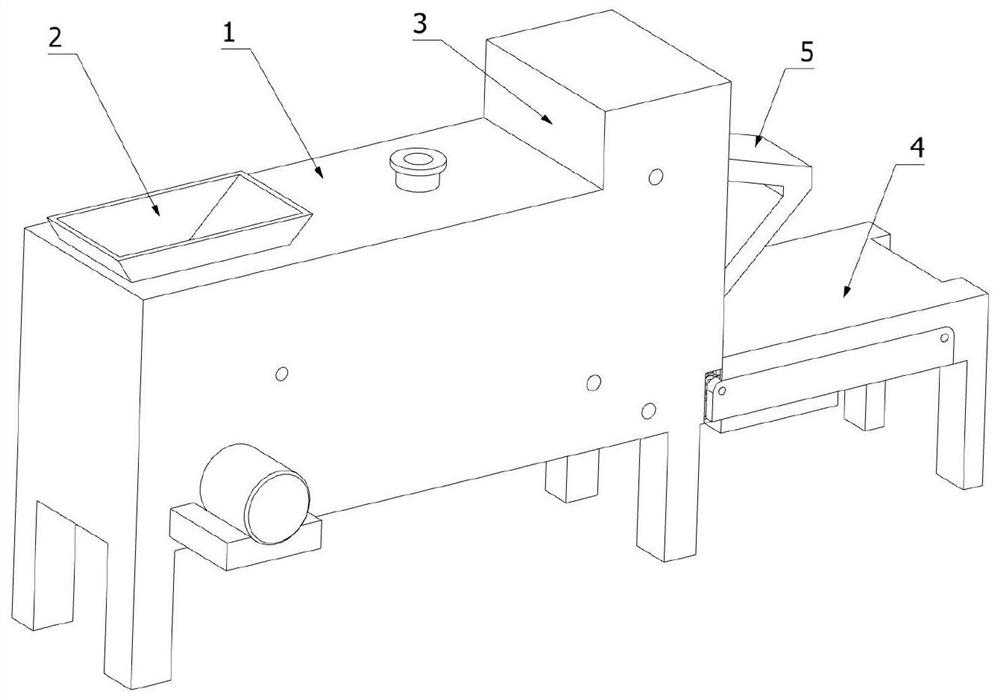

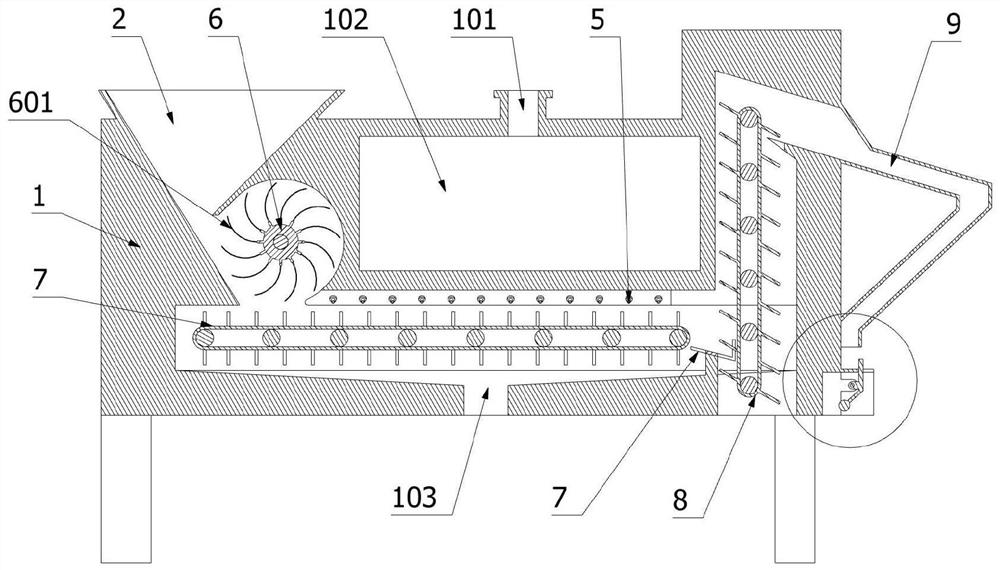

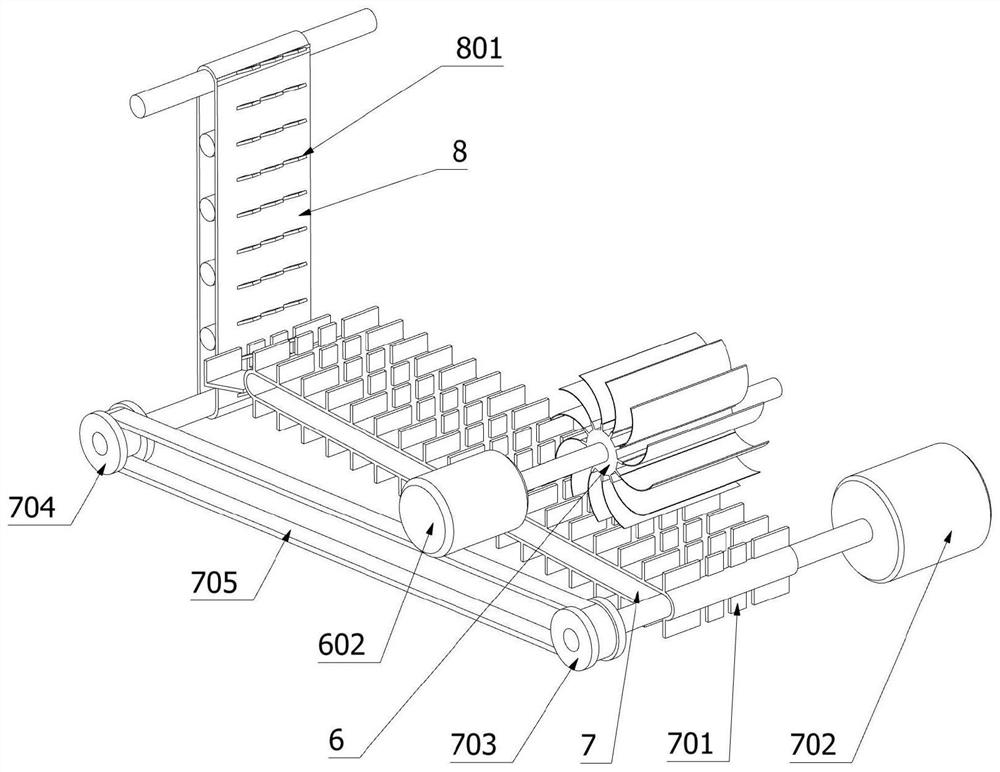

[0058] Such as Figure 1-2 As shown, what this embodiment one provides is a kind of peeling processing device for agricultural corn, including: cleaning box 1, blanking frame 2, discharge box 3 and peeling mechanism 4, cleaning box 1 has the first One conveyor belt 7, the first conveyor belt 7 is horizontally arranged; The blanking frame 2 is arranged on the front portion of the cleaning box 1; the discharge body is connected to the rear of the cleaning box 1, and there is a first Two conveyer belts 8, the second conveyer belt 8 is vertically arranged; The peeling mechanism 4 is arranged on the rear of the discharge box body 3, and has a casing 401, a grain frame 10, a pole frame 11 and a stripping mechanism 4 in the peeling mechanism 4. Grain grinding wheel 12, the grain output frame 10 is arranged below the casing 401; the strut frame 11 is arranged on the top of the grain output frame 10, a lead screw motor is installed on the outside of the casing 401, the lead screw motor...

Embodiment 2

[0071] Such as Figure 1-2 As shown, what this embodiment two provides is a kind of peeling processing device of agricultural corn, comprising: cleaning box 1, blanking frame 2, discharge box 3 and peeling mechanism 4, cleaning box 1 has the first One conveyor belt 7, the first conveyor belt 7 is horizontally arranged; The blanking frame 2 is arranged on the front portion of the cleaning box 1; the discharge body is connected to the rear of the cleaning box 1, and there is a first Two conveyer belts 8, the second conveyer belt 8 is vertically arranged; The peeling mechanism 4 is arranged on the rear of the discharge box body 3, and has a casing 401, a grain frame 10, a pole frame 11 and a stripping mechanism 4 in the peeling mechanism 4. Grain grinding wheel 12, the grain output frame 10 is arranged below the casing 401; the strut frame 11 is arranged on the top of the grain output frame 10, a lead screw motor is installed on the outside of the casing 401, the lead screw motor...

Embodiment 3

[0075] Such as Figure 1-2 As shown, what this embodiment three provides is a kind of peeling processing device of agricultural corn, comprising: cleaning box 1, blanking frame 2, discharge box 3 and peeling mechanism 4, cleaning box 1 has the first One conveyor belt 7, the first conveyor belt 7 is horizontally arranged; The blanking frame 2 is arranged on the front portion of the cleaning box 1; the discharge body is connected to the rear of the cleaning box 1, and there is a first Two conveyer belts 8, the second conveyer belt 8 is vertically arranged; The peeling mechanism 4 is arranged on the rear of the discharge box body 3, and has a casing 401, a grain frame 10, a pole frame 11 and a stripping mechanism 4 in the peeling mechanism 4. Grain grinding wheel 12, the grain output frame 10 is arranged below the casing 401; the strut frame 11 is arranged on the top of the grain output frame 10, a lead screw motor is installed on the outside of the casing 401, the lead screw mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com