One-piece type paper diaper production process

A production process and technology for diapers, applied in the fields of medical science, clothing, underwear, etc., can solve the problems of large bonding area, many three-dimensional protective materials, and large amount of non-woven fabrics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The scheme of this application is further described in conjunction with the accompanying drawings as follows:

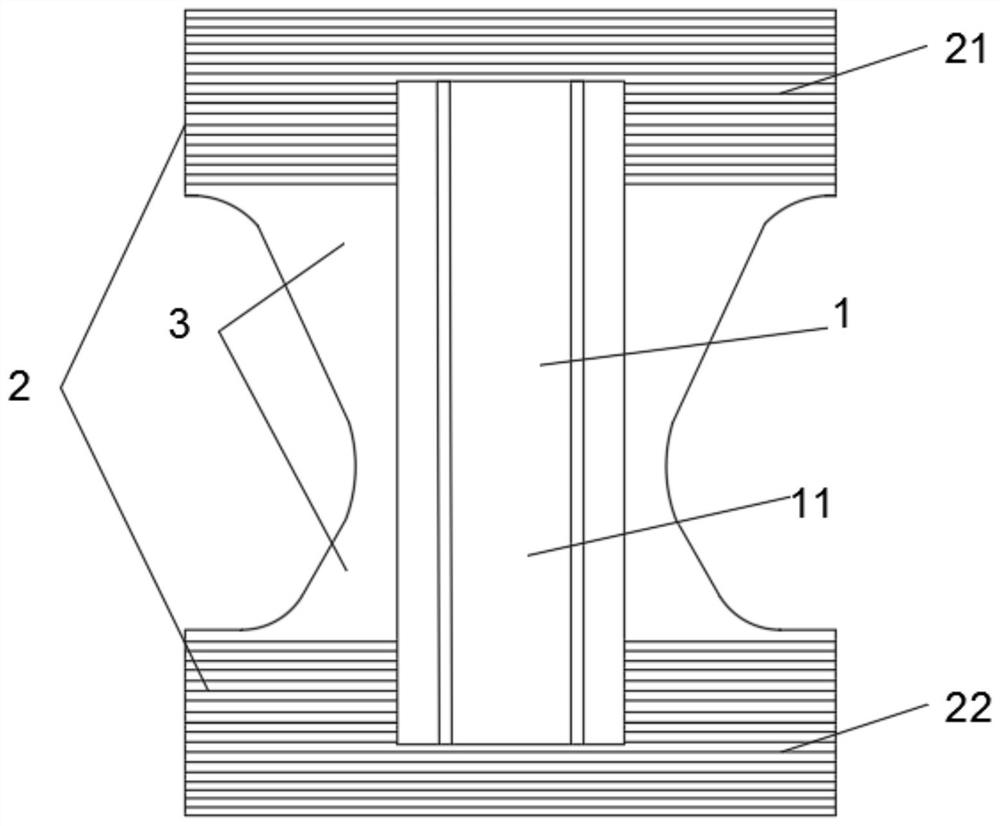

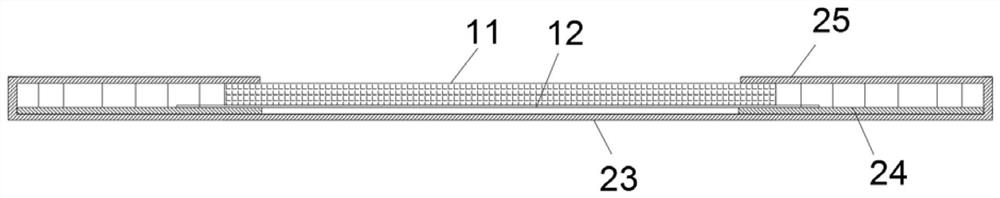

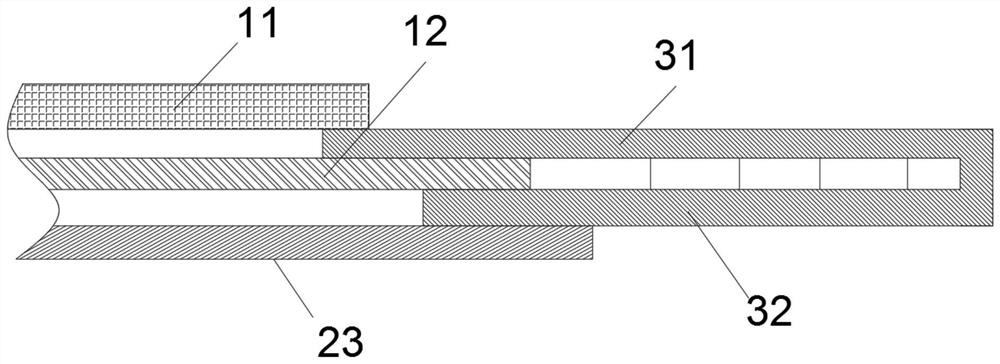

[0020] See attached Figure 1-3 A production process for one-piece diapers, comprising a water-absorbing body 1 and an elastic waist 2, the elastic waist 2 is provided with a front elastic waist 21 and a rear elastic waist 22, and the water-absorbing body 1 is arranged on the front elastic waist 21 and the rear elastic waist 22 Between them, the water-absorbing body 1 is provided with a water-absorbing core 11, a positioning PE film 12, and a bottom non-woven fabric 23 from top to bottom, and the elastic waist 2 is provided with a surface non-woven fabric 25, a middle The non-woven fabric 24 and the bottom non-woven fabric 23 are also provided with three-dimensional guards 3 on the left and right sides of the water-absorbing body 1, and the production process of the water-absorbing body 1 is as follows:

[0021] S1 Lay the front waist elastic and the back wai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com