Filament lamp assembling device

A technology for assembling devices and filament lamps, which can be used in other household appliances, household appliances, applications, etc., can solve problems such as wire leakage, achieve high efficiency, and avoid the effect of wire leakage defects in lamp holders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

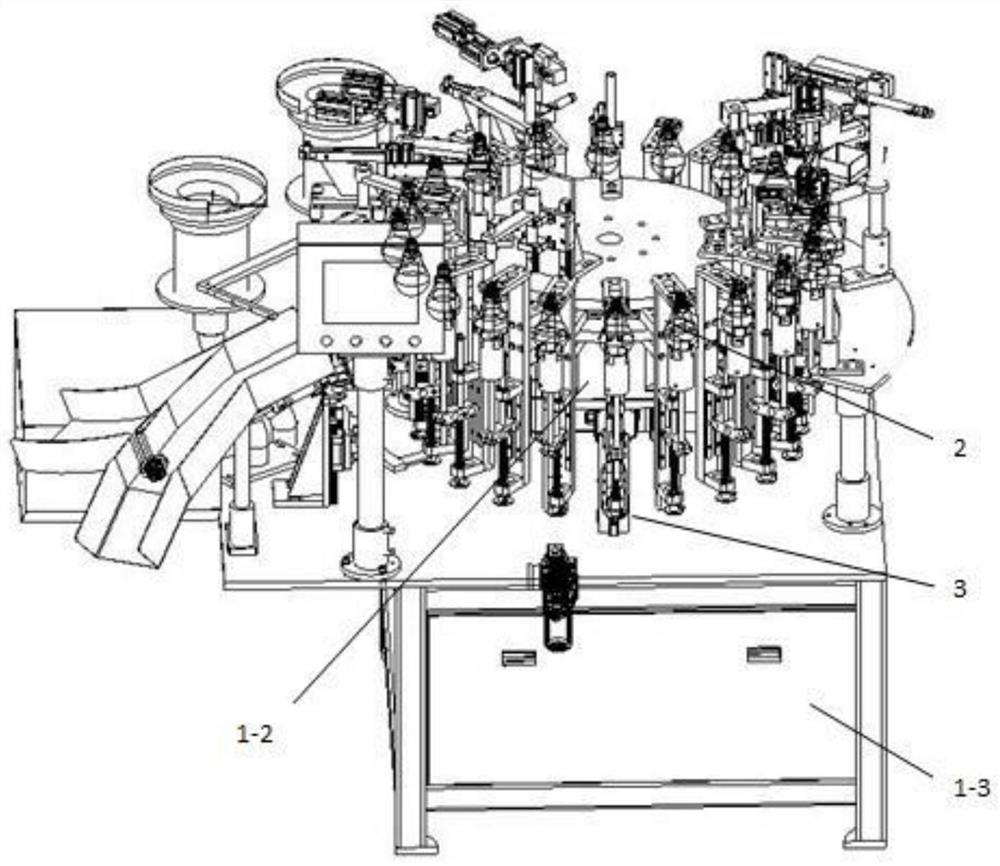

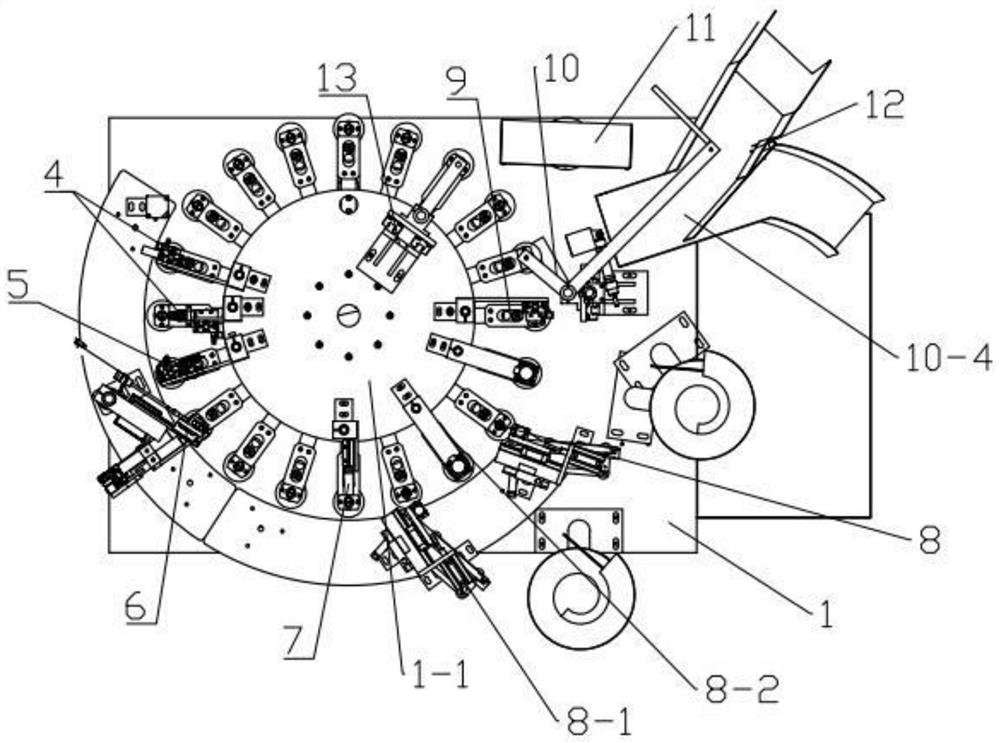

[0032] like figure 1 , figure 2 In the illustrated embodiment, a filament lamp assembly device includes a frame 1, a plurality of workstations 2 provided on the frame for fixing the filament lamps to be riveted, a pressing mechanism 3, a guide wire processing mechanism 4, and a wire drawing mechanism 5. , a wire cutting mechanism 6 , a bending mechanism 7 for bending guide wires, a rivet installation mechanism 8 , a detection mechanism 9 and a blanking mechanism 10 . The above components are arranged on the frame in sequence according to the process sequence.

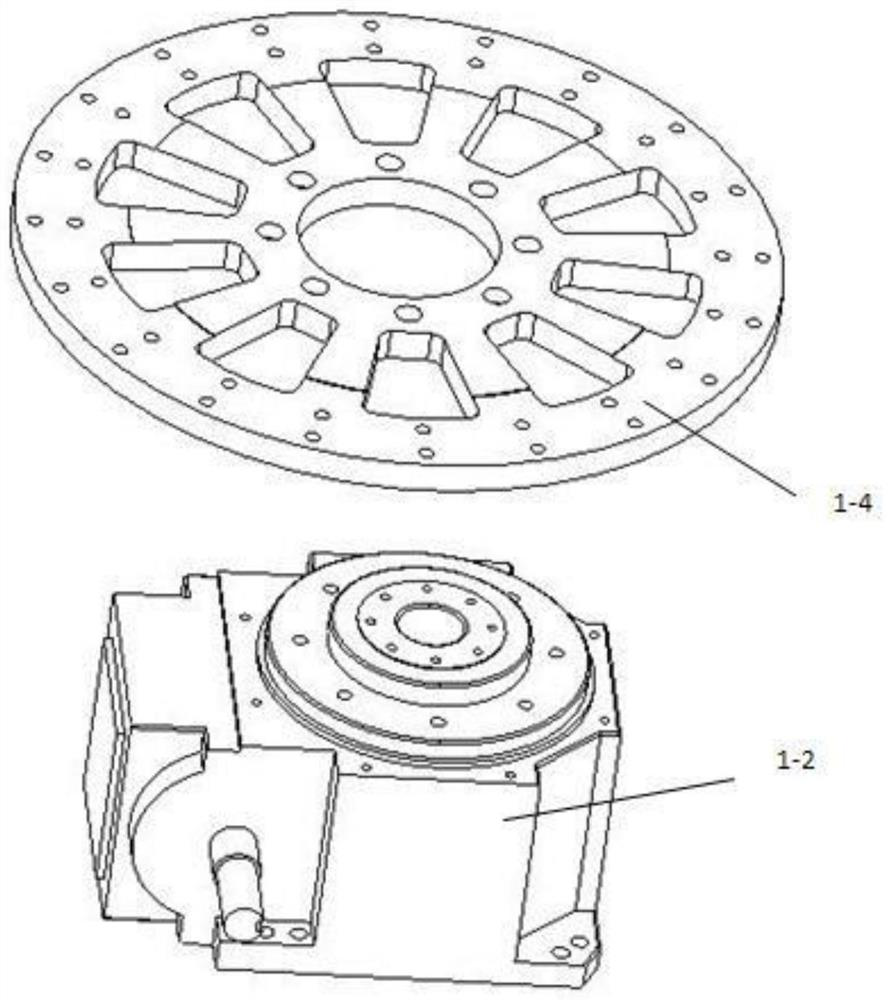

[0033] like image 3 As shown, the frame includes a base 1-3, a disk-shaped worktable 1-1 and a rotating mechanism 1-2, the base is placed on the ground in a square shape, the rotating mechanism is arranged on the base, and the disk-shaped worktable is supported on the rotating mechanism On the static part of the rotating mechanism, flanges 1-4 are connected to the output end of the rotating mechanism.

[0034] lik...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap