Automatic composite film machining machine

A composite film and processing machine technology, applied in the direction of lamination device, lamination auxiliary operation, lamination system, etc., can solve the problems of inconvenience, waste of time, and reduced quality of composite film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

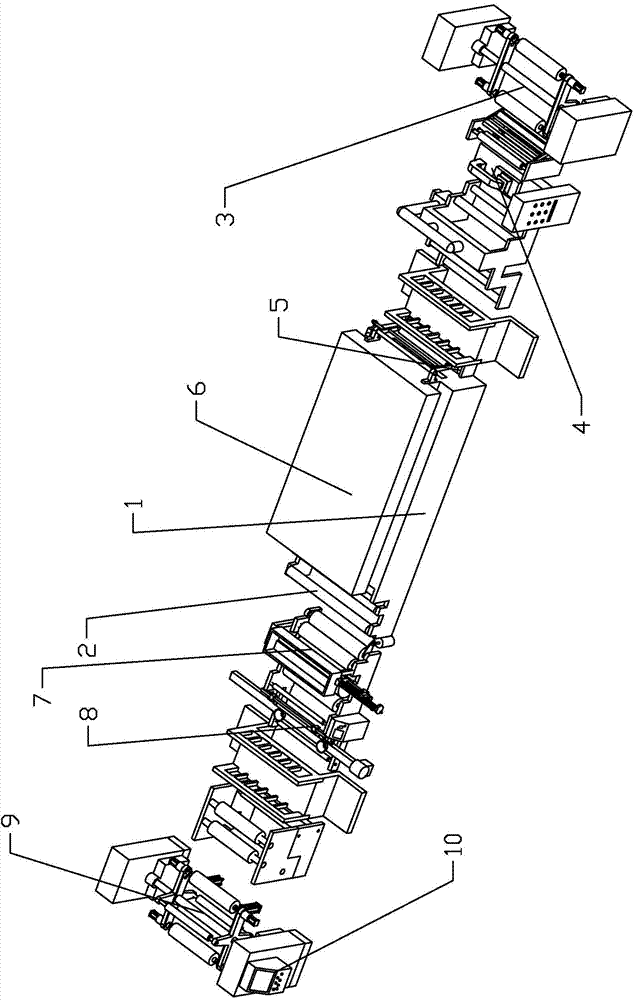

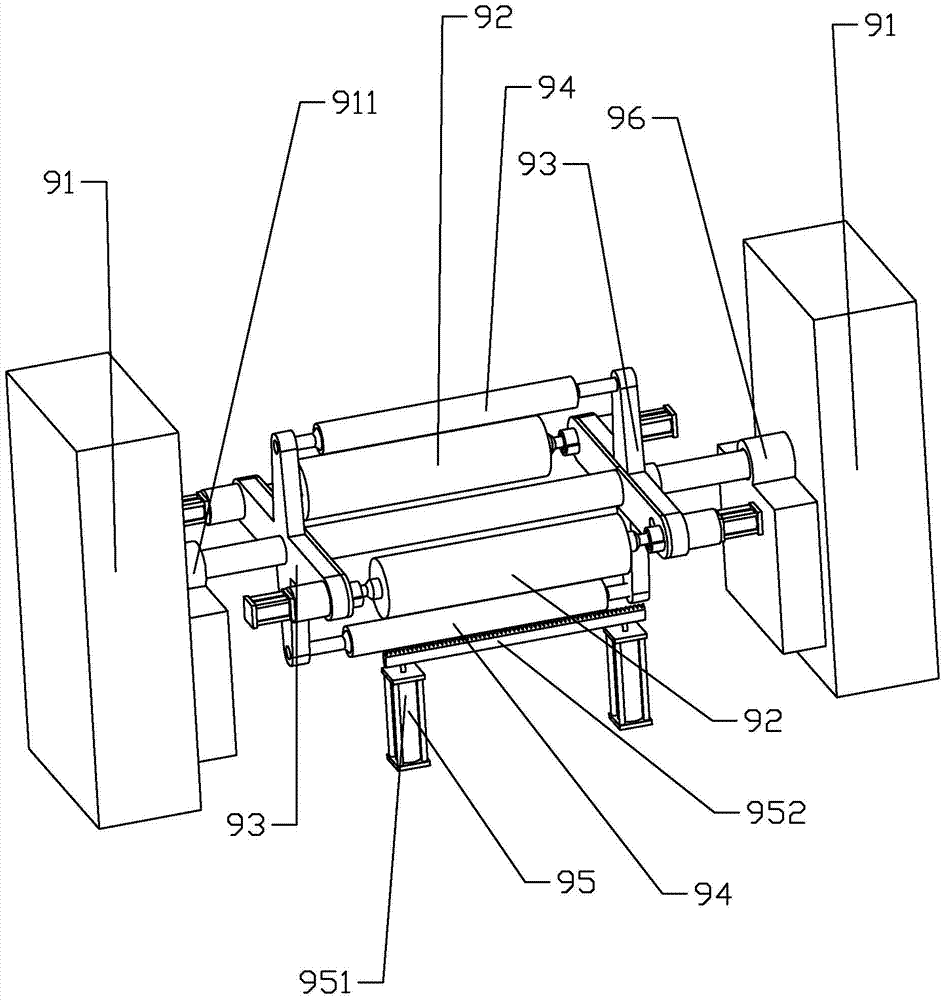

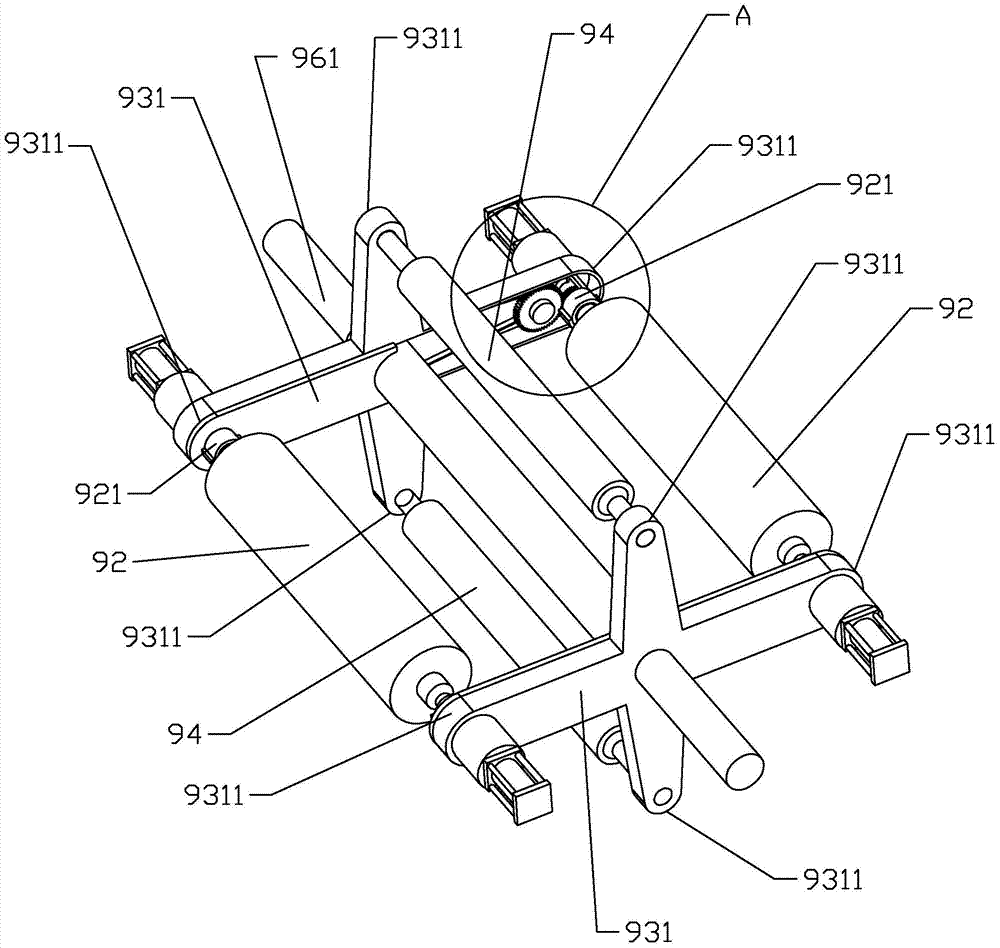

[0036] As shown in the figure, the present invention discloses an automatic composite film processing machine, which includes a main frame 1, on which several transfer rollers 2 for transfer are sequentially arranged, and the main frame 1 is sequentially arranged along the transfer direction of the transfer rollers It is equipped with a composite film developing device 3, a drying device 4, an adhesive device 5, a heating device 6, a coating device 7, a shearing device 8 and a receiving device 9, a developing device 3, a drying device 4, and an adhesive device 5. The heating device 6, the coating device 7, the shearing device 8 and the receiving device 9 are circuit-connected with a controller 10 for controlling the above devices. The receiving device 9 includes a receiving frame 91, and the receiving frames 91 on both sides There are rewinding rollers 92 and a rewinding motor 96 that drives the rewinding rollers 92 to rotate detachably. The rewinding frame 91 is provided with...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap