Saw band feeding automatic speed changing sawing machine

A technology of automatic speed change and sawing machine, applied in the field of sawing machine, can solve the problems of slow response time, inaccurate speed change, single control mode, etc., and achieve the effect of fast response speed, reduced saw band life, and precise speed change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

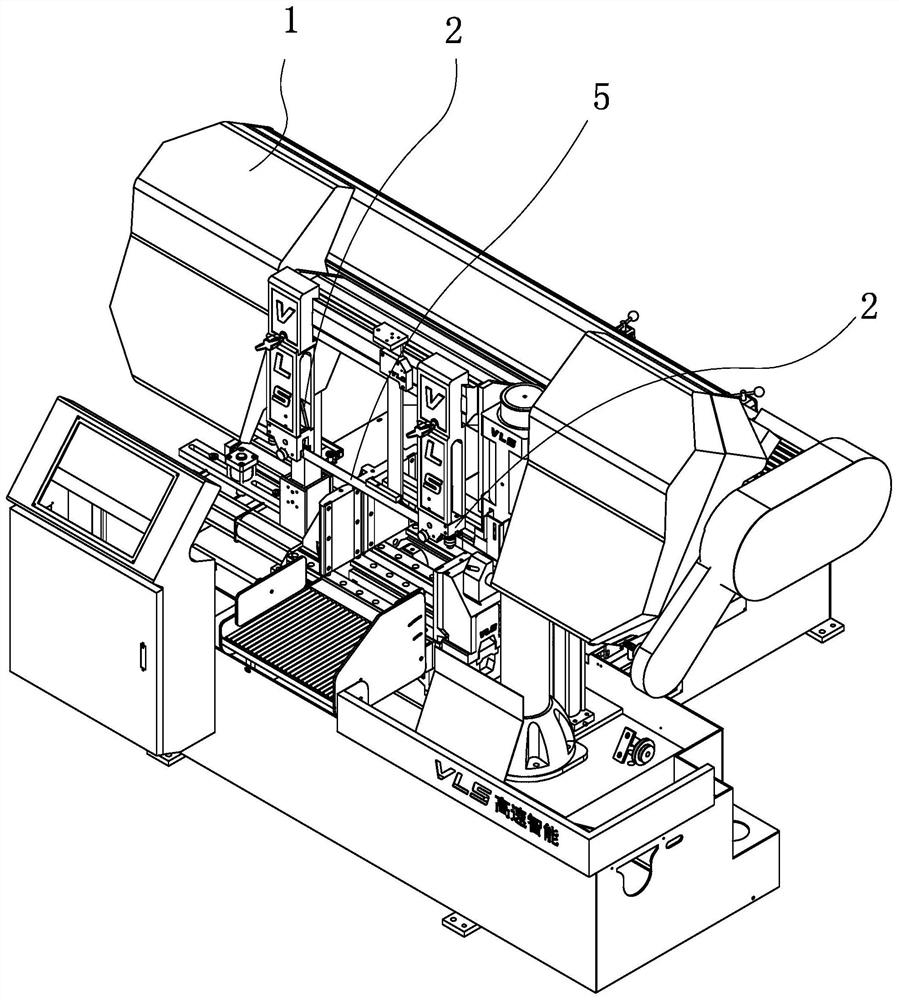

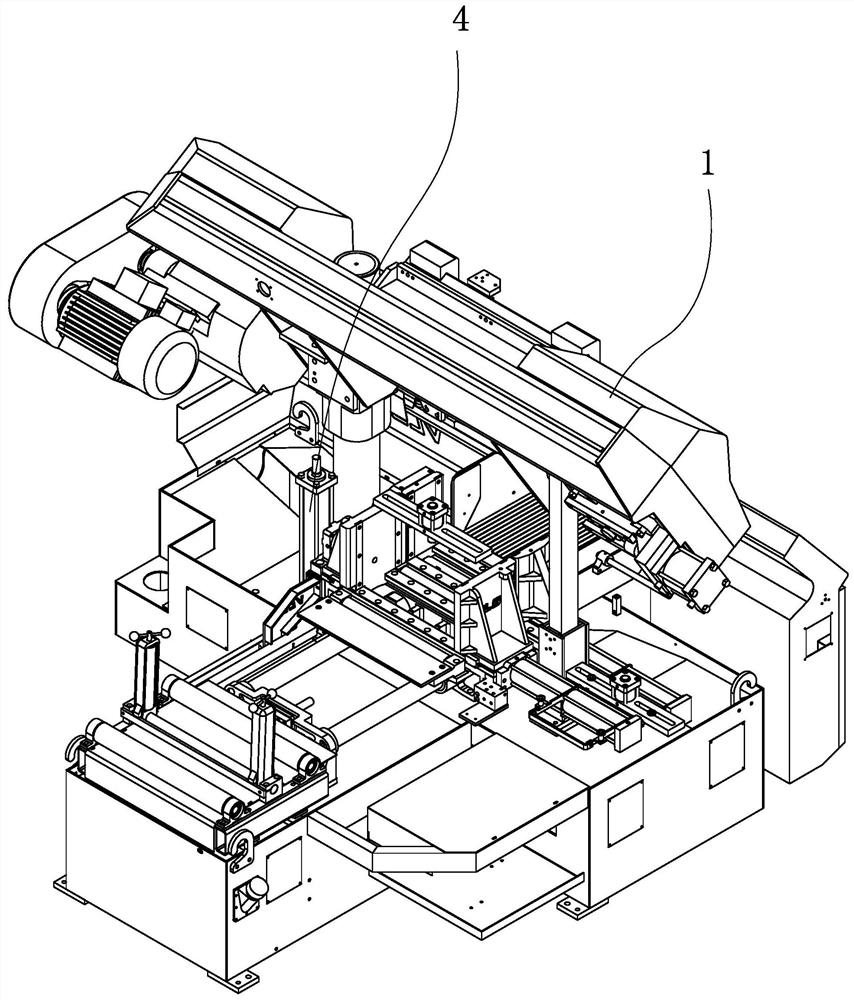

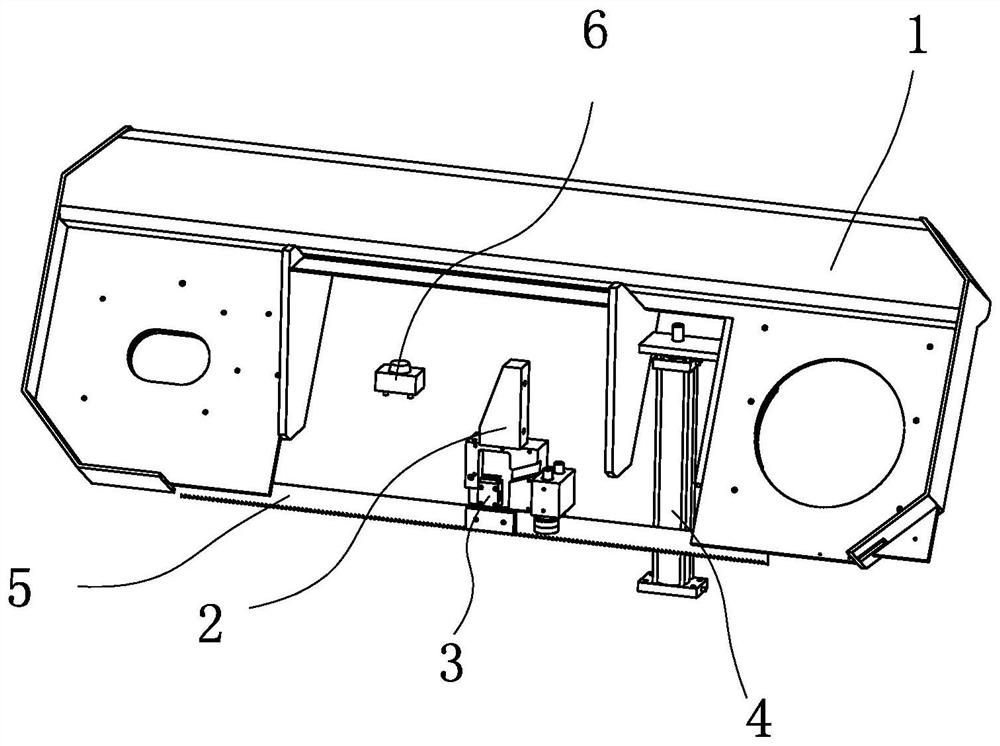

[0036] like figure 1 , figure 2 , image 3 , Figure 4 In the shown embodiment 1, a sawing machine with automatic speed change of the saw band feed includes a saw frame 1, a saw band 5 for sawing, a lifting device for controlling the lifting of the saw frame 1 and a saw band for fixing the saw frame. 5 guide assembly, the saw band 5 is fixed on the guide assembly, and the guide assembly is fixed on the saw frame 1. The lifting device controls the lift of the guide assembly by controlling the lifting of the saw frame 1 and then controls the lifting of the saw band 5. The guide assembly includes The guide head 2 is provided with a clamping device for fixing the saw band 5 and a speed regulating valve 3 for controlling the lifting speed of the lifting device on the guiding head 2. The lifting device includes a lifting cylinder 4, and the speed regulating valve 3 and the lifting cylinder 4 pass through The oil pipe is connected, that is, the speed regulating valve 3 and the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com