A drilling and milling tool device for wall grooving

A drilling, milling and cutting tool technology, which is applied in the field of mechanical technology for hydropower installation wall grooving, can solve the problems of short service life, time-consuming, and increased grooving cost of blades, so as to improve service life and work efficiency, reduce wear, The effect of preventing knife jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

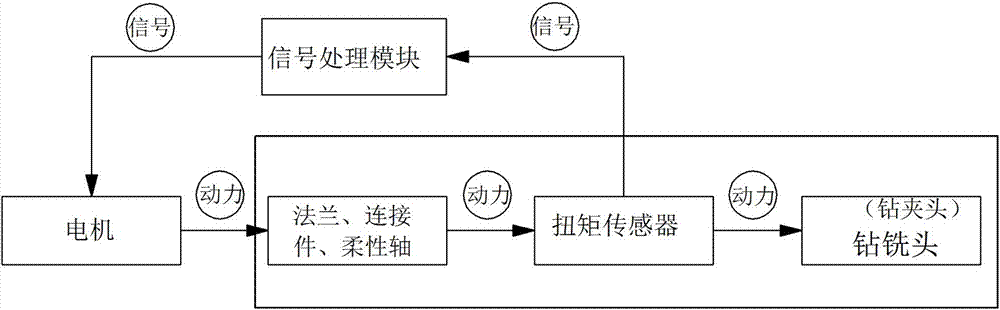

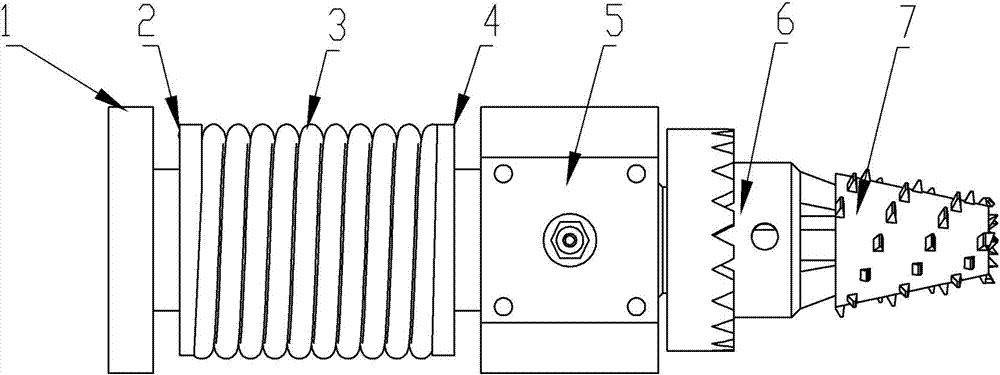

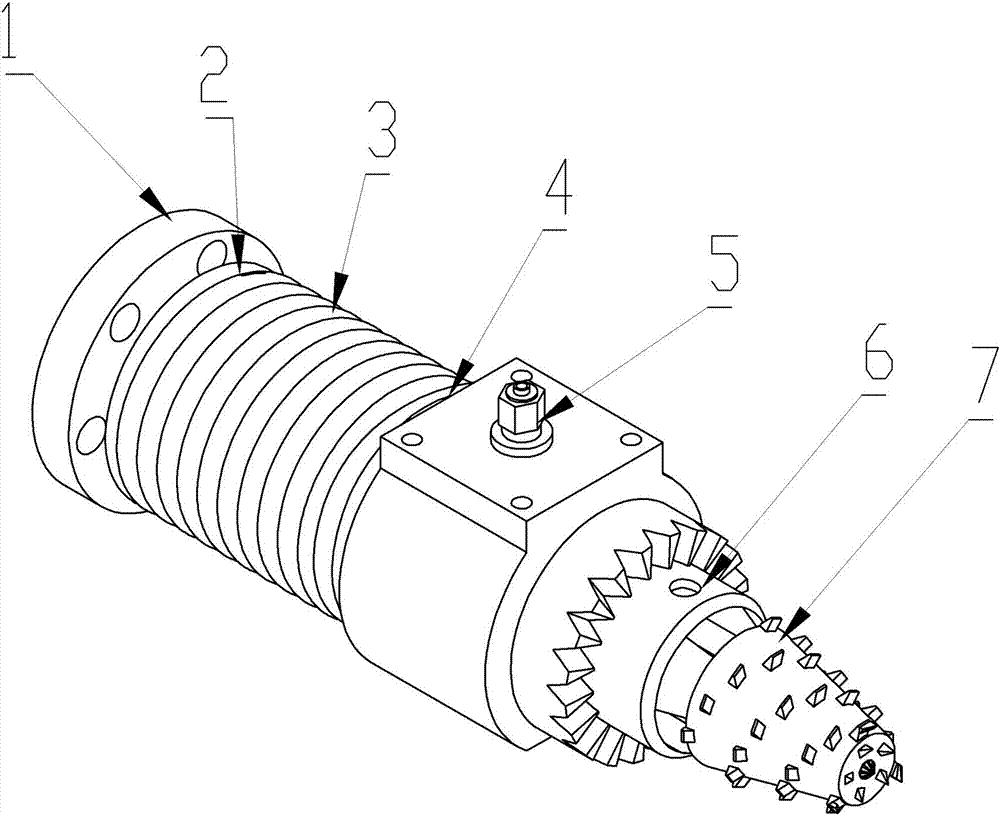

[0026] Embodiment 1, the present invention is a kind of drilling and milling tool device for hydropower installation wall grooving, it mainly comprises rotating shaft and drill bit, and rotating shaft is connected with power unit, and described drill bit comprises drill chuck 6 and drilling and milling head 7. A drilling and milling head 7 is installed on the front end of the drill chuck 6; the rotating shaft adopts a flexible shaft 3, and a torque sensor 5 is arranged between the flexible shaft 3 and the drill chuck 6, that is, the flexible shaft 3 is connected to the torque sensor 5 through the torque sensor 5. The drill chuck 6 is connected; the rear end of the flexible shaft 3 is connected with the power device, and the electric signal of the torque sensor 5 is connected with the power device through the signal processing module to realize the control of the electric signal. The signal processing module is the signal processing module The signal interface of the torque sens...

Embodiment 2

[0027] Embodiment 2, the torque sensor 5 of the present invention is mainly used to measure the torque value generated when the drilling and milling head works in real time, and transmit it back to the variable frequency motor, and the torque value is used as a given program parameter to control the speed of the motor , so that the drilling and milling head can automatically adapt to the working speed of different wall conditions, which is conducive to improving the service life and working efficiency of the slotting tool. refer to Figure 1 to Figure 6 . All the other are the combination of any one of the above embodiments or two above embodiments.

Embodiment 3

[0028] Embodiment 3, the rotating shaft of the present invention adopts a spring-like flexible shaft 4. The use of the flexible shaft plays a role of buffering and anti-vibration for the slotting machine, which is beneficial to protect the drilling and milling head and prevent the cutter from jamming and chipping. refer to Figure 1 to Figure 6 . All the other are the combination of any one of the above embodiments or two above embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com