Patents

Literature

34results about How to "Realize automatic speed regulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

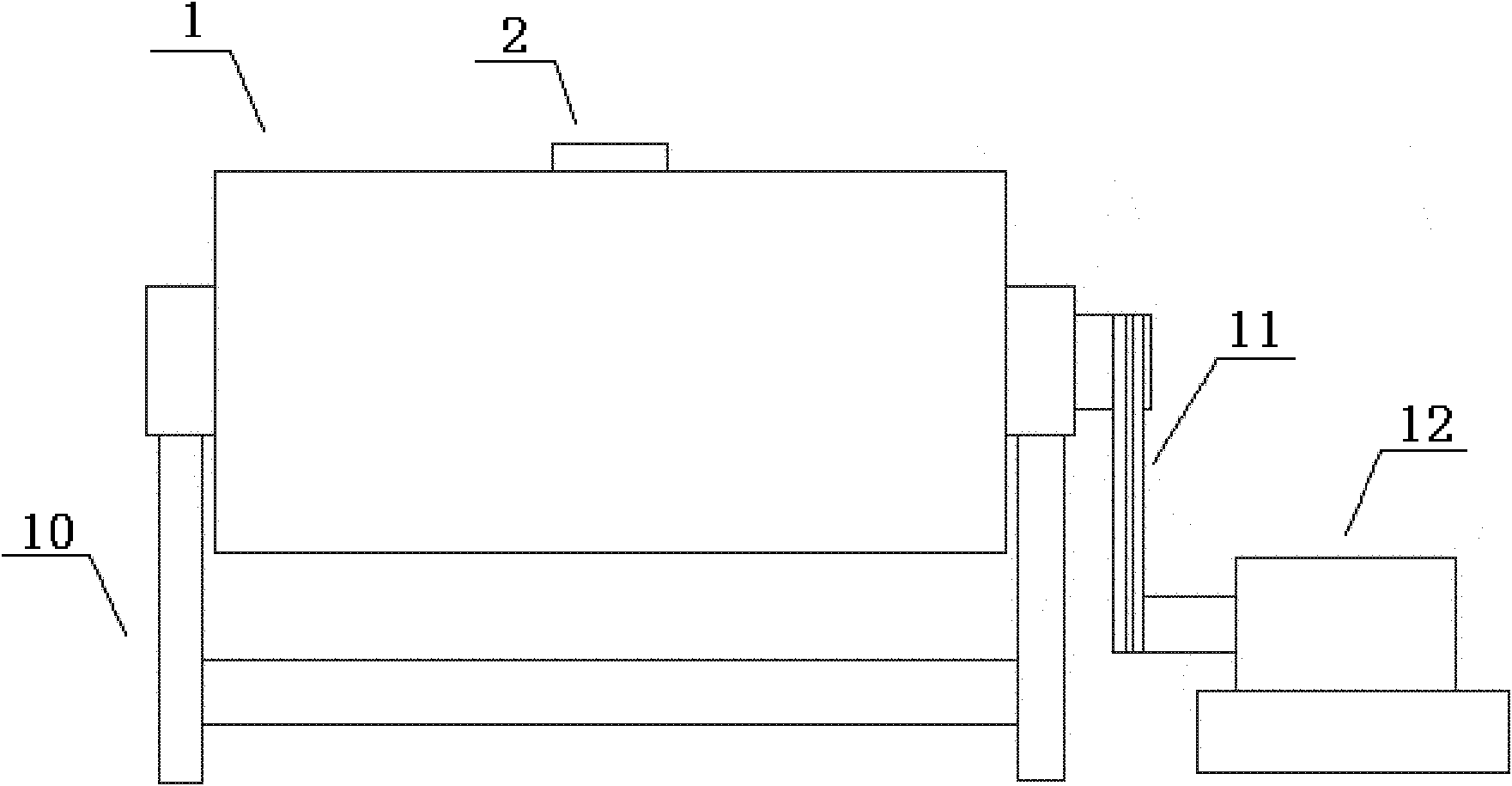

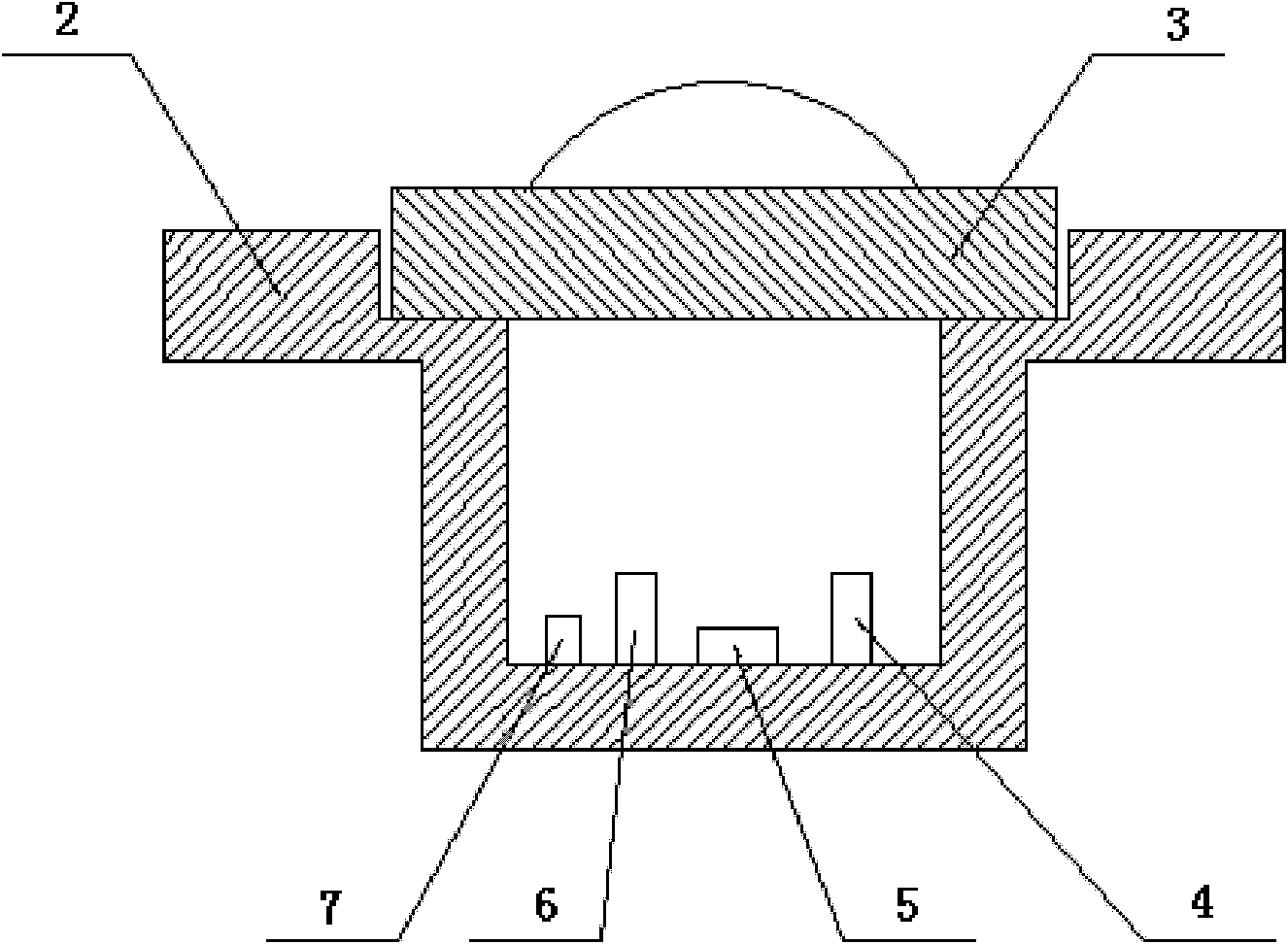

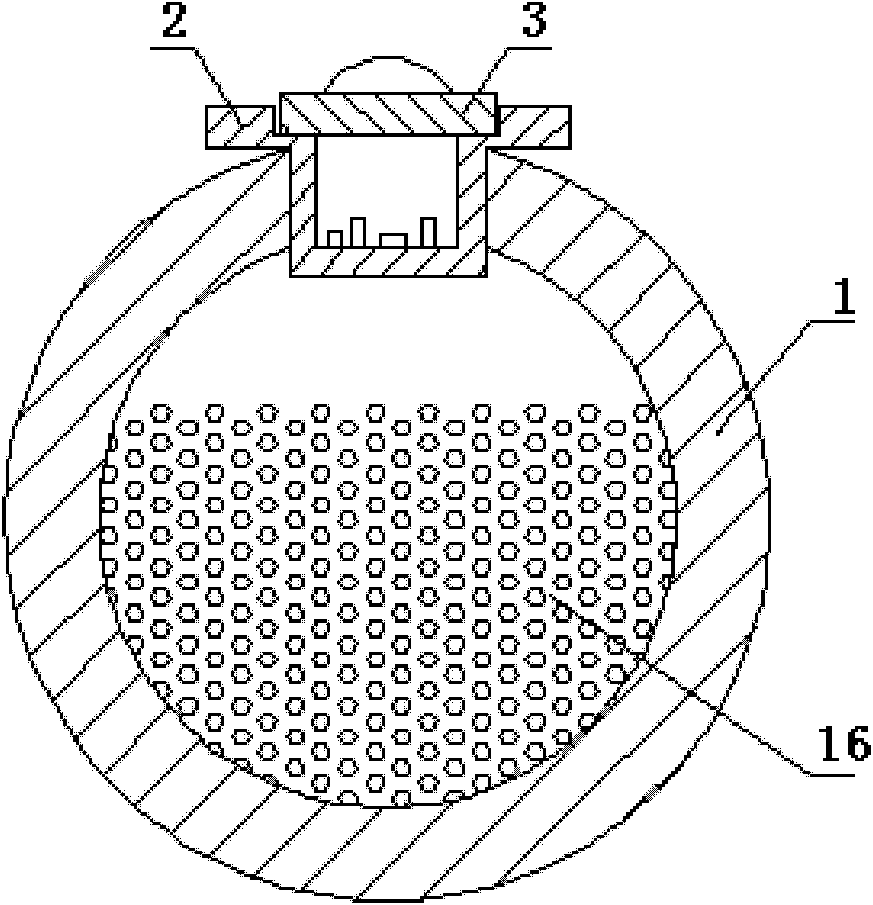

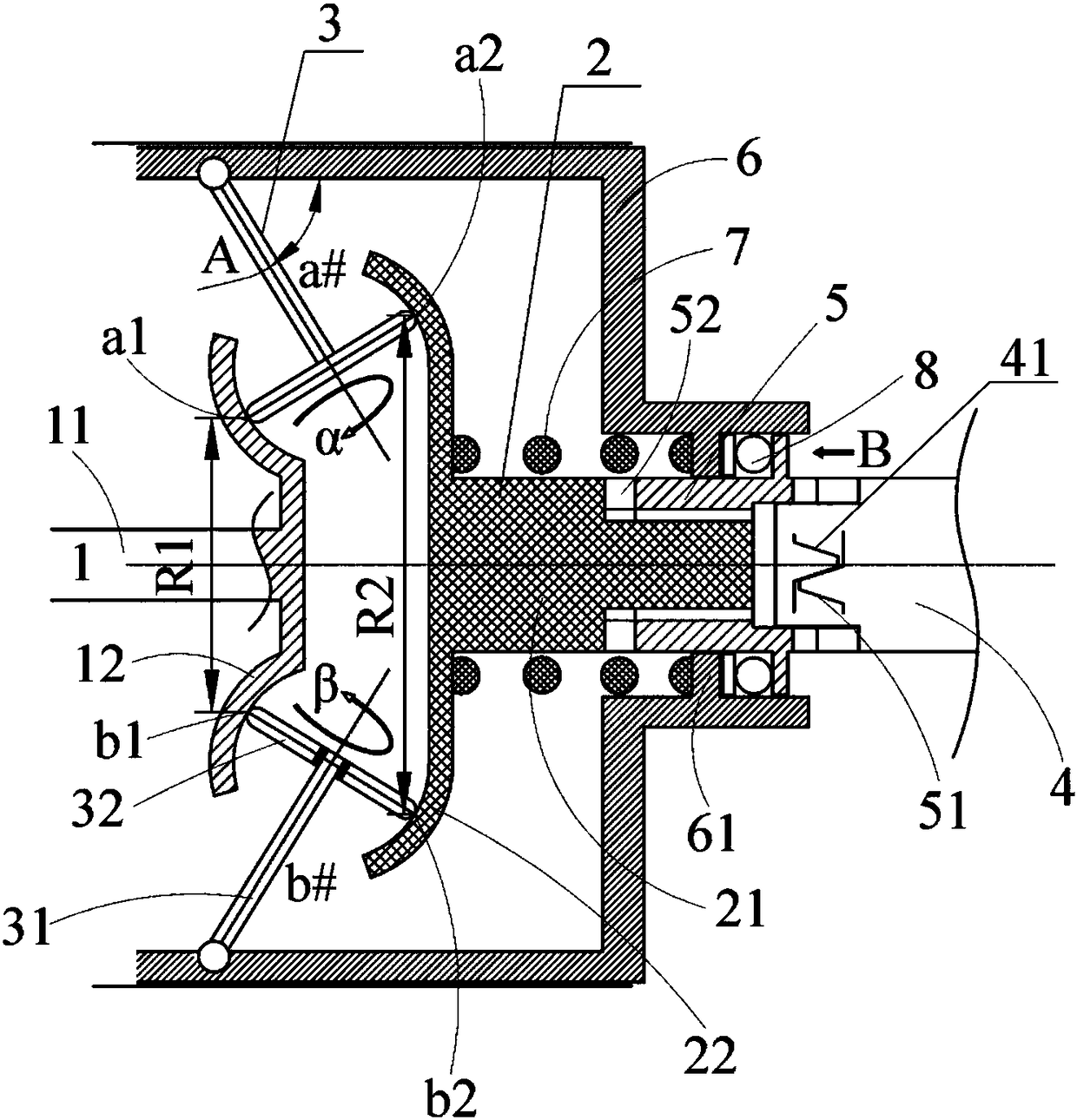

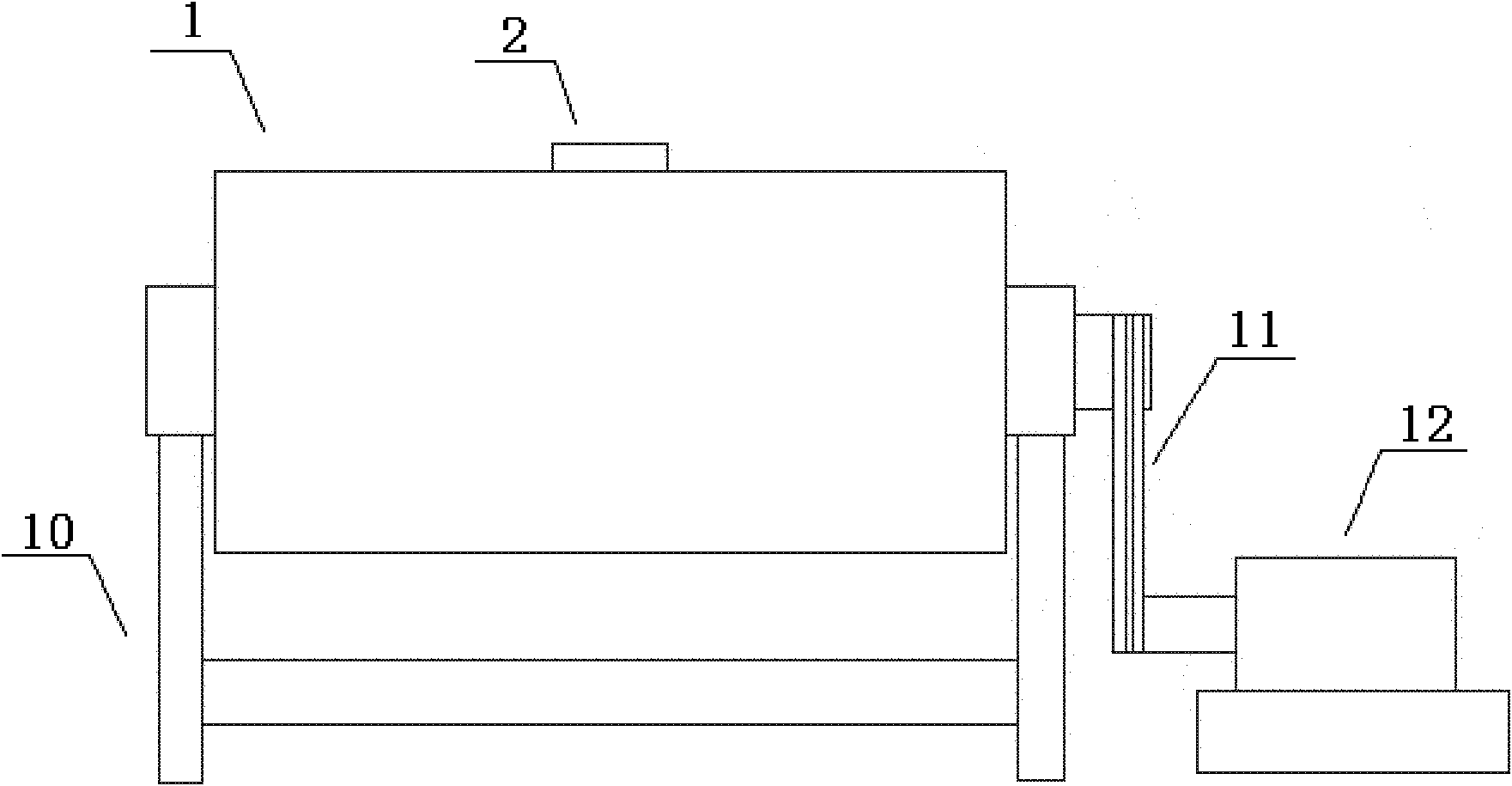

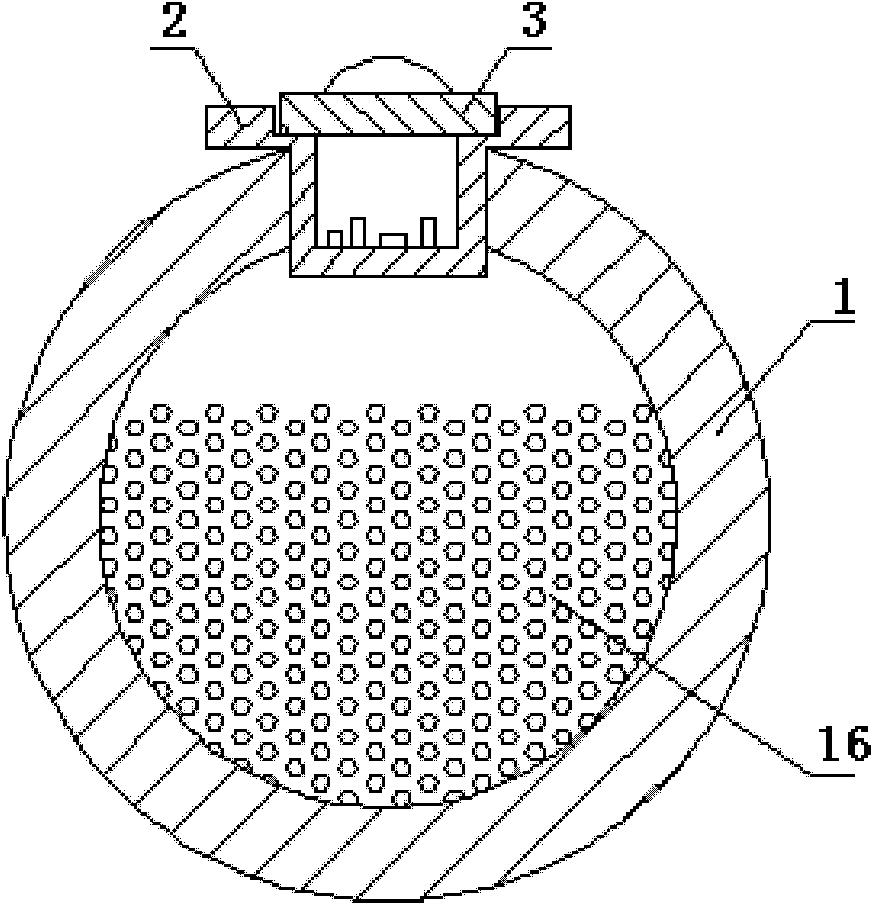

Automatic speed regulation system and method for ball milling machine

InactiveCN102179278ASimple structureImprove work efficiencyGrain treatmentsSignal processing circuitsAgricultural engineering

The invention relates to the field of milling engineering machinery, in particular to a ball milling machine. An automatic speed regulation system for the ball milling machine comprises a ball milling machine main body, a strain transducer, and a wireless signal receiving module; the ball milling machine main body is connected with an electric motor; the ball milling machine main body is providedwith a ball milling machine cover; the outer side of the bottom of the ball milling machine cover is directly contacted with the interior of the ball milling machine main body; the strain transducer is connected with a signal processing circuit; the signal processing circuit is connected with a wireless signal emission module; the wireless signal receiving module is connected with a speed regulation signal circuit; the input end of the speed regulation signal circuit is also connected with a rotation speed detection device; the speed regulation signal circuit is connected with a speed regulator; and the speed regulator is connected with the electric motor. An automatic speed regulation method for the ball milling machine comprises the following steps of: 1) acquiring data; 2) processing and analyzing the data; and 3) regulating the speed and controlling. The speed regulation system has a simple structure and can fulfill the aim of automatic grinding, and by the speed regulation method, the working efficiency of the ball milling machine can be effectively improved.

Owner:SHANDONG UNIV OF TECH

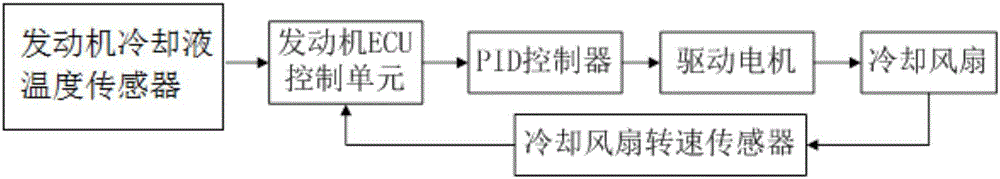

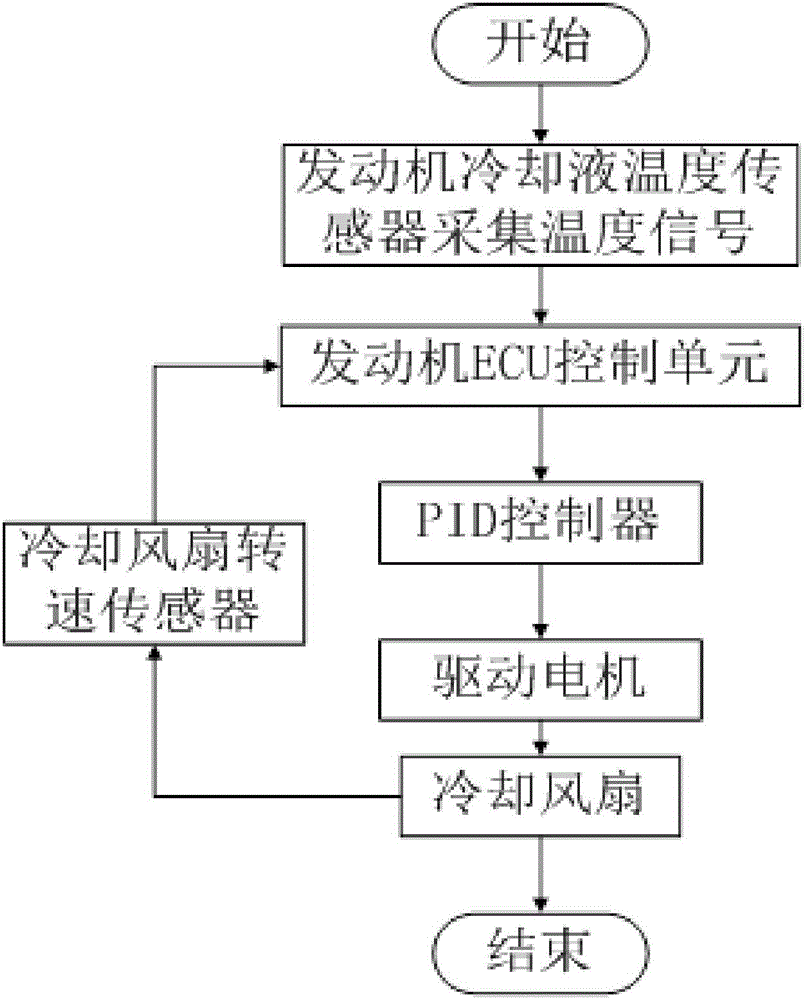

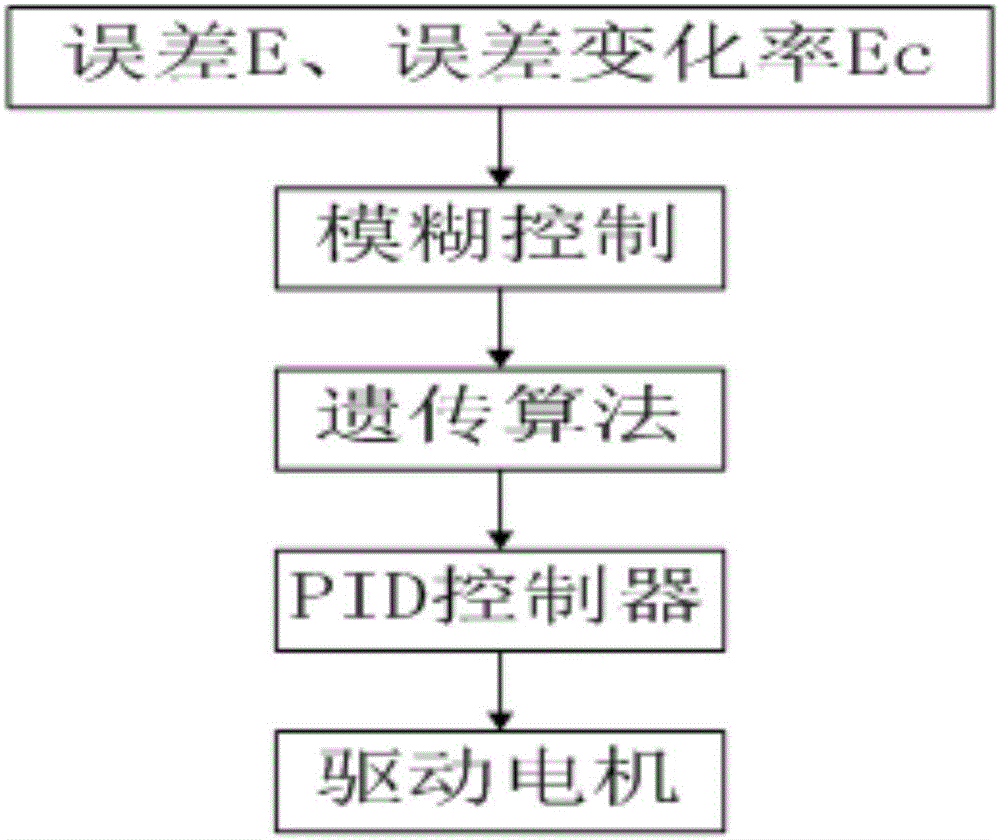

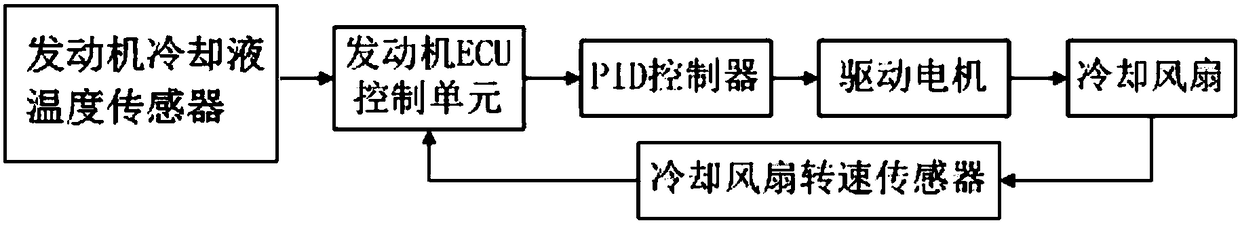

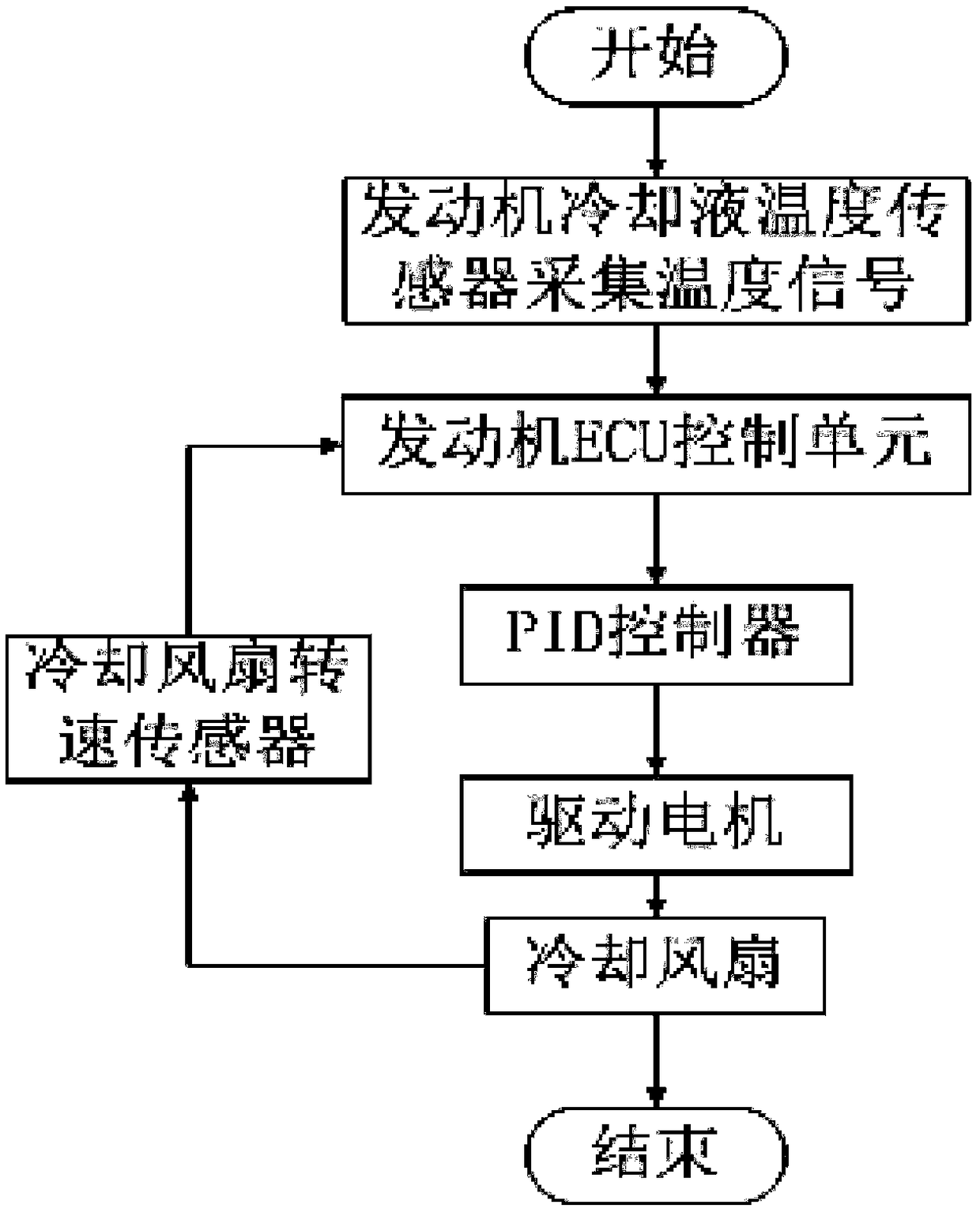

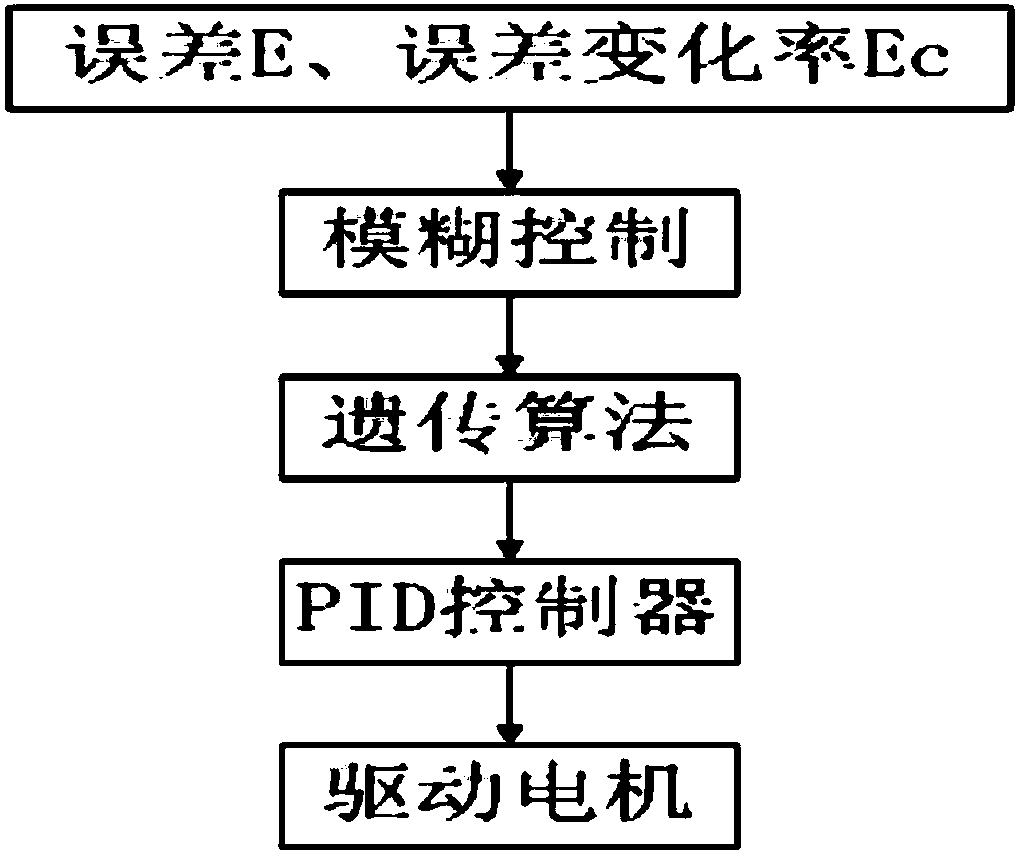

Speed regulation method based on PID algorithm for engine cooling fan

ActiveCN106368790AChange speedRealize automatic speed regulationCoolant flow controlPump controlElectronic control unitDrive motor

The invention relates to a speed regulation method based on the PID algorithm for an engine cooling fan. An electronic control unit (ECU) of an engine controls the rotation speed of the cooling fan. The method includes the steps that 1, in the running process of an automobile, a temperature sensor of engine coolants transmits temperature signals of the engine coolants to the ECU of the engine; 2, the temperature signals are processed by the ECU of the engine, and the ECU of the engine outputs control signals to a PID controller; and 3, the PID controller regulates the rotation speed of a drive motor according to the received control signals, the drive motor changes the rotation speed of the cooling fan, and a cooling fan sensor collects the rotation speed information of the cooling fan and feeds back the rotation speed information of the cooling fan to the ECU of the engine. According to the method, the speed of the cooling fan can be automatically regulated.

Owner:张家港长安大学汽车工程研究院

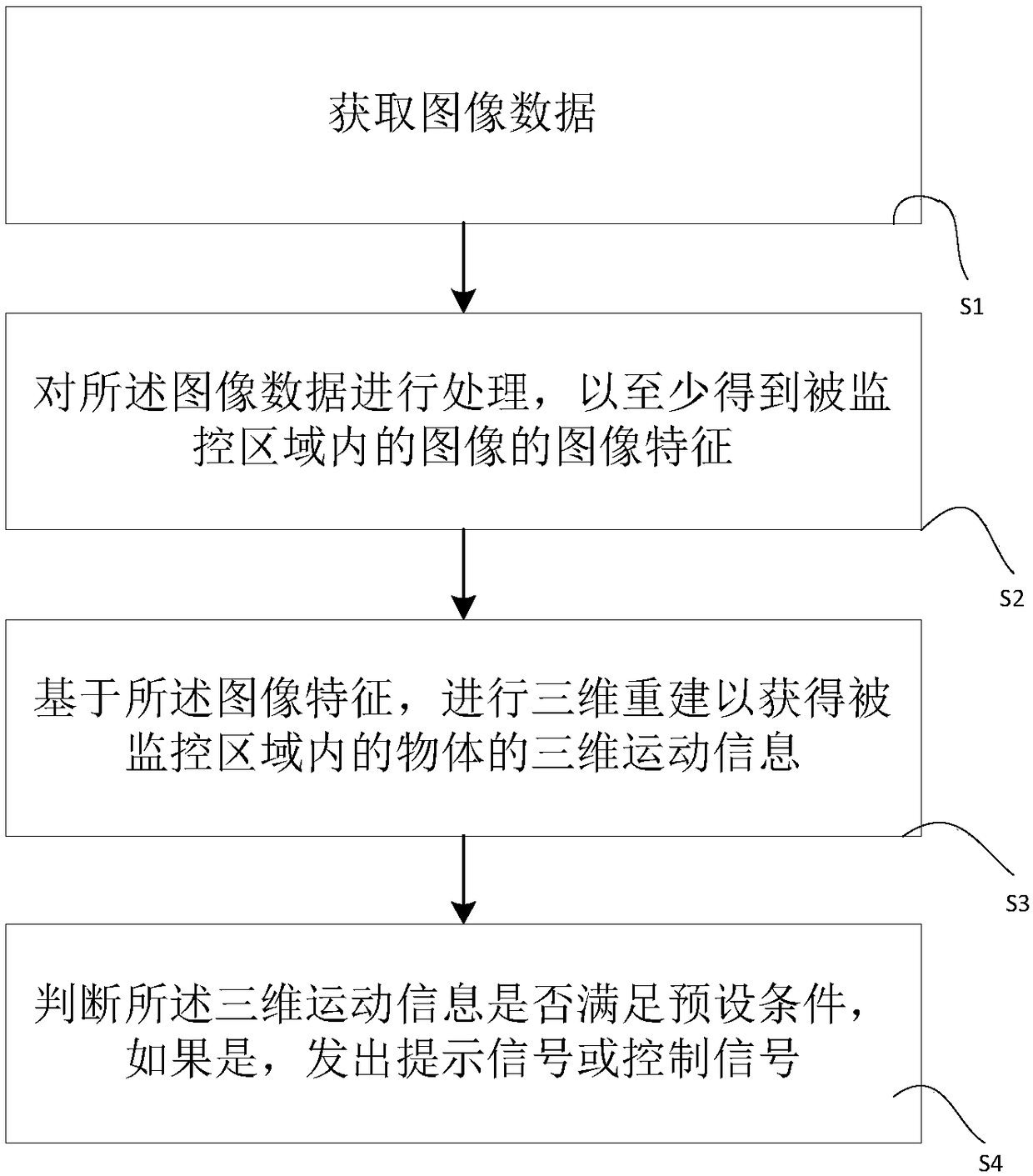

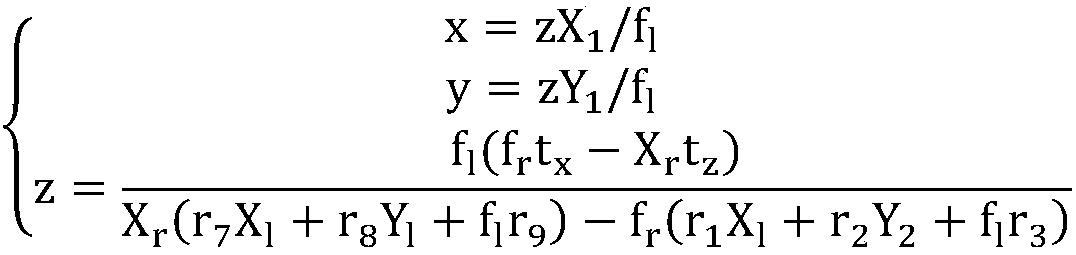

Image monitoring method based on computer vision

InactiveCN108668109ARealize automatic speed regulationIncrease productivityCharacter and pattern recognitionClosed circuit television systemsForeign matterVideo monitoring

The invention discloses an image monitoring method based on computer vision. The image monitoring method comprises the following steps: acquiring image data; processing the image data by using a processor so as to as least obtain an image feature of an image in a monitored region; performing three-dimensional reconstruction based on the image feature by using the processor, thereby acquiring three-dimensional motion information of an object in the monitored region; and judging whether the three-dimensional motion information satisfies a preset condition by using the processor; if the three-dimensional motion information satisfies the preset condition, sending out a prompt signal or a control signal. Through the image monitoring method based on the computer vision provided by the invention,the cooperative operation values of various equipment resources are deeply mined and optimized, and the method is especially suitable for developing an efficient and energy-saving intelligent video monitoring software platform and hardware product suitable for safety production of the coal mine, the automatic speed-regulation of the coal mine conveyor belt, the automatic identification of the coal transportation and sale behavior, and the advance pre-control on the intrusion of the dangerous region personnel and the abnormal detection can be automatically identified, the mine production efficiency and the safety protection level are improved, and the energy-saving and consumption reduction can be realized.

Owner:北京纽科曼科技有限公司

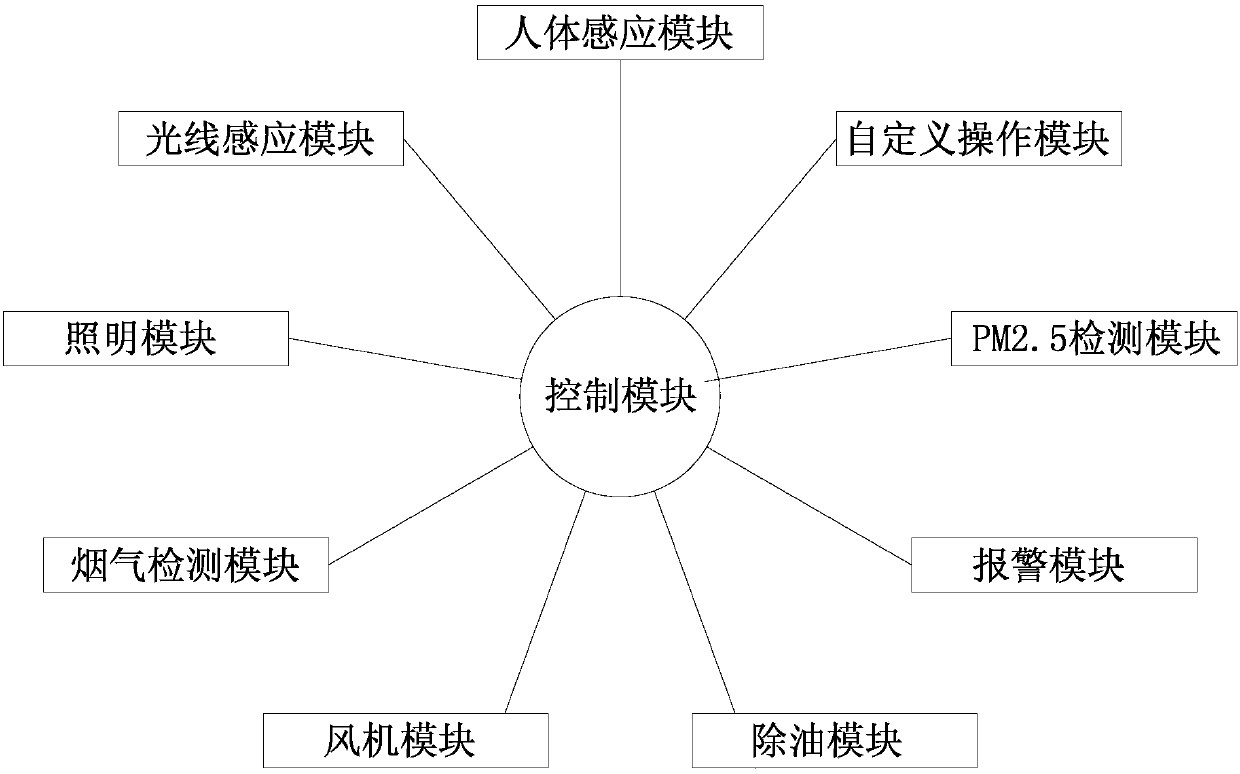

Intelligent operation method of range hood

InactiveCN107702173ARealize automatic lightingRealize automatic speed regulationDomestic stoves or rangesLighting and heating apparatusUser needsLight sensing

The invention discloses an intelligent operation method of a range hood. The range hood comprises a control module. The control module is connected with a human body sensing module, a light sensing module, a lighting module, a smoke detecting module, a draught fan module and an oil removing module. The intelligent operation method of the range hood comprises the steps that the human body sensing module continuously senses whether a person stays in a work area of the range hood; when a person stays in the work area of the range hood, the control module enables the range hood to be in the work state; when no people stay, the control module enables the range hood to be in the stand-by state. By the adoption of the intelligent operation method of the range hood, the mode that a user needs to operate a traditional range hood through manual action or voice is changed, simplification is achieved, the range hood can automatically and intelligently operate, the range hood can automatically start and stop to exhaust oily fume, automatically conduct lighting, automatically adjust speed, automatically conduct cleaning and the like, the user does not need to conduct any operation in the period,and the user can really experience the joy of modern high-technology life.

Owner:广东村田智能科技有限公司

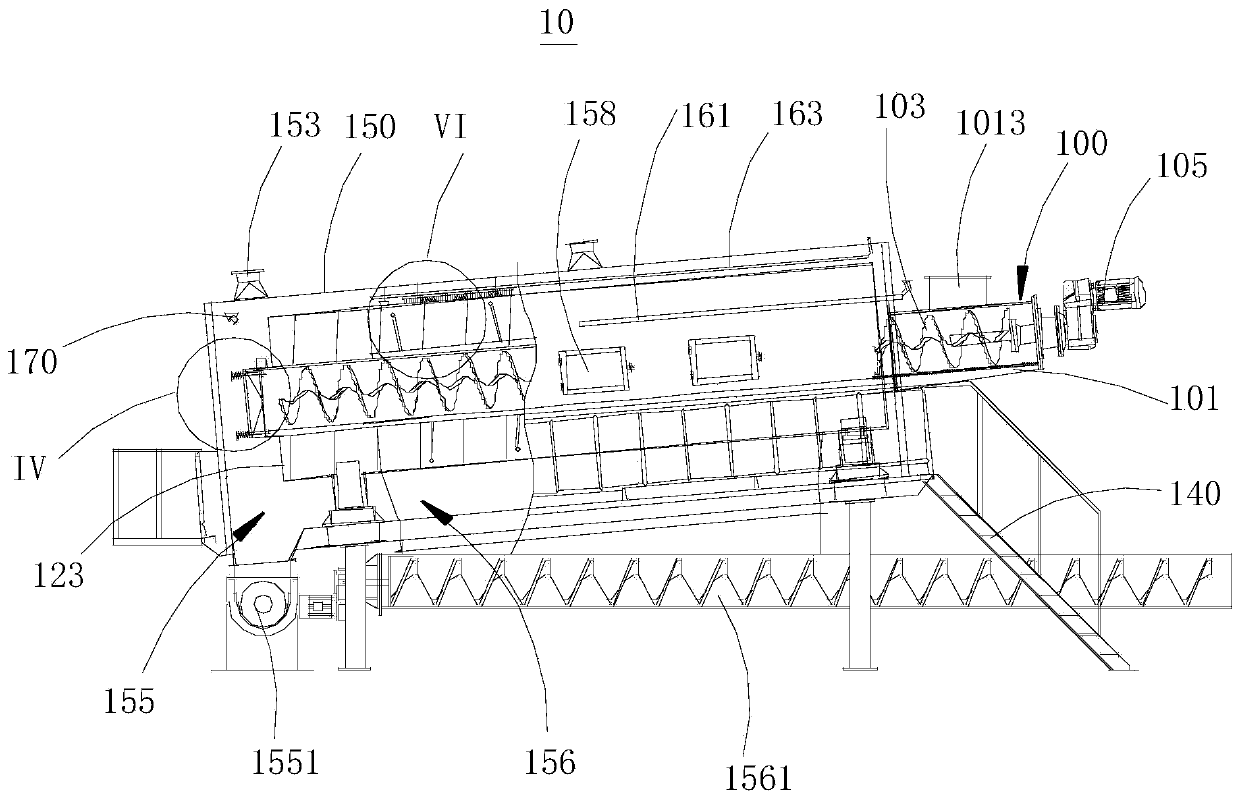

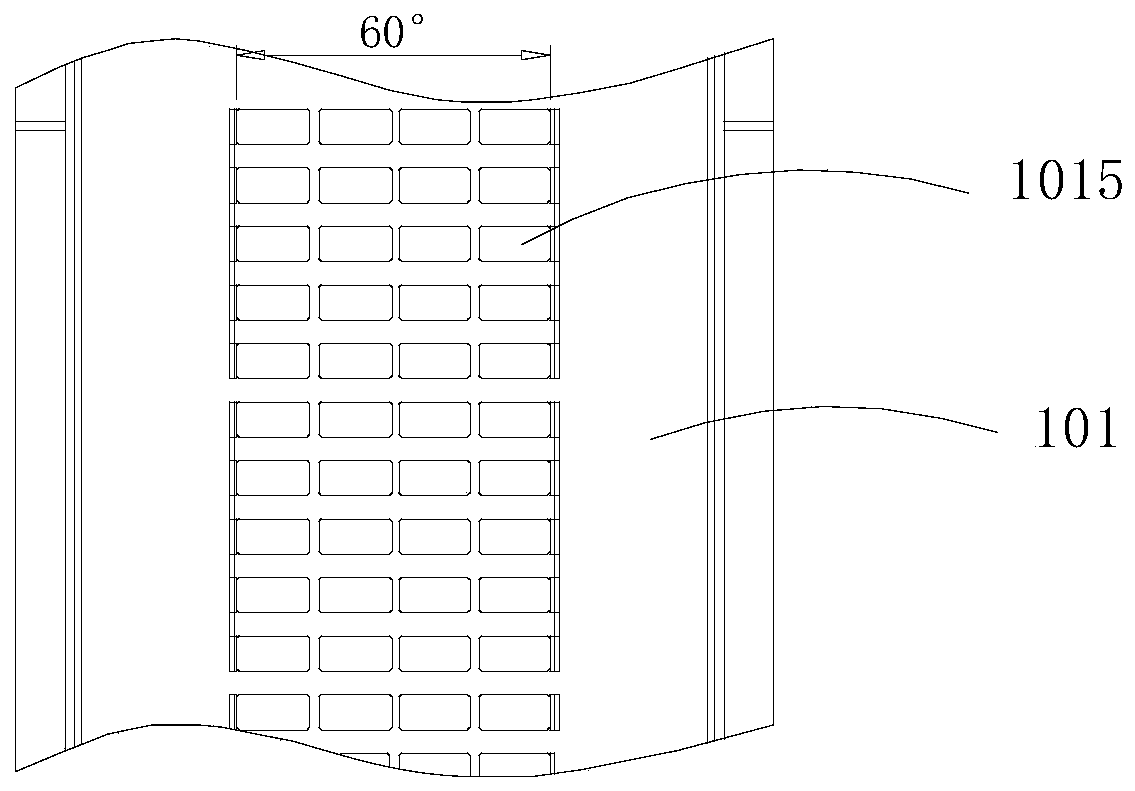

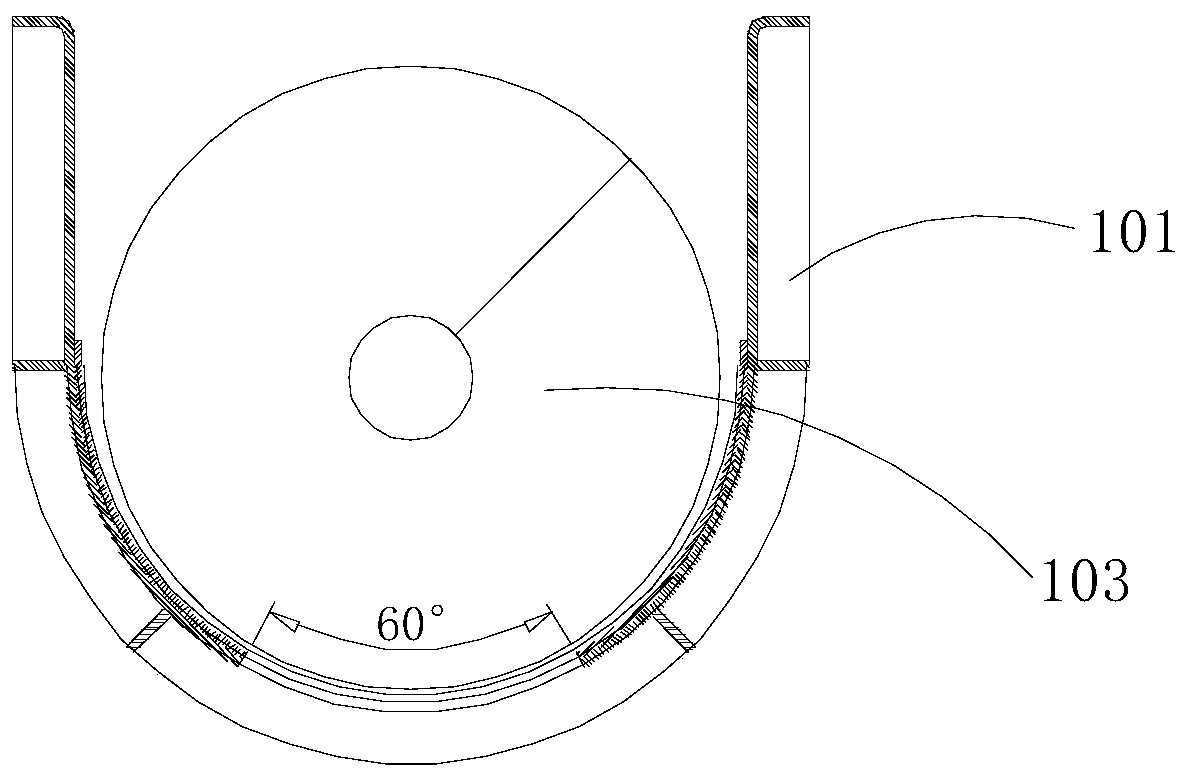

Sorting equipment for kitchen waste

PendingCN110340120AExtended service lifeAvoid it happening againSievingScreeningPulp and paper industrySieve

The invention discloses sorting equipment for kitchen waste, and relates to the field of environmental protection. The sorting equipment for the kitchen waste comprises a feeding spiral sorting machine, a roller and a first driving mechanism, wherein the feeding spiral sorting machine comprises a material conveying barrel, a spiral conveying blade, a second driving mechanism and an extruding mechanism, the material conveying barrel is provided with a material inlet, a first material outlet, first-stage sieve holes and filter holes, the spiral conveying blade is arranged in the material conveying barrel, the second driving mechanism is in transmission connection with the spiral conveying blade, the extruding mechanism is arranged at the material discharging end of the material conveying barrel, so that material residues obtained after first-stage sieving undergo the extruding treatment to be discharged through the first material outlet, the second end of the roller is lower than the first end of the roller and is provided with a second material outlet, the roller sleeves the material conveying barrel, moreover, a second-stage sieve cavity is formed between the roller and the outer wall of the material conveying barrel, second-stage sieve holes are formed in the roller, and the first driving mechanism is in transmission connection with the roller. According to the sorting equipment, the purpose of synchronously performing two stages of screening can be realized, and meanwhile, the service life of the sorting equipment for the kitchen waste is prolonged.

Owner:青海洁神环境科技股份有限公司

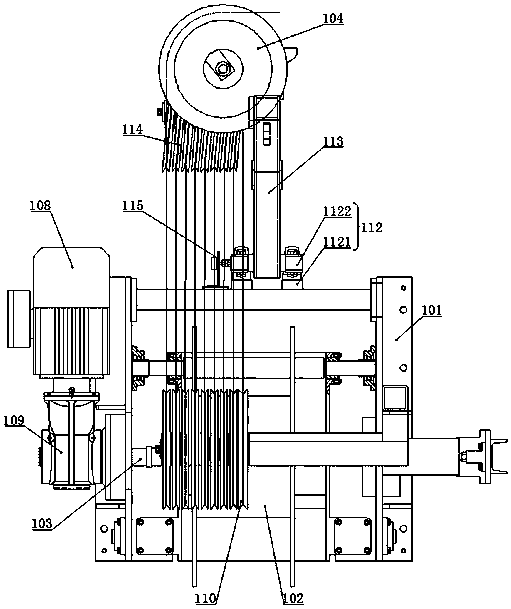

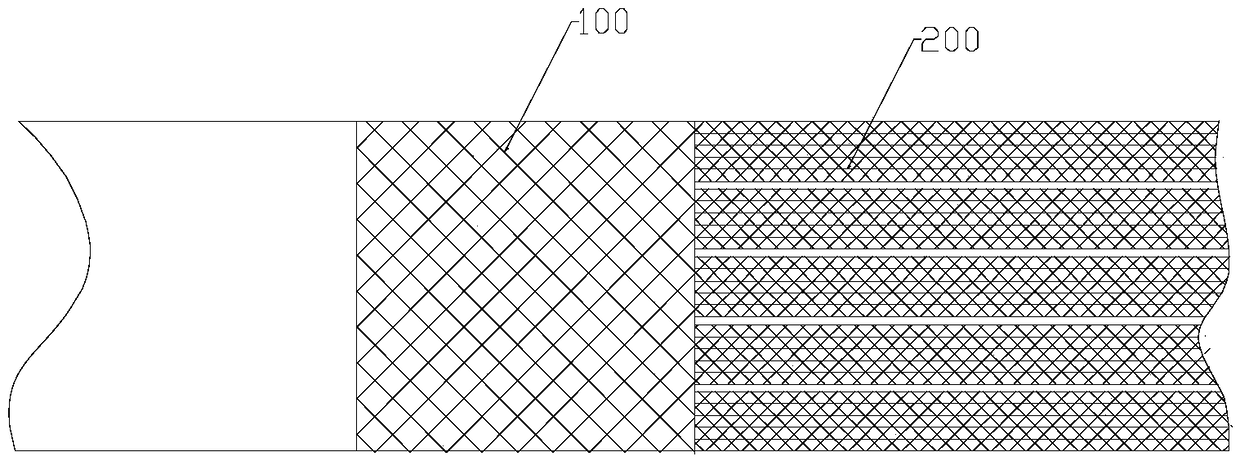

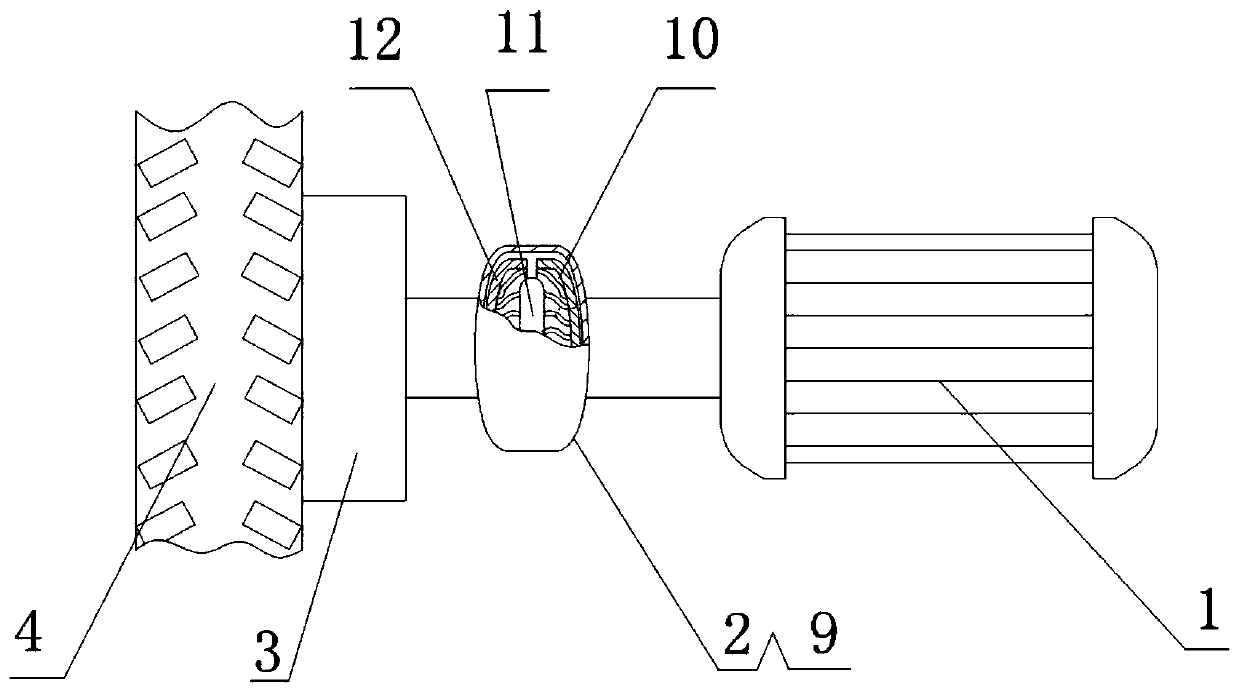

Feeding device for tire wire winding machine

The invention discloses a feeding device for a tire wire winding machine and aims to solve problems of poor steel wire friction quality, proneness to accumulation and instability of steel wire tensionin the prior art. Two ends of a spool are supported on a let-off supporting frame through a let-off rotating shaft and a clamping part, and one end of the spool is in detachable connection with one end of the let-off rotating shaft. A let-off frequency-variable motor is mounted on one side of the let-off supporting frame, and an output shaft of the let-off frequency-variable motor is in transmission connection with the other end of the let-off rotating shaft through a let-off speed-reduction diverter. A let-off fixed wheel set is rotationally supported on the let-off supporting frame througha fixing support arm, and a let-off moving wheel set is rotationally supported at an output end of the let-off supporting frame through a moving support arm. An angular displacement sensor between thelet-off supporting frame and a rotating connector is in electrical connection with a controller, and the controller is in electrical connection with the let-off frequency-variable motor through a frequency converter. The feeding device has advantages that friction of steel wires is avoided, high quality and tension stability of steel wires are realized, butt joints are less prone to breakage, stability in operating and braking of the spool is achieved, and less proneness to accumulation is realized.

Owner:PRINX CHENGSHAN (QINGDAO) IND RES & DESIGN CO LTD

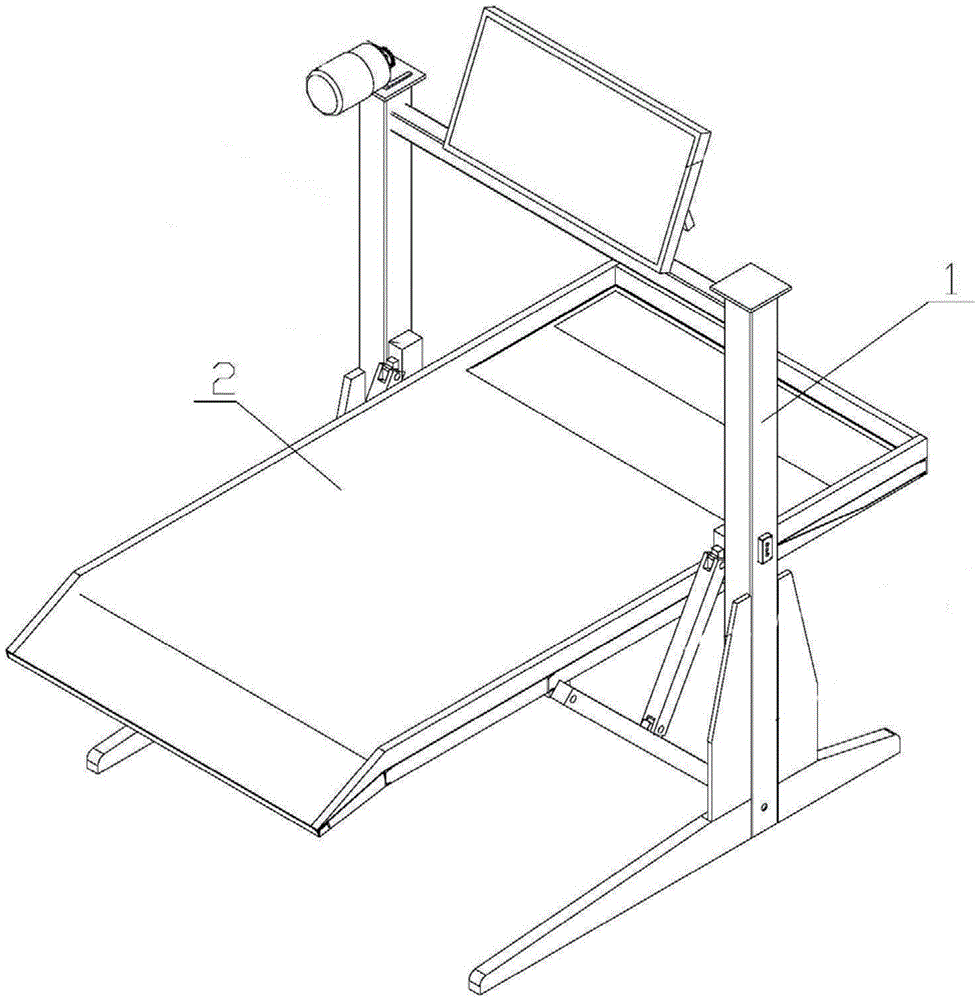

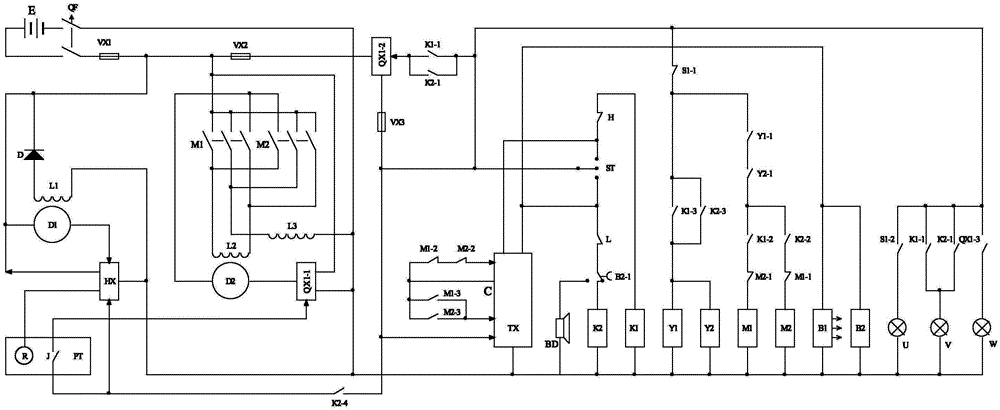

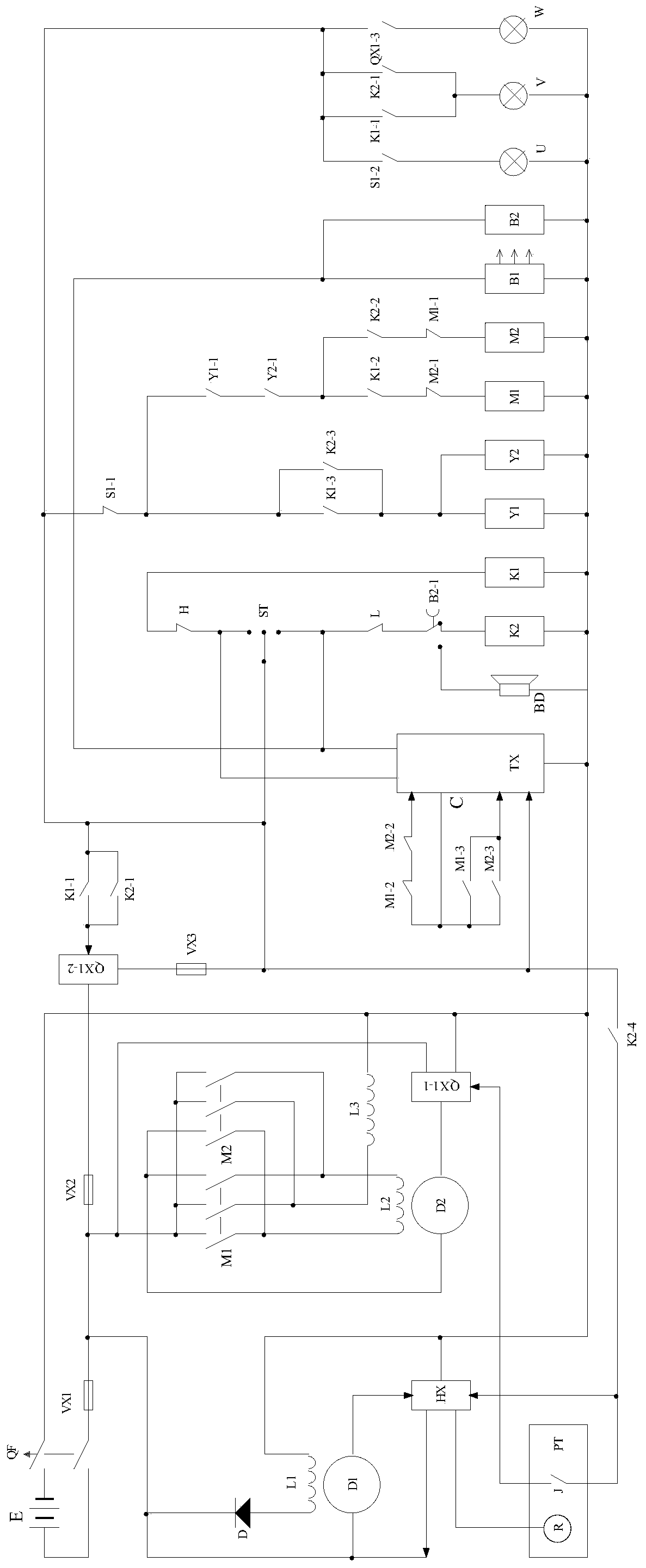

Household parking garage with direct-current motor

ActiveCN105577038AAvoid shockTo achieve the purpose of energy savingAc motor stoppersMechanical energy handlingElectricityDescent direction

The invention provides a household parking garage with a direct-current motor. The household parking garage comprises a garage framework, a parking platform, a storage battery E, a power module, a damping power generation module and a lifting control module; the storage battery E supplies working power supply to the power module, the damping power generation module and the lifting control module; the power module and the damping power generation module are in line connection with the lifting control module; the parking platform is connected with the garage framework; the power module drives the parking platform to move on the garage framework; when the parking platform declines, the damping power generation module generates resistance opposite to the declining direction of the parking platform; and simultaneously, gravitational potential energy is converted into electrical energy and stored in the storage battery E. Declining is carried out by utilizing self gravity of the garage and an automobile; the gravitational potential energy is converted into electrical energy and stored; consumption of power electricity is supplied; the purpose of saving energy is achieved; the damping power generation module generates the resistance opposite to the gravity direction while generating power; and thus, the problem that the garage is impacted due to the fact that the declining speed of the parking platform is too rapid because of the gravity action can be avoided.

Owner:创客帮(山东)科技服务有限公司

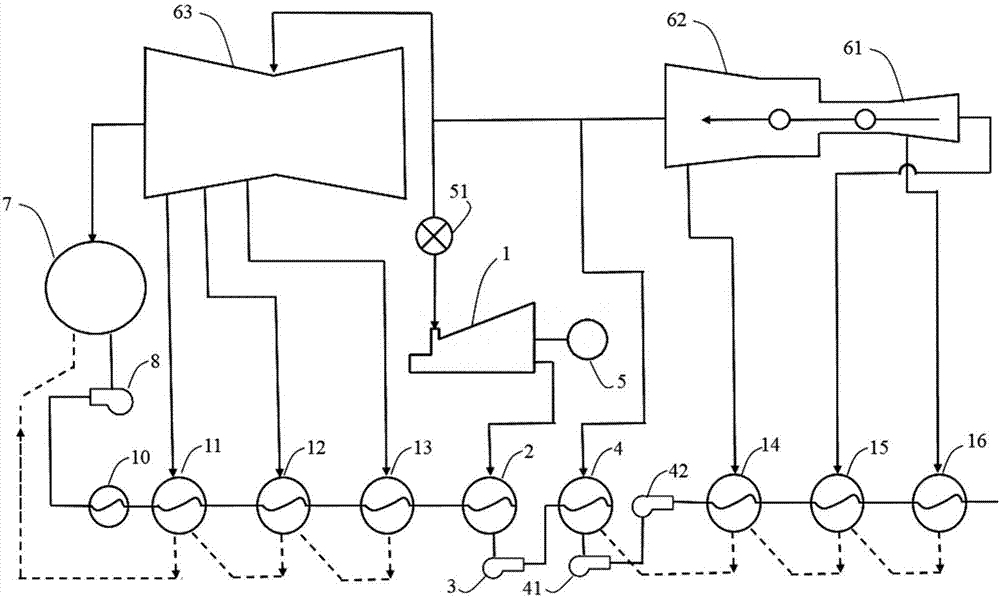

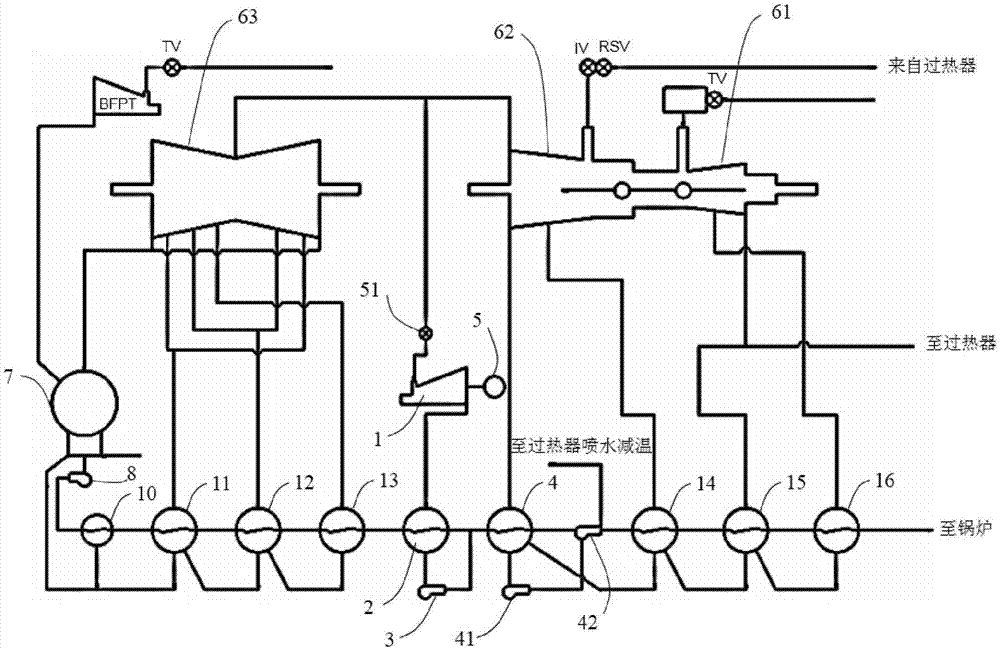

Thermodynamic system for driving steam turbine

InactiveCN107269332AReduce lossesRealize automatic speed regulationSteam engine plantsDifferential pressureEngineering

The invention belongs to the technical field of steam turbines, and provides a thermal system for driving a steam turbine, comprising: a driving steam turbine, which is driven by exhaust steam from an intermediate pressure cylinder of a main steam turbine; a condensing deaerator, which receives the The exhaust steam of the driving steam turbine is used to provide a certain back pressure for the driving steam turbine so that the driving steam turbine can output power. The drive steam turbine thermal system provided by the present invention can provide the power interface provided by the low-power steam turbine, which not only simply creates a powerful power center (interface), but also reduces the loss of the cold end of the main engine and utilizes the differential pressure of steam extraction It is a brand new heat recovery system with high efficiency and energy saving.

Owner:北京质为科技有限公司

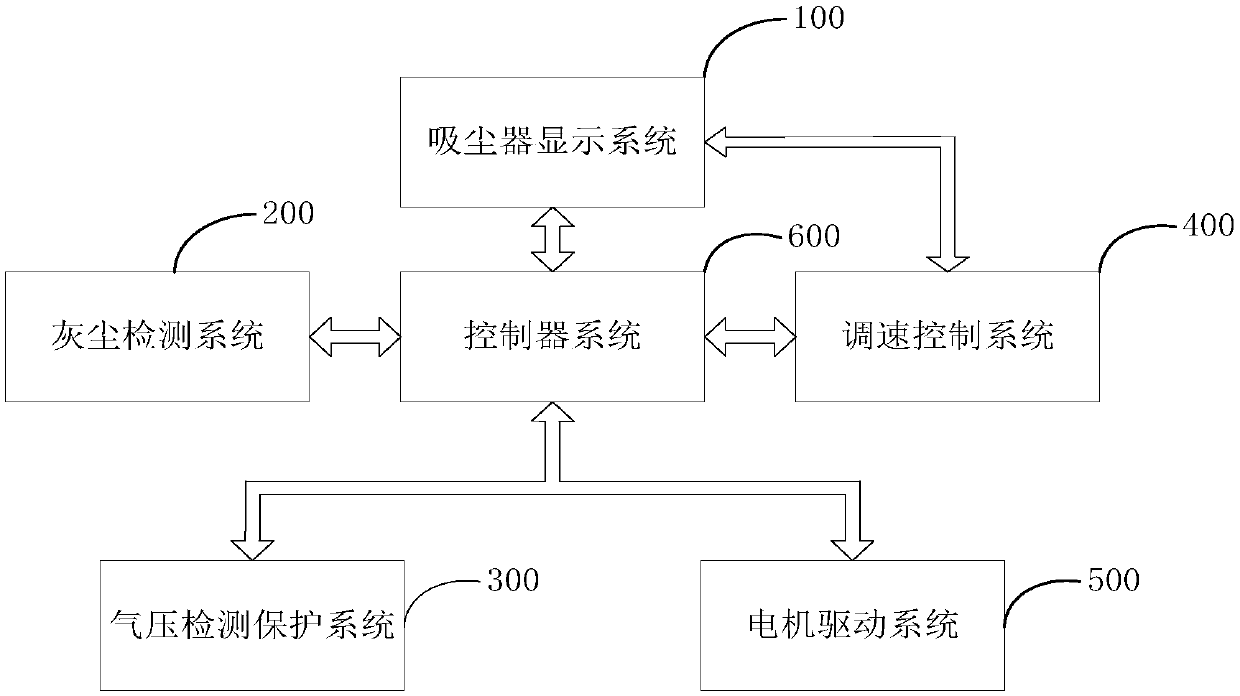

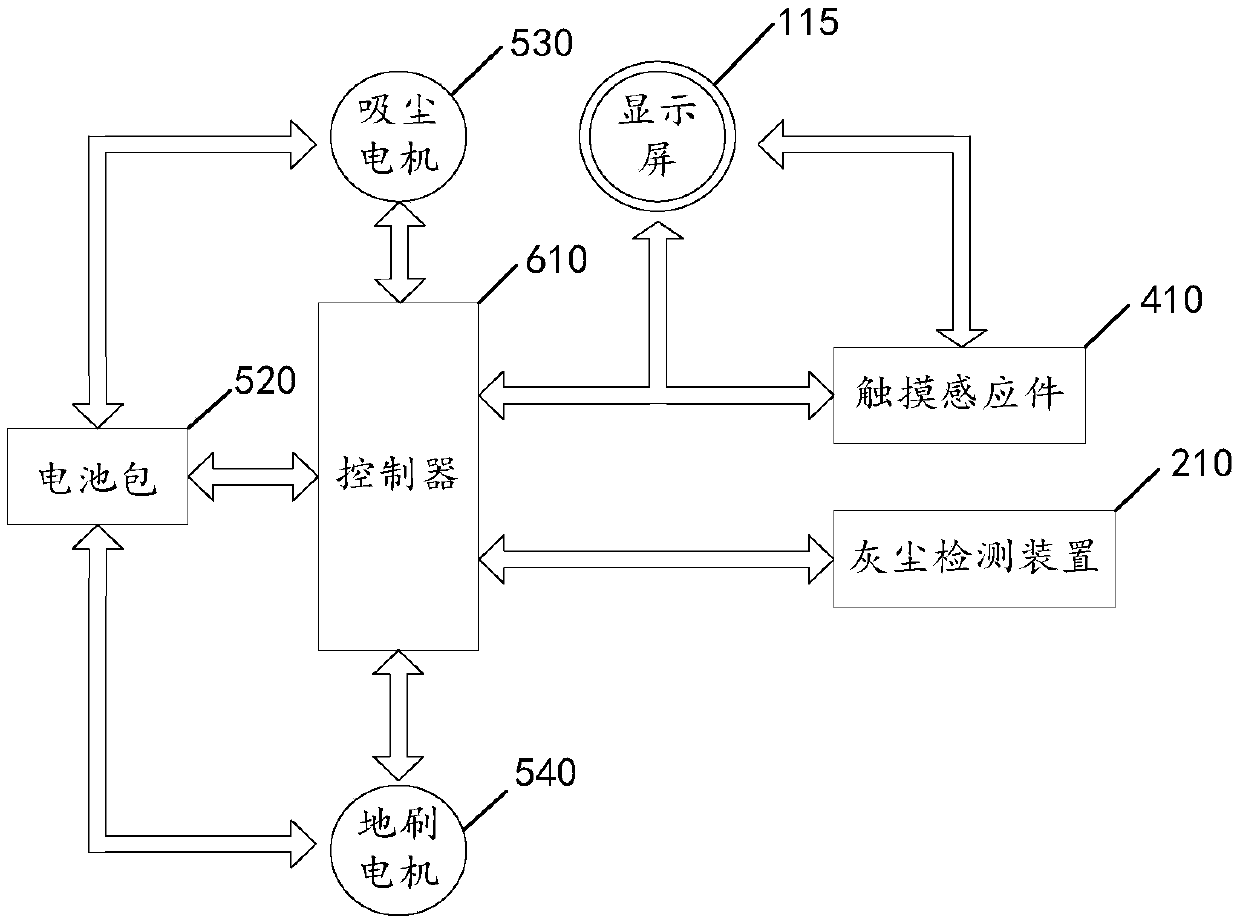

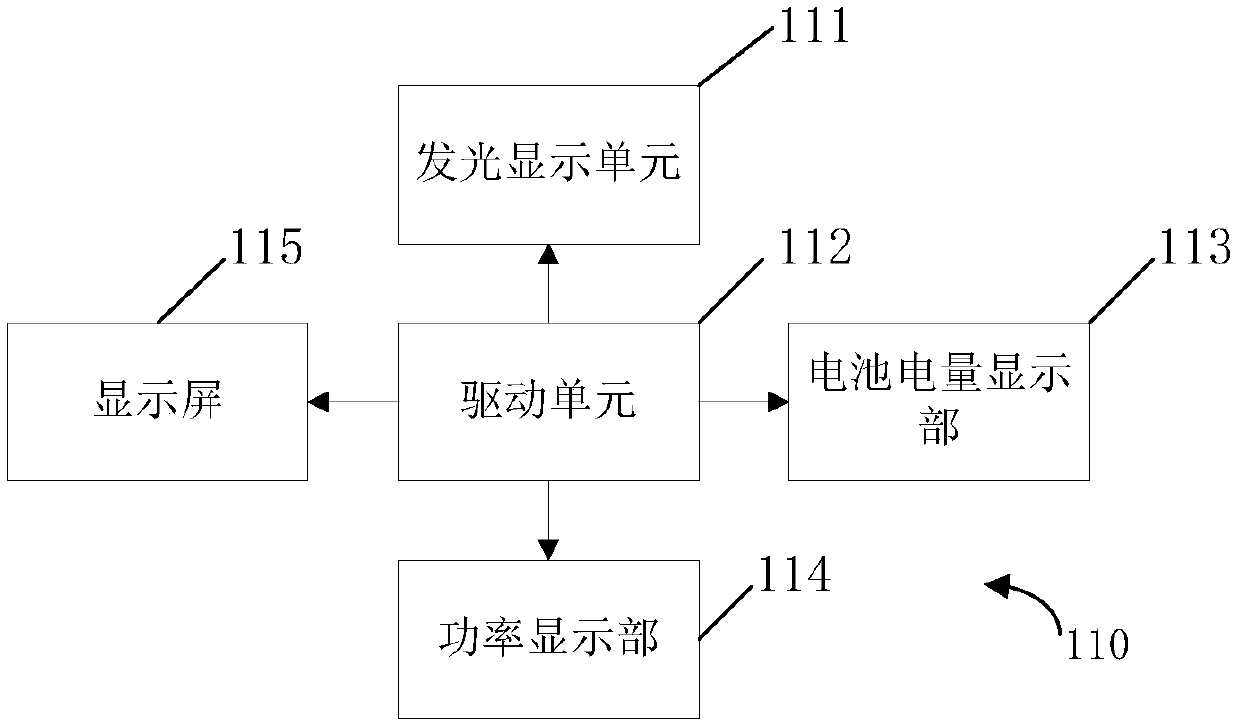

Dust collector speed regulation control system and dust collector

ActiveCN111134565AImprove experienceGet the technical effect of speed regulationElectric equipment installationPower controllerConverters

The invention relates to the field of dust collectors, in particular to a dust collector speed regulation control system and a dust collector. The dust collector speed regulation control system comprises a touch sensing part, a second converter, a second controller and a power control device which are electrically connected in sequence; the touch sensing part is arranged on the surface of a dust collector shell; the second converter is used for receiving touch induction electric signals and converting the touch induction electric signals into power indication signals or rotating speed indication signals which can be identified by the second controller; the second controller is used for receiving the power indication signal or the rotating speed indication signal, and generating a power given signal corresponding to the power indication signal or a rotating speed given signal corresponding to the rotating speed indication signal under the control of an internal control element; and thepower control device is used for controlling a motor of the dust collector to move according to the power given signal or the rotating speed given signal. Compared with the prior art, the technical effect of stepless speed regulation on the dust collector is achieved, and the user experience is improved.

Owner:TIANKE INTELLIGENT TECH CO LTD

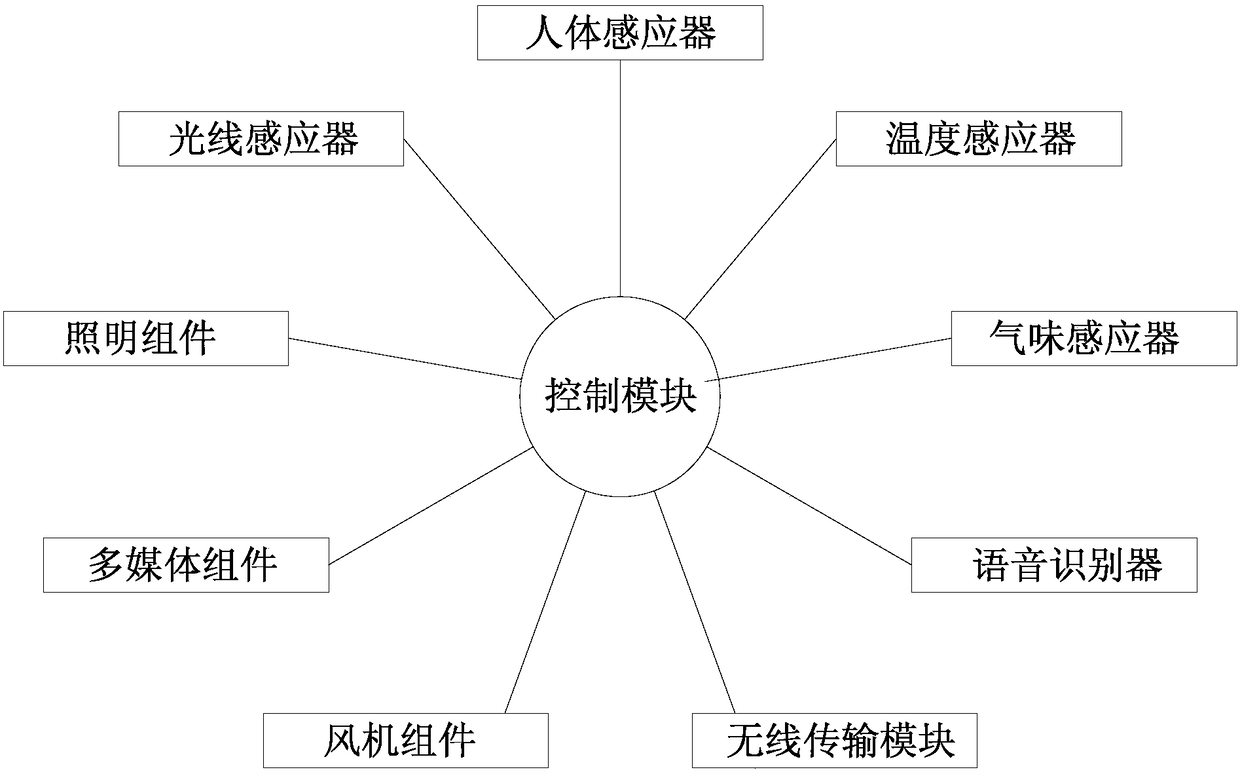

Control method of intelligent range hood without controlling by hands

InactiveCN108224531ARealize automatic speed regulationImprove experienceDomestic stoves or rangesLighting and heating apparatusElectricityWireless transmission

The invention discloses a control method of an intelligent range hood without controlling by hands. The intelligent range hood comprises a control module, wherein the control module is electrically connected with a human body sensor, a light sensor, a temperature sensor, a smell sensor, a voice identifier, a wireless transmission module, a multimedia component, a lighting component, and a draughtfan component. The control method of the intelligent range hood comprises the steps that the human body sensor senses whether a person stays in a range hood working area or not; if a person stays in the range hood working area, the control module enables the range hood to be in an automatic working state, and all the modules and components are enabled; if no person stays in the range hood workingarea, the control module enables the range hood to be in a standby state, and all the modules and components are disabled. The intelligent range hood can turns on or off automatically according to whether the person stays in the working area or not, and the range hood can run intelligently and automatically according to the detected environment state and does not need to be operated by hands.

Owner:GUANGDONE SHUNDE CUNTIAN ELECTRIC APP CO LTD

DC motor home parking garage

ActiveCN105577038BAvoid shockTo achieve the purpose of energy savingAc motor stoppersMechanical energy handlingElectricityDescent direction

Owner:创客帮(山东)科技服务有限公司

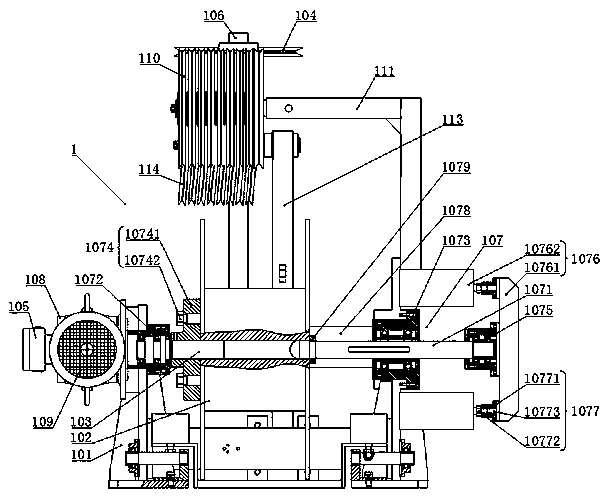

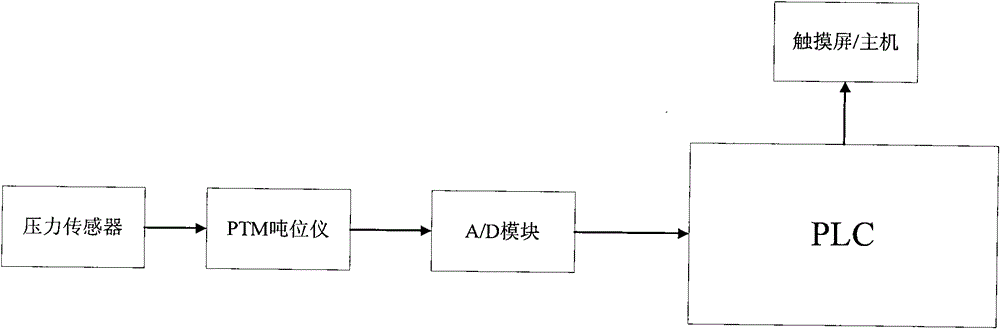

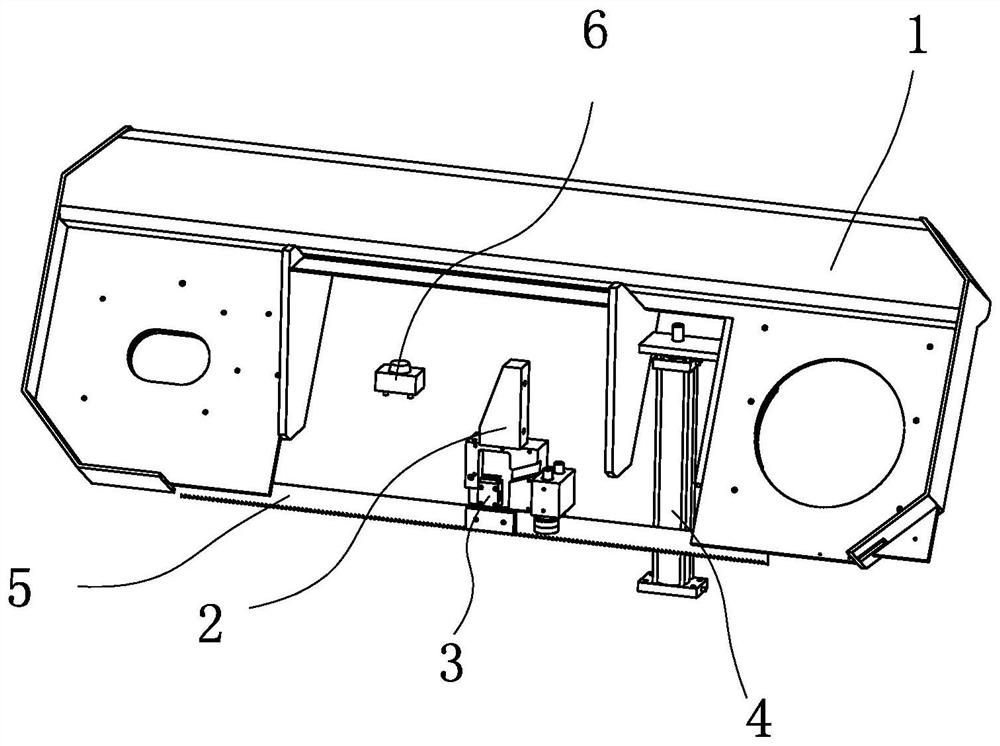

Method and controller for controlling position, pressure measurement and safe control of sliding block of forging machine tool

ActiveCN101819424BLow costSimple structureProgramme controlComputer controlNumerical controlMotor speed

The invention discloses a method and a controller for controlling the position, the pressure measurement and the safe control of a sliding block of a forging machine tool. By the method, the position detection and the pressure monitoring of the sliding block are integrated into a whole; meanwhile, the position and the pressure of the sliding block can be acquired; the position corresponds to the pressure to obtain a position-pressure curve according to the time; the position-pressure curve obtained by multiply acquiring position and pressure data during normal processing is set to be a standard curve; the quality of products can be controlled and production personnel are prompted to find the reasons of faults by using the curve; the controller carries out double-circuit output on control output; double circuits are connected in series; and the controller transmits a control signal to a motor of a numerical control machine tool and automatically adjusts the motor speed according to preset value. The invention integrates the position monitoring of the sliding block and the pressure monitor of the machine tool into a controller and realizes multifunctional control by combining automatic speed regulation, alarm and the like; meanwhile, the invention realizes the quality control of products and the safe and accurate control of the machine tool.

Owner:NANJING ESTUN AUTOMATION CO LTD

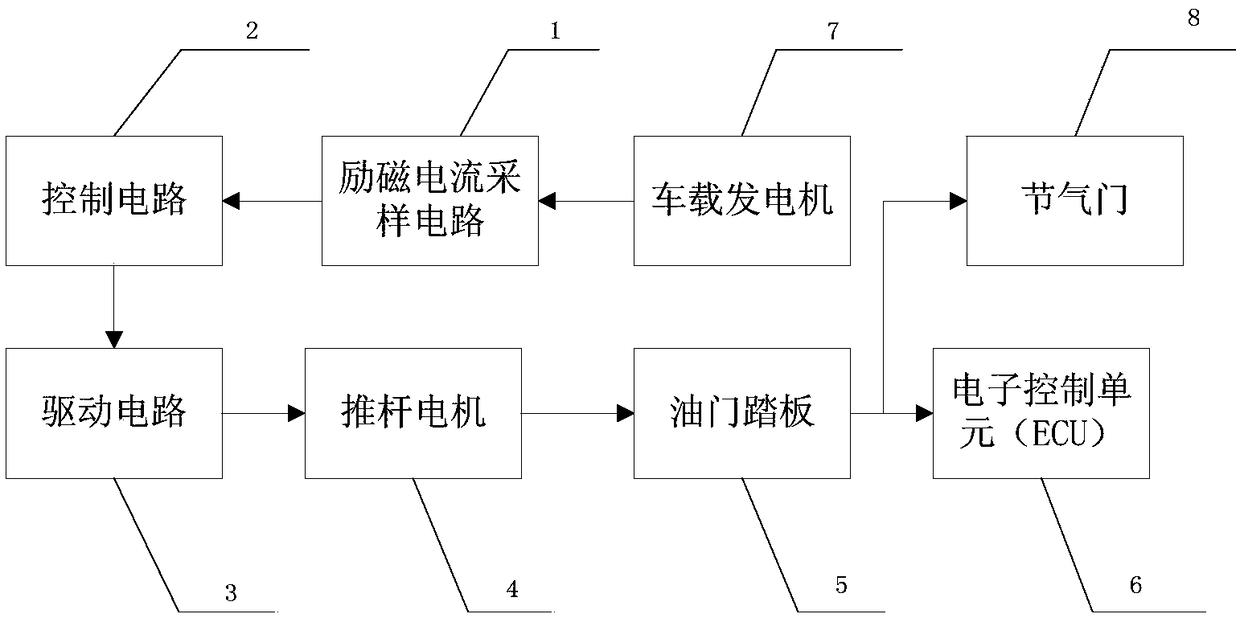

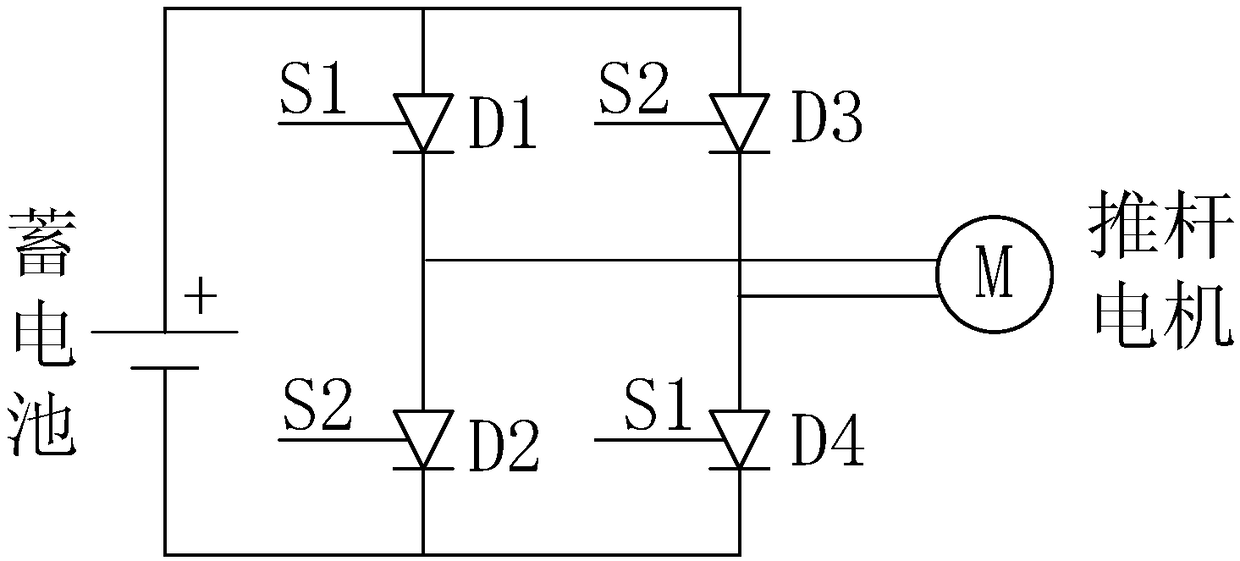

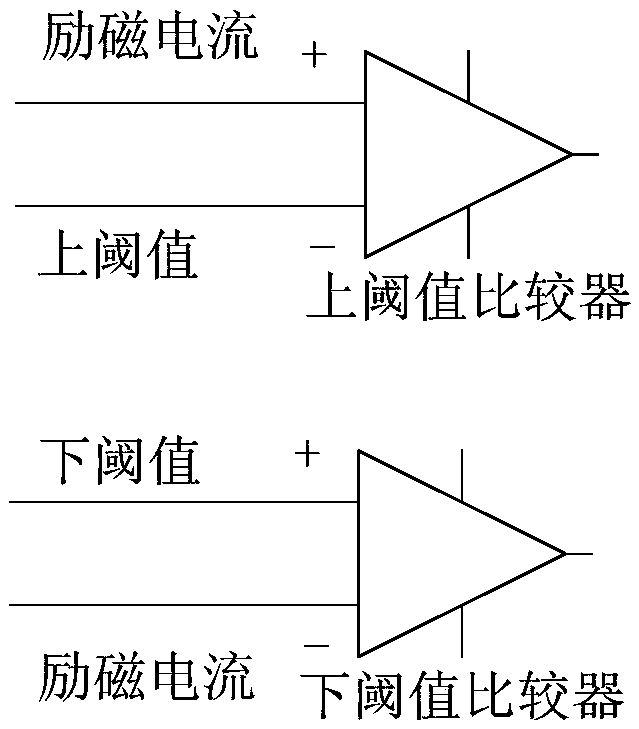

Method and device used for automatic speed regulation of vehicle engine

ActiveCN108625993AReduce manual operationsReduce mechanical wearSpeed sensing governorsMachines/enginesEngineeringControl circuit

The invention provides a method and device used for the automatic speed regulation of an engine when a special vehicle needs more power. The device comprises four parts, namely an exciting current sampling circuit, a control circuit, a driving circuit and a push rod motor. The method used for the automatic speed regulation of the vehicle parking engine is as follows: the exciting current samplingcircuit collects the exciting current value of a vehicle-mounted generator in real time; the control circuit judges whether the exciting current value is in a normal threshold range or not; and if exciting current exceeds the threshold and output power cannot meet load power, the control circuit outputs a positive voltage driving signal, a positive voltage driving axle arm of the driving circuit is electrified, the push rod motor clockwise rotates, the extension length of a push rod is longer, an accelerator pedal is pressed, the stroke is increased, and the rotating speed of the engine increases; and when the exciting current is lower than the threshold interval, the control circuit outputs a negative voltage driving signal, a negative voltage driving axle arm of the driving circuit is electrified, the push rod motor counterclockwise rotates, the extension length of the push rod is shorter, the stroke of the accelerator pedal is reduced, and the rotating speed of the engine decreases.

Owner:BEIJING PULIMEN ELECTRO MECHANICAL HIGH TECHN CO

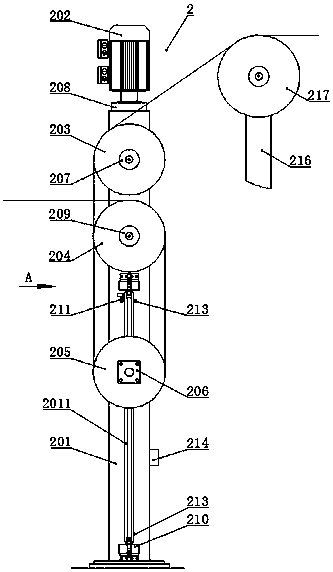

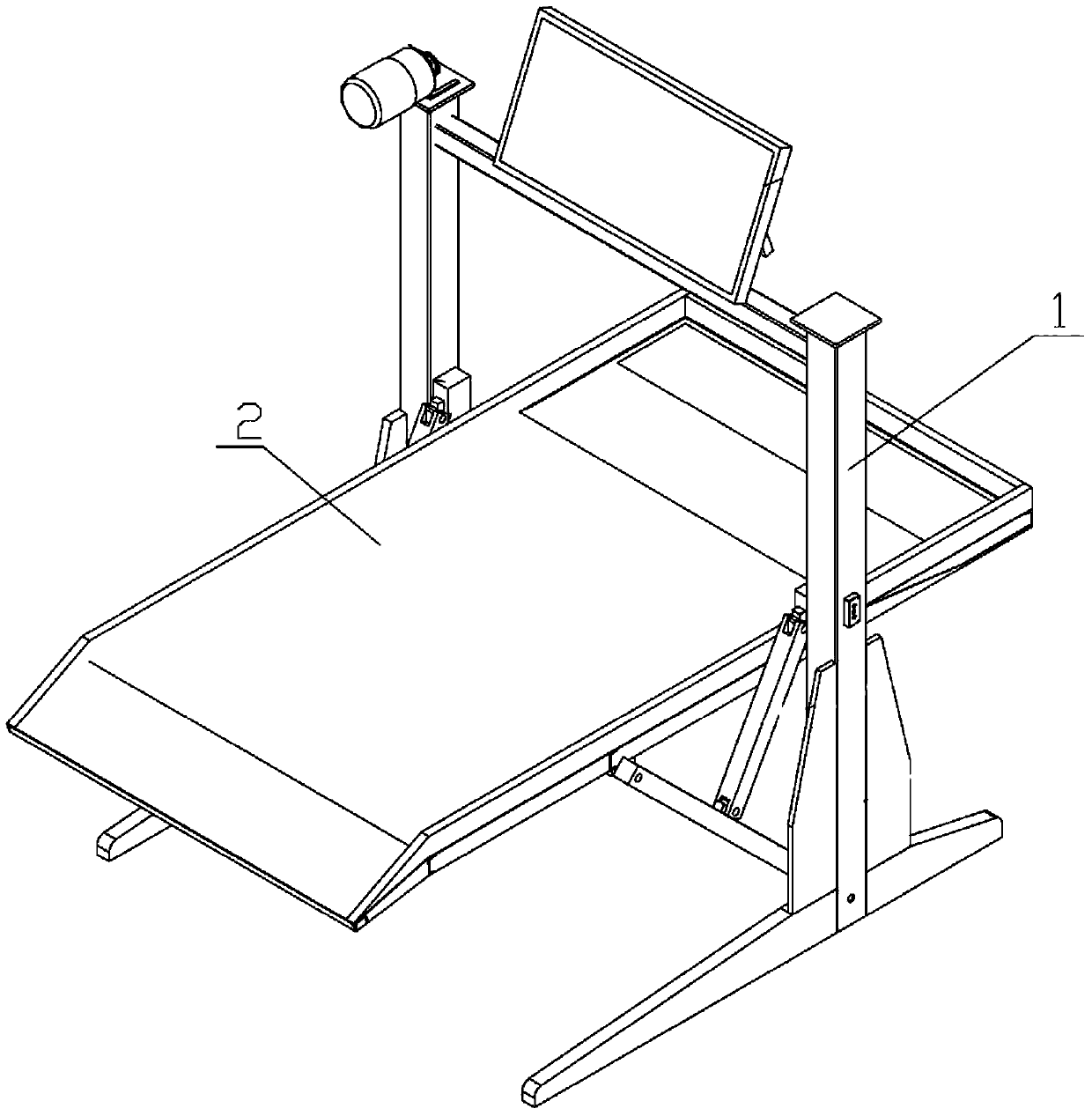

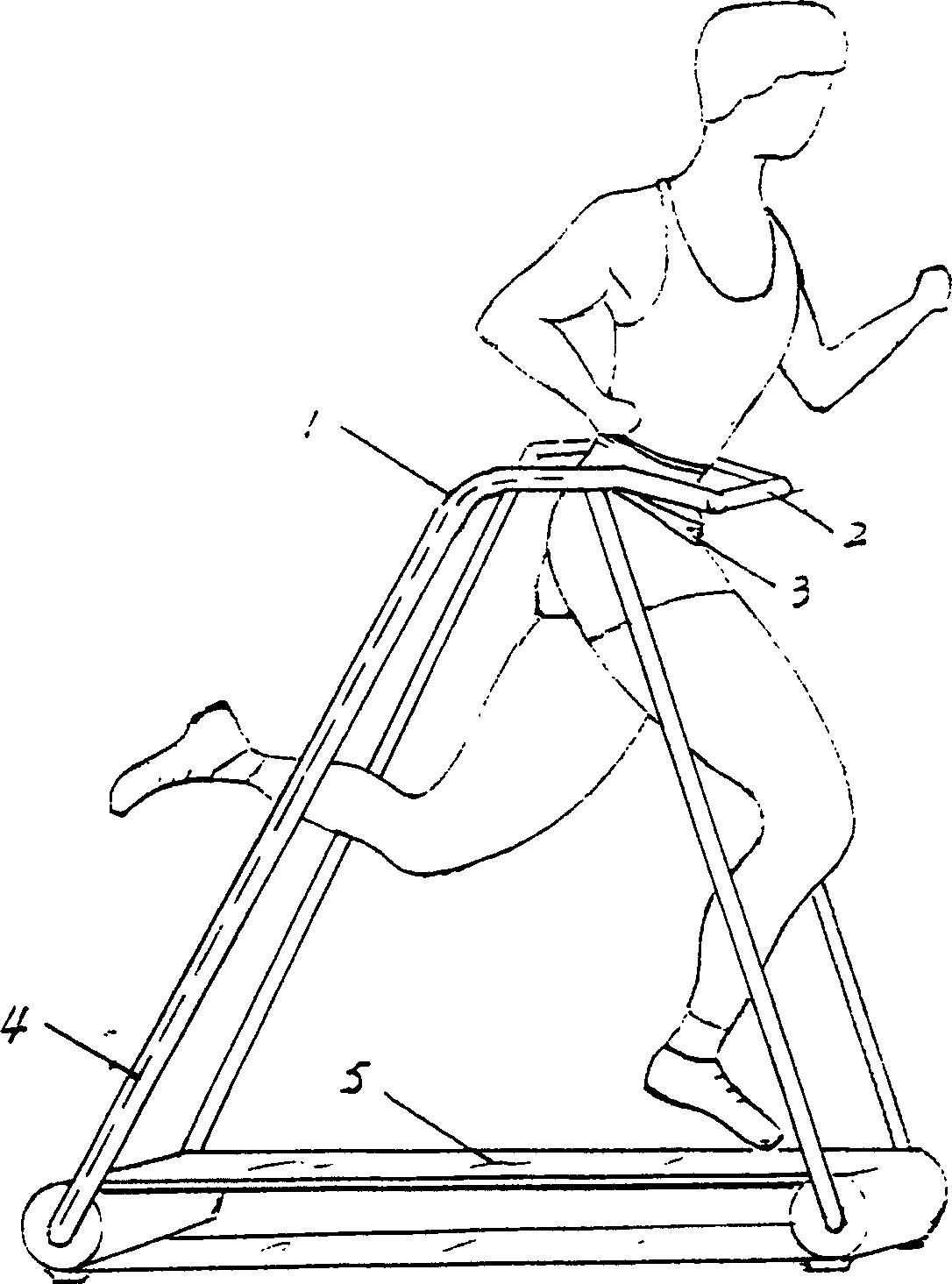

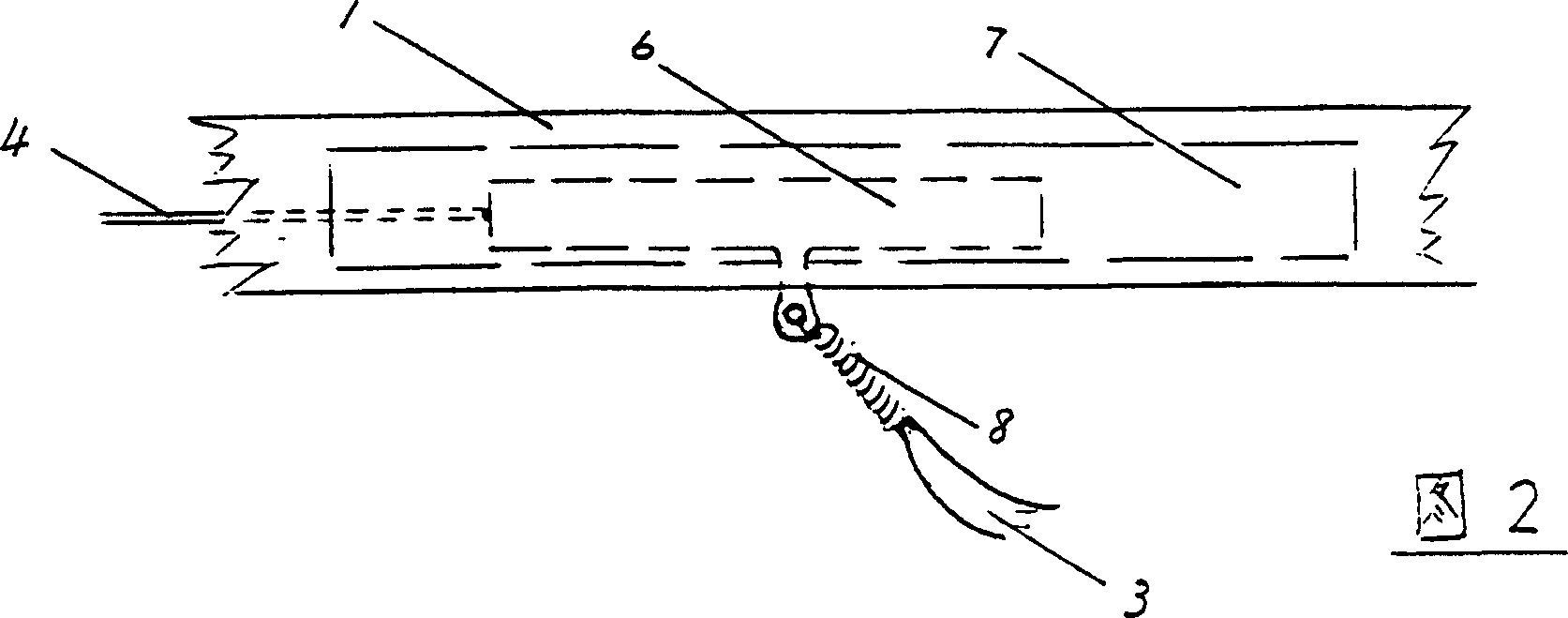

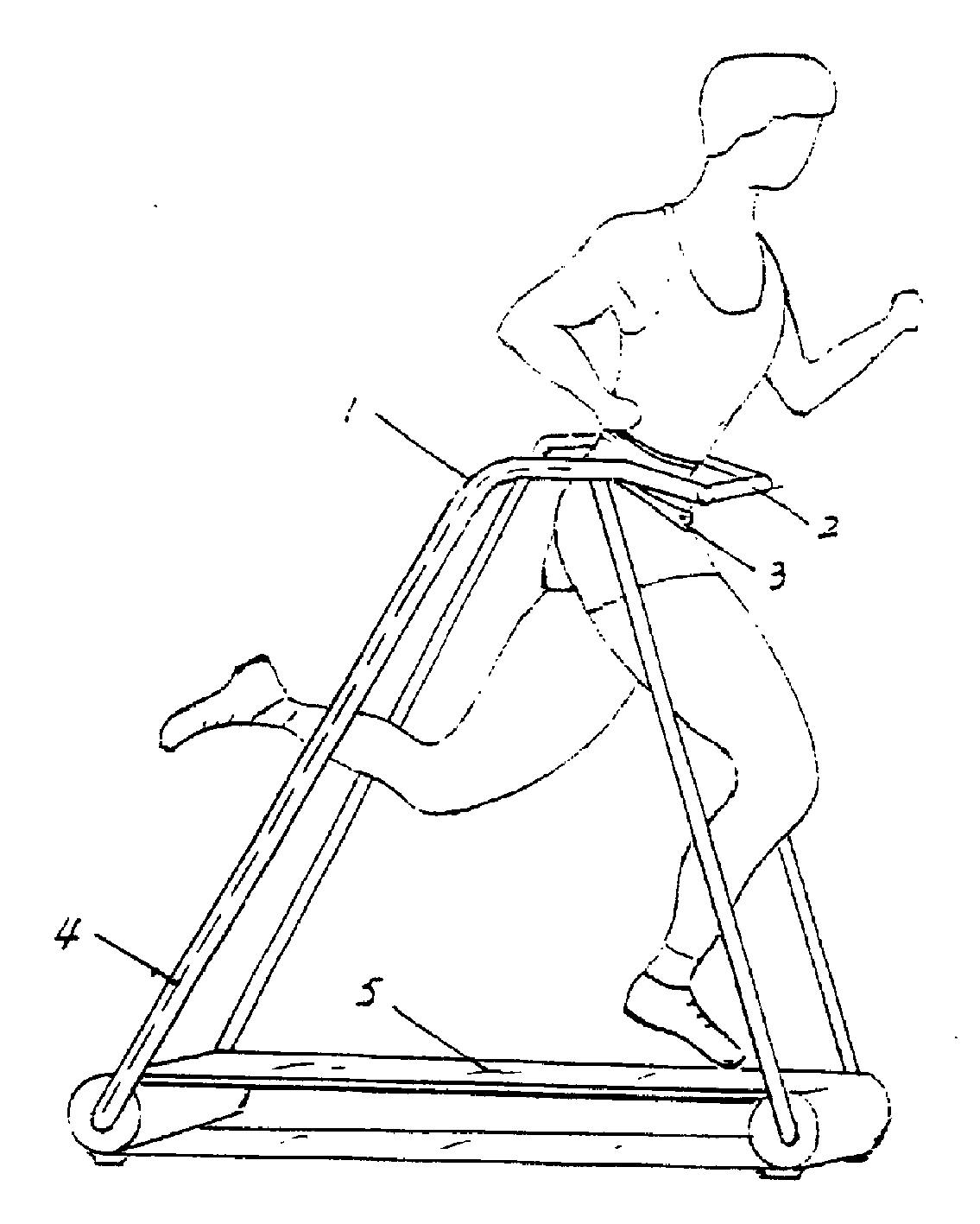

Traction-type automatic speed-regulating walking-running machine

InactiveCN1218759CPlay the role of anti-fallEasy to masterMovement coordination devicesCardiovascular exercising devicesEngineeringRunway

The traction automatic speed-regulating walking and running machine is characterized by that it has an electric runway identical to that of general electric running machine, its front portion has no the devices of handrail, etc. and its two sides are equipped with foldable support respectively, a stretch band is cross-connected between upper ends of two supports, said stretch band is connected with the speed-regulating device of the electric runway by a traction rope. When it is used, firstly the hip is wrapped by said stretch band, and when the person starts to walk or run, the stretch band can be controlled tightly. The traction force can be transferred into the speed-regulating device by traction rope to start electric runway, when the walking or running speed is changed.

Owner:高锡庚

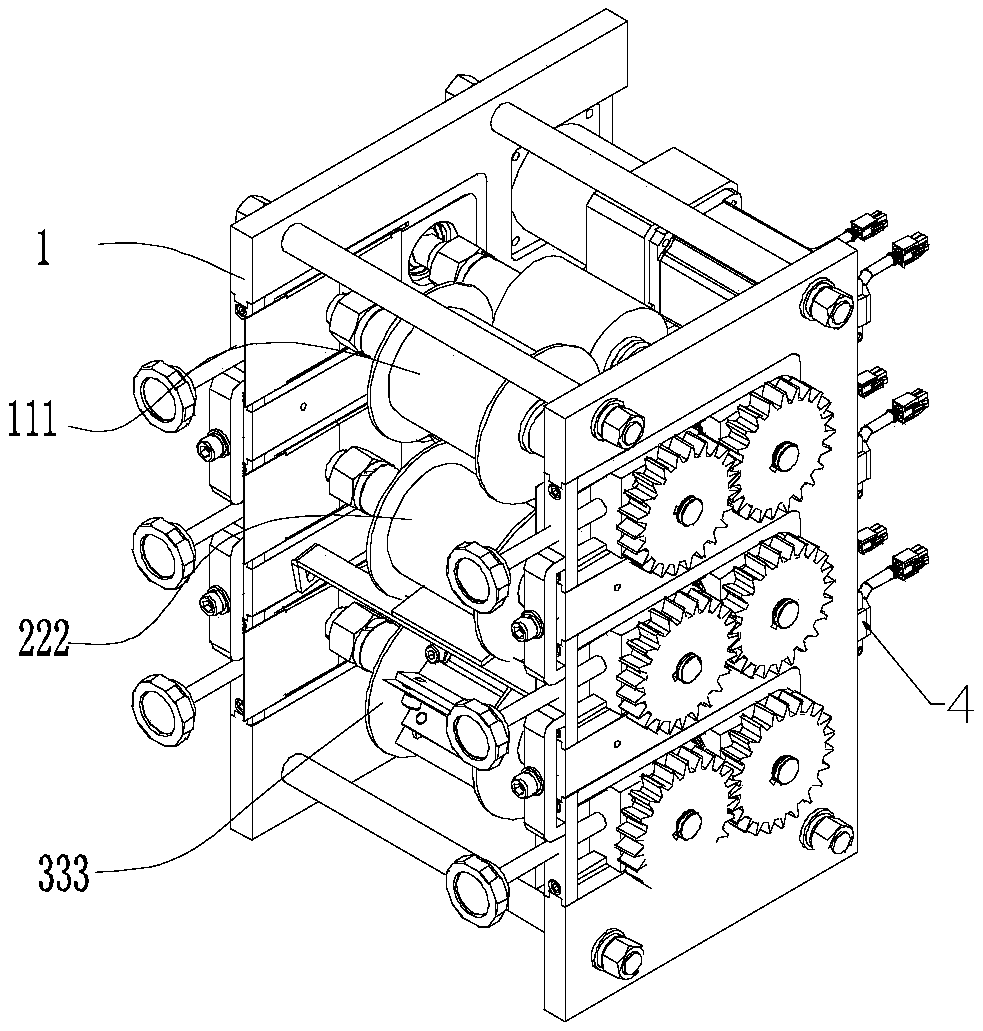

Sectional cutting mechanism of food cut-flower machine

PendingCN109176663AGuaranteed uniformityImprove quality and efficiencyMetal working apparatusCut flowersEngineering

The invention provides a sectional cutting mechanism of a food cut-flower machine, and relates to the technical field of food processing machinery. The technical problems that the working efficiency of wrapper raw materials in the strip cutting process is low, and the cutting is not uniform easily are solved. The device comprises a machine frame, wherein a driving device and two rolling wheels which are synchronously rotate in the opposite direction are arranged in the machine frame, and the driving device and the two rolling wheels are in transmission through gears; the two rolling wheels comprise a feeding rolling wheel and a cutting-off rolling wheel, a plurality of cutters are uniformly mounted on the circumference of the cutting rolling wheel, wrapper is clamped between the feeding rolling wheel and the cutting-off rolling wheel, the rolling wheel is driven by the feeding roller to cut off the rolling wheel, and the wrapper is evenly cut into strips according to the set length. According to the sectional cutting mechanism, the wrapper is uniformly cut into the strips through the cutting rolling wheel under the driving of the feeding rolling wheel, so that the uniformity of thewrapper cutting can be ensured, and the surface quality and the working efficiency of products are improved; and meanwhile, under the friction force of the feeding rolling wheel, the sectional cutting mechanism enters the next food processing procedure, so that the labor cost is reduced, and the management is facilitated.

Owner:LUOHE HENGFENG MACHINERY MOLD

Windscreen wiper control system capable of realizing automatic speed regulation

InactiveCN107697024ARealize automatic speed regulationHigh sensitivityVehicle cleaningMicrocontrollerMicrocomputer

The invention relates to a windscreen wiper control system capable of realizing automatic speed regulation. The windscreen wiper control system comprises an audio collecting device, a windscreen wiperdevice and a control device, wherein the audio collecting device is used for identifying and collecting sound waves which are generated when rainwater drops to hit the automobile glass, and transmitting the sound wave signals to the control device; the windscreen wiper device comprises a windscreen wiper and a drive motor which is connected with the windscreen wiper; the control device comprisesa single chip microcomputer and a memory, wherein the memory is used for storing the sound waves which are generated when rainwater of different amount drops to hit the automobile glass; and the control device is connected with the audio collecting device and the windscreen wiper motor through a signal line and is used for controlling the speed regulation of the drive motor according to the soundwave signal results sensed by the audio collecting device. According to the windscreen wiper control system disclosed by the invention, the audio collecting device is used for sensing and measuring the amount of rainfall, and transmitting the sensed signals to the control device; the sensed signals are compared with the sound waves which are generated by the hitting of drop rainwater against the automobile glass for different amount of rainfall and are stored in the control device; the wiping speed of the windscreen wiper is controlled through the control device; and automatic speed regulationis realized.

Owner:NANJING LVZHICHENG PATENT TECH DEV CO LTD

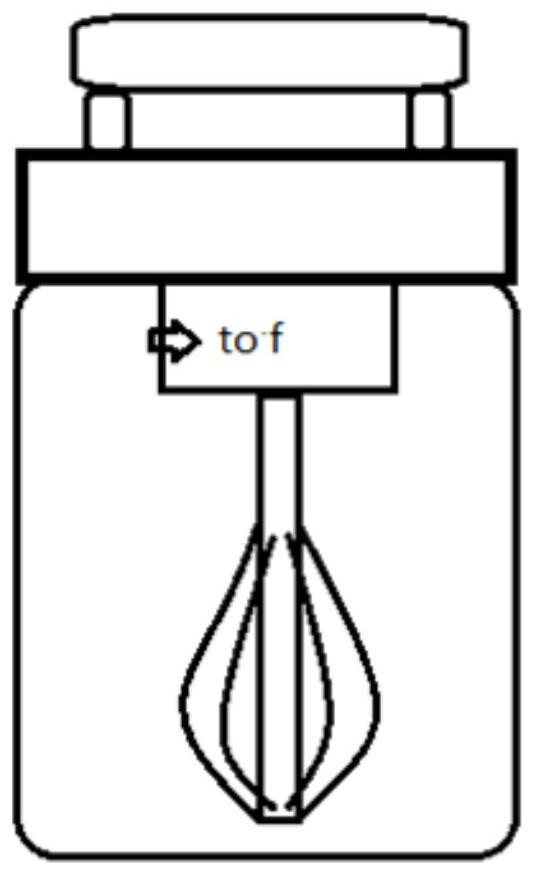

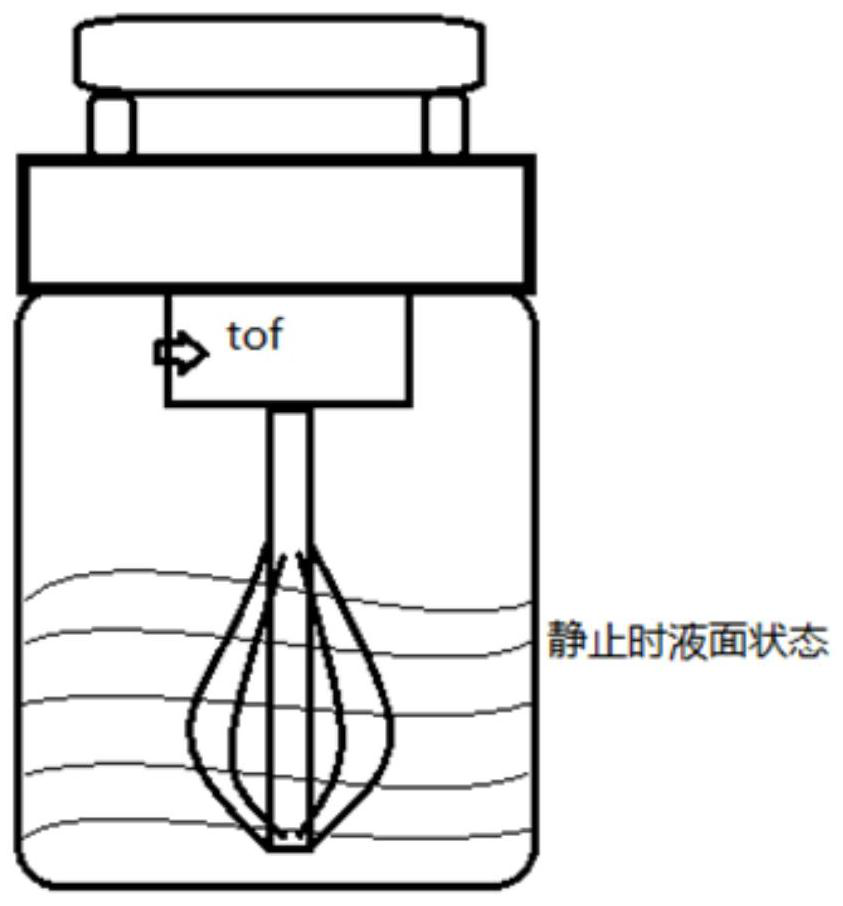

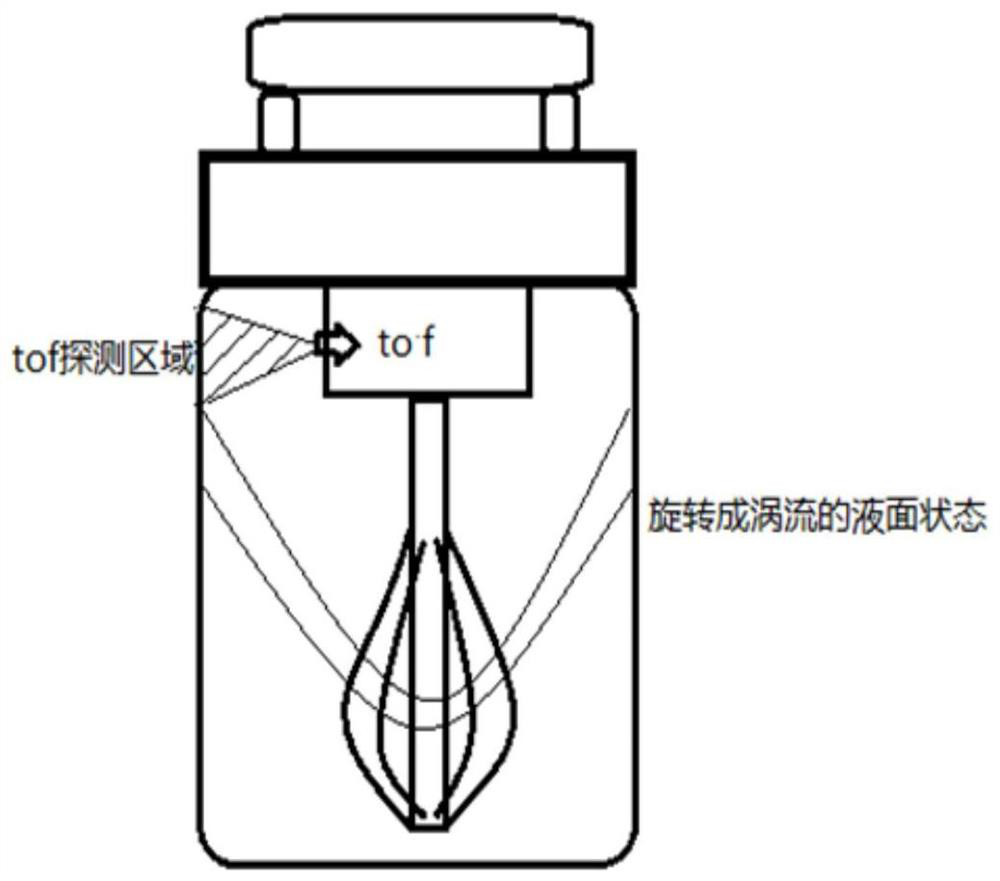

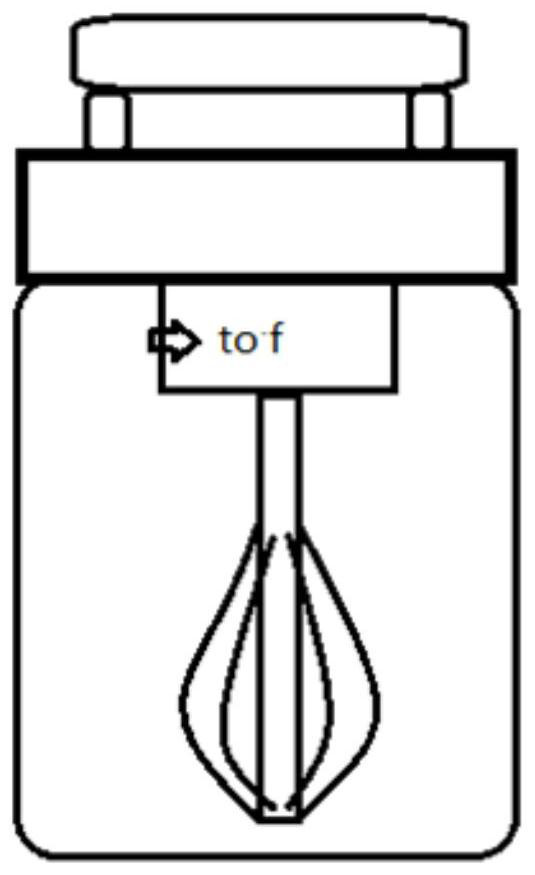

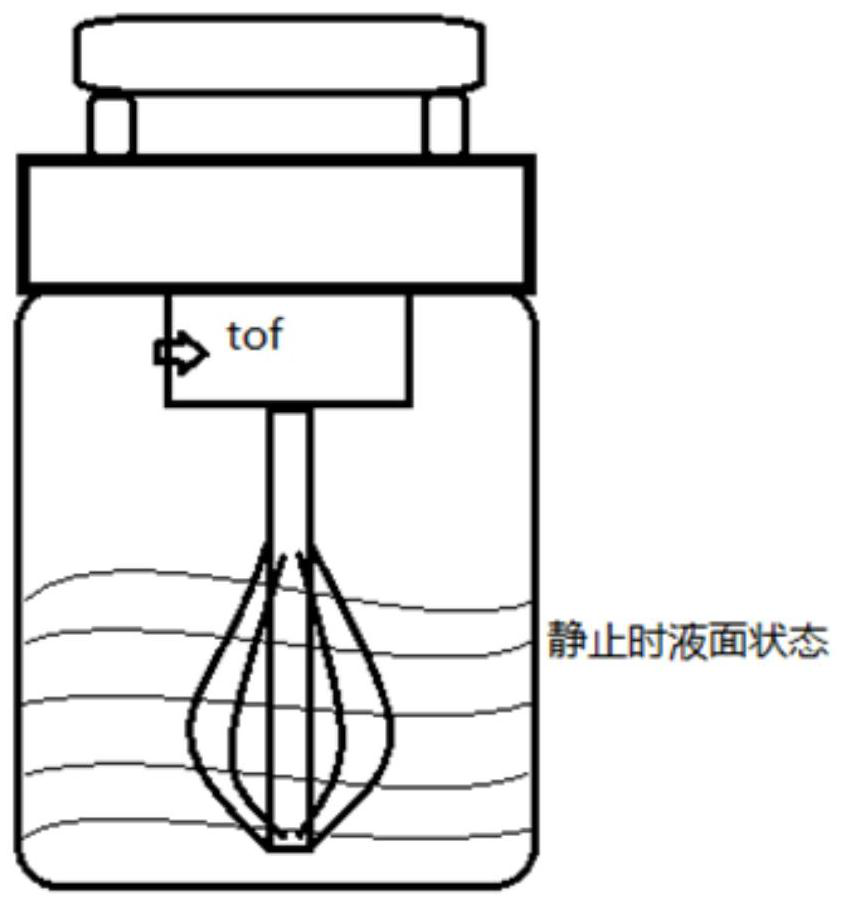

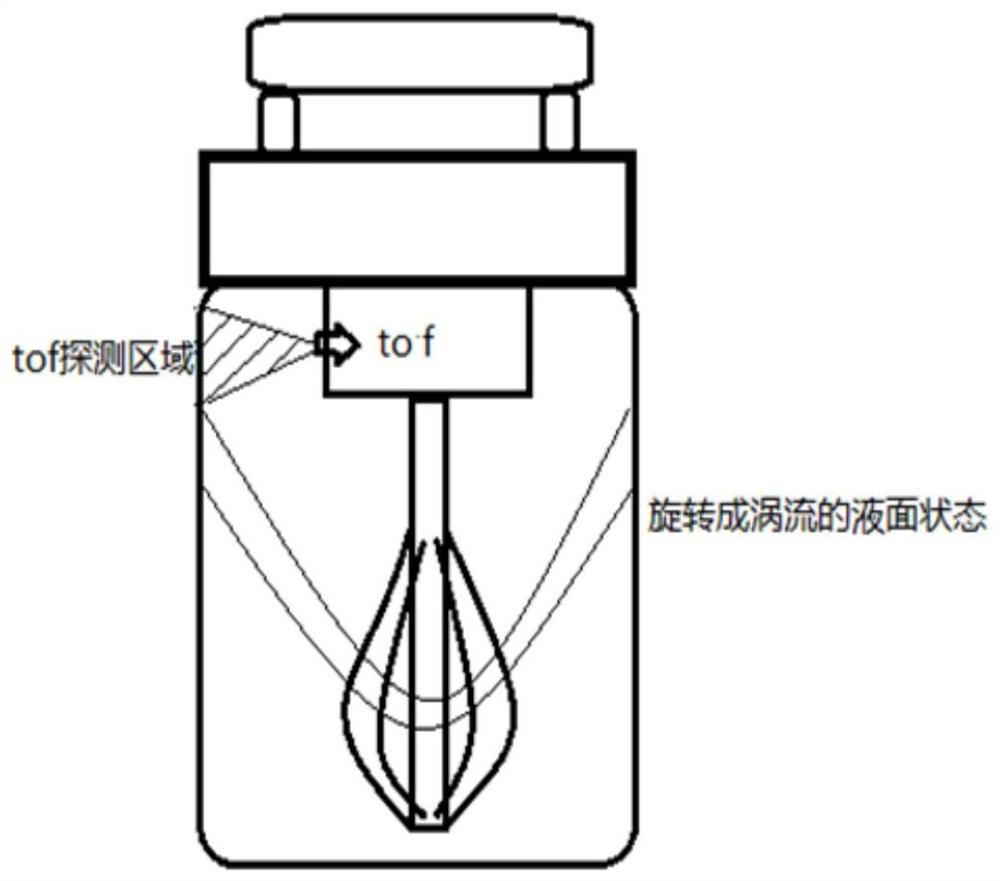

Household automatic speed regulation stirrer and control method thereof

ActiveCN111802930AWon't overflowRealize automatic speed regulationKitchen equipmentSpeed/accelaration control using electric meansHome useElectric machine

The invention relates to the field of household appliances, discloses a household automatic speed regulation stirrer and a control method thereof, whichsolve the problems that an existing household stirrer cannot perform automatic stepless speed regulation and is not intelligent enough. The stirrer comprises a controller, a motor and a distance measuring module, wherein the distance measuring module and the motor are electrically connected with the controller; the distance measuring module is used for detecting distance information of a detection area on the inner wall of the stirrer containerand transmitting the detected distance information to the controller; the controller is used for using the distance information detected by the distance measuring module to establish a model for calibrating a detection area when the stirrer system is started, after the system is started,the distance information detected by the distance measuring module is compared with the model, whether the edgeheight of the content in the stirrer container reaches the lower limit height of the detection area or not is judged, if so, the motor is controlled to keep the current rotating speed, and if not, the motor is controlled to increase the speed step by step until the upper edge height of the content in the stirrer container reaches the lower limit height of the detection area.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

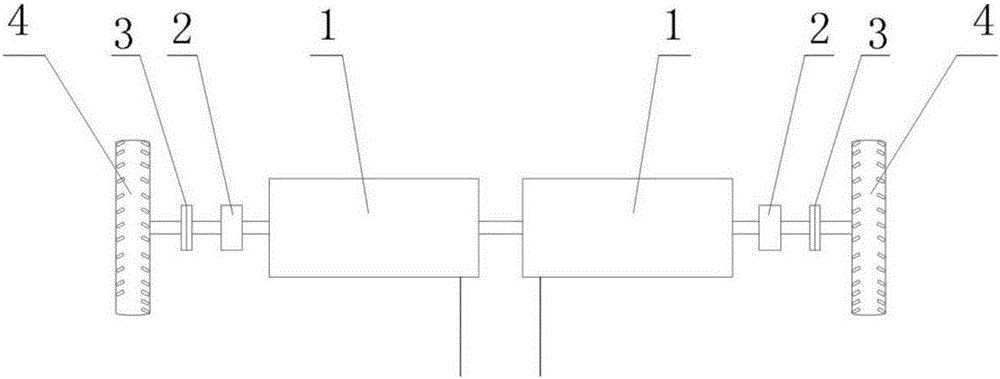

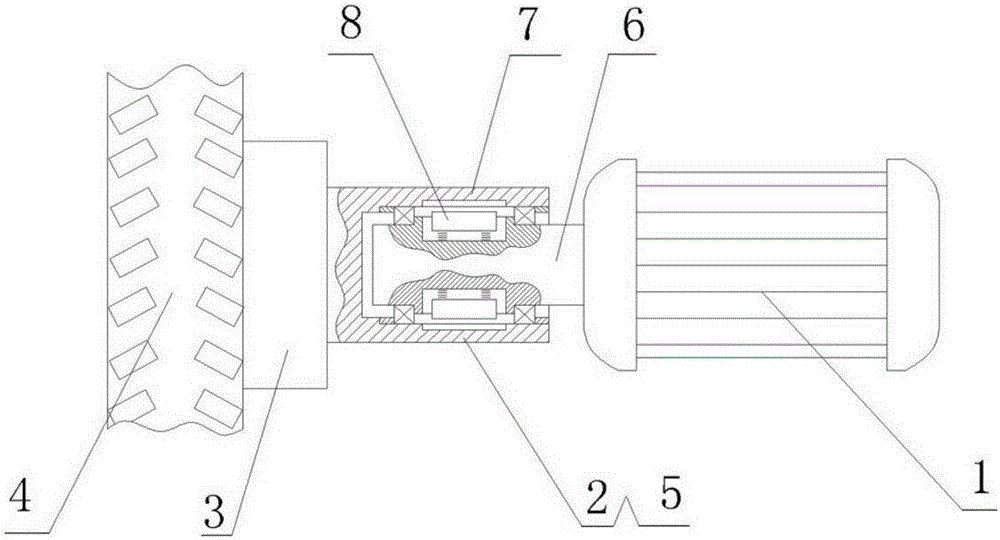

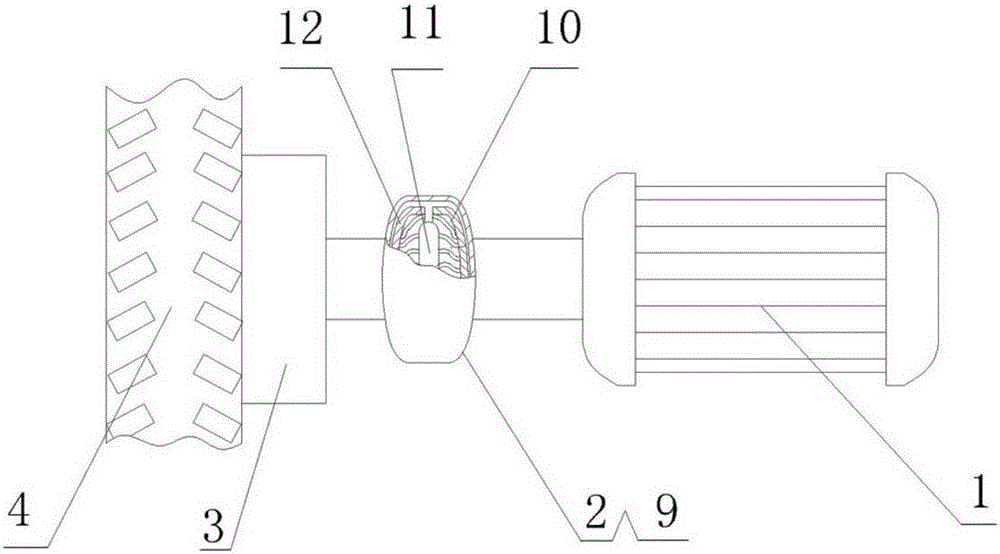

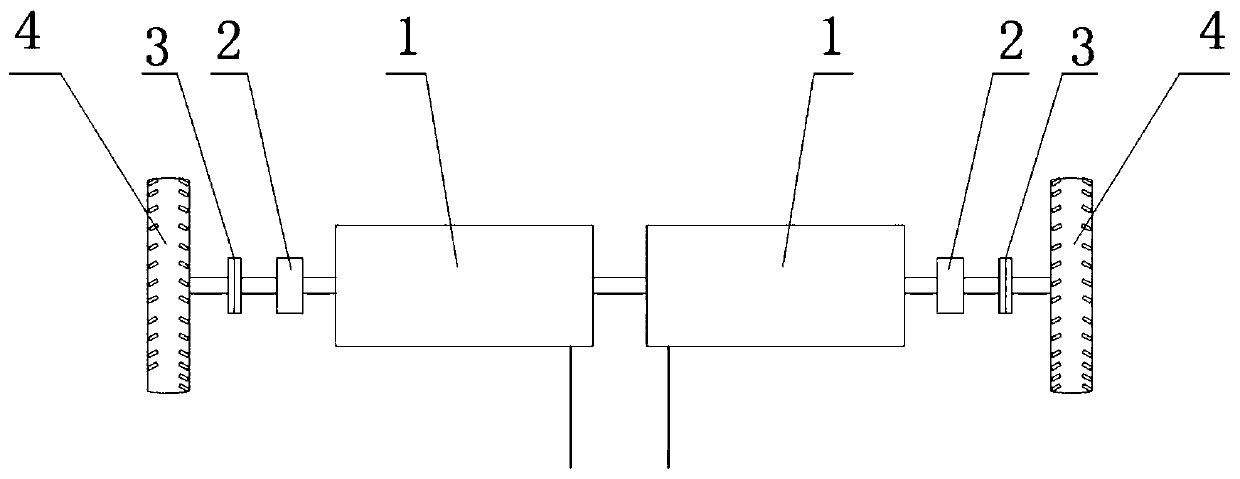

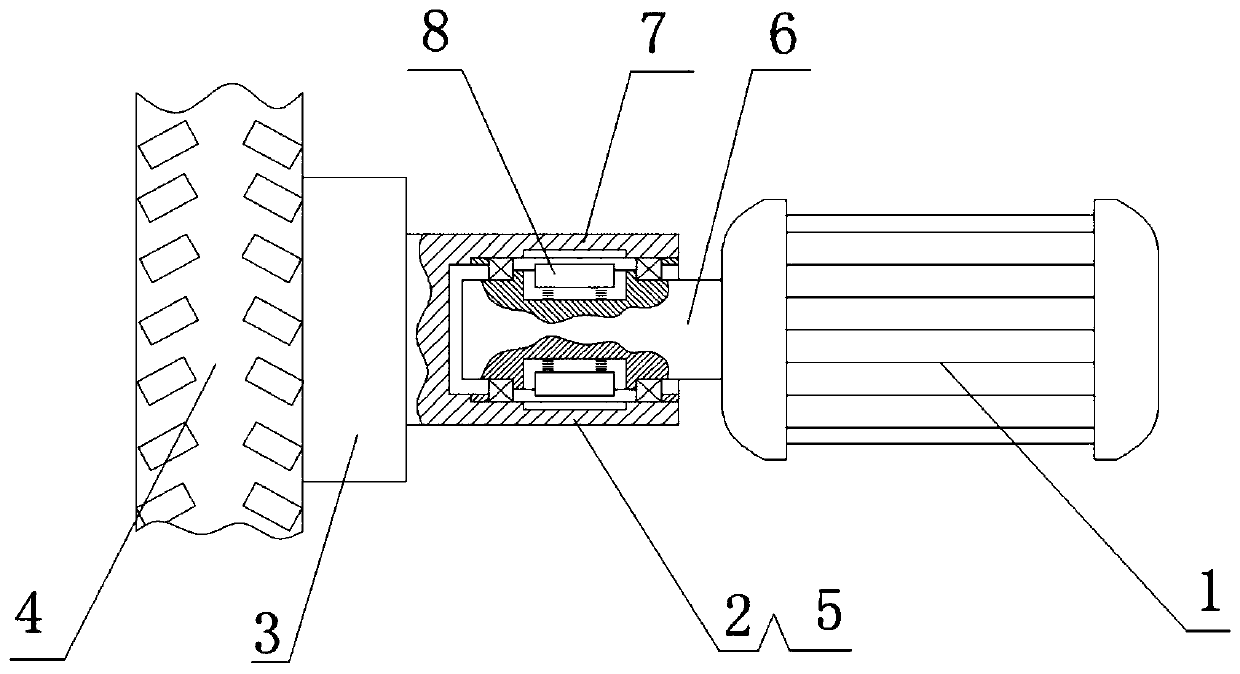

Electric truck

ActiveCN106379161ARealize automatic speed regulationReduce speedControl devicesDrive wheelWork performance

The invention relates to a load-carrying vehicle, i.e. an electric truck. Power output shafts of motors (1) drive driving wheels (4) through speed changers (3); and the electric truck is characterized in that clutches (2) are arranged between the power output shafts of the motors (1) and the speed changers (3). The electric truck has the beneficial effects that rigid driving is changed into flexible driving, so that automatic speed adjustment is realized; when the electric truck is started or passes through a ridge, the rotating speed can be automatically reduced, and the traction is increased, so that the capacity of crossing an obstacle is obviously improved; the specification of the same type of motor is substantially reduced, the working performance is stable and reliable, and the engine is not liable to stop; and the electric truck is particularly suitable for high-load transportation such as a mine.

Owner:中工际华重工(青岛)有限公司

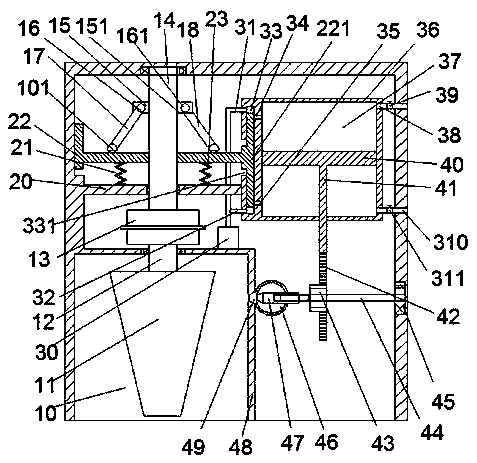

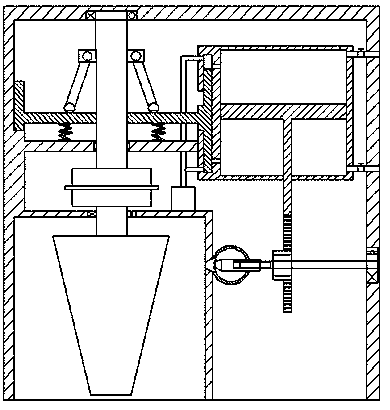

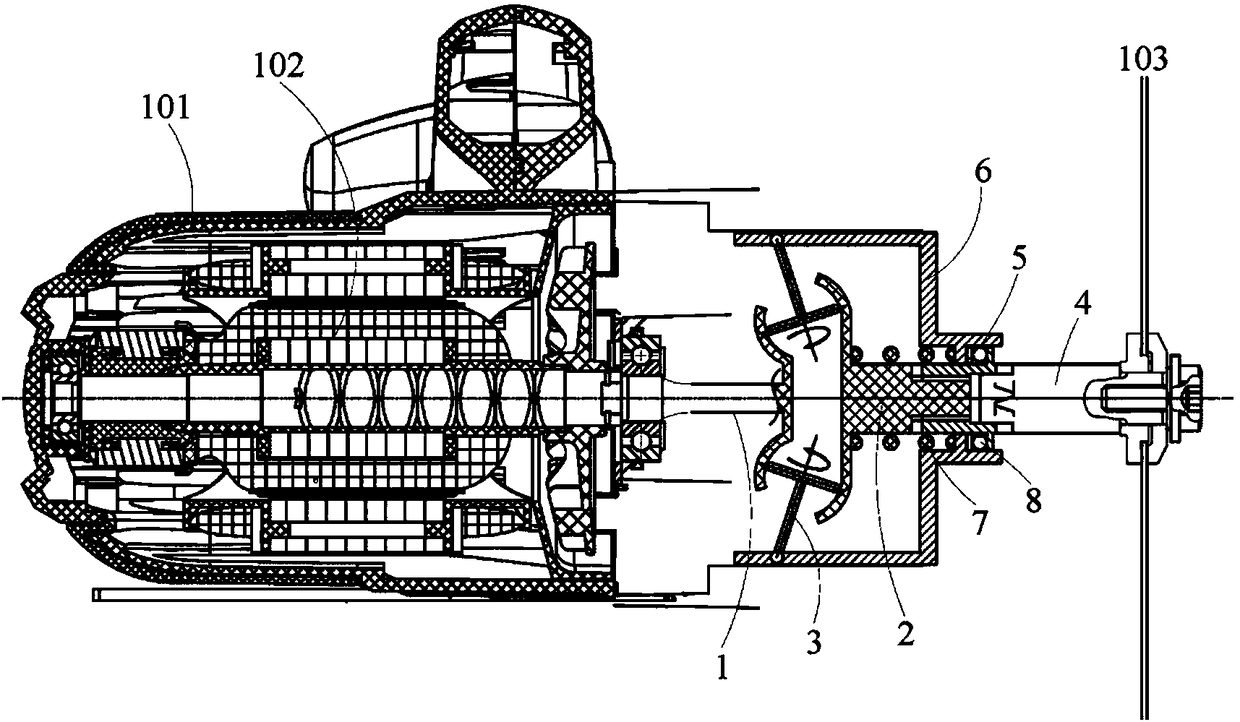

Speed regulating device for rotating arm of single cylinder turbine

InactiveCN108930560AGet Connected WorkSimple structureMachines/enginesEngine controlHydraulic cylinderReduction drive

The invention discloses a speed regulating device for a rotating arm of a single cylinder turbine. The device comprises a main box body. A turbine cavity is formed in the lower part of the left side in the main box body, a speed reducer is arranged on the upper part of the turbine cavity, an oil pump is arranged on the right part of the speed reducer, a fixed plate is arranged on the upper part ofthe speed reducer, a first fixed spring and a second fixed spring are arranged on the fixed plate, a transverse sliding plate is arranged at the upper end of each spring, a rotating arm is arranged on the upper part of the transverse sliding plate, a hydraulic cylinder is arranged on the right side of the rotating arm, a sliding cavity is formed in the left side wall of the hydraulic cylinder, asecond rotating shaft is arranged at the bottom of the hydraulic cylinder, a gear is arranged on the second rotating shaft, an air injection cavity is formed in the left side of the gear, a slide block is arranged in the air injection cavity, and the slide block can regulate the size of an air injection nozzle, so that the rotating speed of the turbine is regulated to achieve the regulating purpose.

Owner:叶丛杰

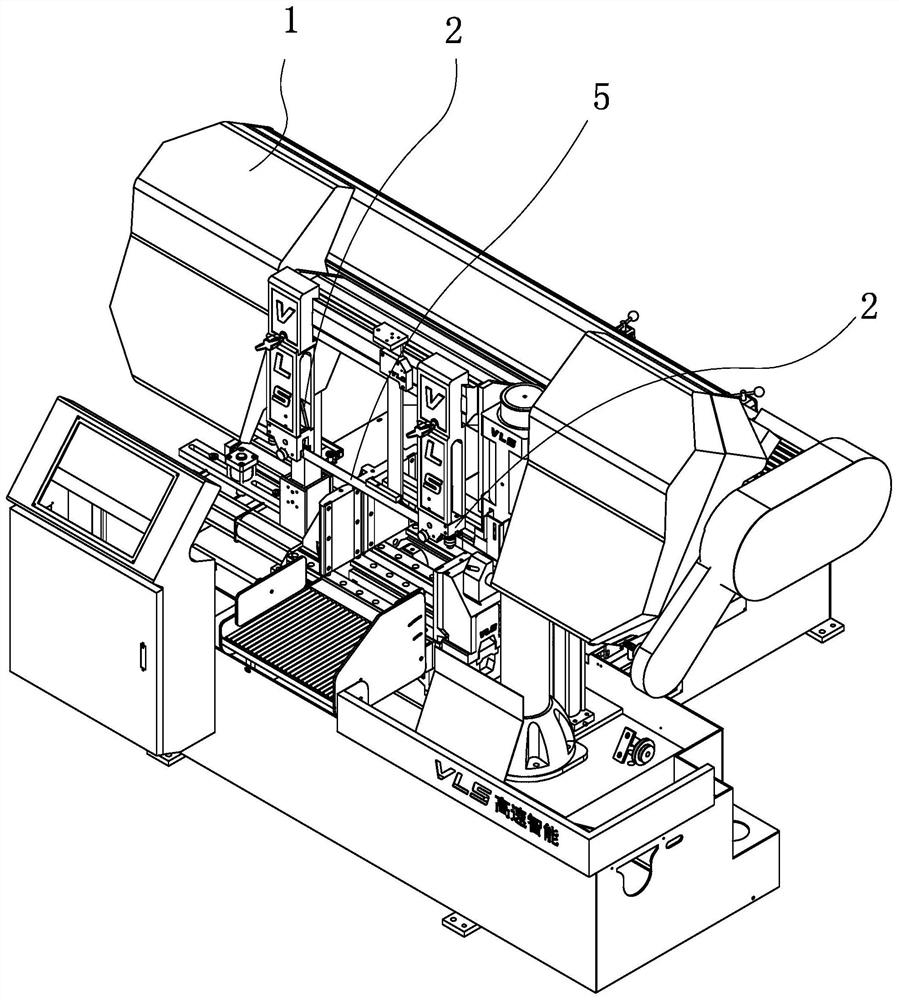

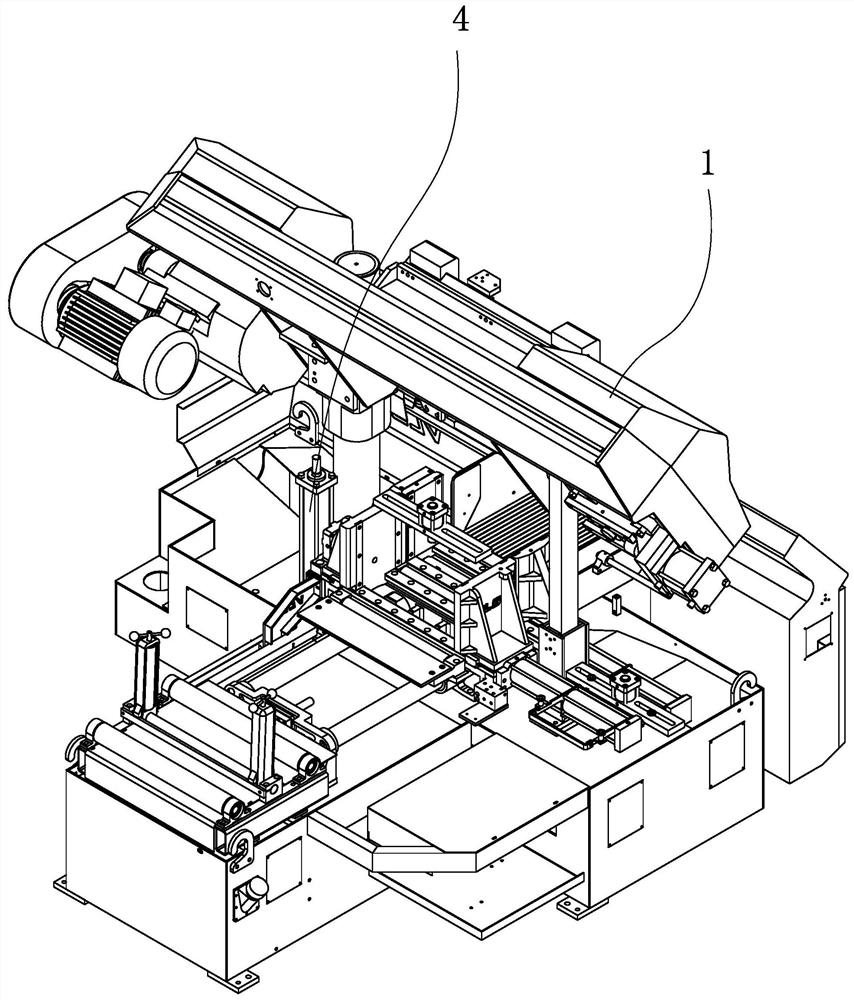

Saw band feeding automatic speed changing sawing machine

InactiveCN113351938ARealize automatic speed regulationShort lifeMetal sawing devicesMetal sawing accessoriesControl engineeringReaction speed

The invention discloses a saw band feeding automatic speed changing sawing machine which comprises a saw frame, a lifting device used for controlling lifting of a saw band, a guide assembly arranged on the saw frame and the saw band fixed to the guide assembly. The guide assembly comprises a clamping device used for fixing the saw band and a speed adjusting valve used for controlling the lifting speed of the lifting device. The speed regulating valve communicates with the lifting device through an oil path. According to the saw band feeding automatic speed changing sawing machine, automatic speed adjusting of saw band feeding is achieved, the response speed is high, and speed changing is accurate; the service life of the saw band is prolonged.

Owner:ZHEJIANG WEILISHI MACHINE

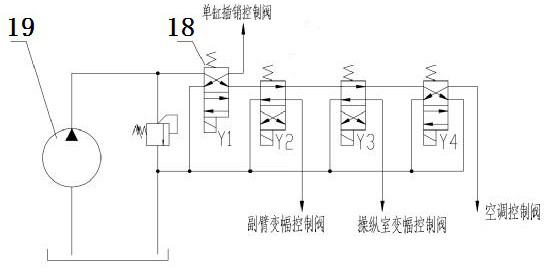

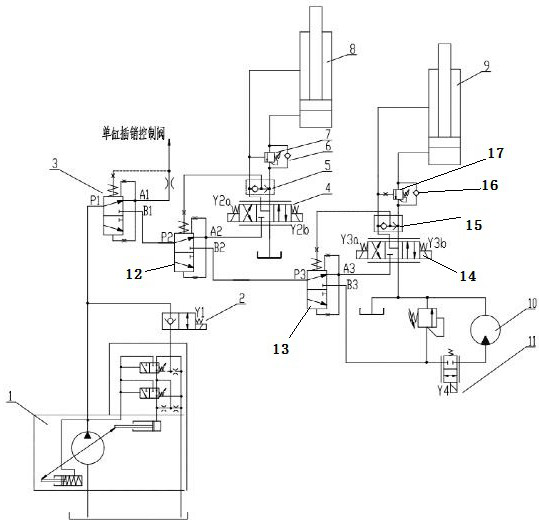

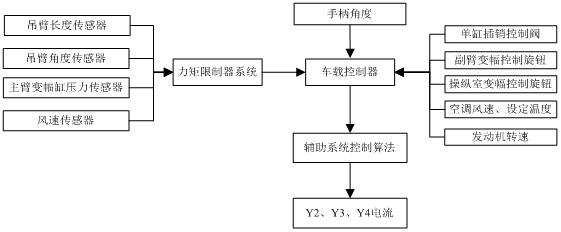

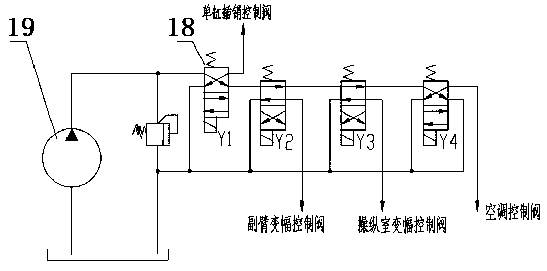

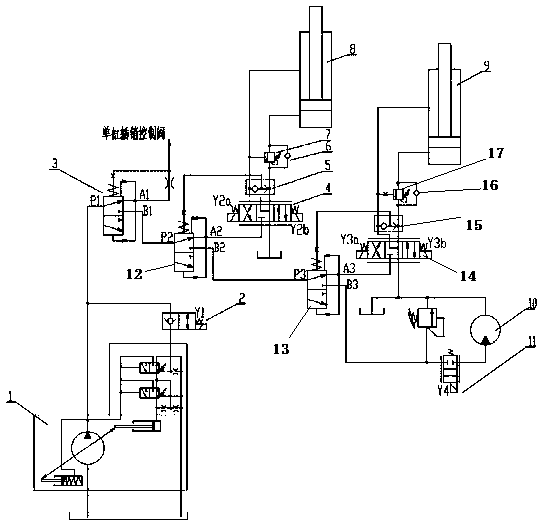

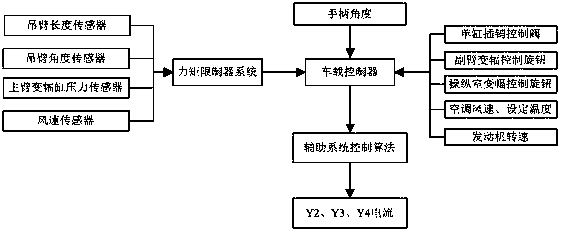

Wheel Crane Auxiliary System and Control Method

ActiveCN110526140BTo achieve priority allocationRealize automatic speed regulationServomotor componentsServomotorsFour-way valveControl valves

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

A household automatic speed-adjusting mixer and its control method

ActiveCN111802930BWon't overflowRealize automatic speed regulationKitchen equipmentSpeed/accelaration control using electric meansHome useElectric machine

The invention relates to the field of household electrical appliances, and discloses a household automatic speed-regulating mixer and a control method thereof, which solves the problem that the existing household mixer cannot perform automatic stepless speed regulation and is not intelligent enough. The mixer includes a controller, a motor and a ranging module, the ranging module and the motor are electrically connected to the controller; the ranging module is used to detect the distance information of the detection area on the inner wall of the mixer container and transmit the detected distance information to the controller The controller is used to establish a model for calibrating the detection area by using the distance information detected by the ranging module when the mixer system is started. After the system is started, the distance information detected by the ranging module is compared with the model to judge the mixer container. Whether the edge height of the content in the container reaches the lower limit height of the detection area, if so, the control motor maintains the current speed, if not, the control motor increases step by step until the upper edge height of the content in the mixer container reaches the lower limit height of the detection area.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

electric truck

ActiveCN106379161BRealize automatic speed regulationReduce speedControl devicesDrive wheelWork performance

Owner:中工际华重工(青岛)有限公司

Tire crane auxiliary system and control method

ActiveCN110526140ATo achieve priority allocationRealize automatic speed regulationServomotor componentsServomotorsElectricityFour-way valve

The invention discloses a tire crane auxiliary system and a control method. The tire crane auxiliary system comprises a single-cylinder bolt control valve, an auxiliary arm variable-amplitude oil cylinder, a control cabin variable-amplitude oil cylinder and an air conditioner motor, a constant-pressure pump is connected with a two-position two-way valve, and an oil outlet of the constant-pressurepump is connected with the first priority valve; the first priority valve is respectively connected with the single-cylinder bolt control valve and a second priority valve, the second priority valve is respectively connected with an electric proportional three-position four-way valve II and a third priority valve,the third priority valve is respectively connected with an electric proportional three-position four-way valve III and an electric proportional two-position two-way valve IV, and the electric proportional two-position two-way valve IV is connected with the air conditioner motor. According to the present invention, different priorities are set for all the auxiliary actions, several actions can be controlled at the same time, but also the flow can be preferentially supplied to the system with the high priority. The beneficial effects are that the flow priority distribution can be better realized, so that the multi-action compounding is realized; the automatic speed regulation ofthe actions, such as fly jib amplitude variation, control cabin amplitude variation, air conditioning, etc., is realized; the responsiveness of the system is improved, and the waste of the redundantflow is avoided.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

A Speed Regulation Method of Engine Cooling Fan Based on PID Algorithm

ActiveCN106368790BChange speedRealize automatic speed regulationCoolant flow controlPump controlControl signalDrive motor

The invention relates to a speed regulation method based on the PID algorithm for an engine cooling fan. An electronic control unit (ECU) of an engine controls the rotation speed of the cooling fan. The method includes the steps that 1, in the running process of an automobile, a temperature sensor of engine coolants transmits temperature signals of the engine coolants to the ECU of the engine; 2, the temperature signals are processed by the ECU of the engine, and the ECU of the engine outputs control signals to a PID controller; and 3, the PID controller regulates the rotation speed of a drive motor according to the received control signals, the drive motor changes the rotation speed of the cooling fan, and a cooling fan sensor collects the rotation speed information of the cooling fan and feeds back the rotation speed information of the cooling fan to the ECU of the engine. According to the method, the speed of the cooling fan can be automatically regulated.

Owner:张家港长安大学汽车工程研究院

Automatic speed regulation system of ball milling machine and method therefor

InactiveCN102179278BSimple structureImprove work efficiencyGrain treatmentsSignal processing circuitsTransducer

The invention relates to the field of milling engineering machinery, in particular to a ball milling machine. An automatic speed regulation system for the ball milling machine comprises a ball milling machine main body, a strain transducer, and a wireless signal receiving module; the ball milling machine main body is connected with an electric motor; the ball milling machine main body is providedwith a ball milling machine cover; the outer side of the bottom of the ball milling machine cover is directly contacted with the interior of the ball milling machine main body; the strain transducer is connected with a signal processing circuit; the signal processing circuit is connected with a wireless signal emission module; the wireless signal receiving module is connected with a speed regulation signal circuit; the input end of the speed regulation signal circuit is also connected with a rotation speed detection device; the speed regulation signal circuit is connected with a speed regulator; and the speed regulator is connected with the electric motor. An automatic speed regulation method for the ball milling machine comprises the following steps of: 1) acquiring data; 2) processing and analyzing the data; and 3) regulating the speed and controlling. The speed regulation system has a simple structure and can fulfill the aim of automatic grinding, and by the speed regulation method, the working efficiency of the ball milling machine can be effectively improved.

Owner:SHANDONG UNIV OF TECH

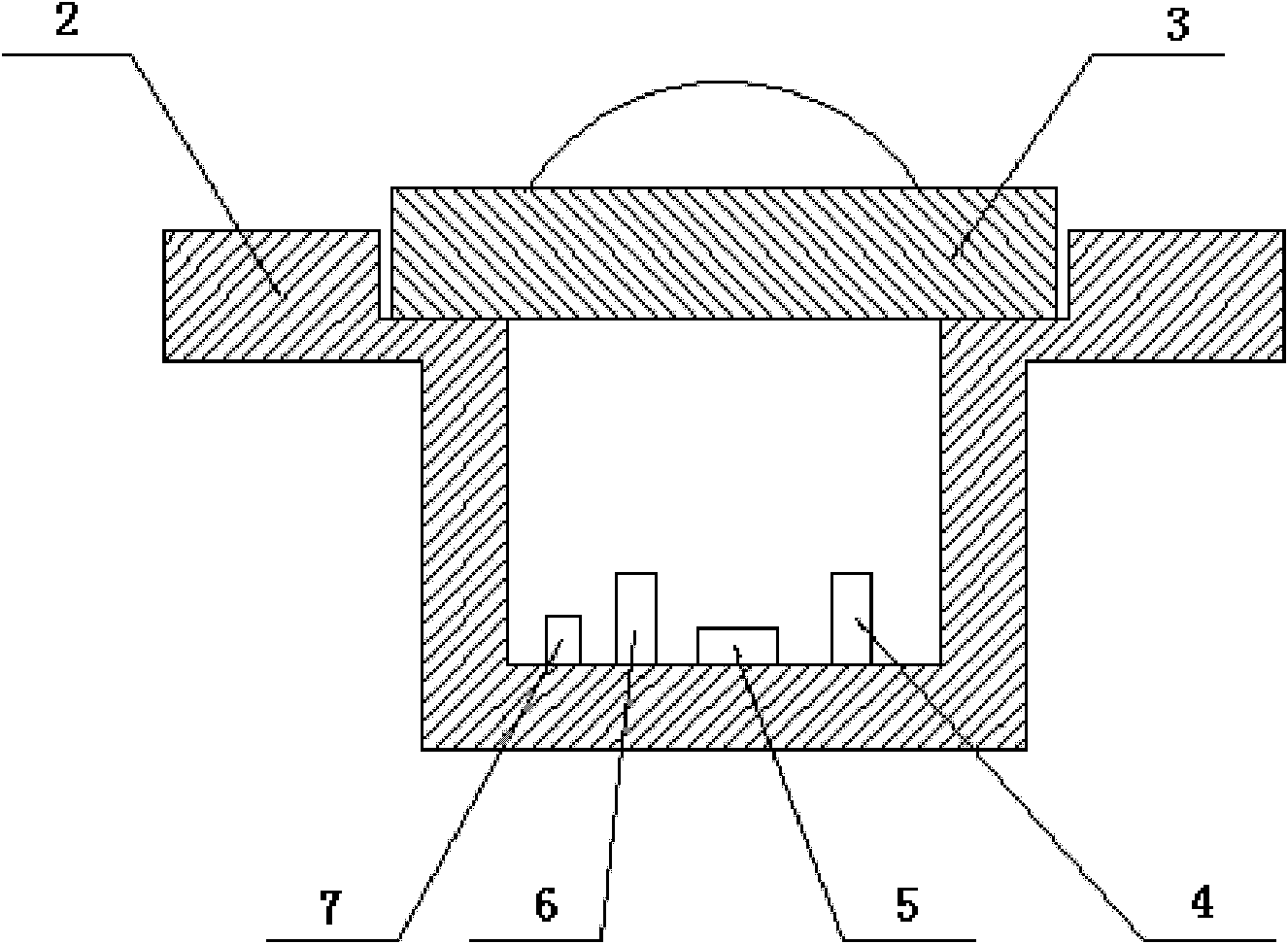

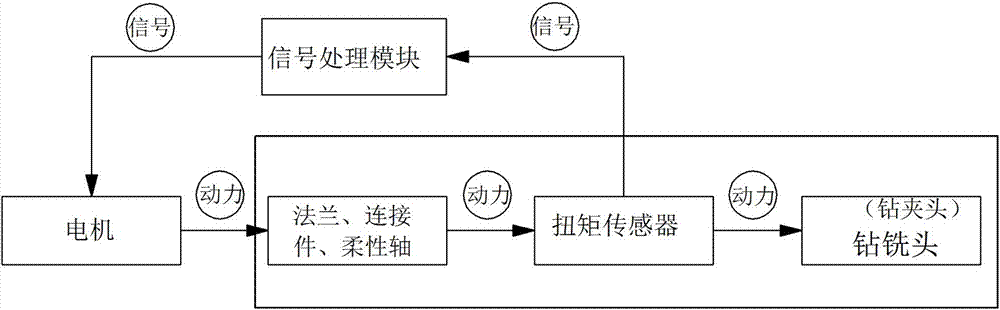

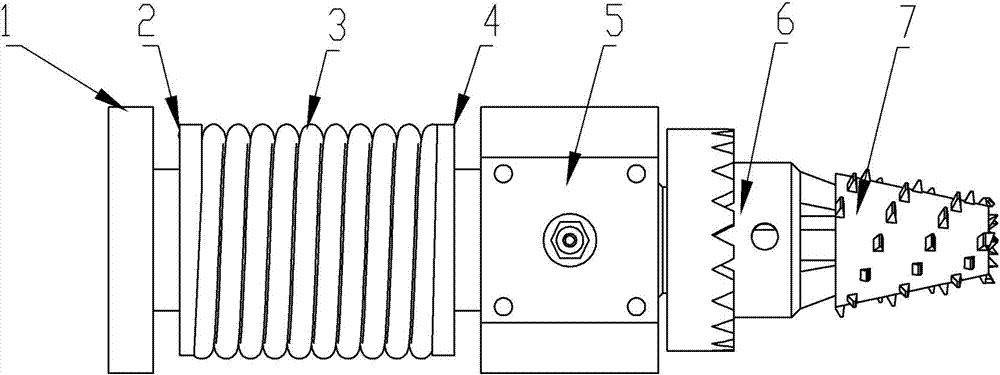

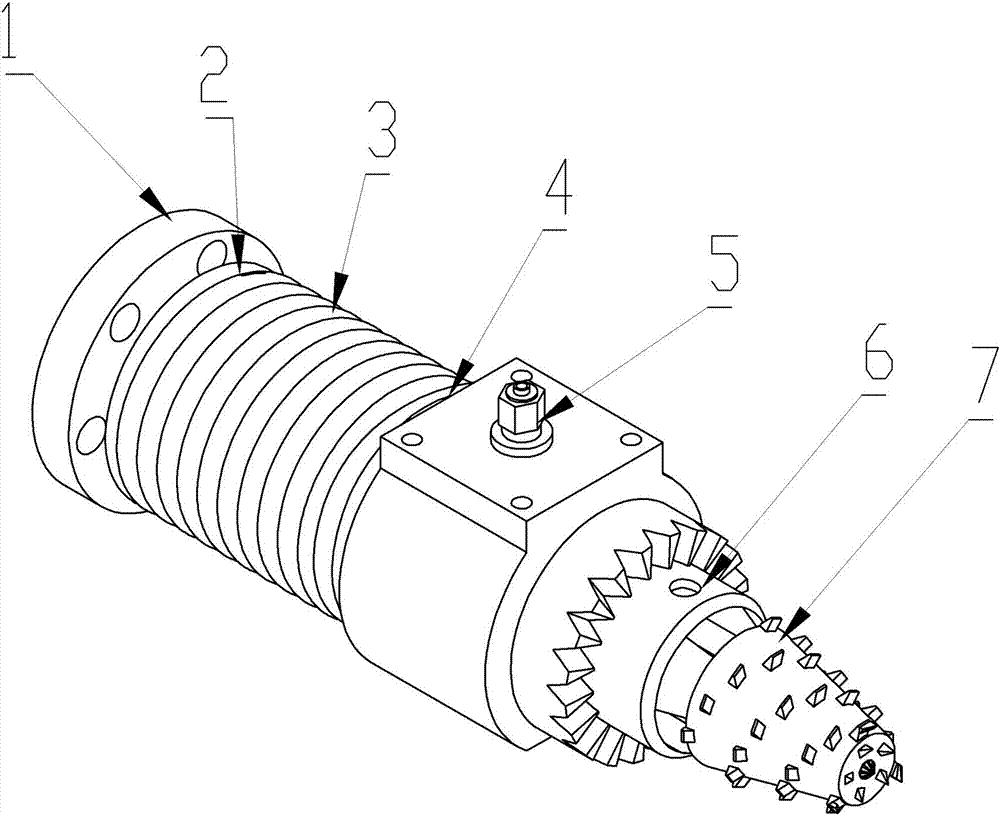

A drilling and milling tool device for wall grooving

InactiveCN105856431BImprove efficiencyGuaranteed safe lifeWorking accessoriesStone-like material working toolsMilling cutterSignal processing

Disclosed is a drilling and milling cutter device used for wall grooving. Through the drilling and milling cutter device, the technical problems of cutter blocking, cutter fracture, short service life of a blade and low work efficiency of an existing grooving machine are mainly solved. According to the main points of the technical scheme of the drilling and milling cutter device, the drilling and milling cutter device comprises a flexible shaft (3), a torque sensor (5), a drill chuck (6) and a drilling and milling head (7); the flexible shaft (3) is connected with the drill chuck (6) through the torque sensor (5); the drilling and milling head (7) is installed at the front end of the drill chuck (6) in a matched mode; the rear end of the flexible shaft (3) is connected with a power device; and an electrical signal of the torque sensor (5) is connected with the power device through a SIGNAL processing module so as to achieve control over the electrical signal. The drilling and milling cutter device is mainly applied to decoration of dwellings, office buildings and the like.

Owner:XIANGTAN UNIV

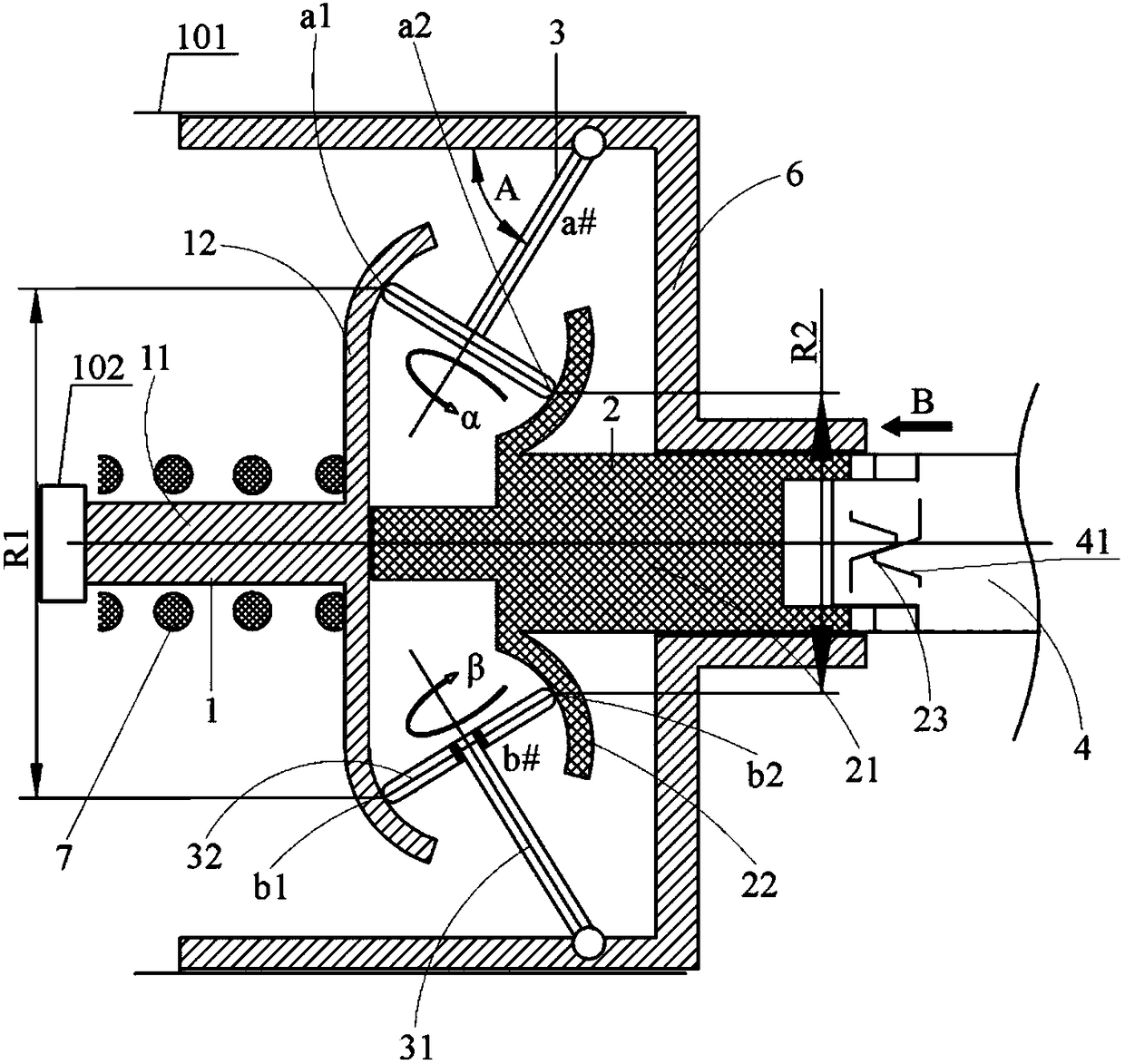

Continuously variable transmission device capable of automatically adjusting motion state and method of use thereof

InactiveCN105840760BRealize automatic speed regulationSimple structureGearingTransmission elementsAuto regulationDrive shaft

Owner:TONGJI UNIV

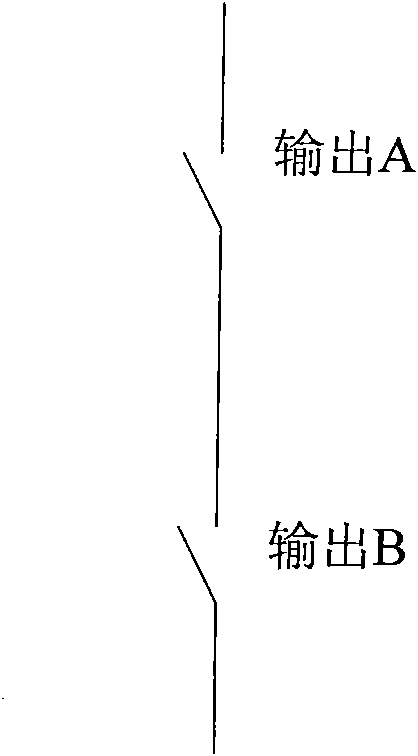

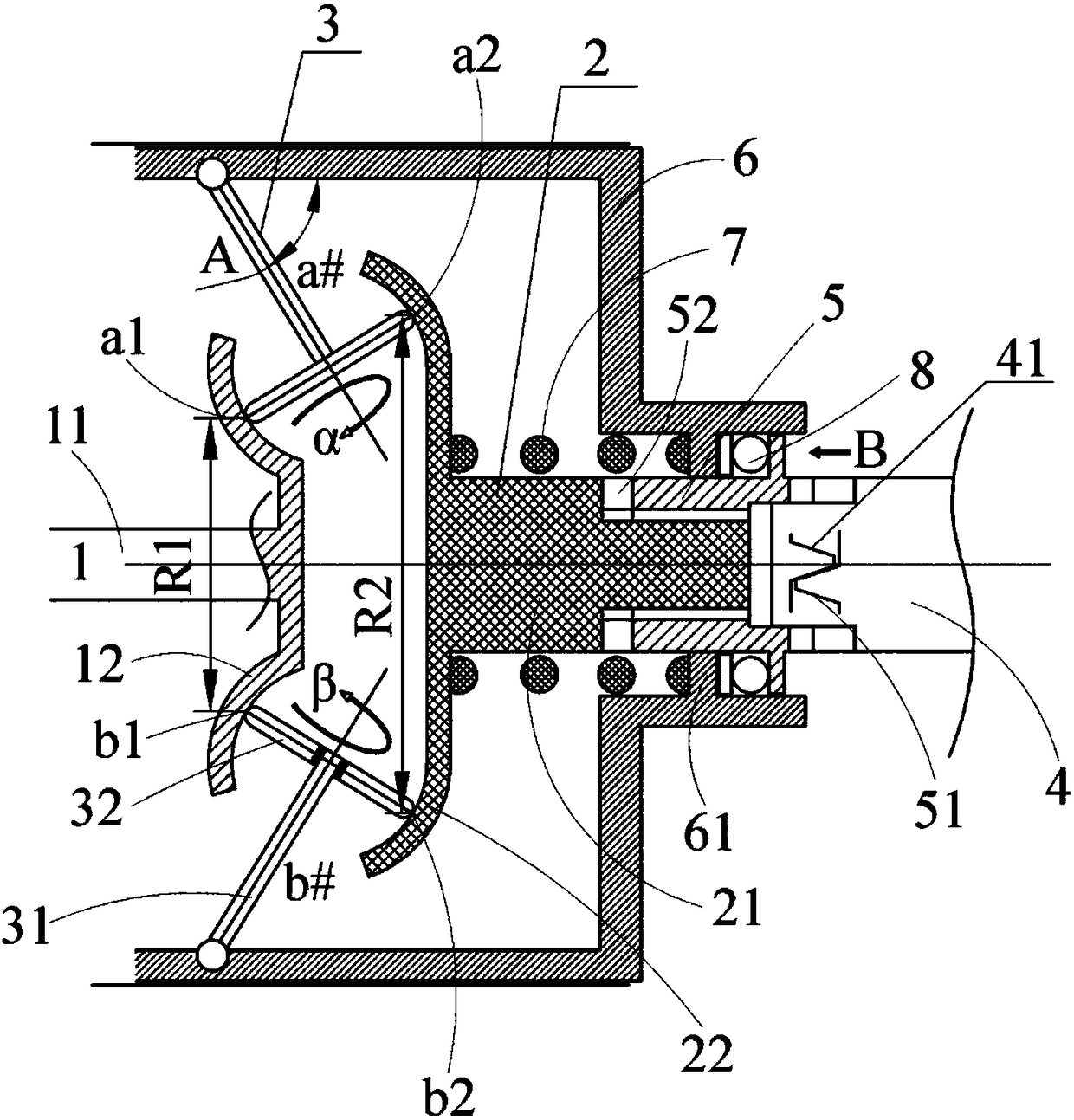

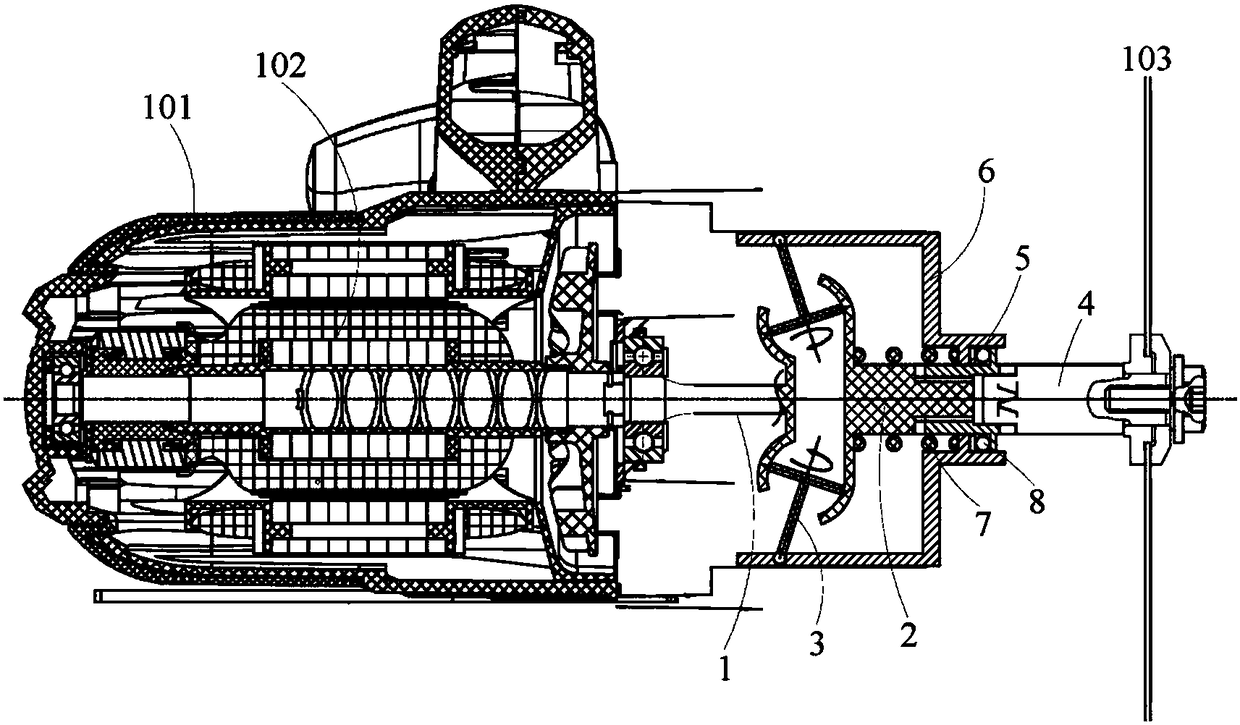

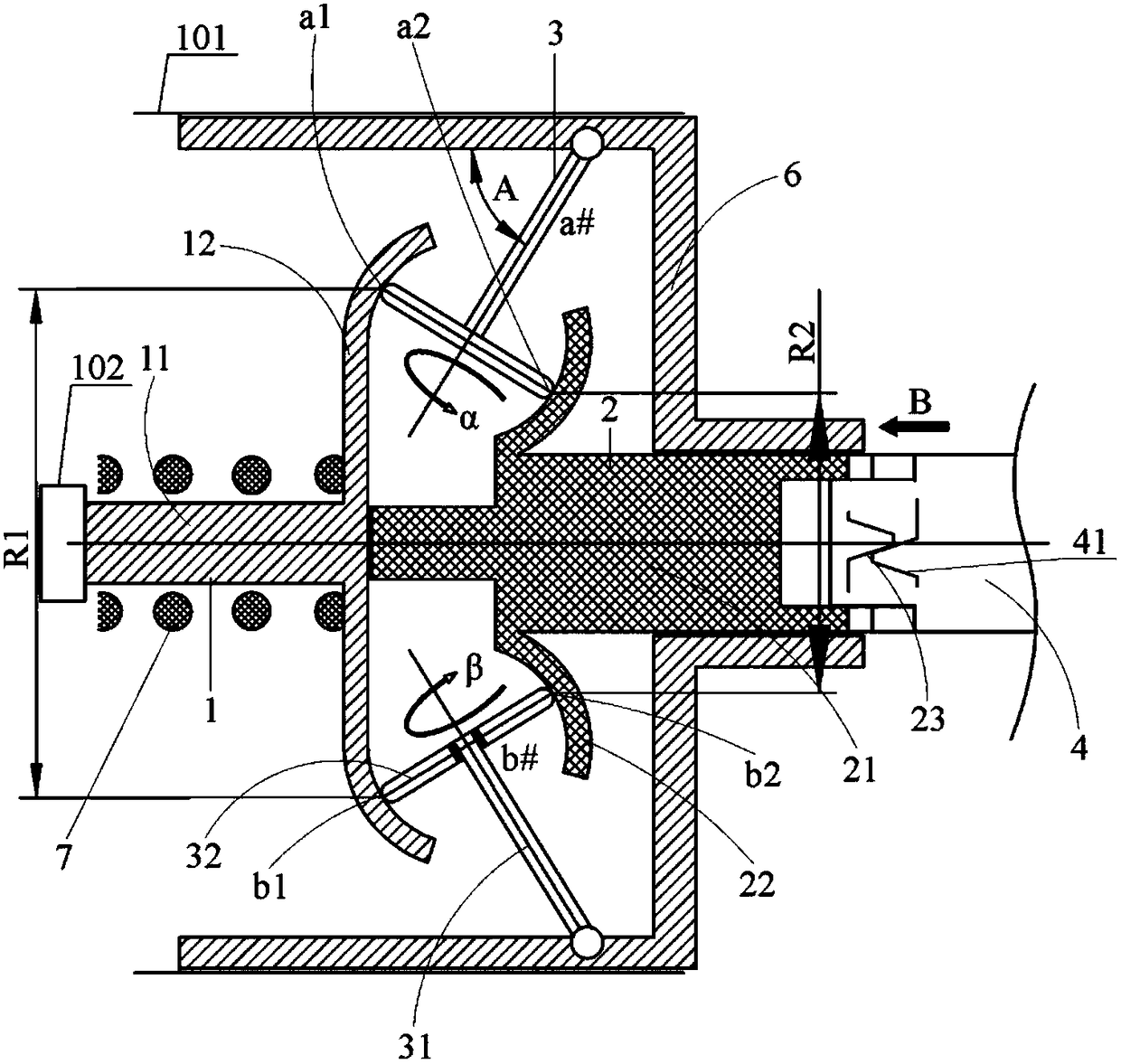

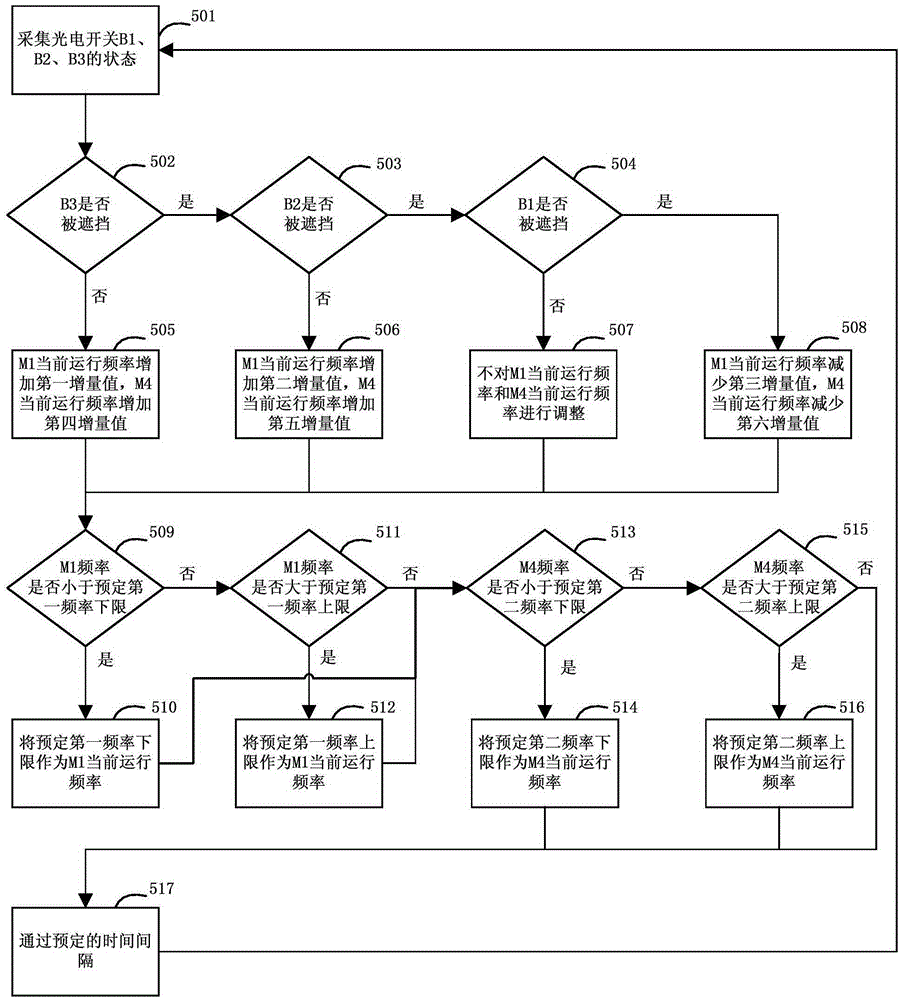

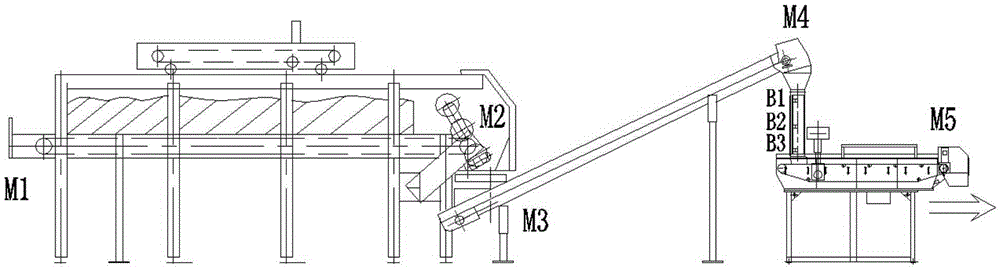

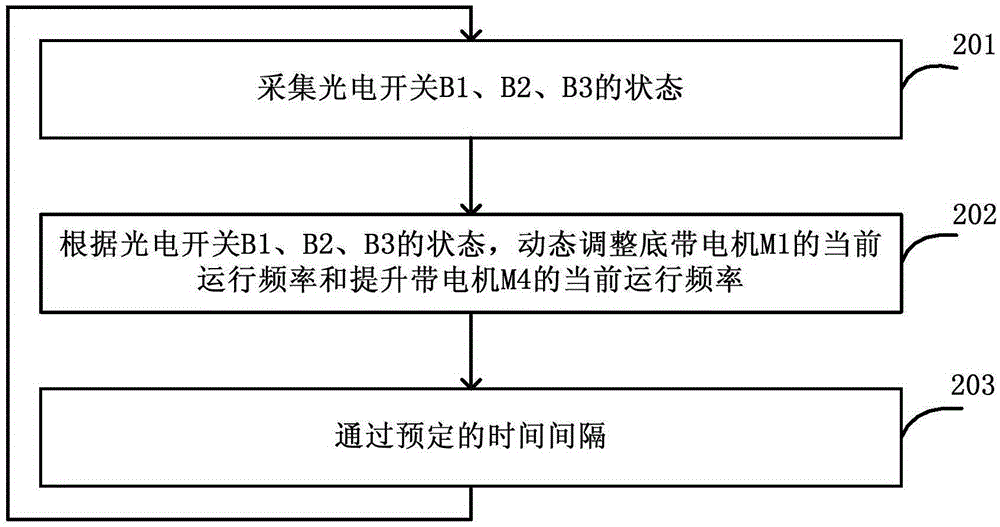

Tobacco cabinet feeder exit control method and device

ActiveCN103523493BRealize automatic speed regulationReduce labor intensityControl devices for conveyorsMechanical conveyorsComing outElectric machinery

The invention discloses a control method and device for coming out of a cabinet of a tobacco cabinet type feeding machine. The method comprises the steps of collecting states of photoelectric switches B1, B2 and B3, enabling B1 to be a high-material-level photoelectric switch, enabling B2 to be a medium-material-level photoelectric switch, and enabling B3 to be a low-material-level photoelectric switch; according to the states of the photoelectric switches B1, B2 and B3, dynamically adjusting current running frequency of a base belt motor M1 and current running frequency of an elevating belt motor M4; and repeatedly collecting the states of the photoelectric switches B1, B2 and B3 after predetermined time intervals. By detecting whether the high-material-level photoelectric switch, the medium-material-level photoelectric switch and the low-material-level photoelectric switch of limiting pipes, the running frequency of the base belt motor M1 and the running frequency of the elevating belt motor M4 are rapidly automatically adjusted, automatic speed adjustment in the whole process of the cabinet type feeding machine is achieved, and materials stable in flow are provided for a downstream mainframe device; the control method simultaneously guarantees that the device runs stably and continuously, starting and stopping frequencies are reduced, and labor intensity of operators is reduced to the largest extent.

Owner:XIAMEN TOBACCO IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com