Electric truck

A truck and electric technology, applied in vehicle components, control devices, transportation and packaging, etc., can solve the problems of high road smoothness, the lack of popularization of electric trucks, and low transmission performance, so as to achieve stable and reliable working performance and overcome obstacles The effect of capacity improvement and specification reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The general idea of the present invention is: a clutch is arranged between the power output shaft of the electric motor and the transmission. The specific structure of the above-mentioned device can have many kinds, all should belong to equivalent mechanical structure. Introduce three kinds of embodiments below in conjunction with accompanying drawing:

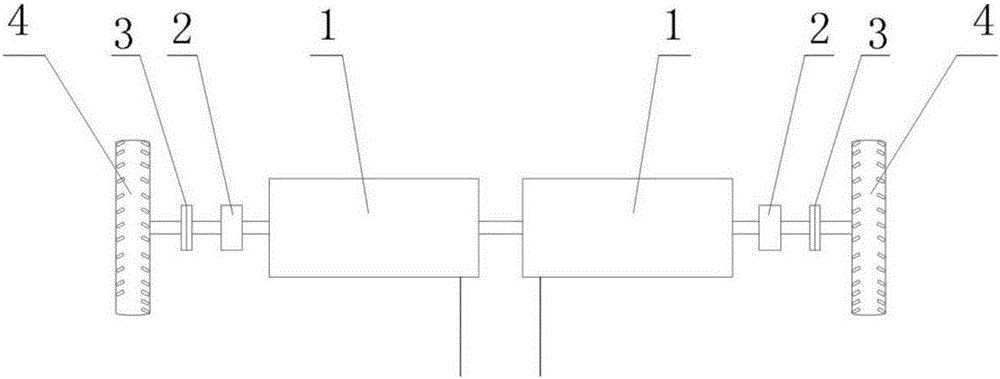

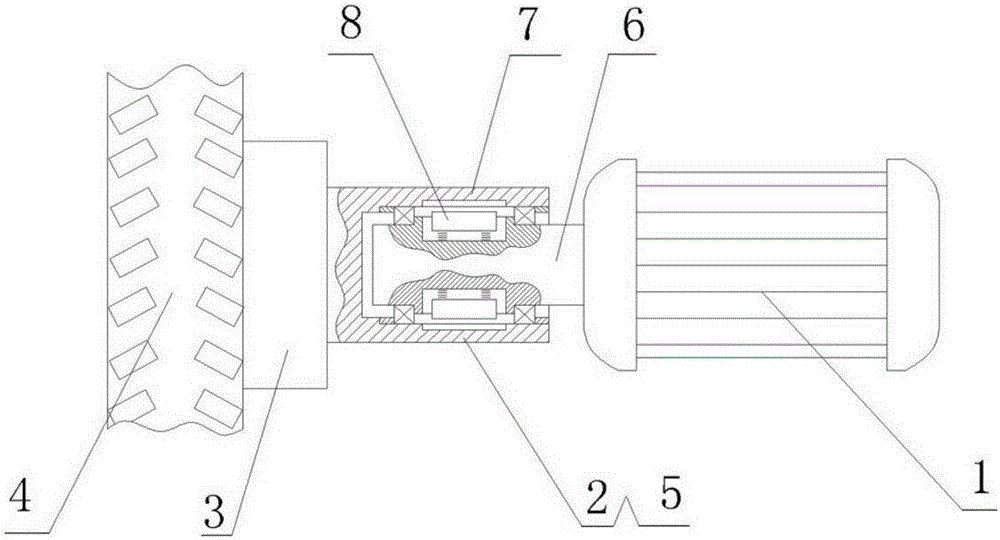

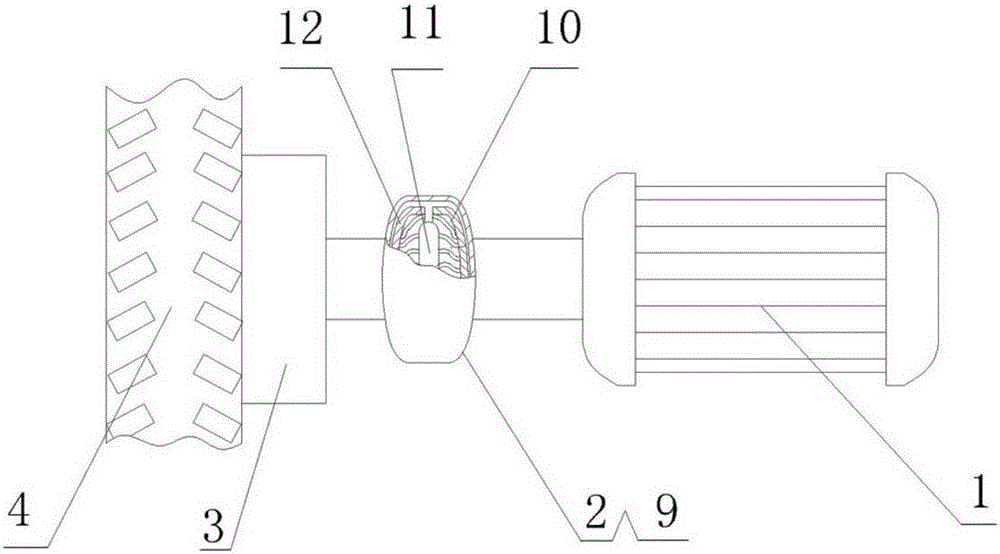

[0020] The first embodiment: figure 1 An electric driving mechanism of an electric truck is introduced. It can be seen in the figure that the power output shaft of the electric motor 1 of this electric truck drives the driving wheel 4 through the transmission 3. Its characteristics are: the power output shaft of the electric motor 1 and the transmission 3 There is a clutch 2 in between. combine figure 2 It can be seen that the clutch 2 is a centrifugal clutch 5 . The driving shaft 6 of the centrifugal clutch 5 is the power output shaft of the motor 1, and the driving shaft 6 and the driven shaft sleeve 10 are in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com