Automatic feeding precision compensation mechanism of numerical control machine tool

A technology of automatic feeding and precision compensation, applied in automatic control devices, metal processing machinery parts, metal processing, etc., can solve problems such as poor response efficiency, affecting product feeding compensation accuracy, and inability to grasp the tool spindle distance, etc., to improve The effect of compensation accuracy, improved automation level, and convenient and flexible observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

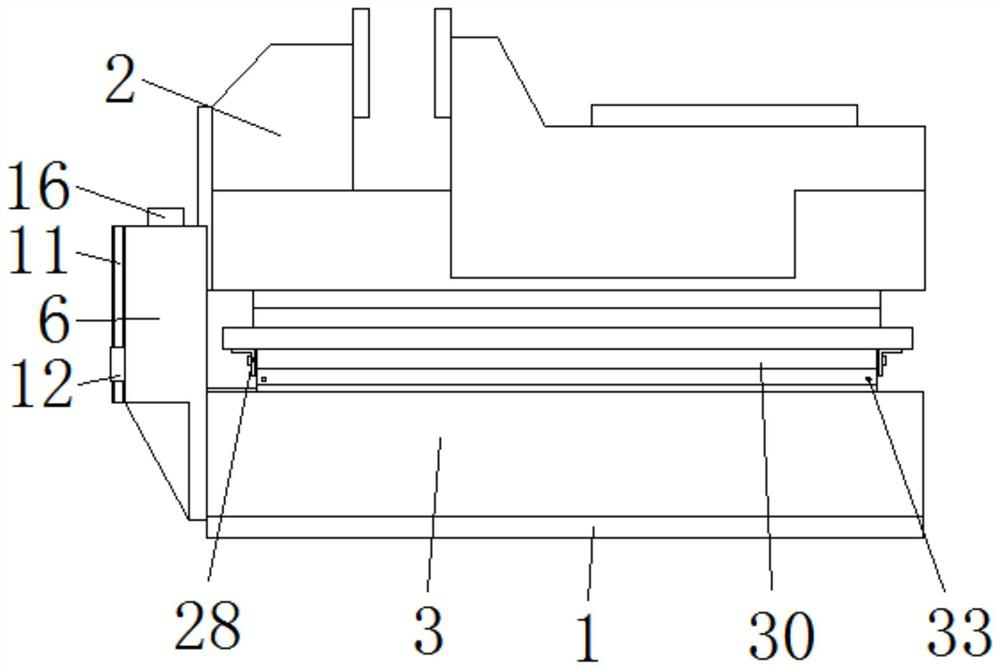

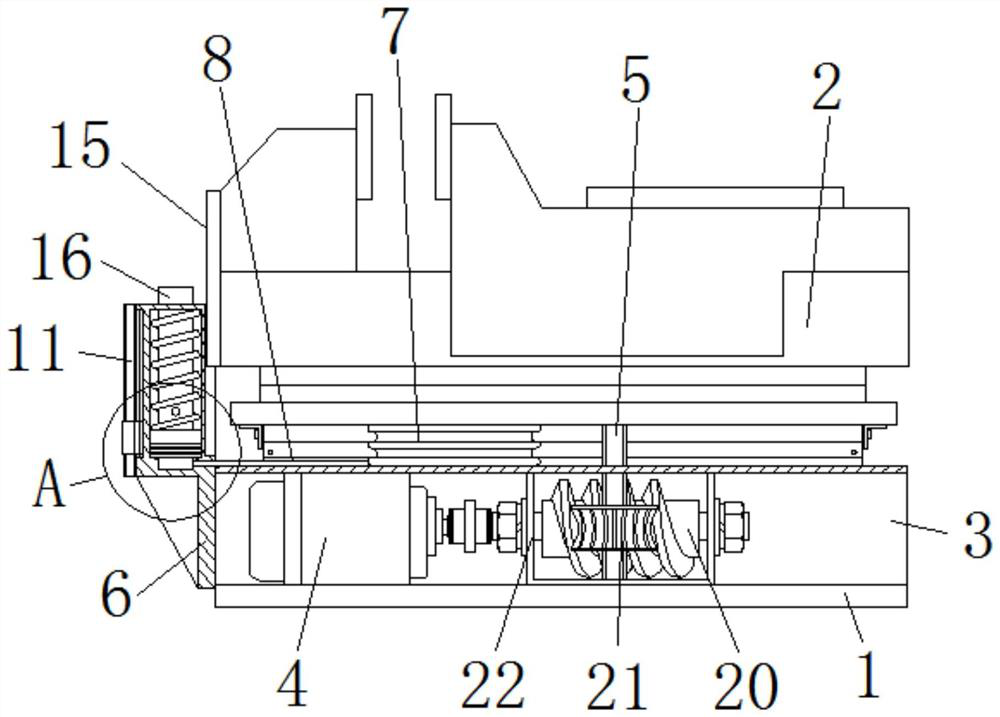

[0029] The present invention provides a CNC machine tool automatic feeding accuracy compensation mechanism, including a connecting plate 1 for installing the structure;

[0030] a fixture 2 arranged on the top of the connecting plate 1 for clamping the workpiece;

[0031] The top of the connection plate 1 is fixedly connected with the support frame 3, the top of the connection plate 1 is fixedly connected with the transmission motor 4 inside the support frame 3, the output end of the transmission motor 4 is fixedly connected with a structure for driving the screw 5 to rotate, the connection plate 1 The top of the screw rod 5 is movably connected to the screw rod 5 through the bearing, and the top of the screw rod 5 runs through the support frame 3 and the tooling fixture 2 in turn and extends to the inside of the tooling fixture 2. Structure for measuring compensation values.

[0032] refer to Figure 6 , the structure used to measure the compensation value is a measuring bo...

Embodiment 2

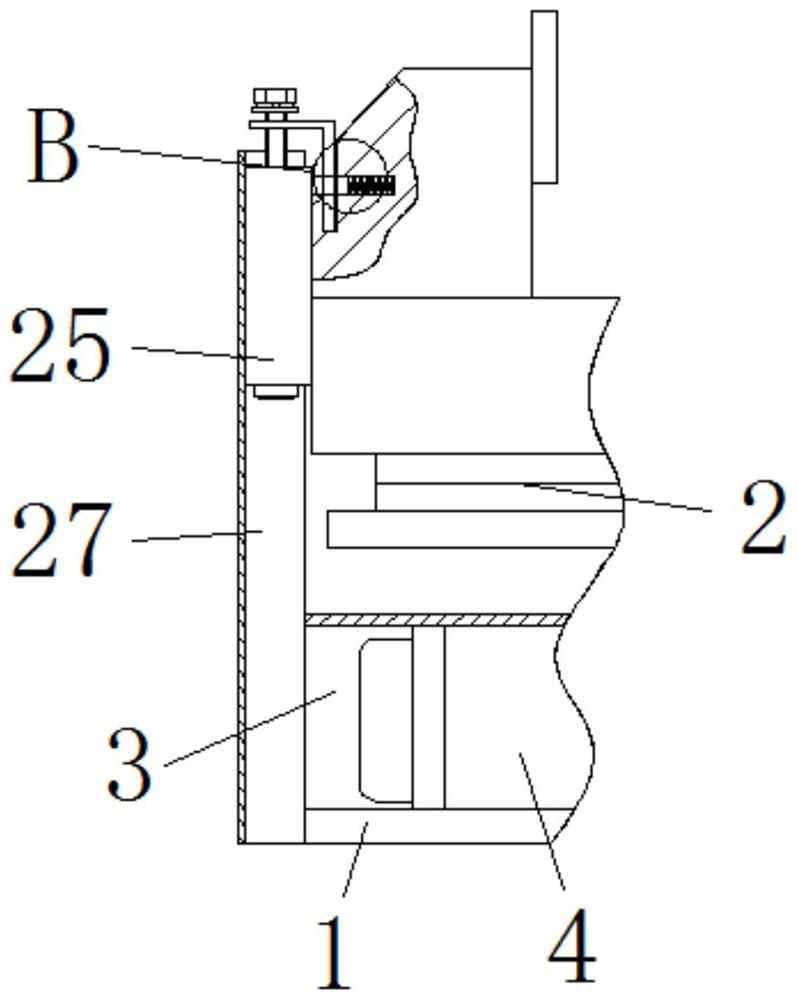

[0047] Such as Figure 7 As shown, in the second embodiment, other structures remain unchanged, and the present invention provides another structure for measuring the compensation value, which includes an opening 23 provided on the top of the fixture 2, and the inside of the opening 23 is slidingly connected with The hook 24, the side of the hook 24 away from the opening 23 runs through the opening 23 and extends to the left side of the fixture 2, the bottom of the hook 24 is provided with an infrared rangefinder 25 located on the left side of the fixture 2, the infrared rangefinder 25 and the tooling The clamps 2 are arranged vertically and parallel to each other, the top of the hook 24 is provided with a bolt 26, and the bottom of the bolt 26 runs through the hook 24 and the infrared range finder 25 in turn and extends to the inside of the infrared range finder 25, the bolt 26 is threaded with the hook 24, The bolt 26 and the infrared range finder 25 are flexibly connected t...

Embodiment 3

[0050] Such as Figure 7 As shown, in the third embodiment, other structures remain unchanged, and the present invention provides another structure for limiting and guiding the fixture 2, including a sleeve 27 fixed on the left side of the support frame 3, the sleeve The top of 27 extends upwards to the left side of the fixture 2. The infrared rangefinder 25 is located inside the sleeve 27 and contacts the inner surface of the sleeve 27. The infrared rangefinder 25 can slide up and down inside the sleeve 27 to connect.

[0051] During use, the transmission motor 4 drives the worm wheel 21 to rotate through the worm 20, and the worm wheel 21 drives the screw 5 to rotate and pushes the fixture 2 to move downward through the threads on the surface of the screw 5, and the fixture 2 drives the infrared rangefinder 25 to move and The distance between it and the working platform is reduced, and the casing 27 can protect the infrared rangefinder 25, reduce the impact of external light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com