Bridge thin-wall anti-floating design waterproof wall

A waterproof wall and bridge book technology, applied in bridge construction, bridges, bridge parts, etc., can solve the problems of poor impact resistance, damage, and high maintenance difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

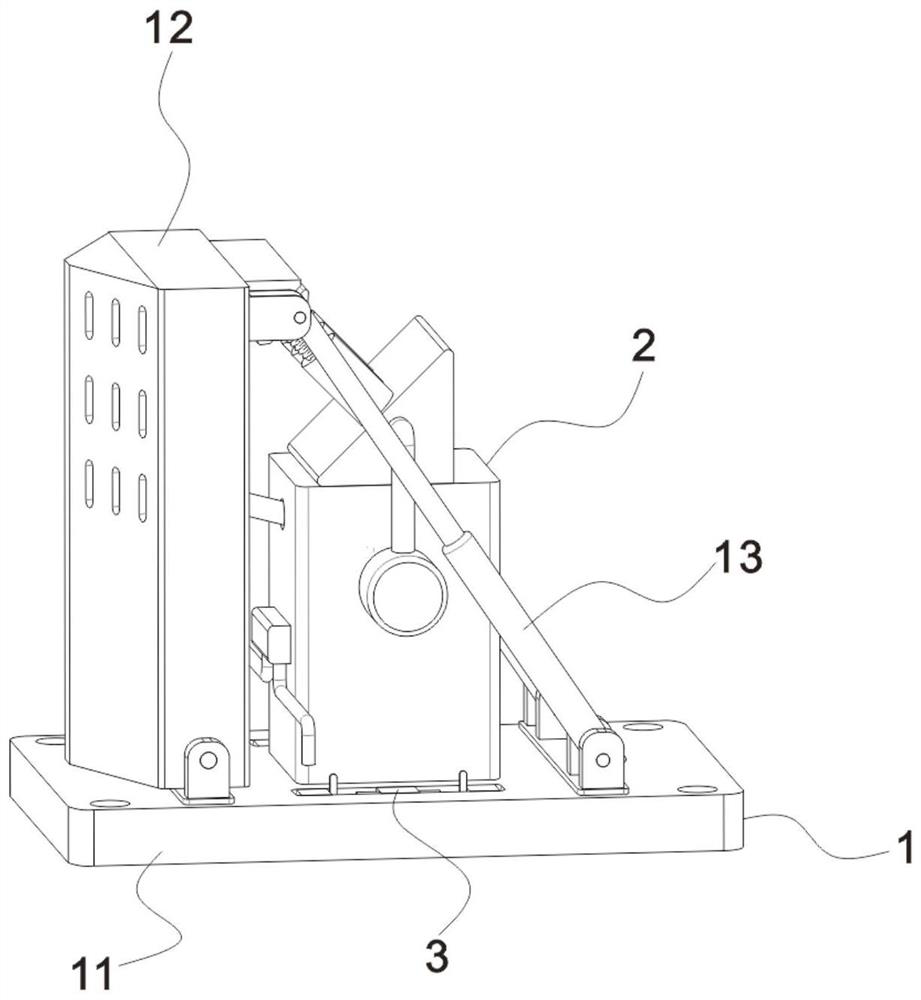

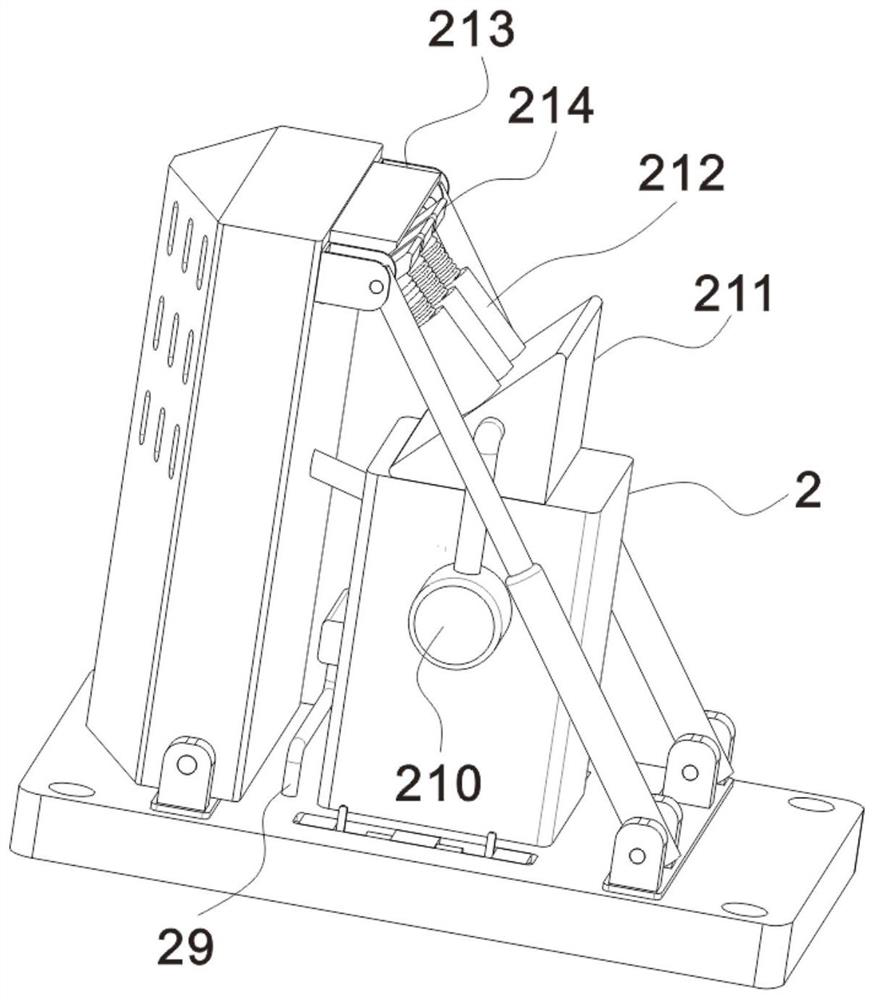

[0024] see Figure 1-4 , the present invention provides bridge thin wall anti-floating design waterproof wall, including,

[0025] The receiving component 1 includes the counterweight base 11, and there are installation holes around the counterweight base 11, which is convenient to fix at the designated position with external fixing parts. The front and rear ends of the right side of the wall panel 12 are hinged to one end of the adjustable support rod 13. The adjustable support rod 13 is widely used in this field and will not be described in detail here. The other end of the adjustable support rod 13 is flexibly connected to the top of the counterweight base 11. ;

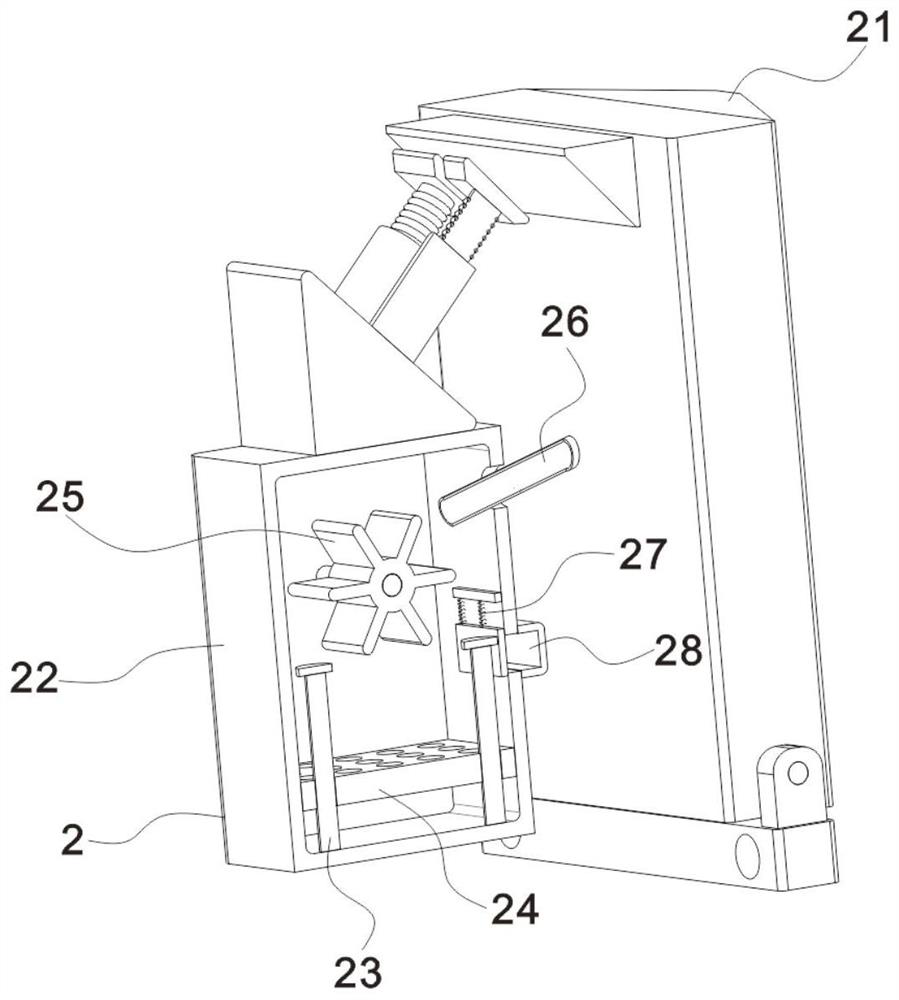

[0026] The slow pressure reinforcement 2, the slow pressure reinforcement 2 includes a triangular guide seat 21 fixed on one side of the waterproof wall panel 12, which guides the impact on the water flow, and a cavity is provided in the guide seat 21 (not shown in the figure). shown), the top of the outer wall ...

Embodiment 2

[0033] see figure 1 with Figure 4 , the maintenance part 3 includes two sets of positioning blocks 31, the left and right sides of the top of the counterweight base 11 are provided with positioning grooves matching the positioning blocks 31, the bottom of the waterproof wall panel 12 is hinged on the top of the left positioning block 31, and the two sets of adjustment support rods 13 The other end is respectively hinged with the front and rear sides of the top of the right positioning block 31, and the front and rear sides of the top of the counterweight base 11 are provided with transverse limiting chute 32, and the limiting chute 32 is located between two sets of positioning blocks 31. 31 and the positioning groove are convenient to play the role of preliminary positioning during installation, and the limiting chute 32 is a T-shaped limiting chute 32;

[0034] see figure 1 with Figure 4 , the middle parts of the two sets of limiting chute 32 are fixed with support block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com