Municipal river garbage collection and treatment equipment

A technology of garbage collection and treatment equipment, which is applied in the direction of waste collection and transfer, cleaning of open water surfaces, water conservancy projects, etc. It can solve the problems of large size and inconvenient movement, and achieve the effect of increasing speed, improving efficiency and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

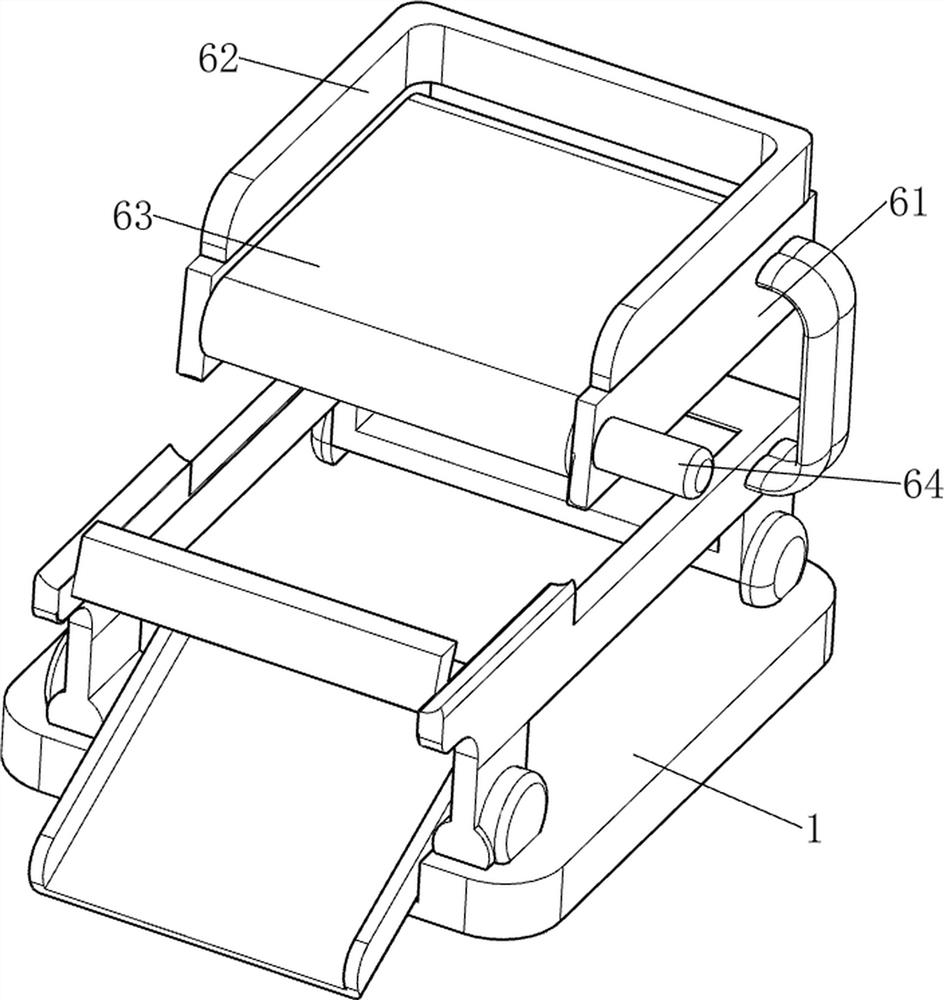

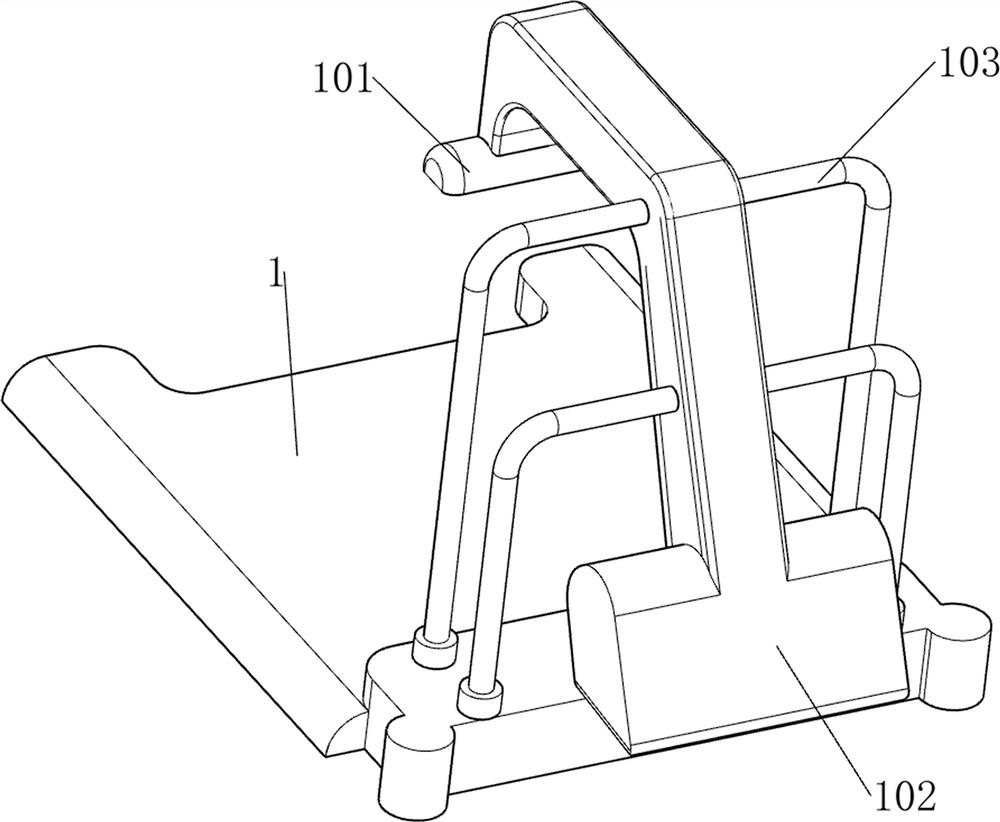

[0063] A kind of municipal river garbage collection and treatment equipment, such as figure 1 As shown, it includes a bottom frame 1, a first baffle plate 2, a second baffle plate 3, a compression block 4, a compression mechanism 5 and a feeding mechanism 6. The lower part of the front side of the frame 1 is slidingly provided with a second baffle 3, the upper part of the front side of the bottom frame 1 is slidingly provided with a compression block 4, the top of the front side of the bottom frame 1 is provided with a compression mechanism 5, and the upper middle part of the bottom frame 1 is provided with a feeding mechanism 6. The feeding mechanism 6 cooperates with the compression mechanism 5.

[0064]When the workers need to collect and process the river garbage, the workers can first place the garbage on the feeding mechanism 6, and then the workers can rotate the feeding mechanism 6, and then the garbage can be sent to the first baffle plate 2 and the second baffle plat...

Embodiment 2

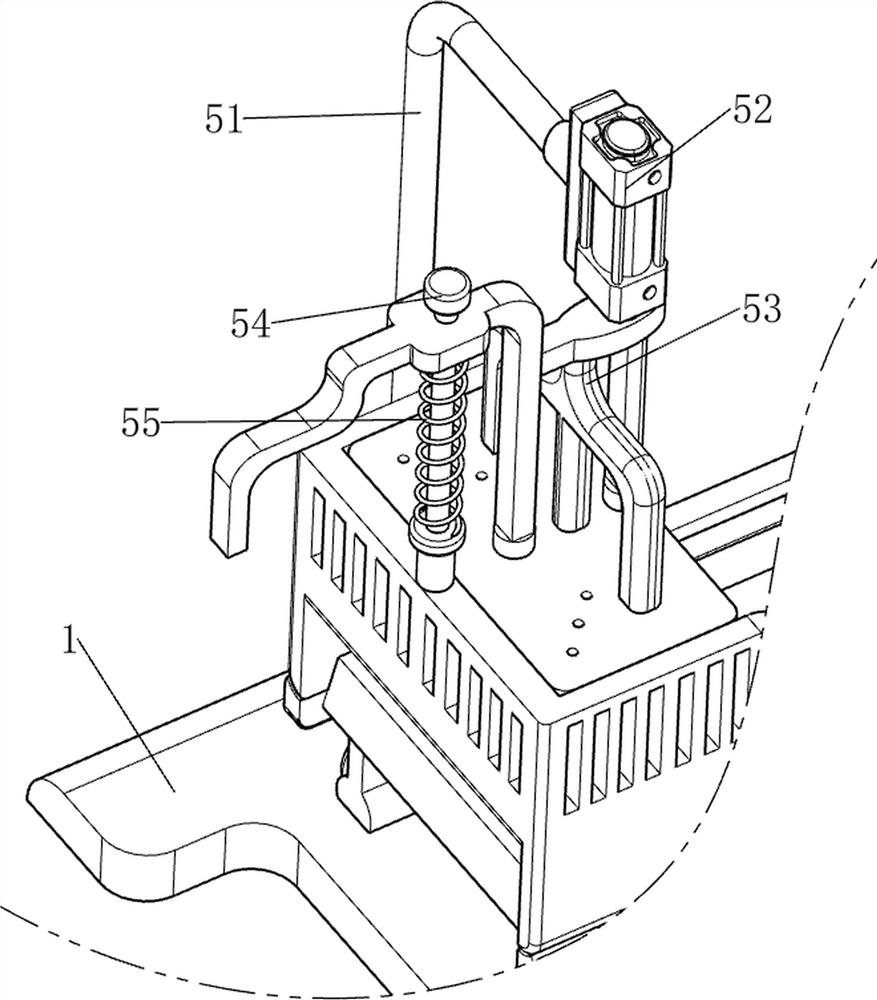

[0066] In a preferred embodiment of the present invention, as Figure 1-Figure 3 As shown, the compression mechanism 5 includes a first support frame 51, a cylinder 52, a lower press frame 53, a first sliding rod 54 and a first spring 55, and the left side of the front part of the underframe 1 is provided with a first support frame 51. Frame 51 top is fixedly connected with cylinder 52 by bolt, and the telescoping rod bottom of cylinder 52 is connected with lower pressure frame 53, and lower pressure frame 53 is connected with compression block 4 tops, and bottom frame 1 front side top is provided with first sliding rod 54, and lower The pressing frame 53 is slidably connected to the first sliding rod 54 , the first sliding rod 54 is sleeved with a first spring 55 , and the two ends of the first spring 55 are respectively connected to the lower pressing frame 53 and the first sliding rod 54 .

[0067] When the worker needs to compact the garbage, the worker can start the cylin...

Embodiment 3

[0071] In a preferred embodiment of the present invention, as Figure 4-Figure 7 As shown, a transmission mechanism 7 is also included, and the transmission mechanism 7 includes a one-way gear 71, a rack 72 and a connecting rod 73. The right part of the rotating shaft 64 at the front side is provided with a one-way gear 71, and the lower pressure frame 53 top rear side A connecting rod 73 is provided, and a rack 72 is arranged on the right side of the connecting rod 73, and the rack 72 meshes with the one-way gear 71.

[0072] The process of workers manually controlling the transfer of garbage is relatively cumbersome, so when the lower pressing frame 53 moves downward, the lower pressing frame 53 will drive the connecting rod 73 to move downward, and then will drive the tooth bar 72 to move downward, and the downward movement of the tooth bar 72 will move downward. Drive the one-way gear 71 to rotate, and then just can drive the rotating shaft 64 to rotate, thereby just can c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com