Pipe pile core digging machine

A technology for pipe piles and mounting frames, which is applied to sheet pile walls, buildings, infrastructure projects, etc., can solve the problems of increasing the limitations and inconveniences of core digging machines, reducing the operating stability of the device, and reducing the service life of components, etc. Convenience of grip and output, increased functionality and practicality, increased flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

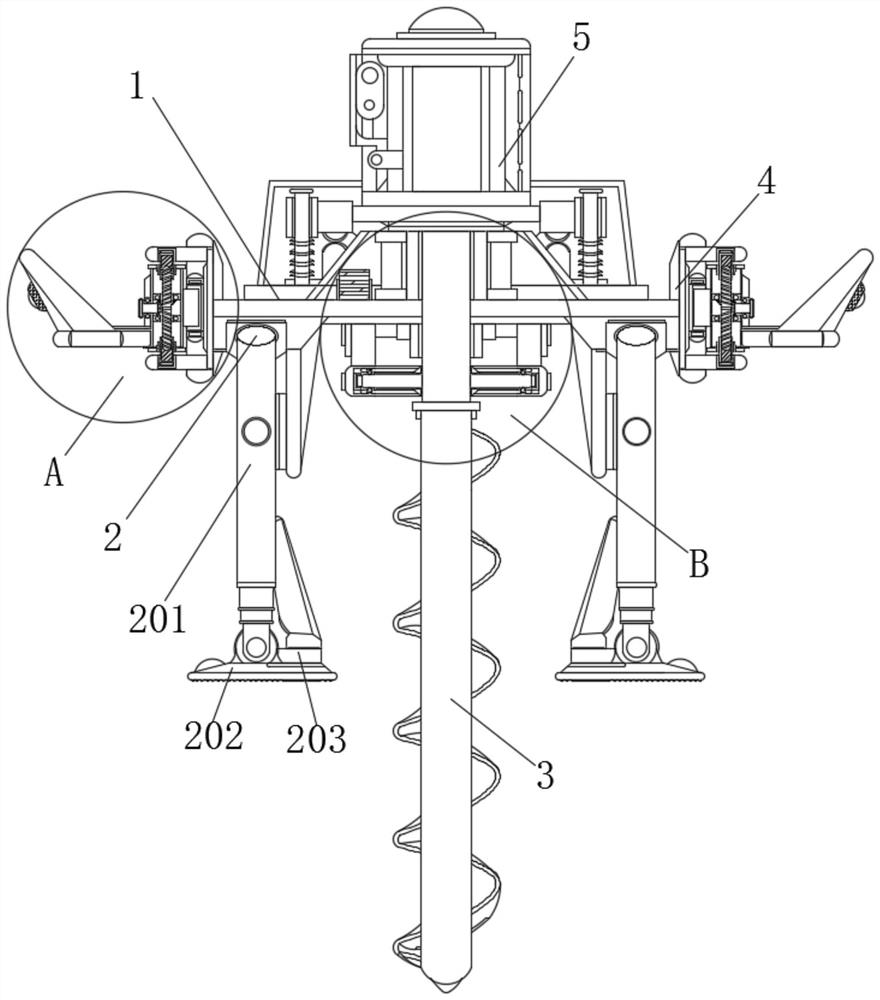

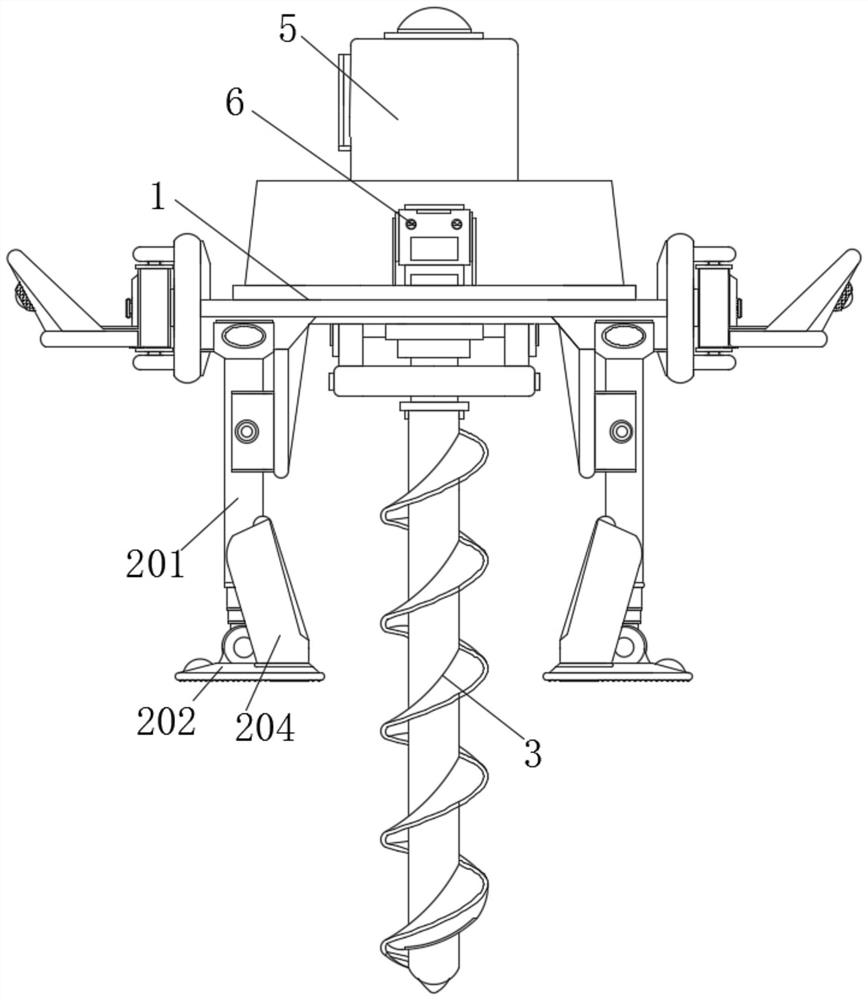

Embodiment 1

[0039] Example 1, such as Figure 1-2 As shown, when two operators press four sets of start buttons 8 at the same time, the pressing of four sets of start buttons 8 is sensed through the electrical connection of the control module 12, and the control panel 6 is used to start the drive device 5 to drive the drive shaft 14 and the auger. Rod 3 is used for drilling and pile clearing operations. When the operator cancels or slips off the support of the two-handed holding frame 7 and the pressing operation of the start button 8, the control panel 6 is used to cancel the activation of the drive device 5 by the control module 12, thereby prompting the auger to The rotation of the rod 3 is automatically stopped, so as to prevent the operator from being injured by the inclination of the corer, which effectively increases the safety and practical value of the device.

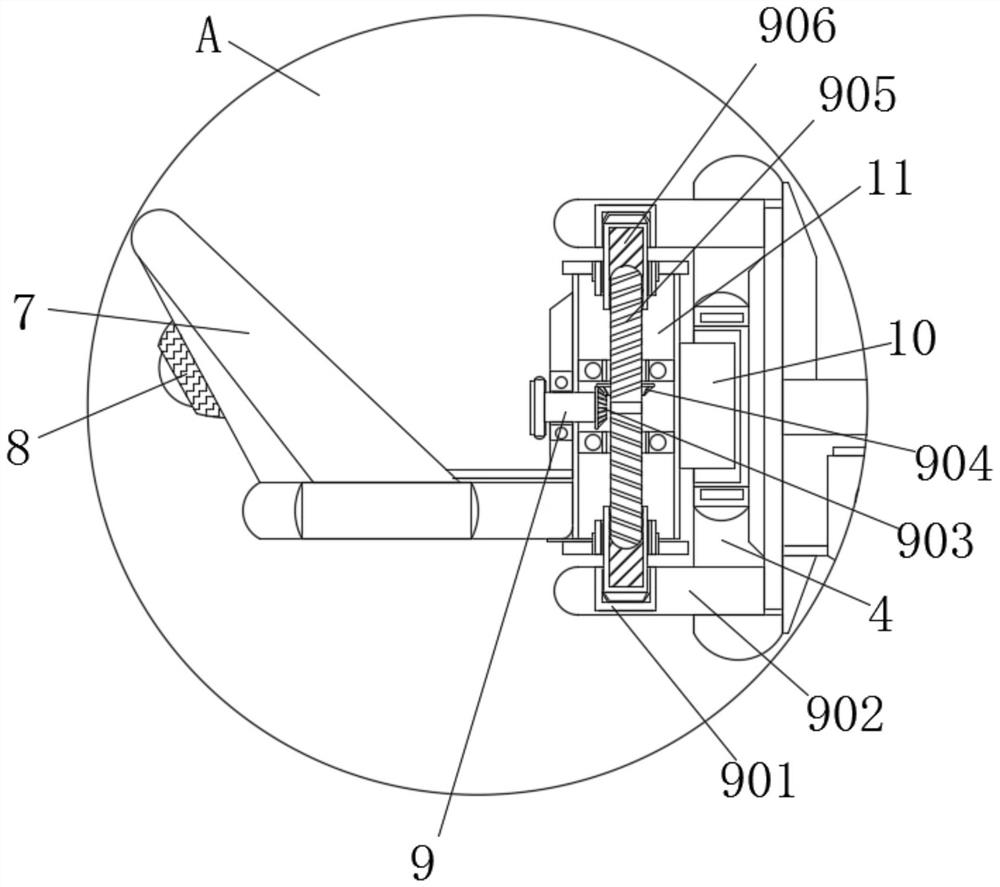

Embodiment 2

[0040] Example 2, such as Figure 1-3 As shown, when the operator supports the holding frame 7 with both hands, the first bevel gear 903 and the second bevel gear 904 can be driven to mesh with each other by manually rotating the rotating rod 9, forcing the second bevel gear 904 to drive the two-way screw rod 905 Rotation, along with the rotation of the two-way screw rod 905 drives two groups of two-way screw rod 905 to cancel the engagement and positioning with the positioning hole 901. At this time, the ring groove 11 can be rotated as a whole to 90° under the cooperation of the rotating column 10, so that both hands can hold The holding angle of the holding frame 7 is turned over as a whole. At this time, the turning rod 9 drives two sets of internal threaded pipes 906 to extend into the positioning holes 901 for fixing, so that the holding angle of the holding frame 7 with both hands can be changed, and the operability of the device is increased. and flexibility.

[0041]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com