Hydraulic deep-well pump impeller locking device and mounting method thereof

A technology for locking devices and deep well pumps, which is applied to pump devices, parts of pumping devices for elastic fluids, pumps, etc., and can solve the problem of internal tooth damage of stop washers, loose lock nuts, and affecting normal operation of equipment Operation and other problems, to achieve high reliability and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

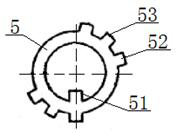

[0041] see Figure 1 to Figure 3, a hydraulic deep well pump impeller locking device, including a pump shaft 1, a hub 2, and an impeller 3 coaxially fixed on the hub 2, the A end 11 of the pump shaft 1 passes through the hub 2 and locks with the inside of the impeller 3 The lock nut 4 is fixedly connected, and the lock nut 4 is an M30*1.5 round nut, and four stop grooves 41 are evenly opened on its outer circumference, and a stop washer is arranged between the upper end surface of the lock nut 4 and the hub 2 5. The inner wall of the stop washer 5 is fixed with an inner tooth 51 matching the keyway 12 on the A end 11, and two outer tooth groups 53 are fixed on the outer circumference, and the outer tooth group 53 includes three and The outer teeth 52 matched with the stop groove 41, the end surface of the A end 11 is provided with a shaft end pressure plate 6 and a fastening assembly 7, and the fastening assembly 7 includes a locking bolt 71 and a self-locking washer 72. The ...

Embodiment 2

[0048] In step 2, the tightening torque is 8Nm, and the width of the gap is 0.02mm;

[0049] In Step 3, the ratio of the loosening torque to the standard tightening torque of the fastening component 7 is 5:10.

Embodiment 3

[0051] In step 2, the tightening torque is 6Nm, and the width of the gap is 0.03mm;

[0052] In Step 3, the ratio of the loosening torque to the standard tightening torque of the fastening component 7 is 4:10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com