A total station reflector sheet steel beam deflection measurement method

A deflection measurement and total station technology, applied to measurement devices, instruments, etc., can solve the problems of difficulty in setting up the operation platform, complicated installation and disassembly, etc., and achieve simple and fast measurement, convenient layout and disassembly, and accurate and reliable observation data. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

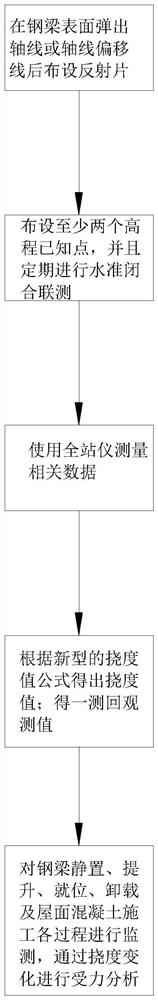

[0050] combine Figure 1 to Figure 3 A method for measuring the deflection of a total station reflector type steel beam comprises the following steps:

[0051] Step Ⅰ, after the ground assembly of the steel beam is completed, the axis or axis offset line is popped up on the surface of the steel beam, and reflectors are arranged at both ends and mid-span of the steel beam;

[0052] Step Ⅱ, lay out at least two known elevation points on the bottom plate under the steel beam, and regularly conduct level closed joint measurement of the known elevation points to ensure that the elevation values of the known points are accurate and reliable;

[0053] Step Ⅲ, use the triangular elevation observation principle of the total station, set up the instrument at any position on the base plate according to the construction environment, directly measure the elevation of one of the known points, calculate the height of the instrument according to the elevation displayed by the total station,...

Embodiment 2

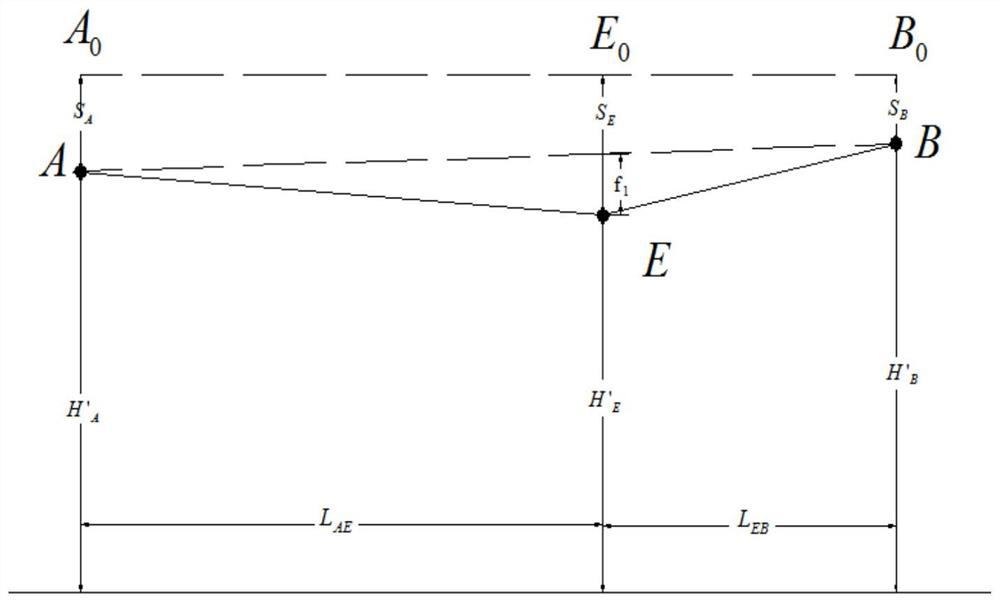

[0066] combine Figure 1 to Figure 3 , the vertical deflection value f of any monitoring point E in step Ⅴ 1 The calculation method is as follows:

[0067] According to the similarity principle of triangle proportion:

[0068]

[0069] Organized:

[0070] (H' B -H' A )×L BE =H' B ×(L BE +L EA )-(f 1 +H' E )×(L BE +L EA )

[0071]

[0072] final:

[0073]

[0074] The deflection change value is positive for downward deflection, and negative for upward arching;

[0075] The E point is at any position on the axis. If the E point is at the center of the axis, the obtained deflection value is the mid-span deflection value. If the E point is at 1 / 4 of the axis, the obtained deflection value is at 1 / 4 of the axis. deflection value. The equipment for ejecting the axis or axis offset line on the surface of the steel beam uses an ink cartridge, and the ejection axis or axis offset line is an ink line; the reflective sheet is a self-adhesive reflective sheet, and...

Embodiment 3

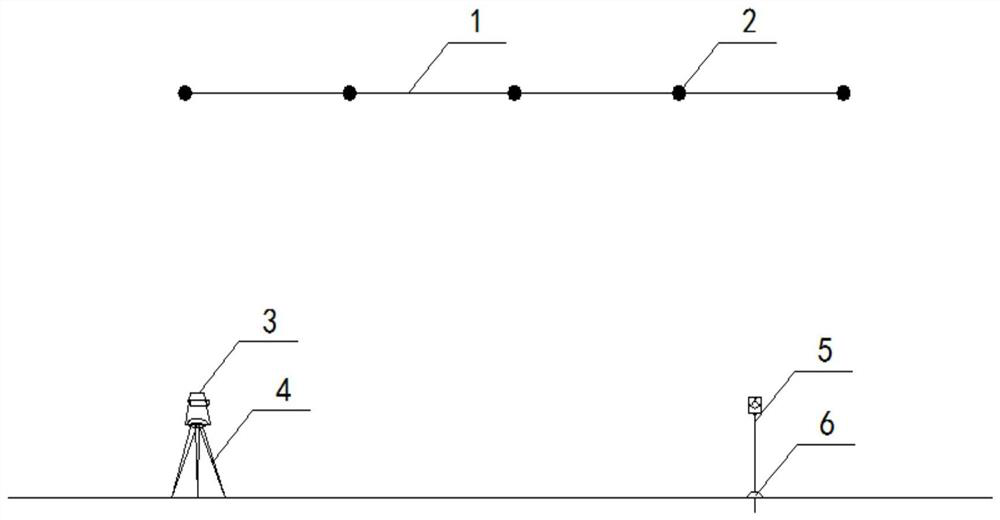

[0077] combine Figure 1 to Figure 3 , a method for measuring the deflection of a steel beam with a total station reflector, including deriving the deflection calculation formula in the code using triangular geometric similarity, laying a reflector 2 on the axis 1 of the steel beam, and knowing the control point 6 on the ground Set up the prism 5 on the top, set up the tripod 4 and the total station 3 at any position on the ground, calculate the height of the instrument by measuring the height of the known control point 6, and reset the station after adjusting the height of the instrument. After the total station switches to the reflector observation mode , the prism height is set to 0, and then the relative coordinates and elevation of the reflection sheet 2 are directly measured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com