Separated motor testing device capable of adjusting rotor eccentricity

A technology for rotor eccentricity and motor testing, applied in motor generator testing, measuring devices, measuring device housings, etc., can solve problems such as reduced practicability, difficult eccentricity detection, and single structure, to ensure accurate displacement and quality. , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be further described below.

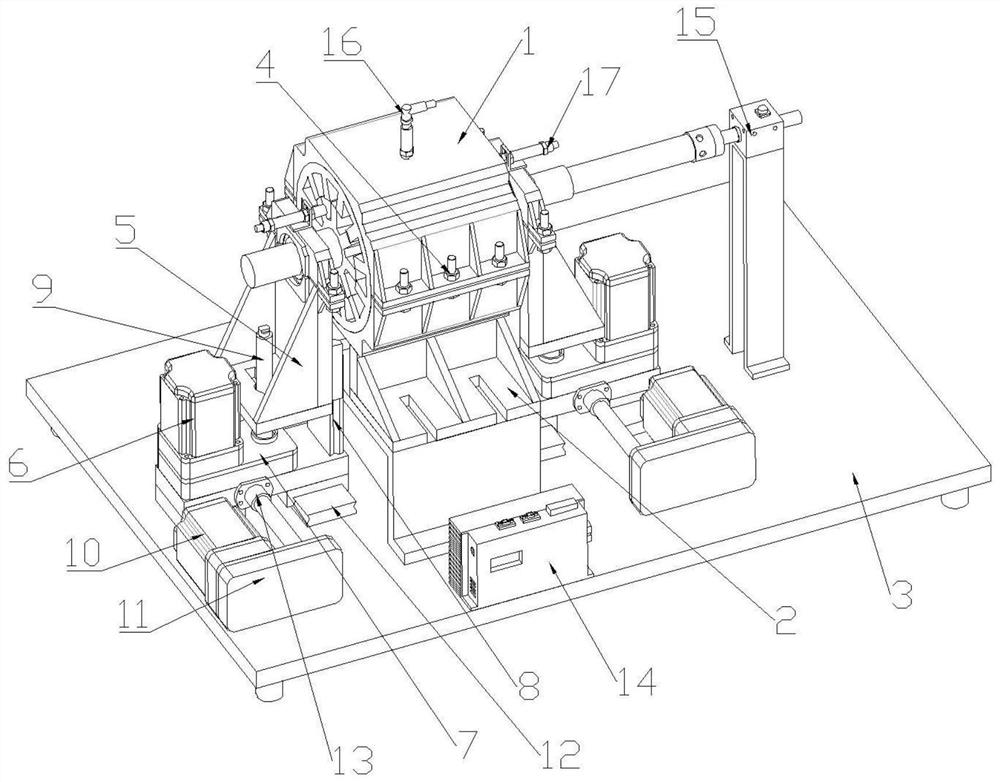

[0030] Such as figure 1 As shown, the present invention proposes a separate adjustable rotor eccentric motor testing device, including a stator supporting shell 1, a stator supporting base 2, two sets of rotor supporting components, a test component and a device base 3;

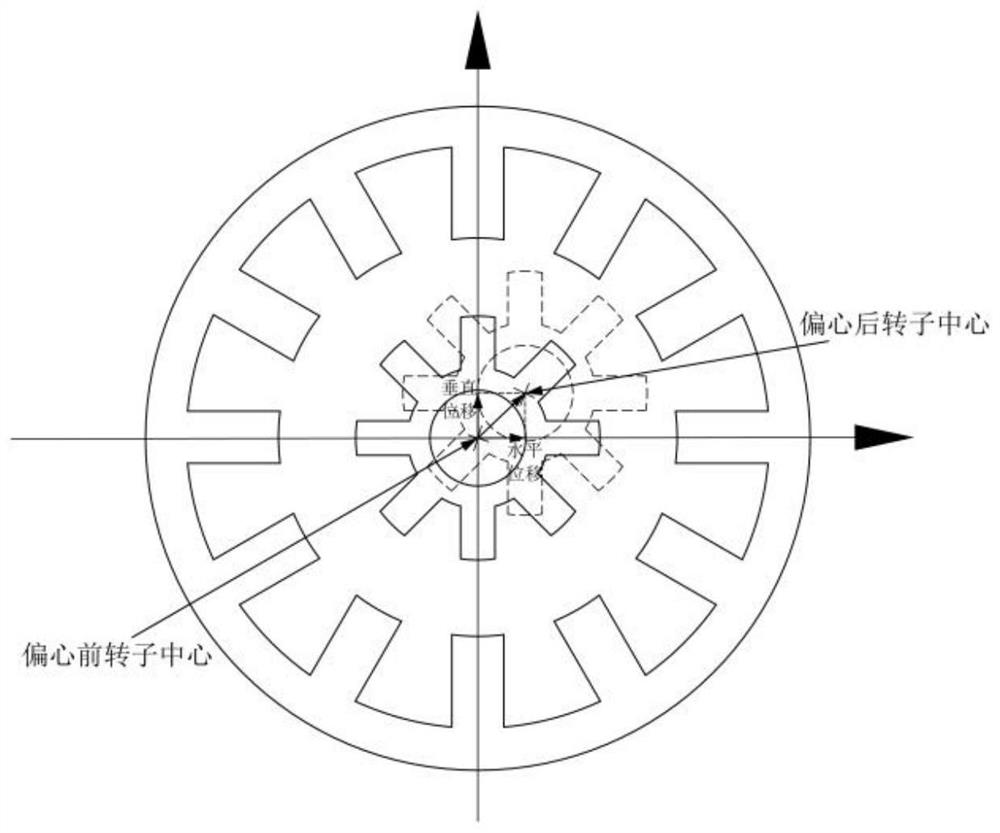

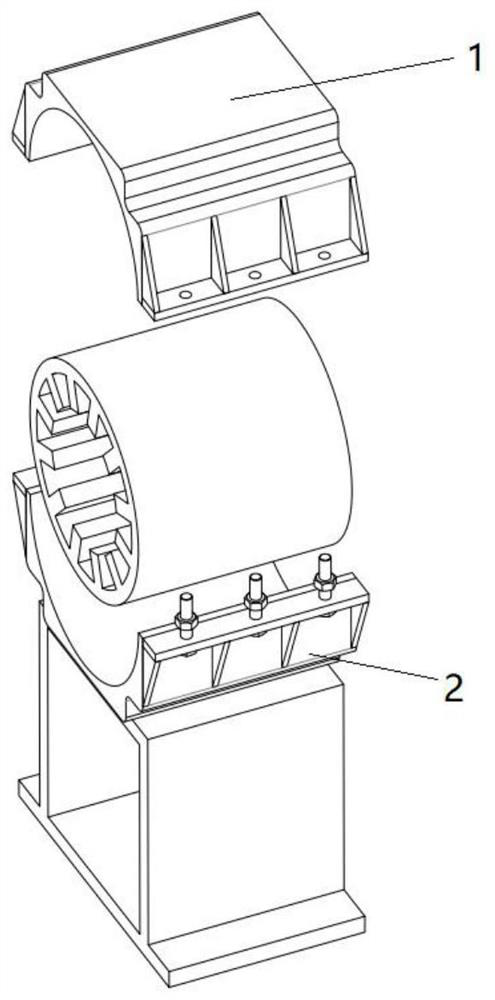

[0031] The stator supporting base 2 is fixed on the device base 3, the upper end of the stator supporting base 2 is provided with a stator fixing groove, and the stator supporting shell 1 is detachably connected with the side edge of the notch of the stator fixing groove through bolts; image 3 with Figure 4 As shown, by adjusting the pre-tightening force of the bolt 4, radial pressure can be applied to the stator and rotor bearings to ensure that the stator and rotor are reliably fixed, and at the same time it is easy to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com